Broken tea refined processing technique

A refining and processing technology, applied in the field of refining and processing of broken tea, can solve the problems of large environmental pollution, unsanitary products, occupying space, etc., and achieve the effects of prolonging cooling time, preventing coking, and accelerating temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

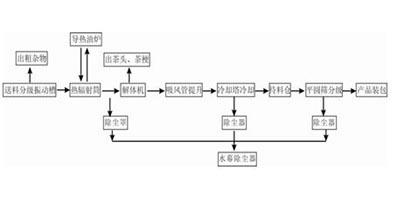

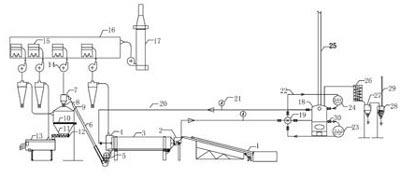

[0014] Such as figure 1 As shown, the equipment of the present invention is connected in the following manner: the feeding grading vibration tank 1 is connected to the feeder 2 of the dryer, the outlet of the heat radiation cylinder 3 of the dryer is inserted into the dust removal cover 4, and the feed hopper of the dismantling machine 5 is connected to the heat of the dryer. The discharge port of the radiant tube 3, the discharge port of the dismantling machine is connected to the bottom of the suction pipe 6, the top of the suction pipe is connected to the Shacron 7, the top air outlet of the Sacron is connected to the induced draft fan 14, and the discharge port at the bottom of the Sacron is connected to the closed air 8, the lower outlet of the air shut-off device is connected to the cooling tower 9, the bottom of the cooling tower is connected to the automatic feeder 10, and its bottom surface receives the silo 11, and the outlet of the silo is connected to the spiral con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com