Paint waste gas processing system and use method thereof

A technology for waste gas treatment and paint, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation to achieve the effect of thorough treatment and low heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

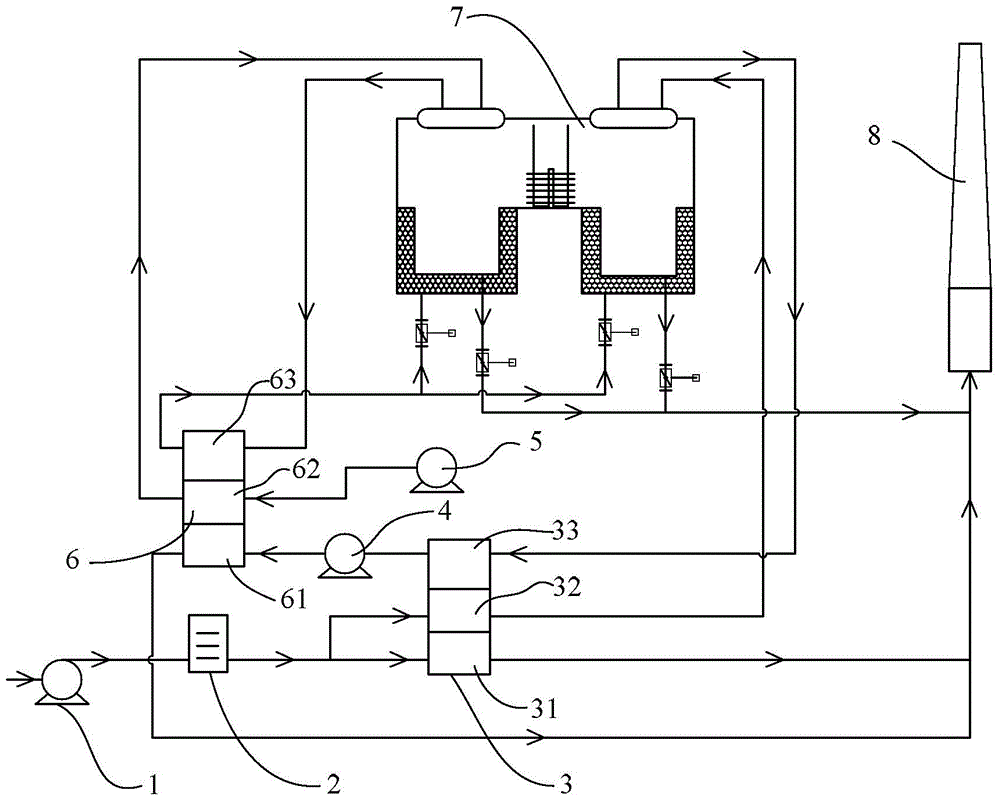

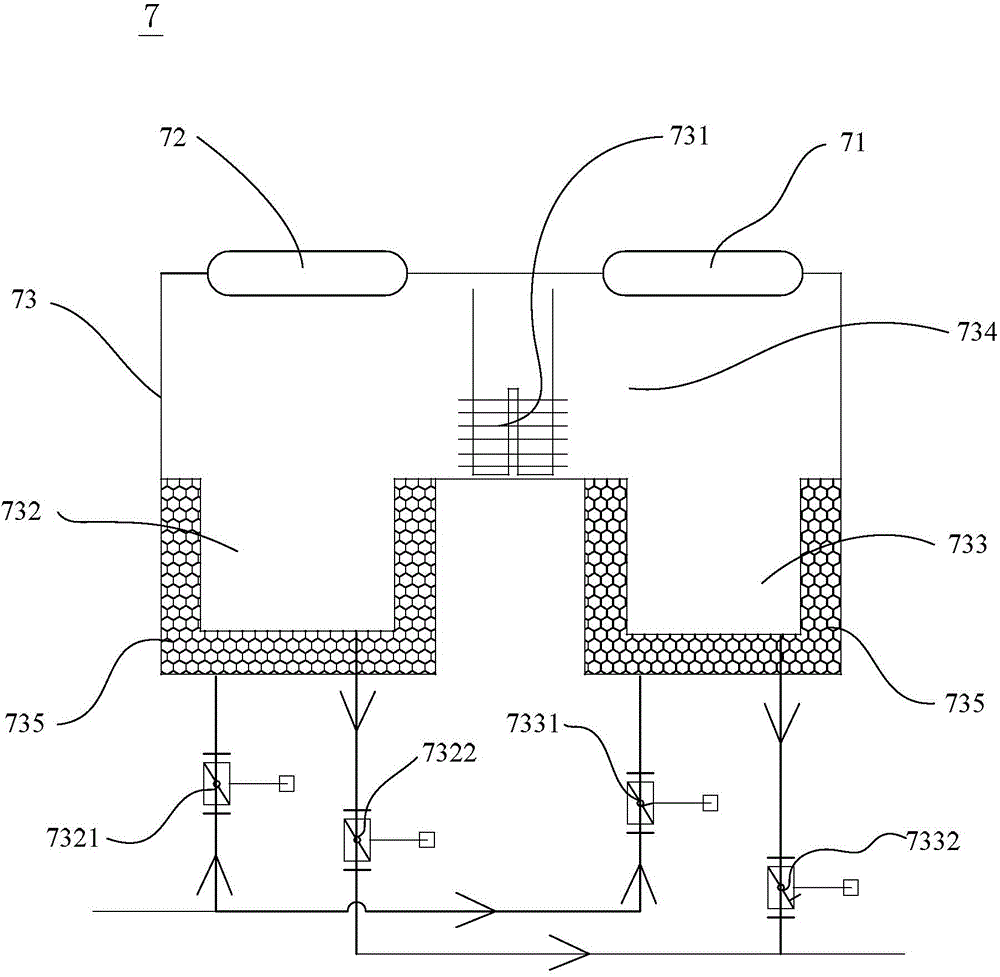

[0018] The paint waste gas treatment system provided by the invention is used to treat the waste gas generated in the paint production process, such as figure 1 As shown, the paint waste gas treatment system provided by the present invention includes a waste gas fan 1, a dry filter 2, a first concentration runner 3, a booster fan 4, an air fan 5, a second concentration runner 6, and a heat exchange oxidation device 7 and chimney8.

[0019] Said first and second concentrating runners 3 and 6 respectively comprise first and second runners and first and second casings (not shown in the figure), said first and second runners are provided with Adsorption material, prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com