Mineral separation process and system for ultra-lean magnetite ore

An ultra-lean magnetite and process technology, applied in the field of ultra-lean magnetite beneficiation process and system, can solve the problems of high energy consumption for grinding and magnetic separation, the need to build tailings ponds, and large water consumption for ore beneficiation, achieving Low storage cost, improved sorting index and filtration efficiency, and reduced grinding fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

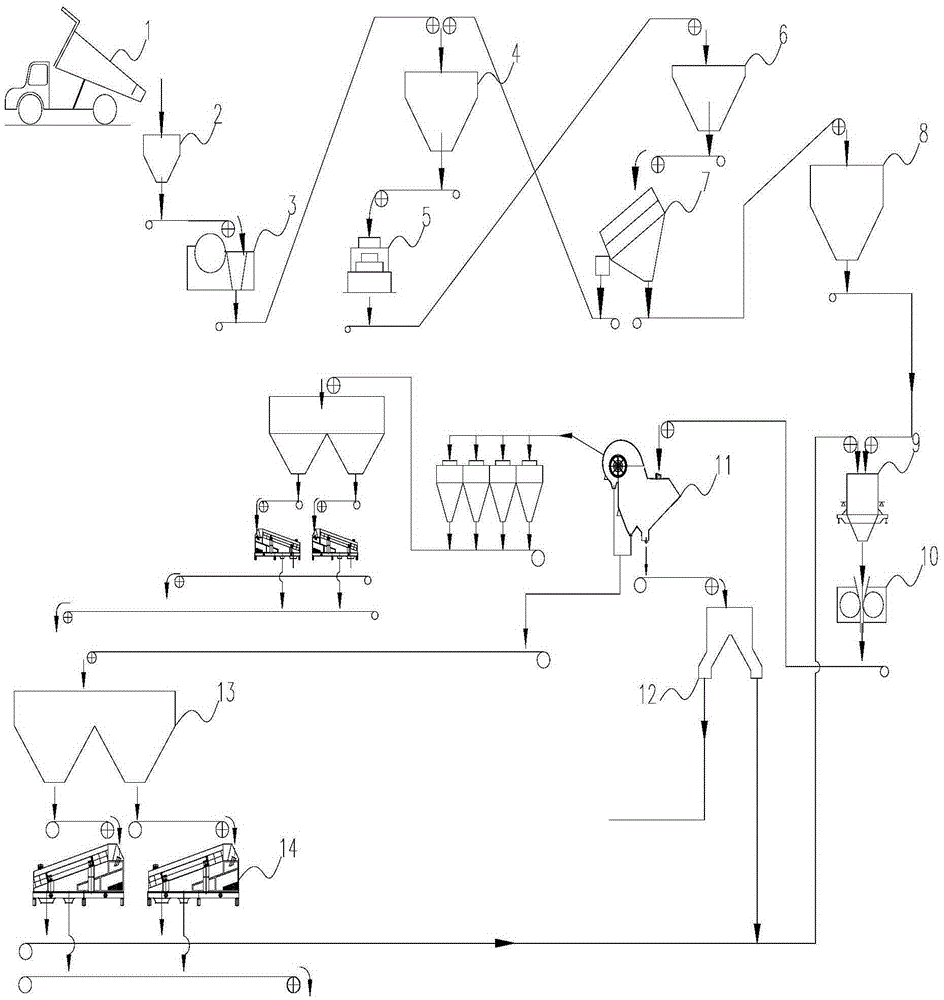

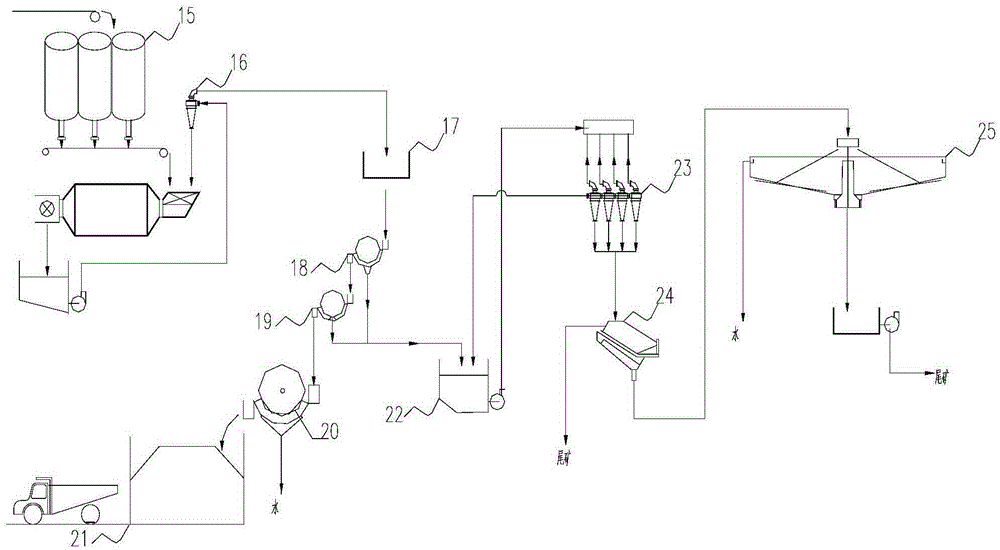

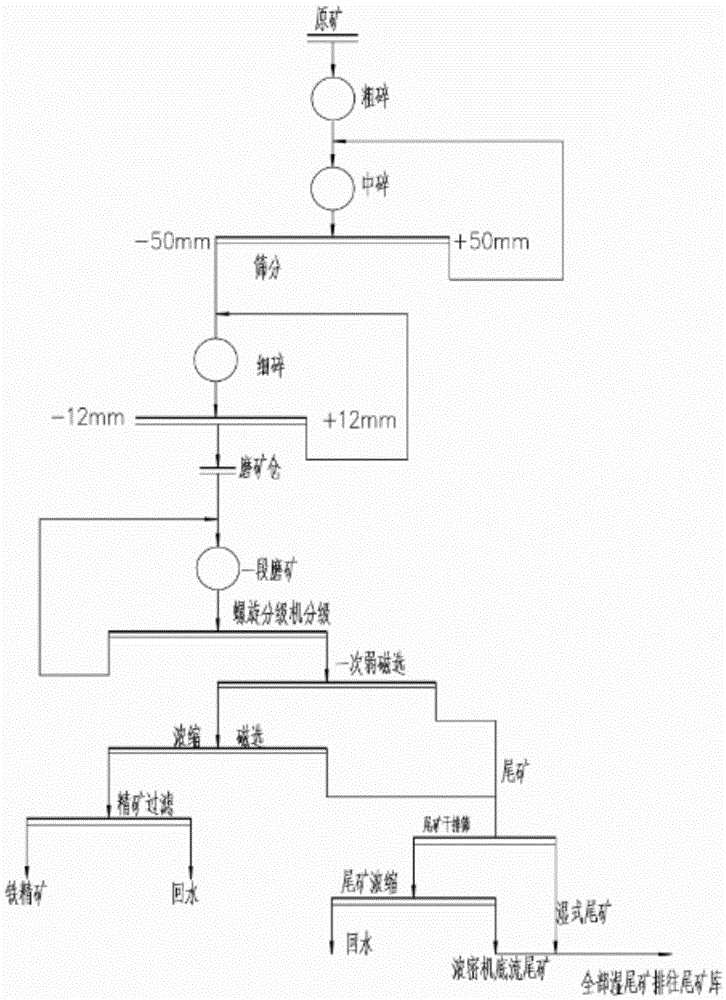

[0053] Such as figure 1 and 2 Shown:

[0054] Step 1, coarse and medium crushing and screening: the processing capacity of raw ore is 16.5 million tons per year, and the raw ore extracted from the stope is unloaded into the coarse crushing buffer bin 2 by the automobile coarse crushing workshop, and the coarse crushing equipment 3 is PEJ- 4 sets of 1200×1500 jaw crushers, 2 sets of CH870 cone crushers and 2 sets of PYH-8C cone crushers for medium crushing equipment 5, YA-2460 circular vibrating screen 7 for screening equipment, after coarse crushing, it enters secondary crushing The buffer bin 4 enters the screening buffer bin 6 after intermediate crushing, and then enters the circular vibrating screen 7 for screening. The material on the screen (above 50mm) returns to the intermediate crushing to form a closed circuit, and the material under the screen (below 50mm) enters the high-pressure roller mill Intermediate storage bin 8.

[0055] Step 2, ultra-fine crushing and cla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com