Ore grinding mineral dressing process for large molybdenum ore

A molybdenum ore and large-scale technology, which is applied in the field of grinding and beneficiation of large-scale molybdenum ore, can solve difficult copper recovery and other problems, achieve rapid failure, reduce equipment investment and operation costs, and reduce processing difficulty and equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

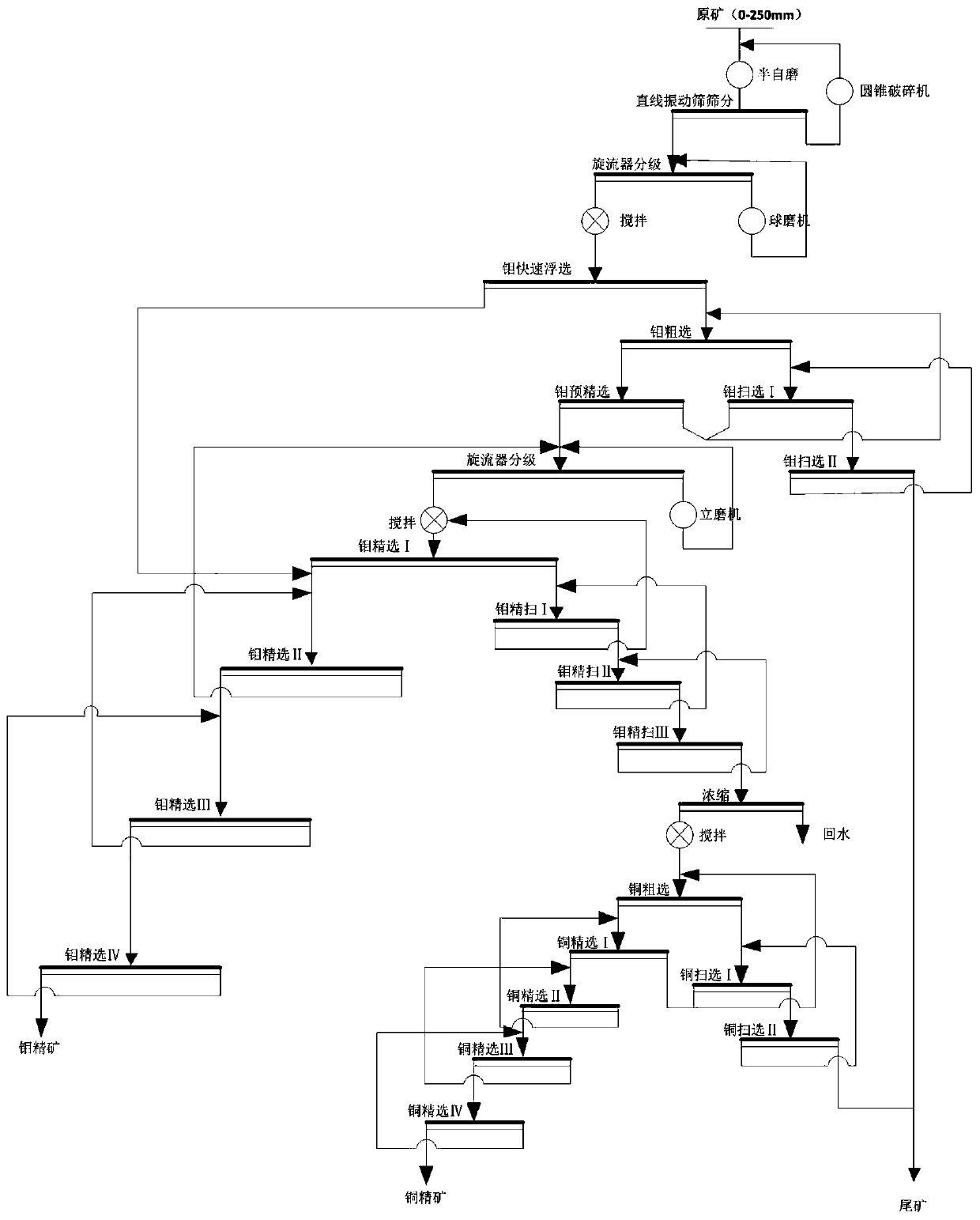

[0018] Embodiment one: if figure 1 Shown, the ore grinding and beneficiation process of a kind of large-scale molybdenum ore involved in the present embodiment, such as figure 1 As shown, in the ore grinding and beneficiation process of the present invention, the raw ore contains molybdenum metal of 0.088%-0.150% and copper metal of 0.016%-0.030%, and its main minerals are molybdenite, chalcopyrite, and chalcocite. Grinding and beneficiation steps are as follows:

[0019] The raw ore with a particle size of 0-250mm, a molybdenum grade of 0.088%-0.150%, and a copper grade of 0.016%-0.030% is fed into the SABC closed circuit composed of semi-autogenous grinding, linear vibrating screen, cyclone, ball mill and cone crusher. Grinding and grading system; the particle size of the grinding product is -0.074mm, accounting for 58-62%, and the pulp with a concentration of 28%-33% is fed into the flotation process after pulping;

[0020] The copper and molybdenum mixed flotation proces...

Embodiment 2

[0024] Embodiment two: if figure 1 Shown, the ore grinding and mineral processing technology of a kind of large-scale molybdenum ore involved in the present embodiment, the medicament system among the present invention is:

[0025] Add collector (kerosene) 30g / t-160g / t to molybdenum selection operation; copper inhibitor (sodium thioglycolate) 80g / t-200g / t; adjuster (liquid sodium silicate) 150g / t-230g / t; Foaming agent (2# oil) 18g / t-60g / t;

[0026] Copper beneficiation operation adds collector (EP type ore dressing agent produced by Beijing Institute of Mining and Metallurgy) 5-10g / t ore feeding, gangue inhibitor (liquid sodium silicate) 30-50g / t ore feeding, pH value adjustment Add 30-100g / t of lime (quicklime) to the ore.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com