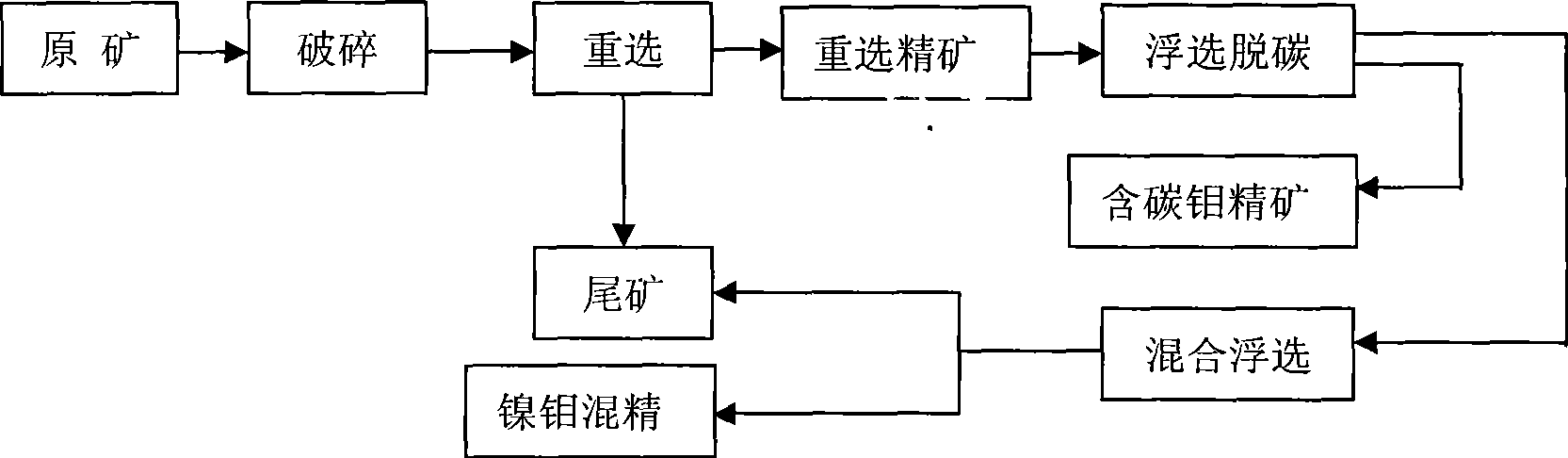

Mineral separation process of high-carbon molybdenum-nickel ore

A beneficiation method and carbon-nickel-molybdenum technology, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of small recovery rate, increase and decrease of flotation recovery rate, etc. The effect of large consumption and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

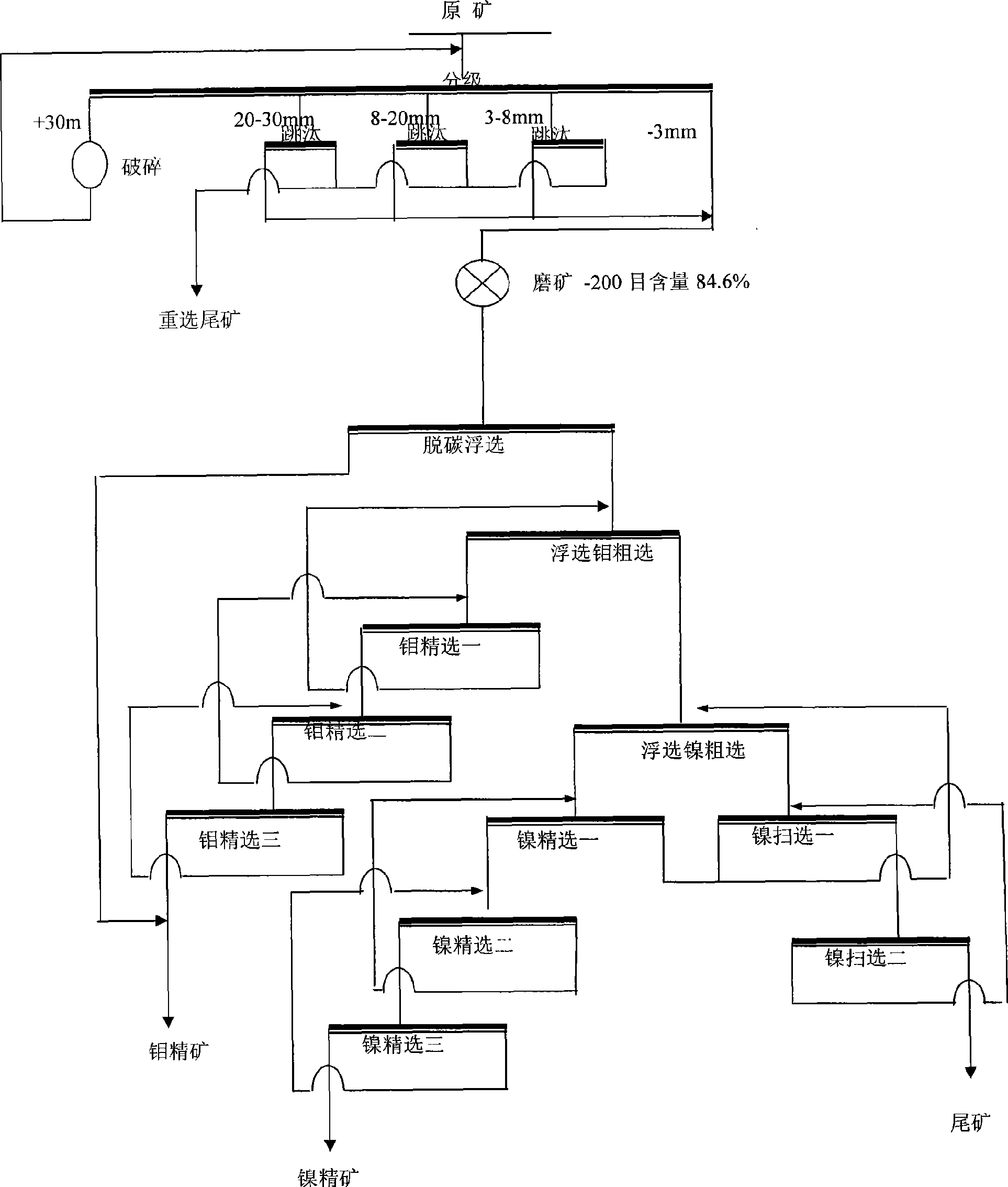

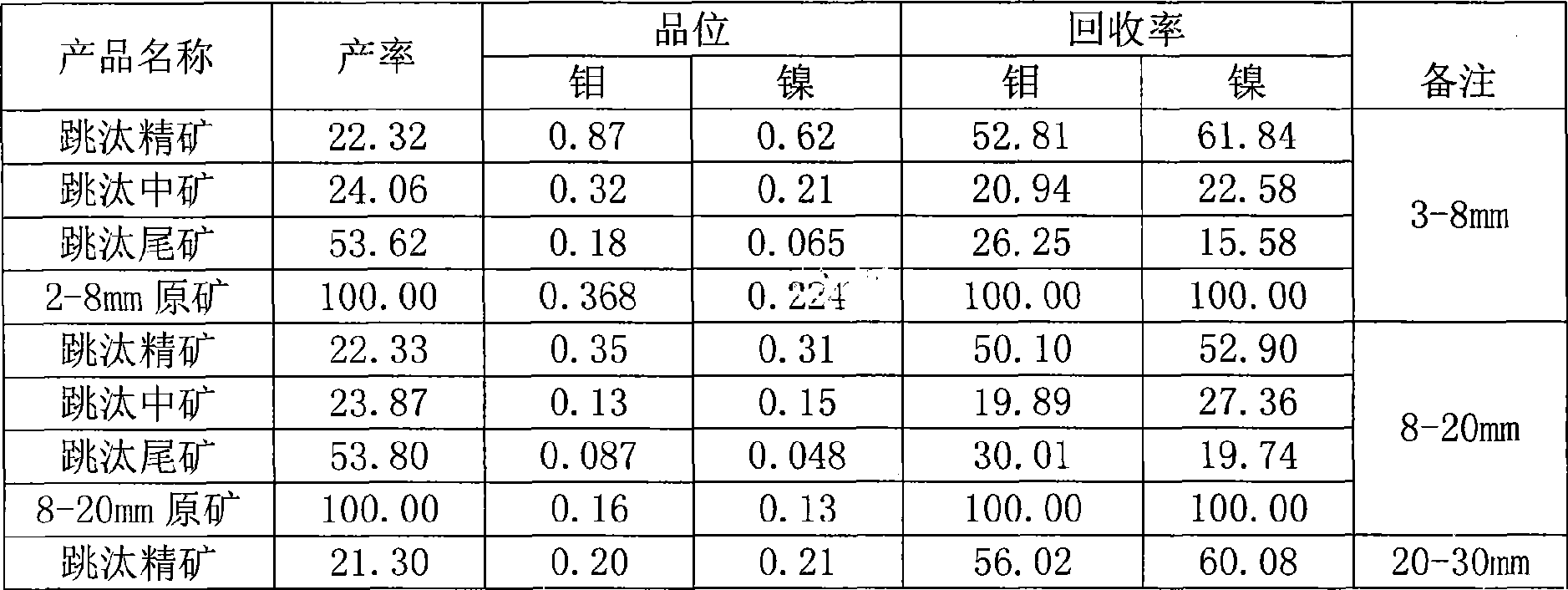

[0022] The nickel-molybdenum ore bulk raw ore is roughly crushed, divided into three grades of 3-8mm, 8-20mm, and 20-30mm, and then undergoes jigging gravity separation respectively. Table 1 shows the results of grading and jigging for the three particle sizes.

[0023] Table 1 Results of graded jigging (%)

[0024]

[0025]

[0026] The combined yield of jigging concentrate and middle ore is 45.91%, molybdenum grade is 0.28%, recovery rate is 73.07%; nickel grade is 0.23%, recovery rate is 80.37%. The yield of jigging tailings is 54.09%, the molybdenum grade is 0.095%, the recovery rate is 26.93%; the nickel grade is 0.065%, the recovery rate is 19.63%.

[0027] Gravity-selected concentrate, medium ore and -3mm raw ore are combined and ground by a ball mill to a fineness of 84.6%-200 mesh. The high-carbon nickel-molybdenum ore contains 40% carbon, which is decarbonized by flotation. Na 2 SiO 3 As an inhibitor of gangue minerals, kerosene and 2 # The oil is used as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com