Purification technique for mineral separation of low-grade fine crystalline flake graphite

A fine-scale, low-grade technology, applied in the field of mineral processing and purification of low-grade fine-scale graphite, can solve the problems of unreasonable ore treatment, low regrinding efficiency, and high beneficiation cost, so as to reduce the cost of beneficiation and improve the fixation of carbon in concentrate content, reducing the effect of enrichment operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

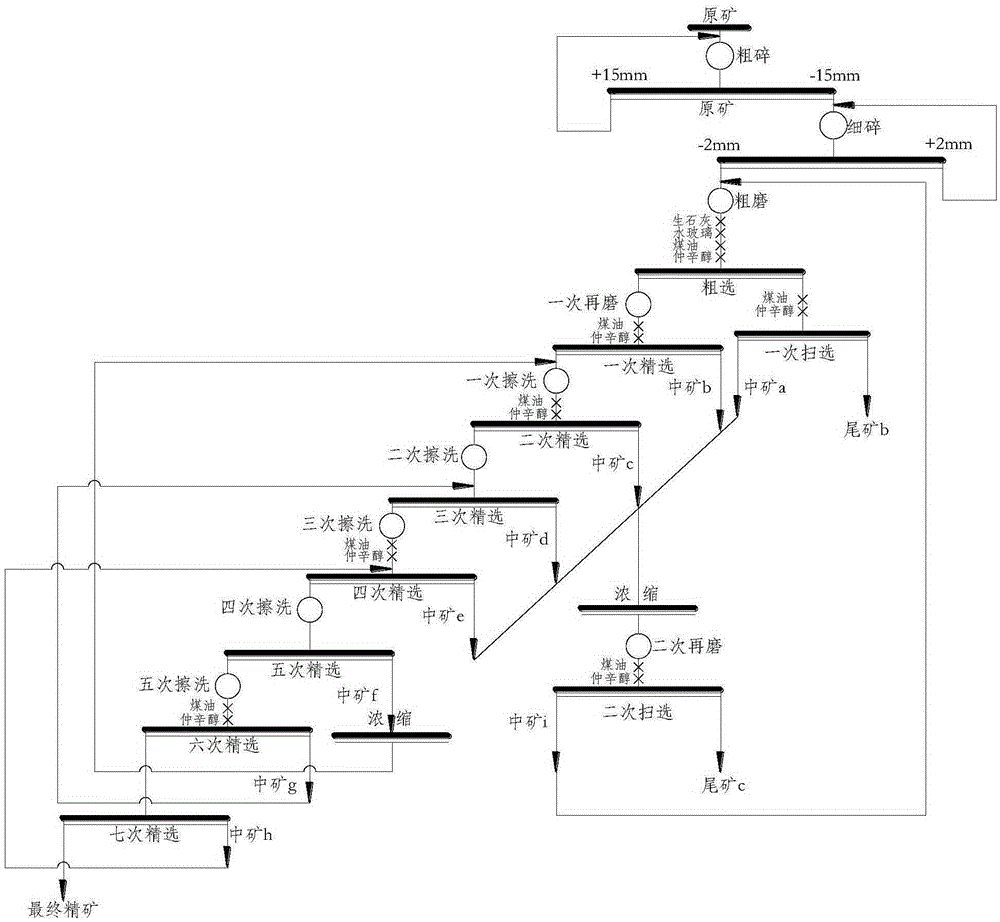

[0031] A low-grade fine flake graphite ore dressing and purification process, the process flow chart is shown in figure 1 , including the following steps:

[0032] A. Put the low-grade fine flake graphite raw ore with fixed carbon content of 8.93% into the jaw crusher for coarse crushing. The particle size of the coarsely crushed product is 10-15mm, and then put the coarsely crushed product into the roller crusher for fine crushing to -2mm. Use conical ball mill for coarse grinding, the grinding concentration is 65%, the grinding fineness is -0.074mm, and the content is 88.95%; add inhibitor quicklime and regulator water glass to the obtained ground low-grade fine flake graphite ore , Collector kerosene and foaming agent 2-octanol are fully stirred and roughed, the roughing concentration is 25%, the roughing time is 6.5min, and the rough concentrate and tailings a are obtained; the roughing agent formula is per ton Add 1500g of quicklime, 800g of water glass, 360g of kerosen...

Embodiment 2

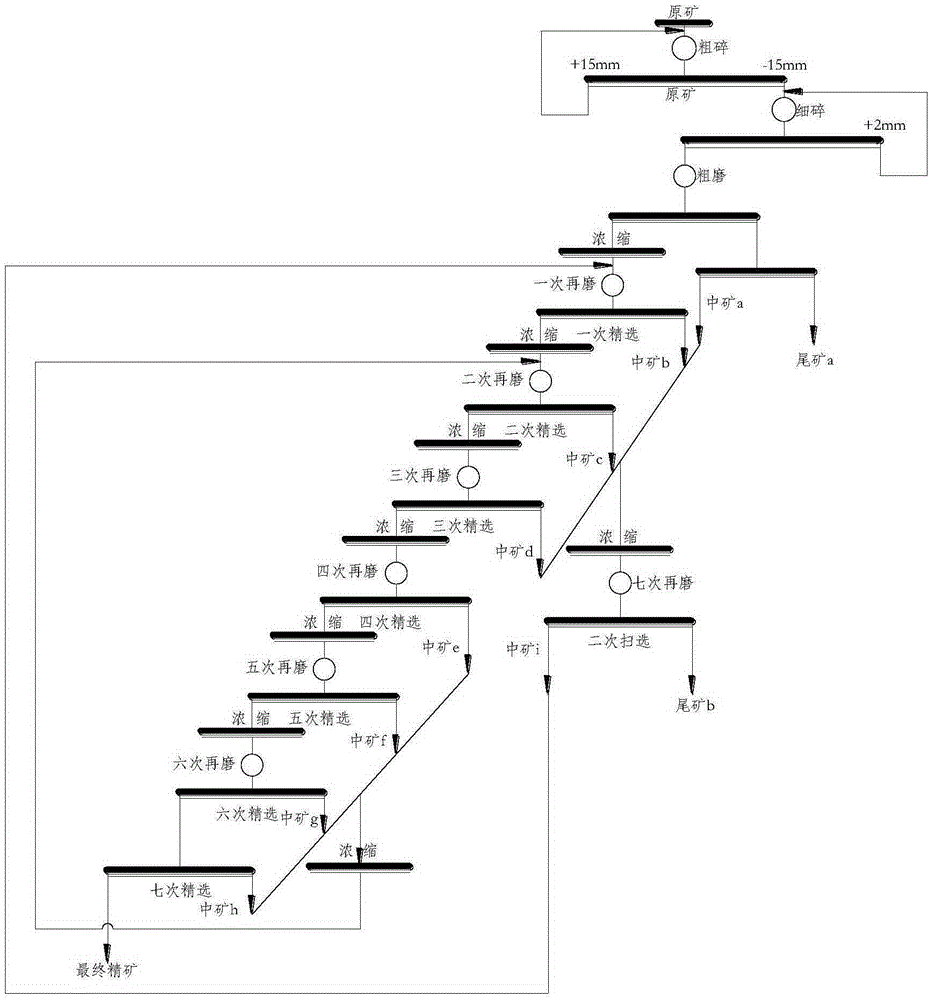

[0043] A low-grade fine flake graphite ore dressing purification process, it comprises the following steps:

[0044] A. Put the low-grade fine flake graphite raw ore with fixed carbon content of 10.55% into the jaw crusher for coarse crushing, the coarse crushed product has a particle size of 10-15mm, and then put the coarse crushed product into the roller crusher for fine crushing to -2mm, Use conical ball mill for coarse grinding, the grinding concentration is 65%, the grinding fineness is -0.074mm, and the content is 87.89%; add inhibitor quicklime and regulator water glass to the obtained ground low-grade fine flake graphite raw ore , Collector kerosene and foaming agent 2-octanol are fully stirred and roughed, the roughing concentration is 25%, the roughing time is 7min, and the rough concentrate and tailings a are obtained; the formula of the roughing agent is low Add 1500g of quicklime, 1000g of water glass, 400g of kerosene and 100g of secondary octanol to the raw ore ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com