Novel organic fertilizer and preparation method thereof

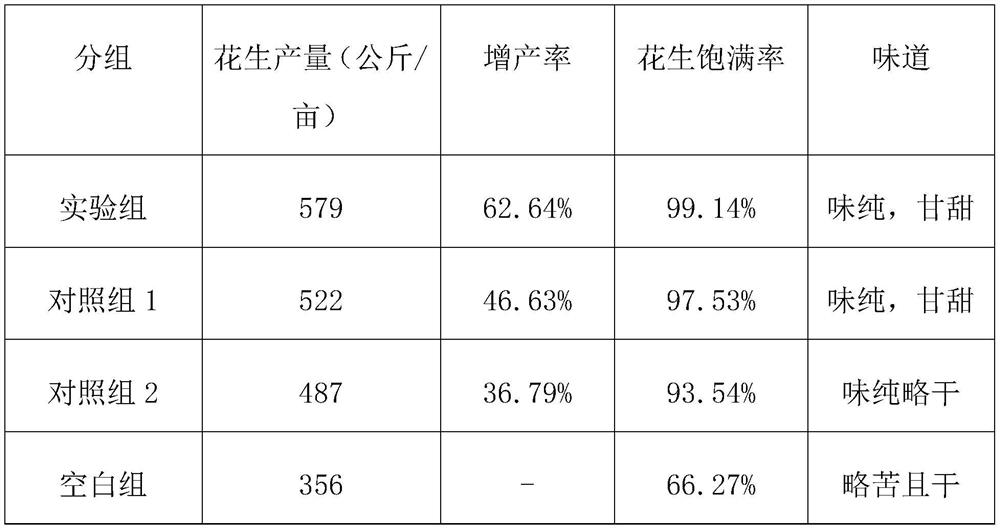

An organic fertilizer, a new type of technology, applied in the field of new organic fertilizer and its preparation, can solve the problems of soil and agricultural product pollution, waste of resources, failure to improve soil, etc., achieve high environmental protection and economic significance, provide yield and taste, and shorten fermentation cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The embodiment of the present application also provides a preparation method of a novel organic fertilizer, the steps of the preparation method comprising:

[0036] Weigh and mix fungus residue, sawdust, bean dregs, plant ash and sheep manure according to the weight ratio, and send the mixture into the fermentation tank; The novel organic fertilizer can be obtained by sieving.

[0037] Preferably, the fungus residue includes ganoderma residue and mushroom residue, and the ganoderma residue is preferred in the present invention, and the ganoderma residue is a culture material for artificially cultivating ganoderma.

[0038] Preferably, the plant ash is ash from burning crop straws or briquetted sawdust, which plays the role of crop straw waste utilization and resource recycling.

[0039] Preferably, the addition ratio of the starter to the mixture is (0.45-0.55) kg: 1m 3 , Organic fertilizer starter is organic material decomposing agent, which can decompose protein, ce...

Embodiment 1

[0046] A new type of organic fertilizer is made from the following raw materials in weight percentage: 15% fungus residue, 10% sawdust, 25% bean dregs, 20% plant ash and 30% sheep manure. The mushroom residue in this embodiment is Ganoderma lucidum residue; the plant ash in this embodiment is the ash from burning crop straw or briquetting sawdust.

[0047] Preparation method: Weigh and mix ganoderma residue, sawdust, bean dregs, plant ash and sheep manure according to the above weight ratio, and send the mixture into a fermentation tank; add a starter to the mixture, and the ratio of the starter to the mixture is 0.5kg: 1m 3 , use the turning equipment to turn the mixture, keep it warm for 3 days after the fermentation temperature reaches 60°C, then turn it over for the second time, keep it warm for 3 days after the fermentation temperature reaches 60°C again, and then turn it for the third time, After the fermentation temperature reaches 60°C, keep it warm for 3 days; send t...

Embodiment 2

[0050] A new type of organic fertilizer is made from the following raw materials in weight percentage: 10% fungus residue, 15% sawdust, 22% bean dregs, 25% plant ash and 28% sheep manure. The mushroom residue in this embodiment is mushroom residue; the plant ash in this embodiment is the ash from burning crop straw or briquetting sawdust.

[0051] Preparation method: Weigh and mix fungus residue, sawdust, bean dregs, plant ash and sheep manure according to the above weight ratio, and send the mixture into a fermentation tank; add a starter to the mixture, and the ratio of the starter to the mixture is 0.55kg: 1m 3 , use the turning equipment to turn the mixture, keep it warm for 3 days after the fermentation temperature reaches 60°C, then turn it over for the second time, keep it warm for 3 days after the fermentation temperature reaches 60°C again, and then turn it for the third time, After the fermentation temperature reaches 60°C, keep it warm for 3 days; send the fermente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com