Method for recovering fine-grained cassiterite

A fine-grained, cassiterite technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problem of hindering the interaction between chemicals and minerals, affecting concentrate grade and recovery rate, and increasing flotation machine pressure, etc. problems, to achieve the effect of increasing the difficulty of flotation, improving the grade and operation recovery rate, and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: In this embodiment, the mixed sulfur collector is made from the following components by mass: sodium alkyl sulfonate 60g, CuSO 4 40g, 60g sodium alkylsulfonate, 40g CuSO 4 The mixed sulfur collector is obtained by mixing uniformly in parts by mass.

[0029] The tin mixed collector of the present embodiment is made from the following components by mass: salicylic hydroxamic acid 20g, benzohydroxamic acid 60g, oleic acid 20g; 20g of oleic acid was mixed uniformly to obtain a tin mixed collector.

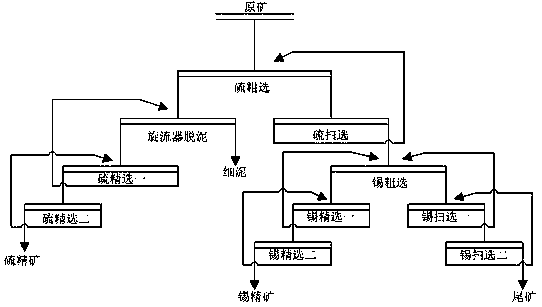

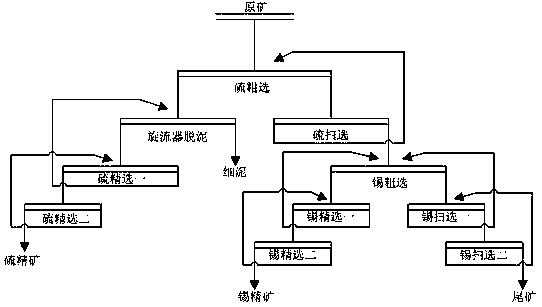

[0030] Use the mixed sulfur collector and tin mixed collector prepared in this example to process a certain fine-grained cassiterite in Wenshan, Yunnan. The raw ore tin grade is 0.119%, such as figure 1 As shown, the specific steps are as follows:

[0031] (1) Slurry the raw ore until the pulp concentration is 38%. Calculated per ton of raw ore, add 40g / t of sulfur mixed collector and 30g / t of foaming agent in sequence, and carry out rough separation of sulfur ...

Embodiment 2

[0036] Embodiment 2: In this embodiment, the mixed sulfur collector is made from the following components by mass: sodium alkyl sulfonate 70g, CuSO 4 30g, 70g sodium alkylsulfonate, 30g CuSO 4 The mixed sulfur collector is obtained by mixing uniformly in parts by mass.

[0037] The tin mixed collector of the present embodiment is made by the component of following mass parts: salicylic hydroxamic acid 30g, benzohydroxamic acid 50g, oleic acid 20g; The salicylic hydroxamic acid of 30g, the benzohydroxamic acid of 50g and 20g of oleic acid was mixed uniformly to obtain a tin mixed collector.

[0038] Use the mixed sulfur collector and tin mixed collector prepared in this example to process a certain fine-grained cassiterite in Wenshan, Yunnan. The raw ore tin grade is 0.138%. The specific steps are as follows:

[0039] (1) Slurry the raw ore until the concentration of the pulp is 40%. Calculated per ton of raw ore, add sulfur mixed collector 60g / t, foaming agent 50g / t in sequ...

Embodiment 3

[0044] Embodiment 3: In this embodiment, the mixed sulfur collector is made from the following components by mass: sodium alkyl sulfonate 90g, CuSO 4 10g, 90g sodium alkylsulfonate, 10g CuSO 4 The mixed sulfur collector is obtained by mixing uniformly in parts by mass.

[0045] The tin mixed collector of the present embodiment is made from the following components by mass: salicylic hydroxamic acid 40g, benzohydroxamic acid 40g, oleic acid 20g; 20g of oleic acid was mixed uniformly to obtain a tin mixed collector.

[0046] Use the mixed sulfur collector and tin mixed collector prepared in this example to process a certain fine-grained cassiterite in Gejiu, Yunnan. The raw ore tin grade is 0.224%. The specific steps are as follows:

[0047] (1) Slurry the raw ore until the concentration of the pulp is 45%. Calculated per ton of raw ore, add 80g / t of sulfur mixed collector and 60g / t of foaming agent in sequence, and carry out rough separation of sulfur to obtain rough sulfur ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com