Cathode catalyst and cathode structure of membrane electrode electrolysis ozone generator

An ozone generator and cathode catalyst technology, which is applied in the field of electrochemistry, can solve the problems affecting the commercialization process of membrane electrode electrolysis ozone generators, the high cost of membrane electrodes, and the high price of precious metals, so as to promote the industrialization process and have a simple structure. , the effect of simple cathode structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, the cathode catalyst of membrane electrode electrolytic ozone generator of the present invention is the iron alloy containing Mo, Cr, Ni, and the composition content of its iron alloy is:

[0026] Mo 2-2.5% Cr 16-16.5% Ni 10-12% S≤0.02% Si≤0.5% Mn≤1% C≤0.02% P≤0.02% The rest is Fe.

Embodiment 2

[0027] Embodiment 2, the cathode catalyst of membrane electrode electrolysis ozone generator of the present invention is the iron alloy containing Mo, Cr, Ni, and the composition content of its iron alloy is:

[0028] Mo 2.5-3% Cr 16.5-17% Ni 11-13% S≤0.03% Si≤1% Mn≤1.5% C≤0.03% P≤0.03% The rest is Fe.

Embodiment 3

[0029] Embodiment 3, the cathode catalyst of membrane electrode electrolysis ozone generator of the present invention is the iron alloy containing Mo, Cr, Ni, and the composition content of its iron alloy is:

[0030] Mo 2-3% Cr 16-18% Ni 10-14% S≤0.03% Si≤1% Mn≤2% C≤0.03% P≤0.035% The rest is Fe.

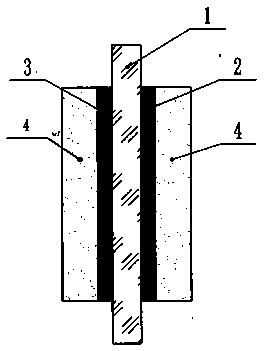

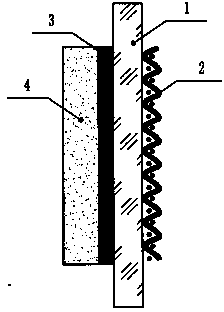

[0031] refer to figure 2 As shown, the membrane electrode structure of the electrolytic ozone generator using the above-mentioned iron alloy as the cathode catalyst is an iron alloy wire mesh 2 (also the cathode catalyst 2) woven from the iron alloy wire of the above-mentioned embodiment, without any other chemical and electrochemical processes. Reprocessing, cutting to the required shape of the membrane electrode, and then directly covering one side of the ion exchange membrane 1. In practice, the mesh size of the ferroalloy mesh is 300-600 mesh is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com