Patents

Literature

53results about How to "Convenience for follow-up production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

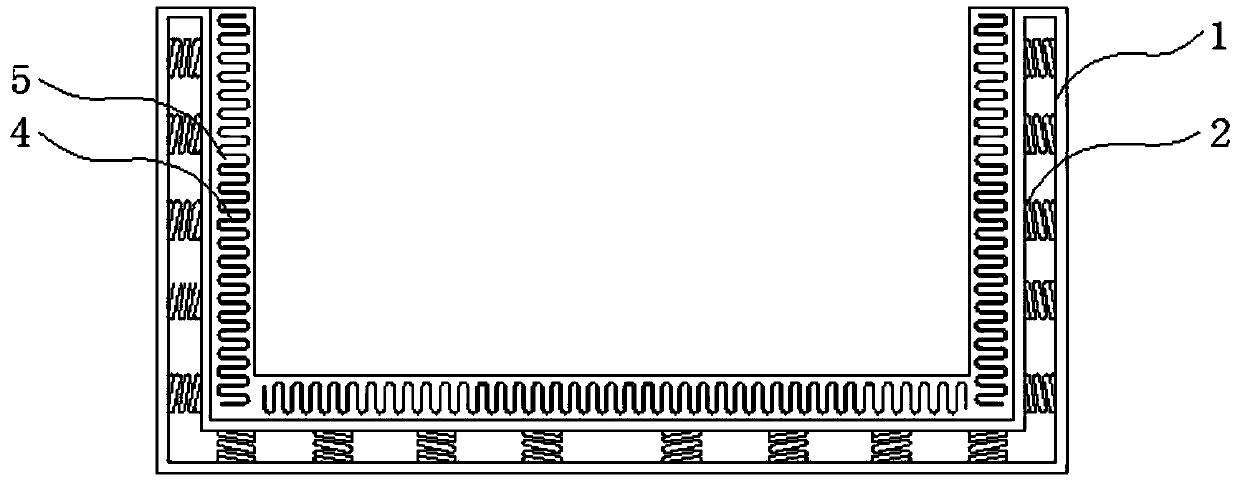

Constant temperature heating paper pulp tank with automatic stirring and dosing function

PendingCN109663531AAvoid LeakageIncrease productivityRotary stirring mixersTransportation and packagingPulp and paper industryAutomatic testing

The invention discloses a constant temperature heating paper pulp tank with an automatic stirring and dosing function. The constant temperature heating paper pulp tank comprises a protection frame, astorage tank, a telescopic support, a filter cavity and a discharge pipe, wherein the inner wall of the protection frame is provided with an anti-collision elastic plate; the inner wall of the anti-collision elastic plate is provided with a paper pulp tank body; the telescopic support is fixedly welded at the middle part of the outer wall of the protection frame; the inner wall of the filter cavity is fixedly connected with a mounting block in a welding manner; the inner wall of the mounting block is respectively provided with a first filter screen and a second filter screen; and the dischargepipe is arranged at the tail end of the filter cavity. In the constant temperature heating paper pulp tank with the automatic stirring and dosing function, the protective frame, the anti-collision elastic plate and the pulp tank are arranged layer by layer in a descending manner, so that a function for protecting the paper pulp tank can be achieved, and the paper pulp tank also has the anti-collision function; and moreover, an electric heating wire is installed in an S shape inside the storage tank, so that raw materials in the paper pulp tank can be heated, the paper pulp tank is always at aconstant temperature state, and the production efficiency of the paper pulp can be increased.

Owner:蒙雪锋

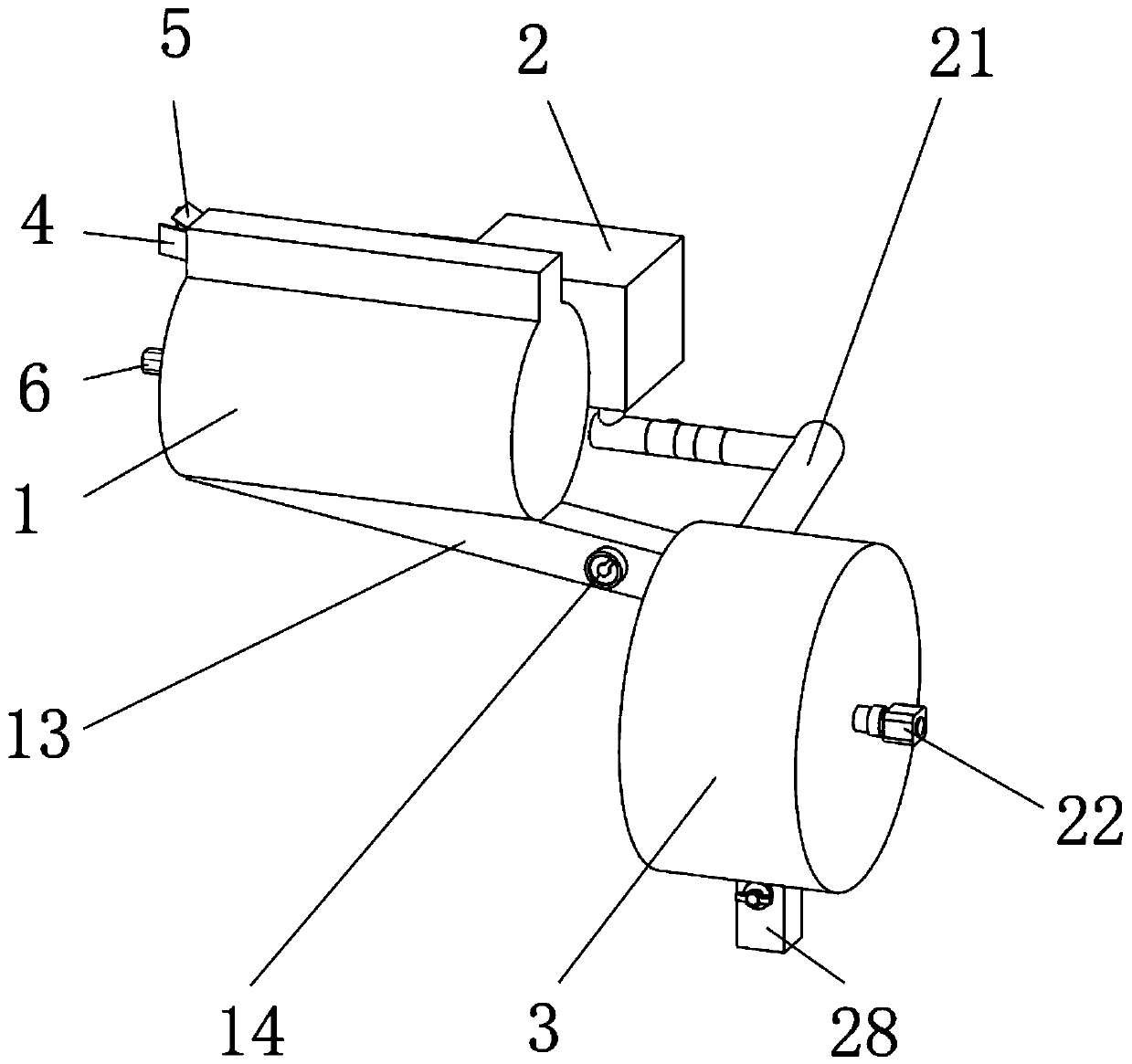

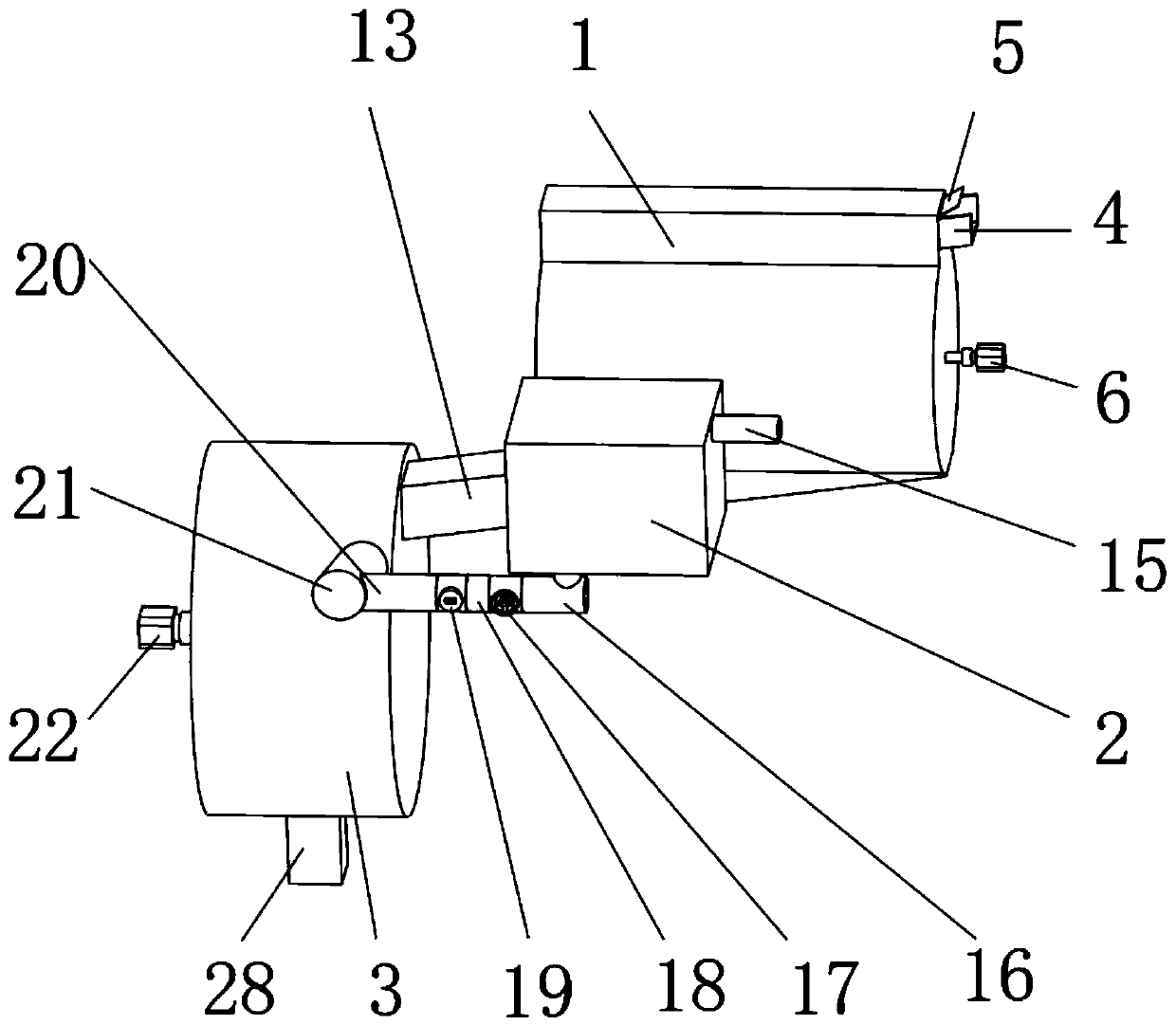

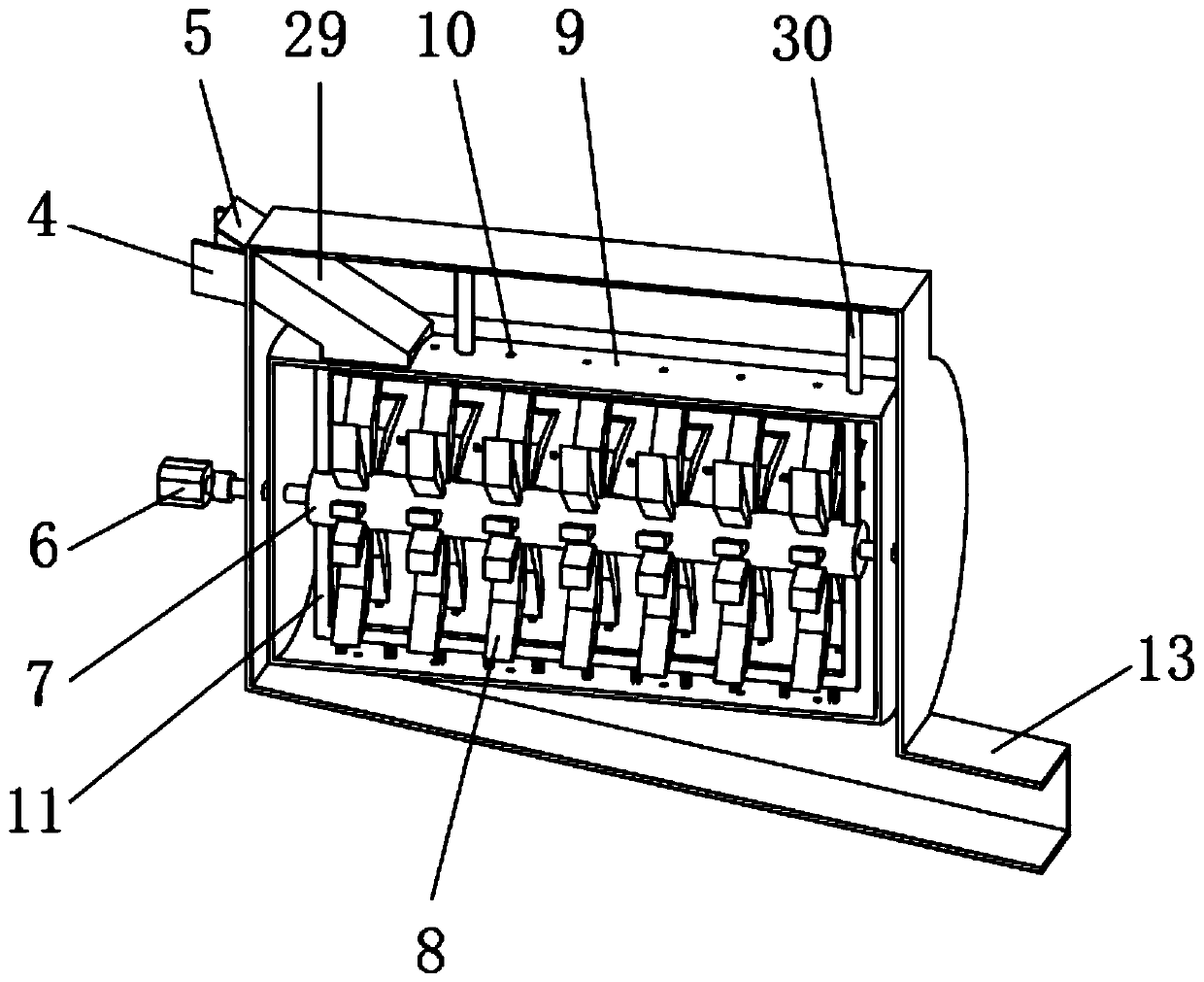

Rim production method facilitating mass material preparation

ActiveCN114102054AGuaranteed welding effectQuality assuranceRimsWheel manufactureCircular sectionManufacturing engineering

The rim production method comprises the following steps that an aluminum plate is cut into rectangular aluminum plate units, and turnups are formed at the ends, in the length direction, of the aluminum plate units; the middles of the aluminum plate units are bent towards the sides where the flanges are located, so that the aluminum plate units form a U-shaped structure; the turned-over edges are pressed to be located in the same plane, the opposite end faces are attached, and the aluminum plate units form a barrel through welding and fixing; machining the barrel into a rim barrel-shaped blank with a circular section; a tire mounting groove and a tire mounting surface are machined in a barrel opening in one end of the rim barrel-shaped blank; carrying out deformity shaping on the rim blank processed with the tire mounting groove and the tire mounting surface; and the shaped rim blank is machined into a rim unit or a rim. According to the rim production method facilitating mass material preparation, rim blanks of the same model can be used for rims of different models and sizes, so that the rim blanks can produce more types of rims, and material preparation and production of the rim blanks are facilitated.

Owner:刘湘平

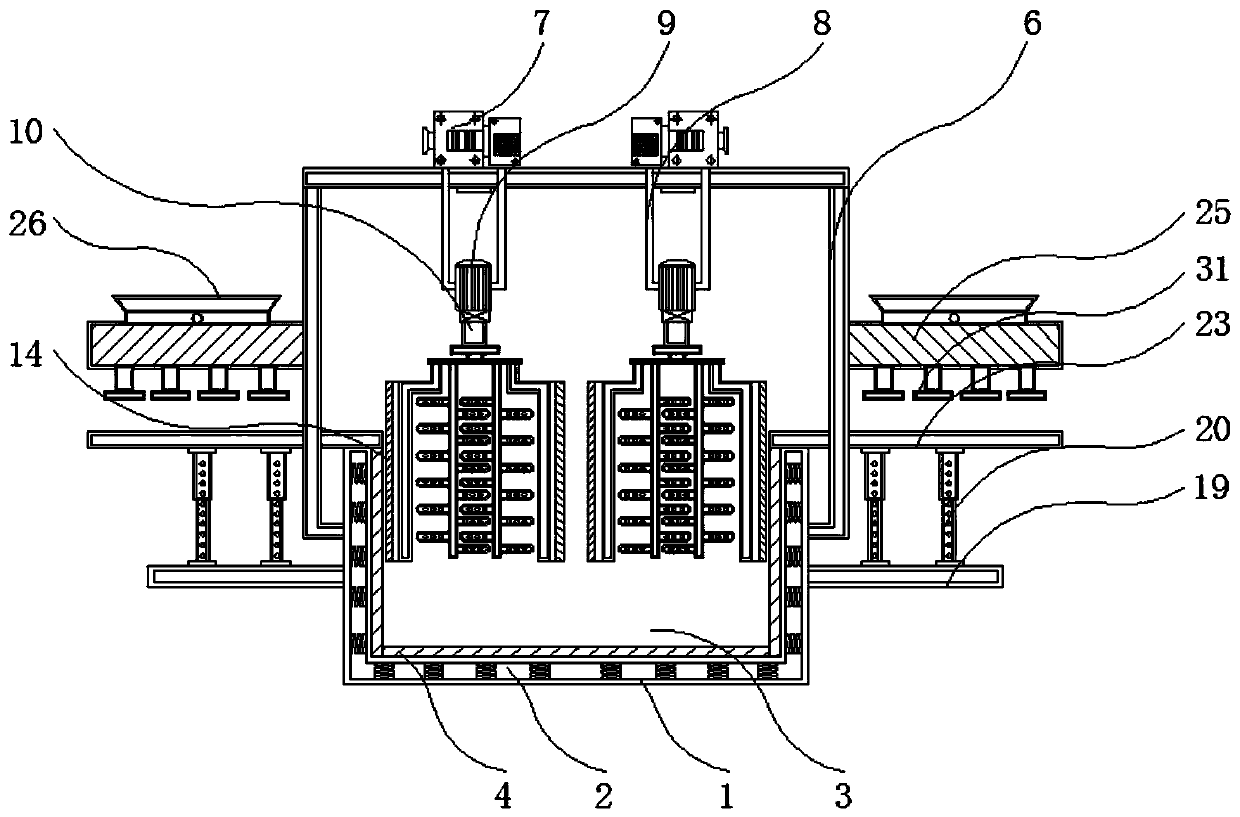

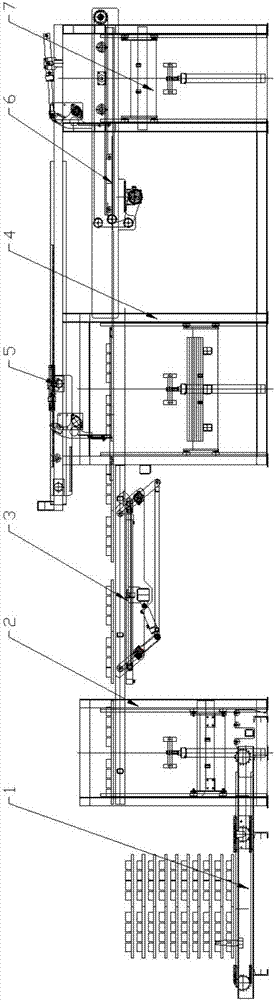

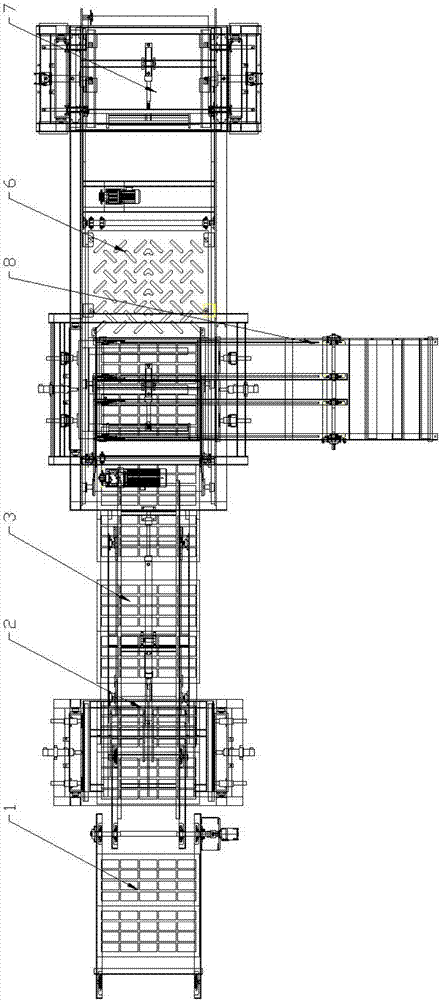

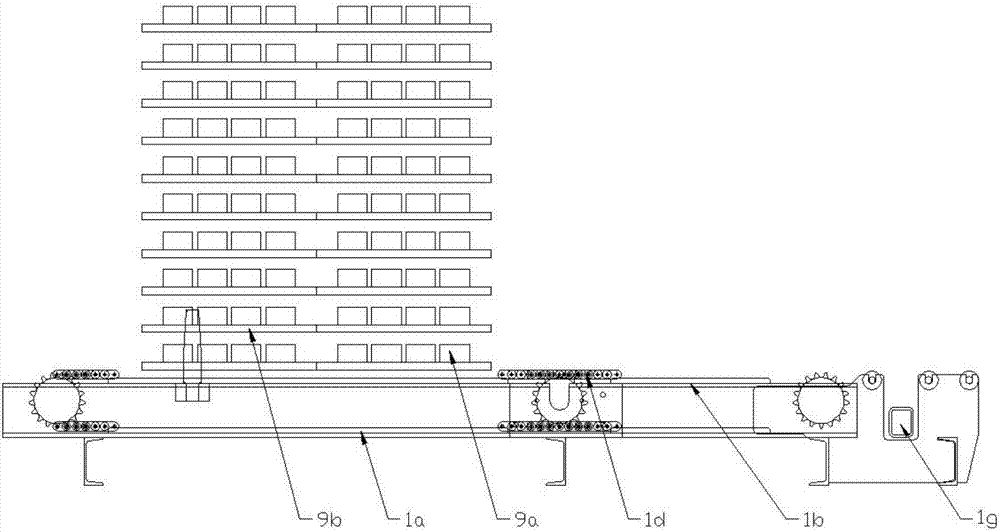

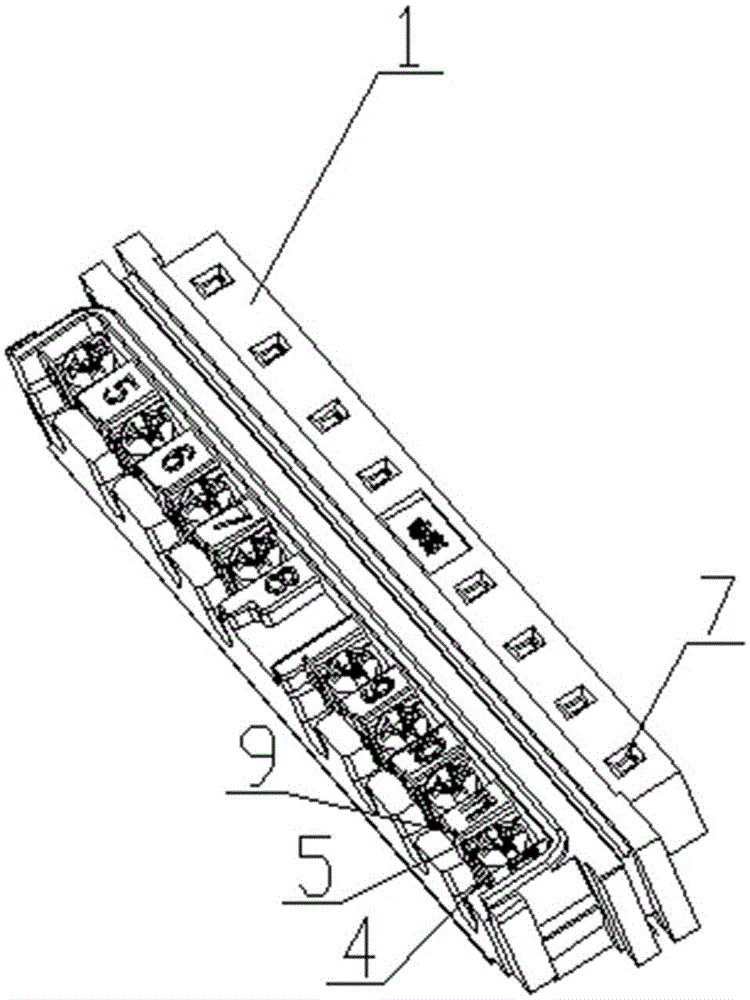

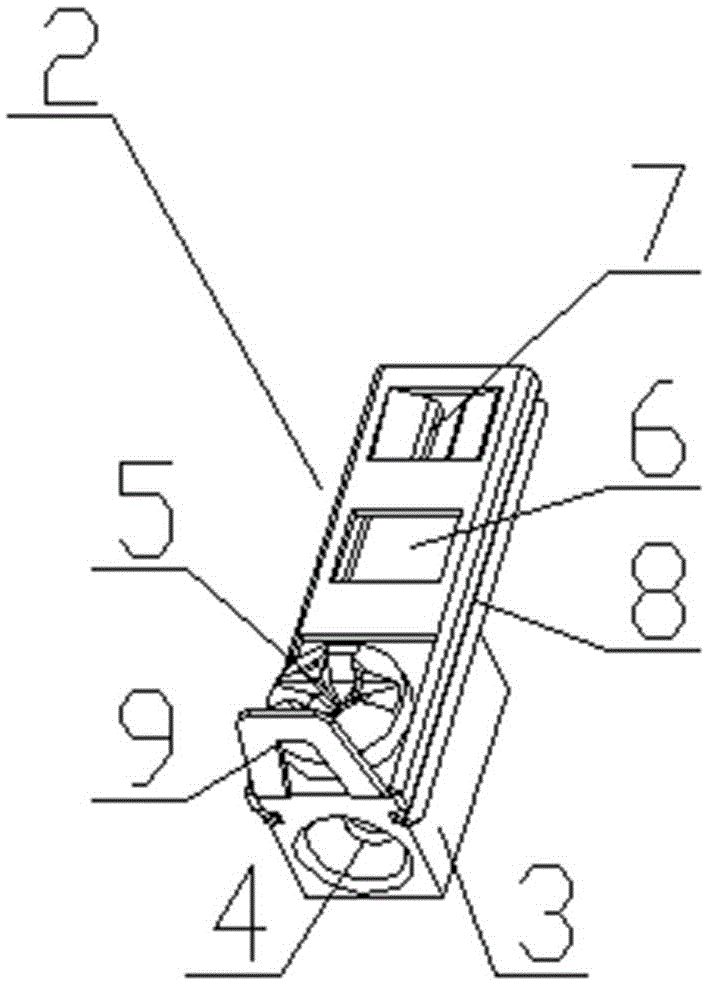

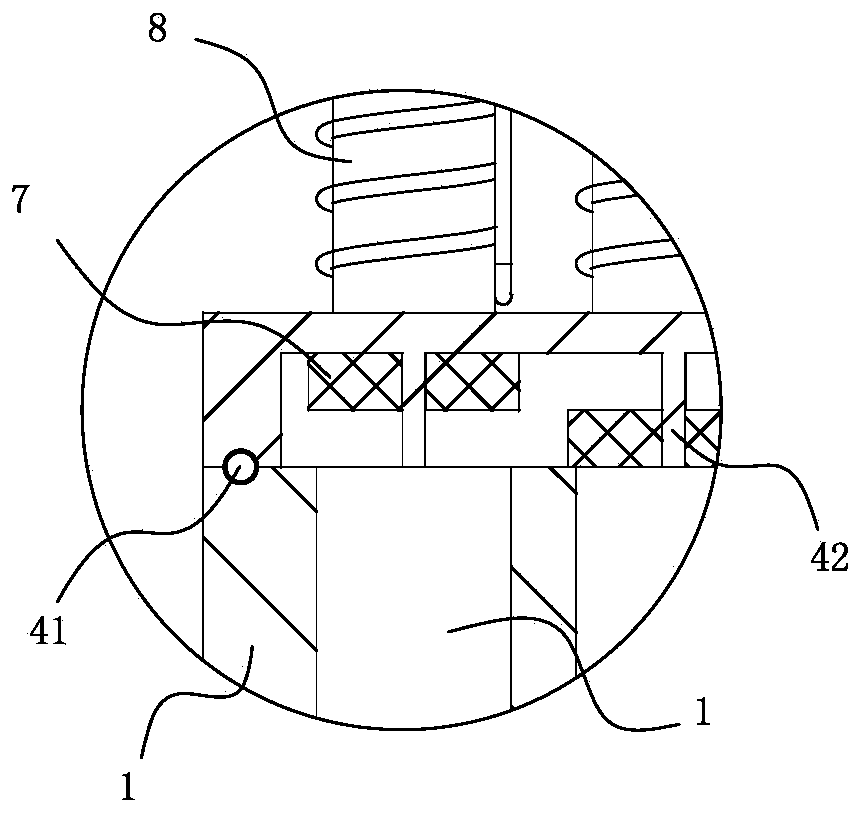

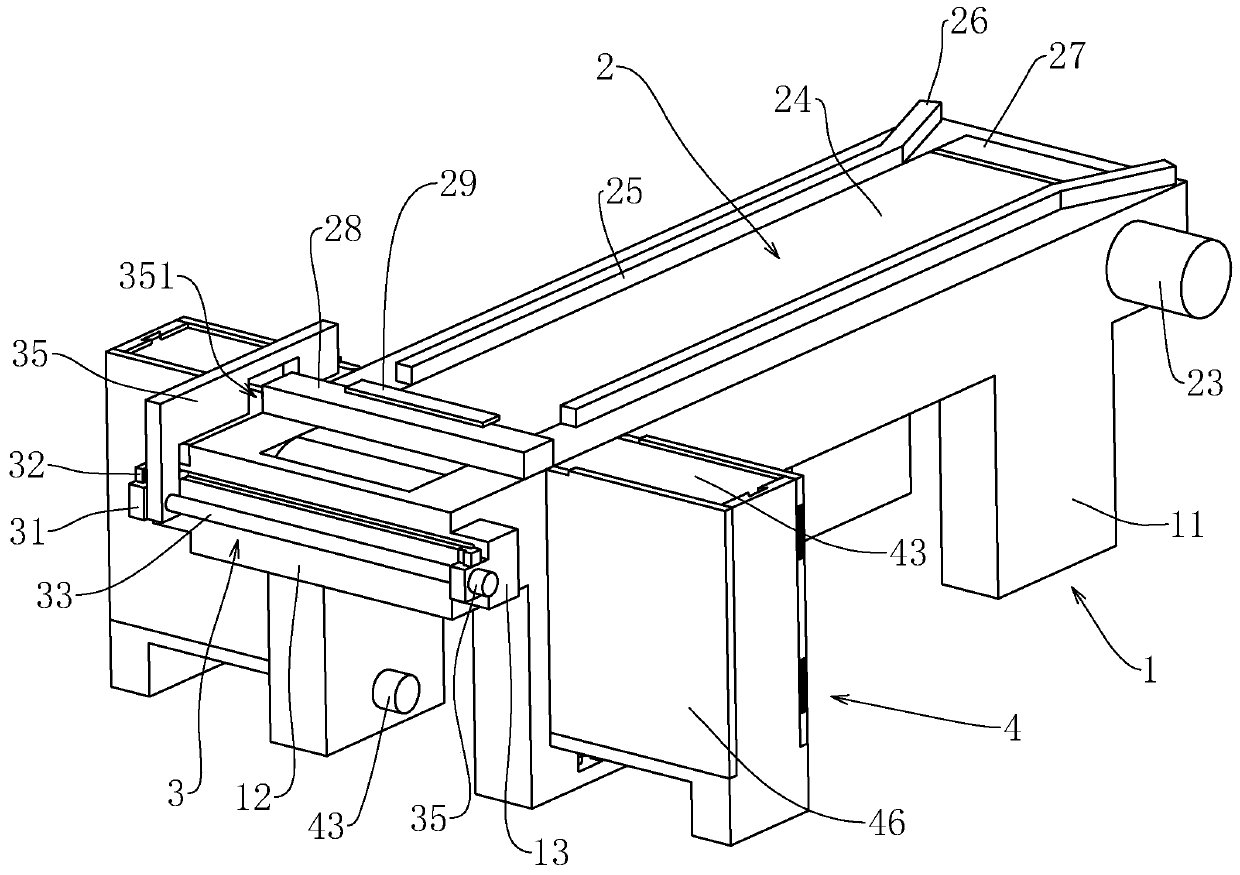

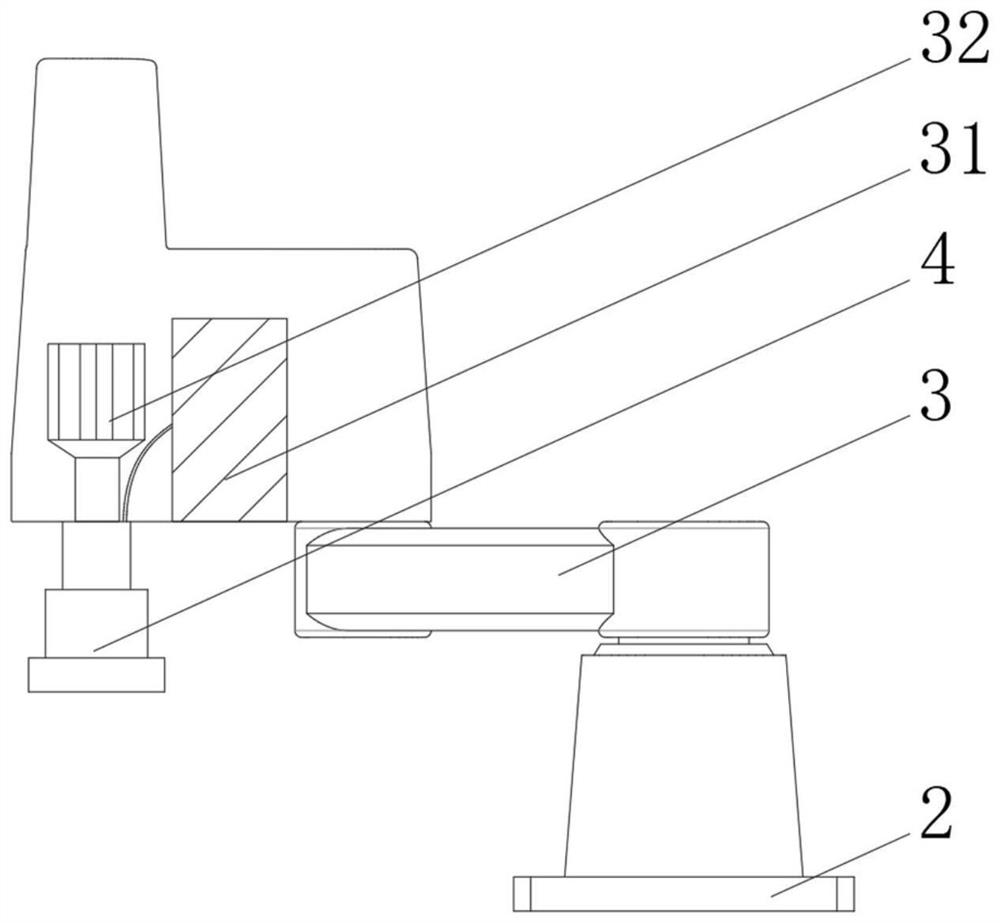

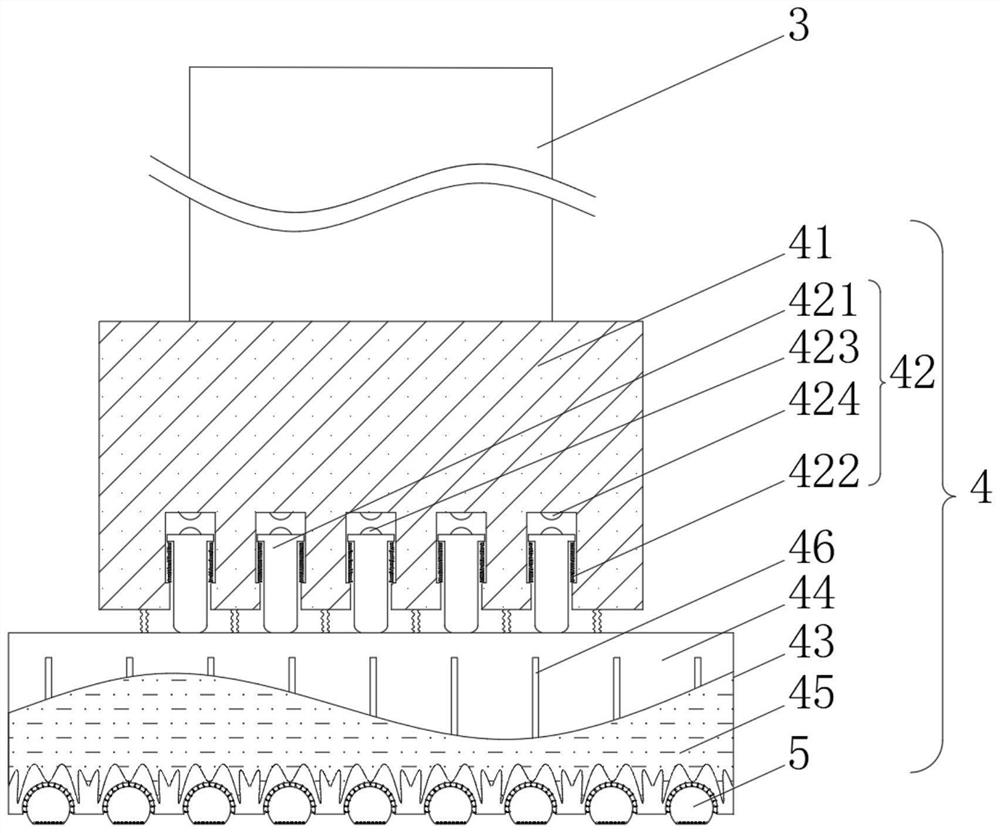

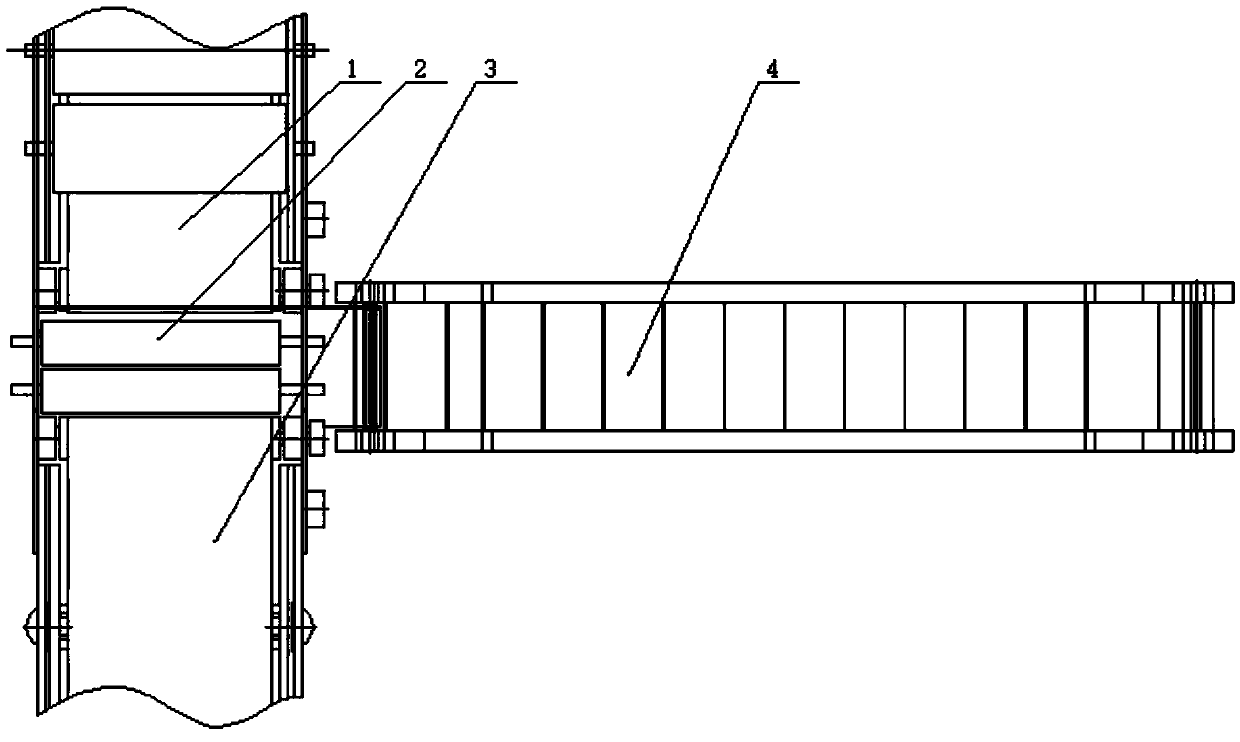

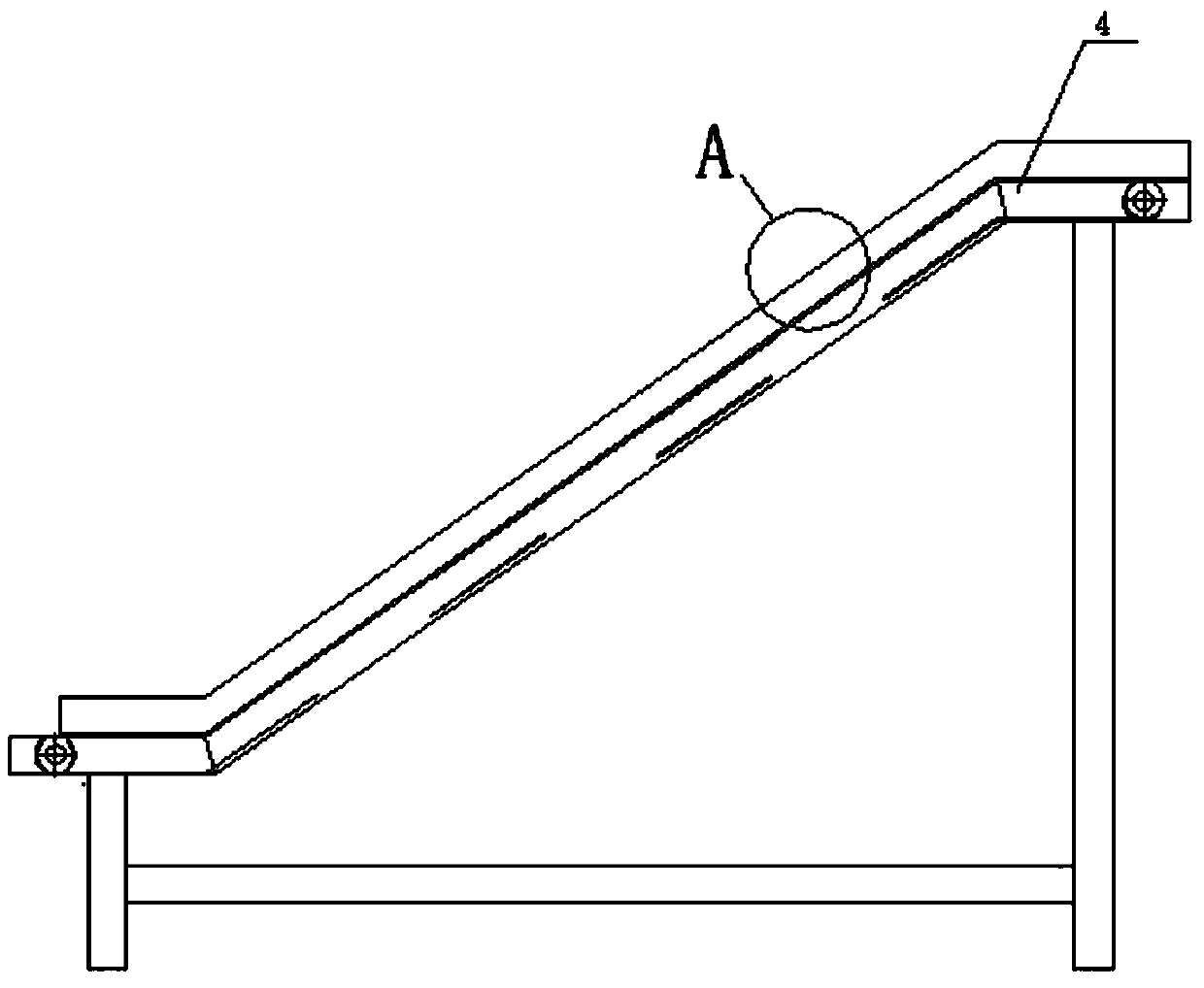

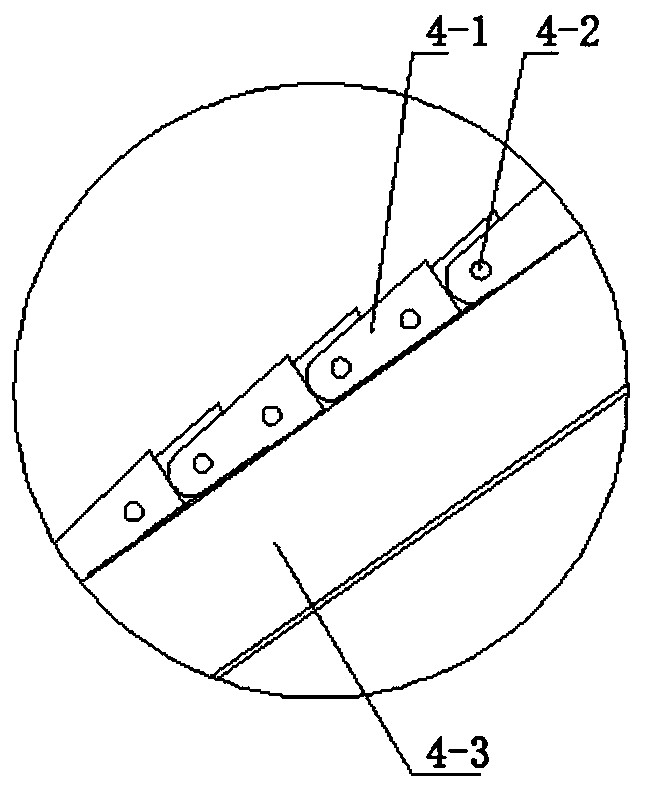

Stacking machine

PendingCN107187883AIncrease productivityReduce labor costsStacking articlesDe-stacking articlesAgricultural engineeringPalletizer

The invention provides a stacking machine which comprises a conveying mechanism, a stack elevating plate machine, a composite conveying mechanism, a plate collecting machine, a plate drawing mechanism, a stacking mechanism and a brick plate raw material. The conveying mechanism, the stack elevating plate machine, the composite conveying mechanism, the plate collecting machine, the plate drawing mechanism and the stacking mechanism are connected sequentially. A brick plate conveying mechanism is arranged on one side of the plate collecting machine. A brick plate separating mechanism is installed above the plate collecting machine. The stacking machine has the beneficial effects that automatic feeding, elevating, plate separating, sorting and stacking are achieved, the production efficiency is improved, and the labor cost is saved; separated carrier plates are stacked, transported and recovered, and convenience is provided for follow-up production and reproduction while automatic production is achieved; and the bridge type structure design is adopted and matched with a mechanical push plate and a bearing sliding way profile, consumable items of the equipment are few, the mass is small, guidance quality of brick body transportation is ensured, bearing loads of the whole equipment and loads of drive equipment are reduced, and the service life is prolonged.

Owner:TIANJIN AIBORUI ENVIRONMENTAL PROTECTION BUILDINGMATERIALS EQUIP CO LTD

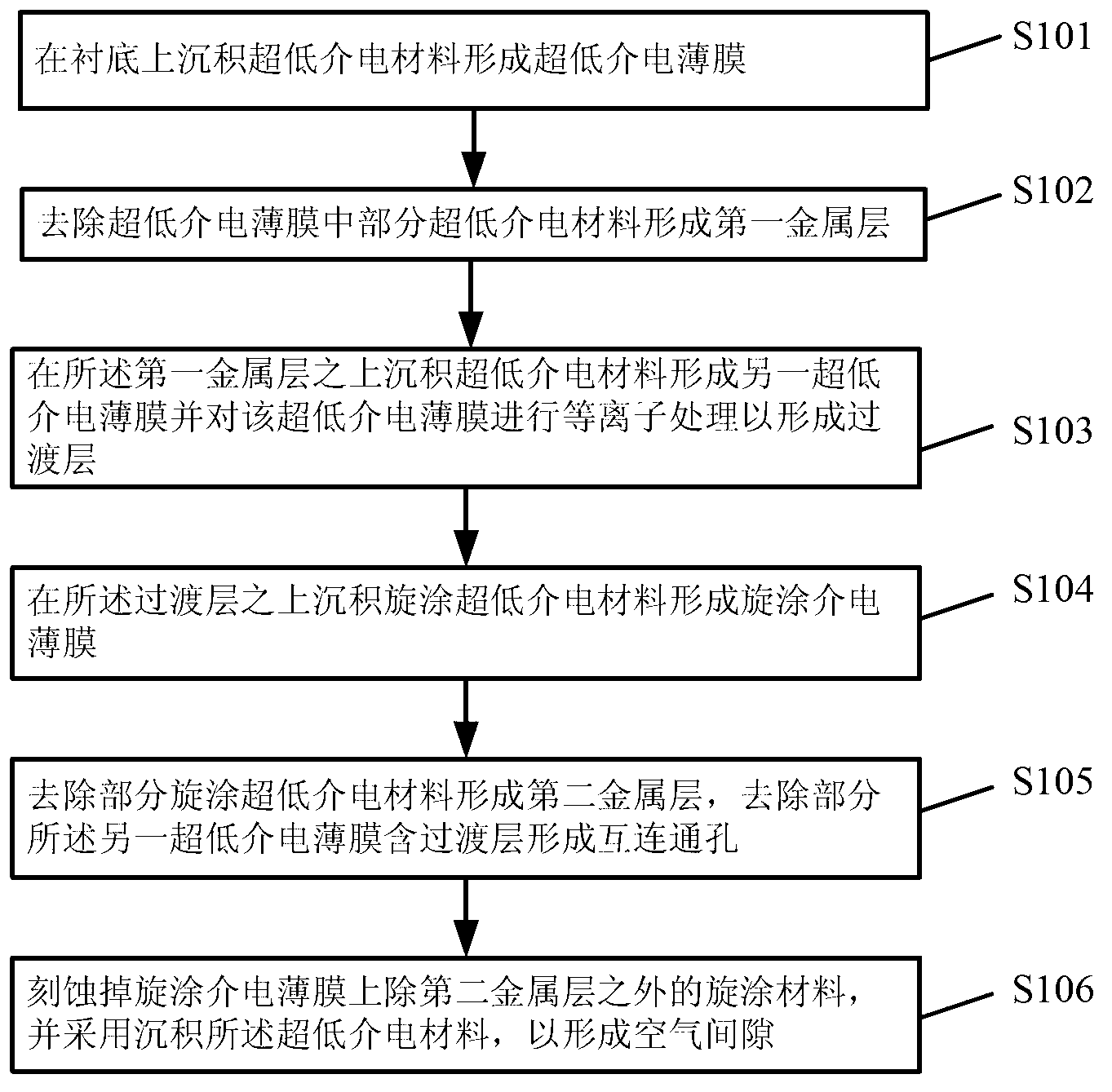

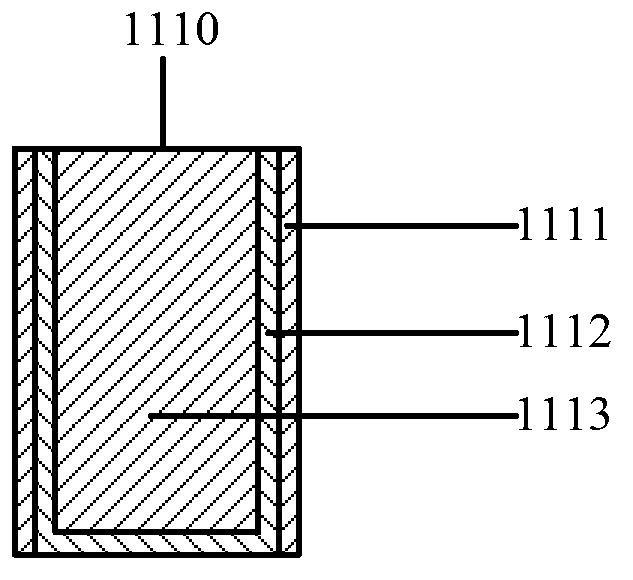

Formation method of local air gaps

InactiveCN103021935ASimple forming processConvenience for follow-up productionSemiconductor/solid-state device detailsSolid-state devicesDielectricElectricity

The invention discloses a formation method of local air gaps. The method includes: depositing ultralow dielectric material on a substrate to form an ultralow dielectric film, and removing part of the ultralow dielectric material to form a first metal layer; depositing ultralow dielectric material on the first metal layer to form another ultralow dielectric film, subjecting the ultralow dielectric film to plasma treatment to obtain a transition layer; depositing spin-coating ultralow dielectric material on the transition layer to form a spin-coating dielectric film, removing part of the spin-coating ultralow dielectric material to form a second metal layer, and removing part of the other ultralow dielectric film with the transition layer to form interconnecting vias; etching to remove the spin-coating material on the dielectric films, except for the part outside the second metal layer, and depositing ultralow dielectric material to form air gaps. The formation process of the local gaps is simplified, and subsequent production is facilitated.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

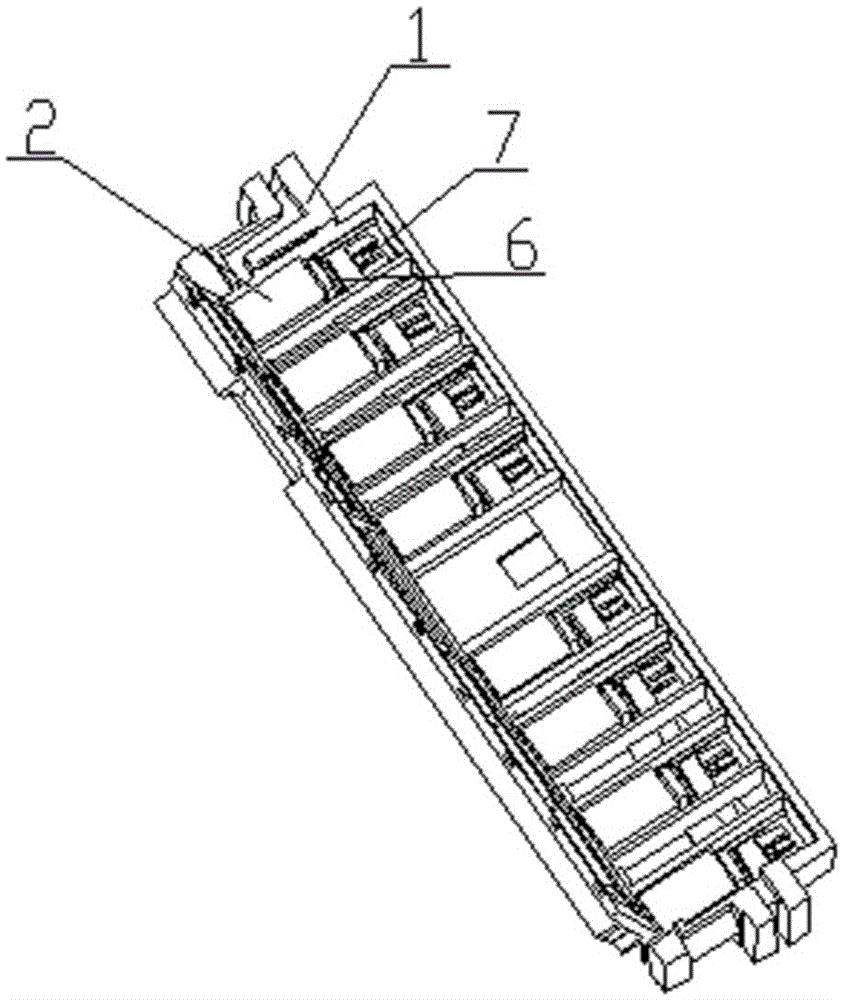

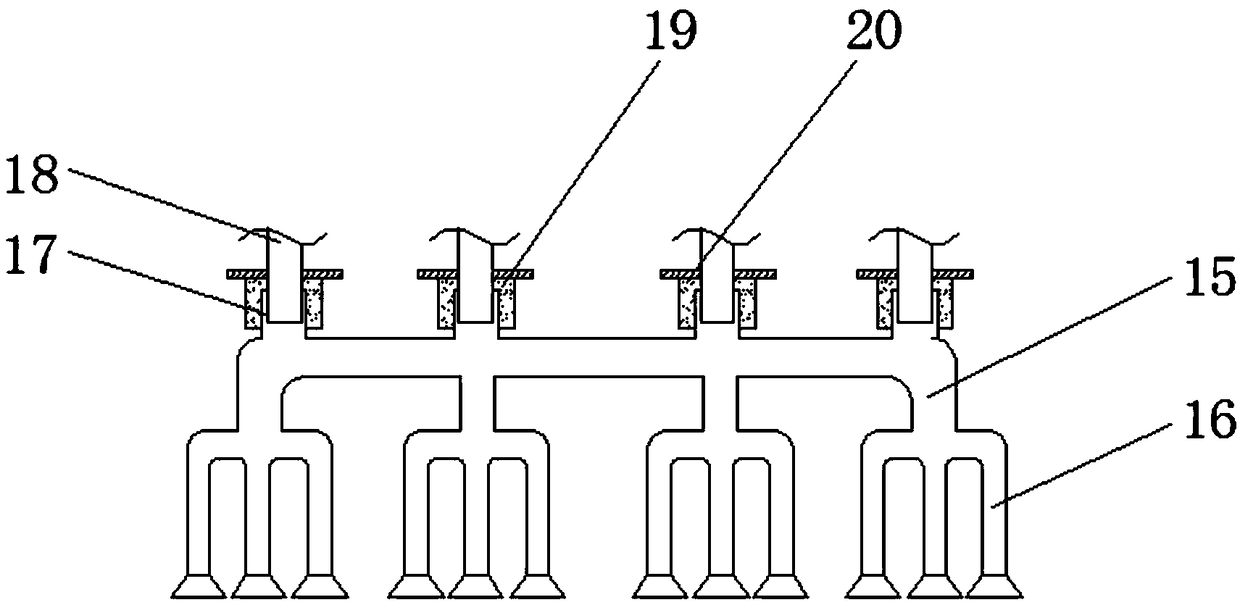

Plug-in terminal strip used for ammeter

ActiveCN105226418ASolve the problem of clutter and breakageAvoid the problem of rigid connection deformationSecuring/insulating coupling contact membersCoupling contact membersEngineeringThin sheet

The invention provides a plug-in terminal strip used for an ammeter. The plug-in terminal strip comprises a housing. The housing is internally provided with at least one terminal assembly. Each terminal assembly comprises a binding post. One end of the binding post is provided with a wiring terminal hole. A downward wire pressing screw is arranged above the binding post. The wire pressing screw penetrates into the wiring terminal hole. A metal thin sheet is arranged between the wire pressing screw and the binding post. The metal thin sheet is provided with an elastic slot. The plug-in terminal strip is reasonable in structure, safe and reliable, and high in installation efficiency.

Owner:HANGZHOU SUNRISE TECH

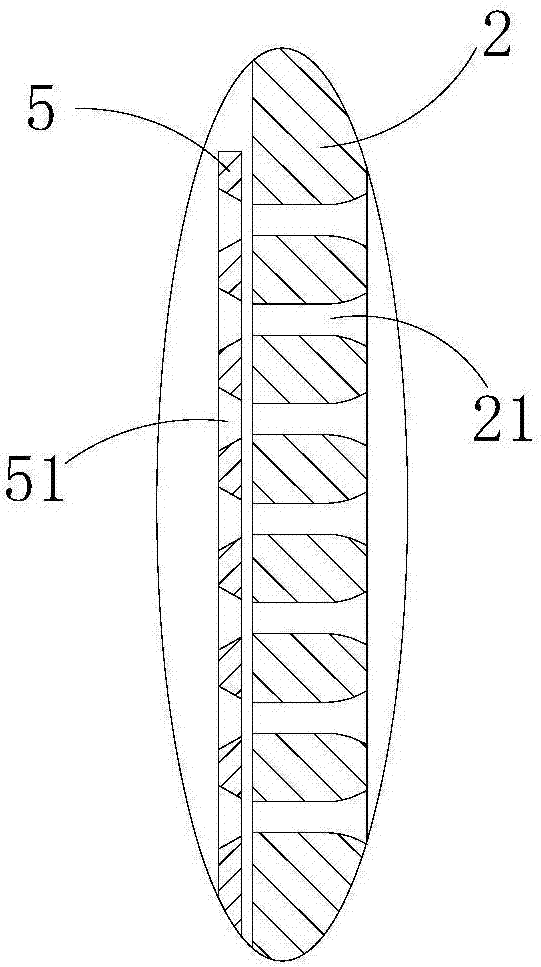

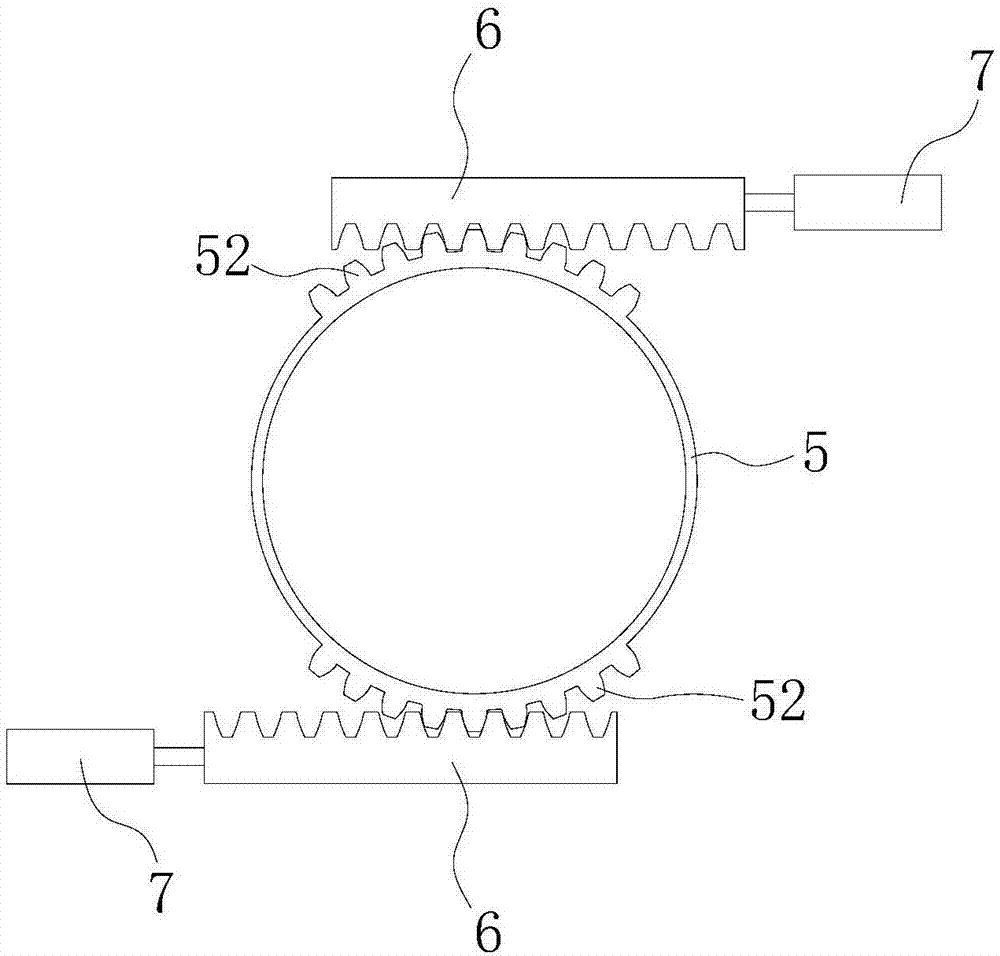

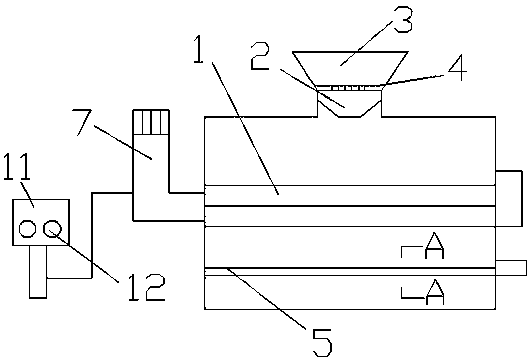

A kind of biomass fuel molding equipment

ActiveCN106427034BImprove cutting efficiencyRealize cutting and conveyingShaping pressEngineeringWear resistance

The invention discloses biomass fuel forming equipment which comprises a fixed base, a fuel extruding barrel, an extruding pushing plate movable plug, an automatic feeding device, a cutting barrel, racks, an air cylinder and a conveying device, wherein the fuel extruding barrel is fixedly mounted on the fixed base; the extruding pushing plate movable plug is horizontally mounted in the fuel extruding barrel; the upper end of the extruding pushing plate movable plug is connected with the automatic feeding device through a plurality of connecting rods; the cutting barrel is matched with the fixed base through a rolling bearing; wheel teeth are arranged at the circumferential two sides of the bottom of the cutting barrel; each wheel tooth is in engaged transmission with one rack; the racks are fixedly connected with a pushing rod of the air cylinder; the air cylinder is fixedly mounted on the fixed base; a conveying device is further mounted on the fixed base; and a plurality of material inlet tubes are further arranged on the fuel extruding barrel, and communicate with the inner cavity of the fuel extruding barrel. The biomass fuel forming equipment disclosed by the invention is strong in scratch and wear resistance, is long in service life, is low in energy consumption and is high in production efficiency.

Owner:甘肃金钒源储电力技术有限公司

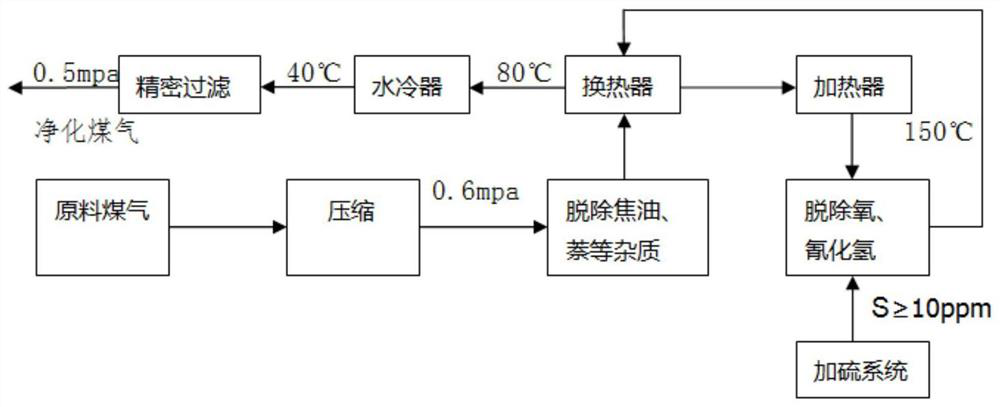

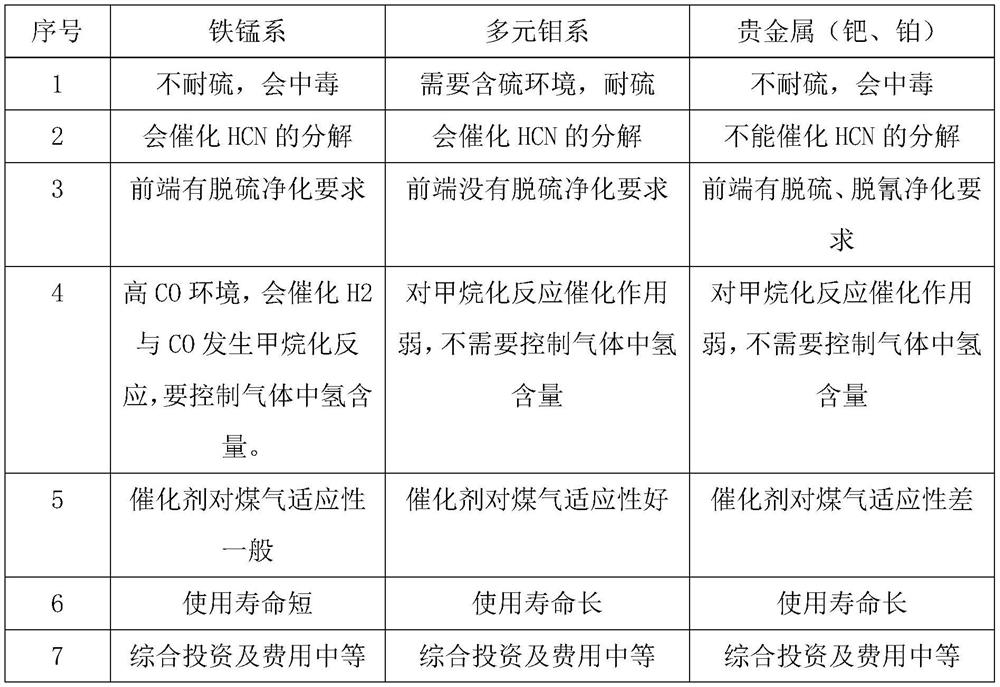

Converter gas purification treatment method

InactiveCN111925837AImprove purification effectKeep aliveGas purification by catalytic conversionLiquid carbonaceous fuelsPtru catalystAdsorption effect

The invention belongs to the technical field of converter gas treatment methods, and discloses a converter gas purification treatment method. According to the method, impurities such as tar, naphthalene and dust in the raw material gas are removed by utilizing the adsorption effect of the activated carbon, and the effect of protecting a subsequent catalyst can be achieved while the impurities areremoved. And then oxygen and cyanide in the coal gas are removed by using a sulfurized molybdenum-based multi-element catalyst, so that the coal gas is fully purified, and subsequent production is facilitated. The activity of the catalyst is kept by adding carbon disulfide, so that the reaction is more efficient, and the purification effect is improved. The treatment method disclosed by the invention is simple to operate, has a good purification effect on the coal gas, and is beneficial to production of ethanol through biological fermentation of the converter coal gas.

Owner:CHENGDU JUTAO OIL ENG CO LTD

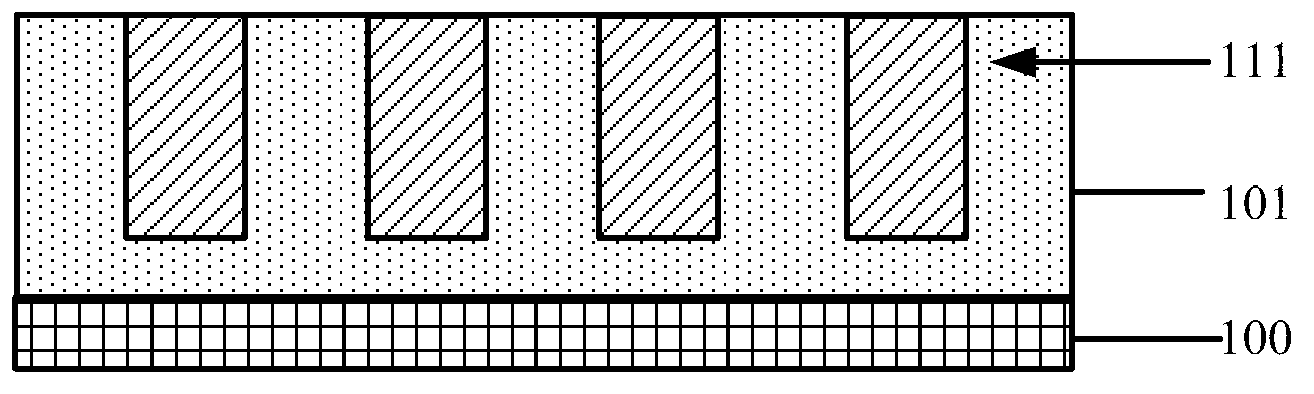

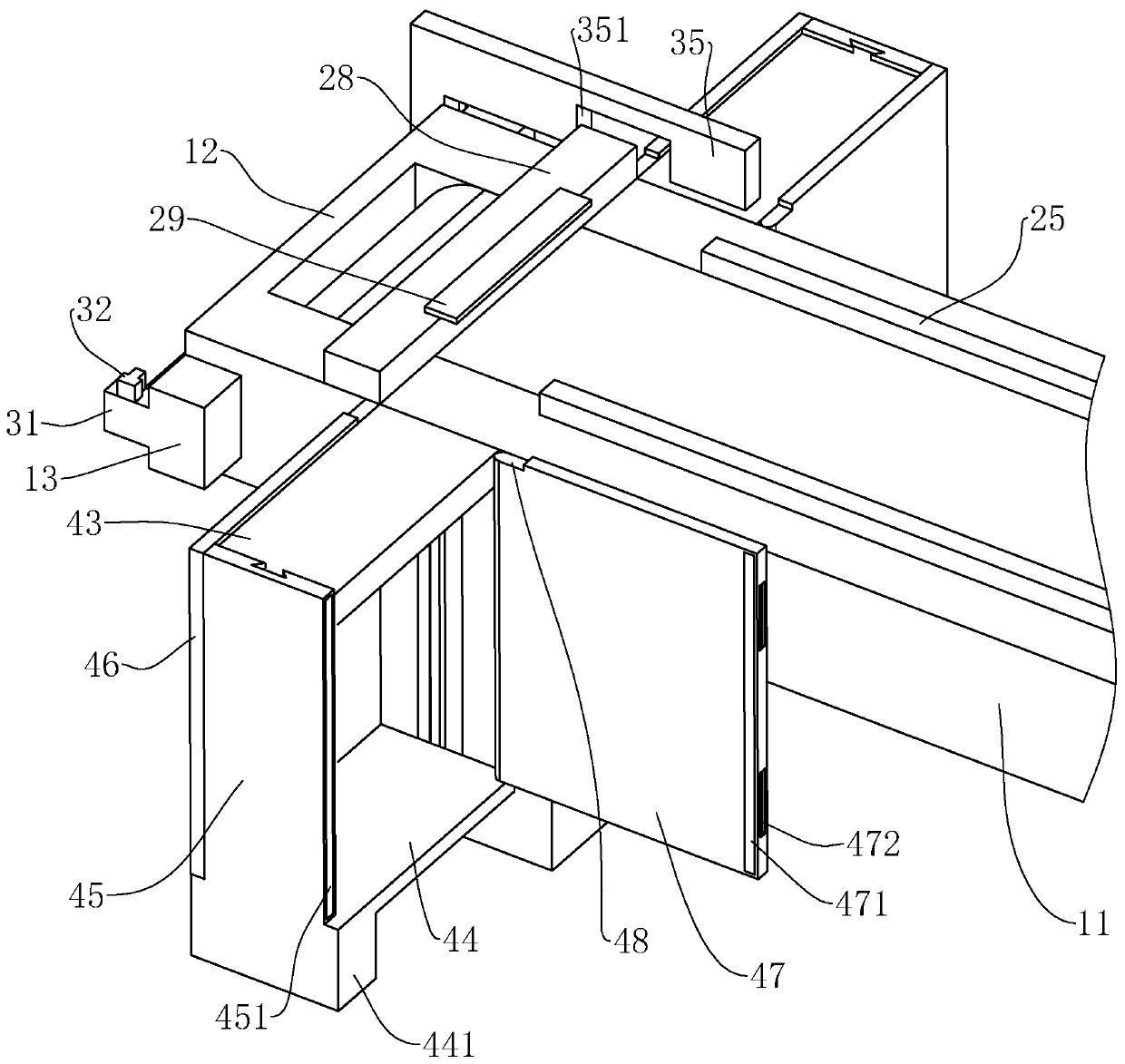

Production method suitable for pickup head for microchip mass transfer

ActiveCN110504192AIncrease spacingImprove handling speedSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingCeramic sinteringMethods of production

The invention relates to a production method suitable for a pickup head for microchip mass transfer. The method comprises following steps of first, sintering a column-shaped pickup head once by usinga ceramic sintering technology, wherein M*N gas channels are simultaneously processed and shaped downward on the upper end surface of the pickup head; second, collecting a micro gas channel between the lower end of each gas channel and the lower end surface of the pickup head; third, providing a sealing shell; fourth, punching on the sealing shell, then installing an air vent valve and an air suction valve that communicate with an inner cavity of the sealing shell; and fifth, connecting the sealing shell and the upper end of the pickup head in a sealing manner, and guaranteeing that each valveis opposite to an upper opening of each gas channel. Due to use of a mechanism of single mass transfer, chip transfer efficiency is improved greatly.

Owner:义乌臻格科技有限公司

Chromium-plated part cleaning solution and use method thereof

The invention provides a chromium-plated part cleaning solution. The chromium-plated part cleaning solution is aqueous solution containing sulfuric acid, nitric acid and hydrofluoric acid, and the concentrations of sulfuric acid, nitric acid and hydrofluoric acid are 15-25 ml / L, 45-80 ml / L and 5-20 ml / L, respectively. In use, duster cloth is dipped in the chromium-plated part cleaning solution to wipe the surface of a chromium-plated part, or the chromium-plated part cleaning solution is smeared on the surface of the chromium-plated part and duster cloth wipes the surface of the chromium-plated part, and the chromium-plated part is flushed with clear water for at least twice; the cleaning of the chromium-plated part cleaning solution to the chromium-plated part is more complete, and the chromium corrosion is hardly caused; furthermore, the cleaning cost is low, the operation is simple, the time is saved, the reduction of the labor intensity and the improvement of the working efficiency are facilitated, the safety and the reliability are achieved, the quality of a cleaned work piece is ensured, and the subsequent production is facilitated.

Owner:天津市津一电镀有限公司

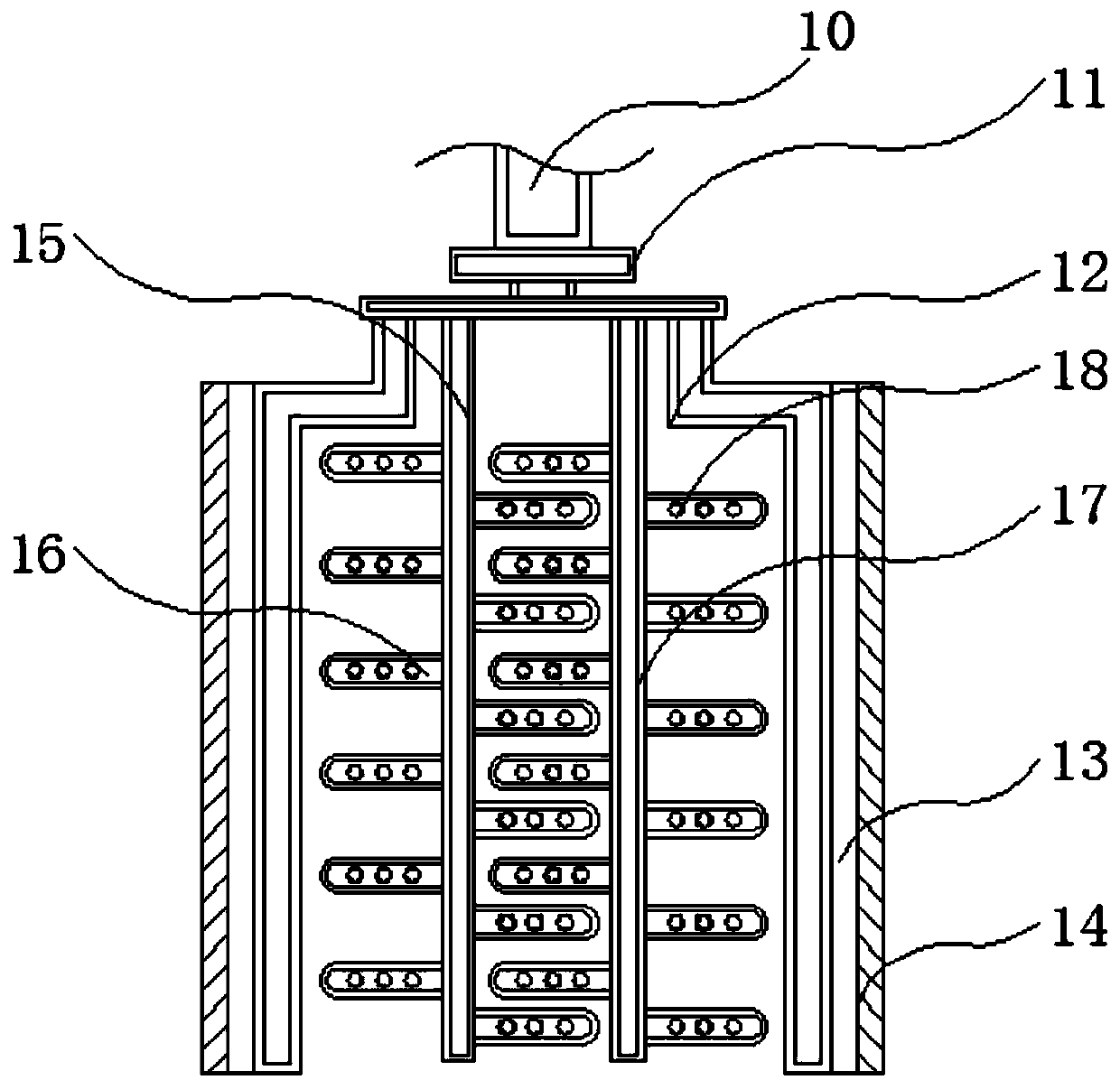

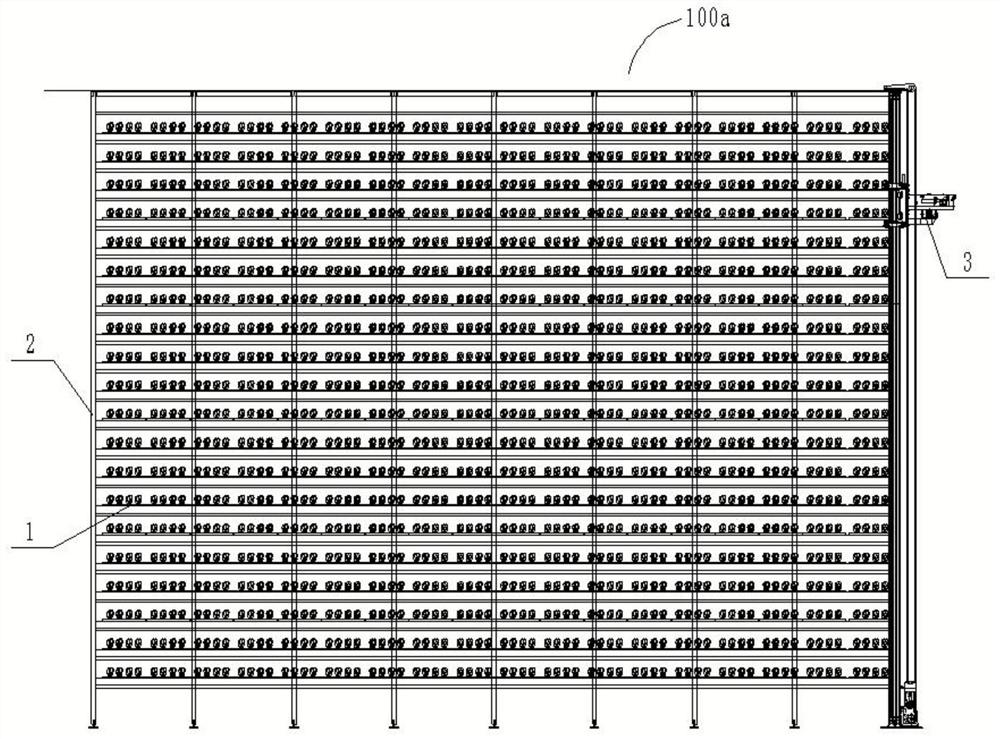

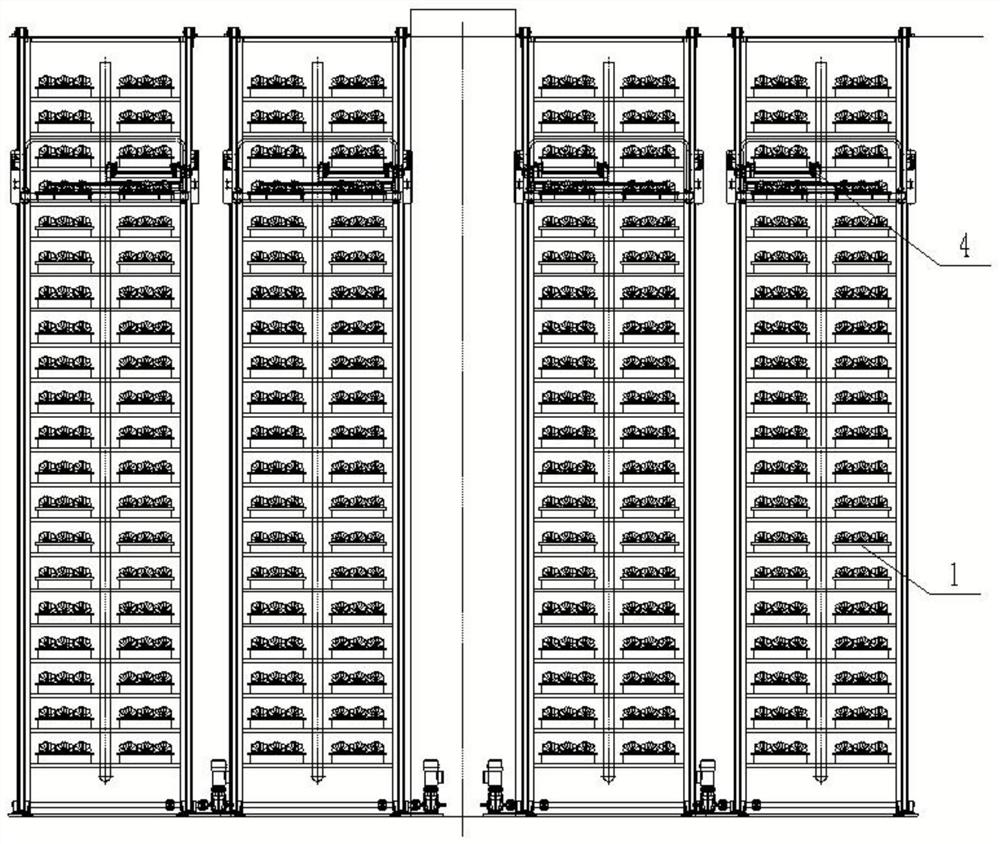

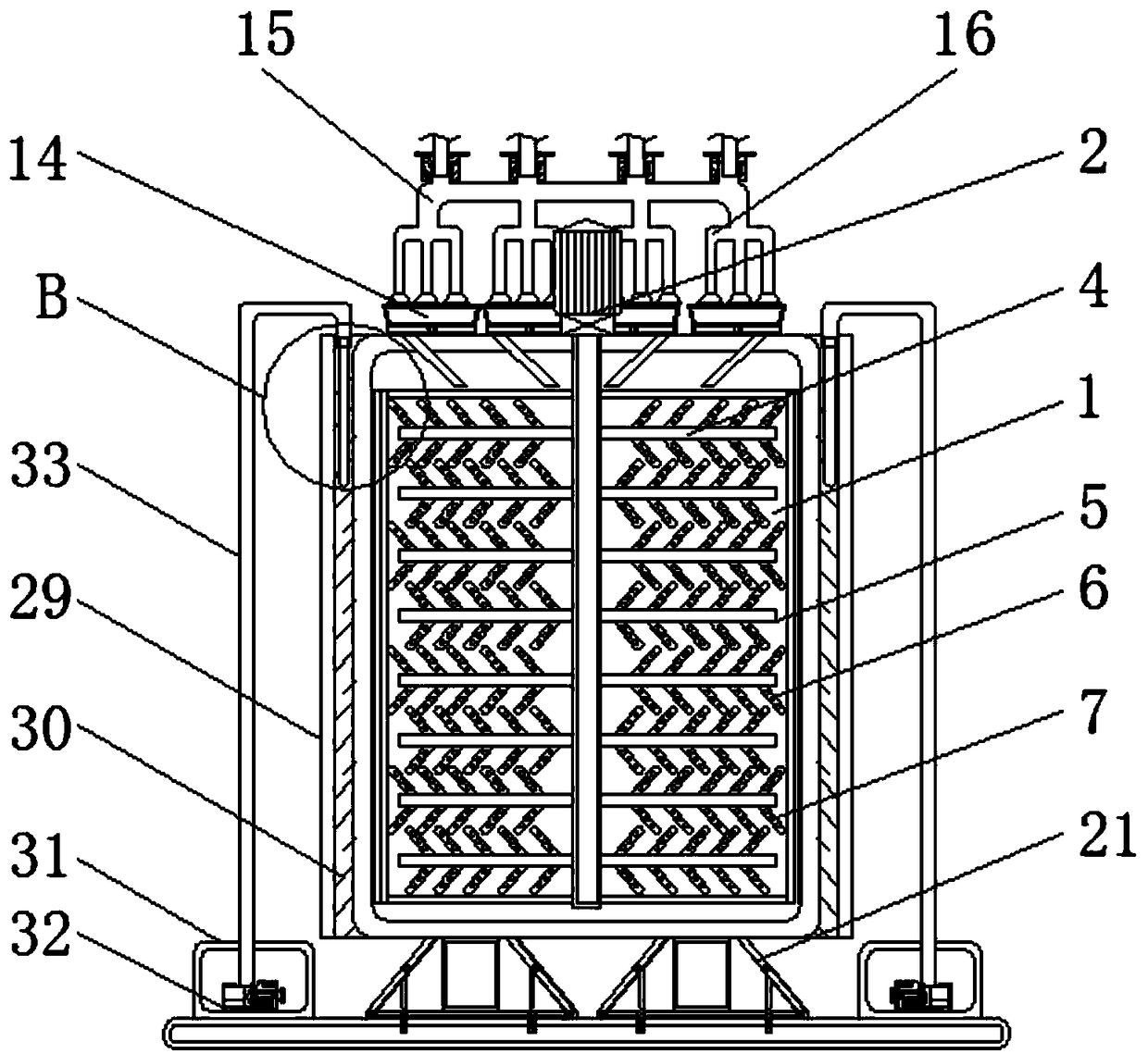

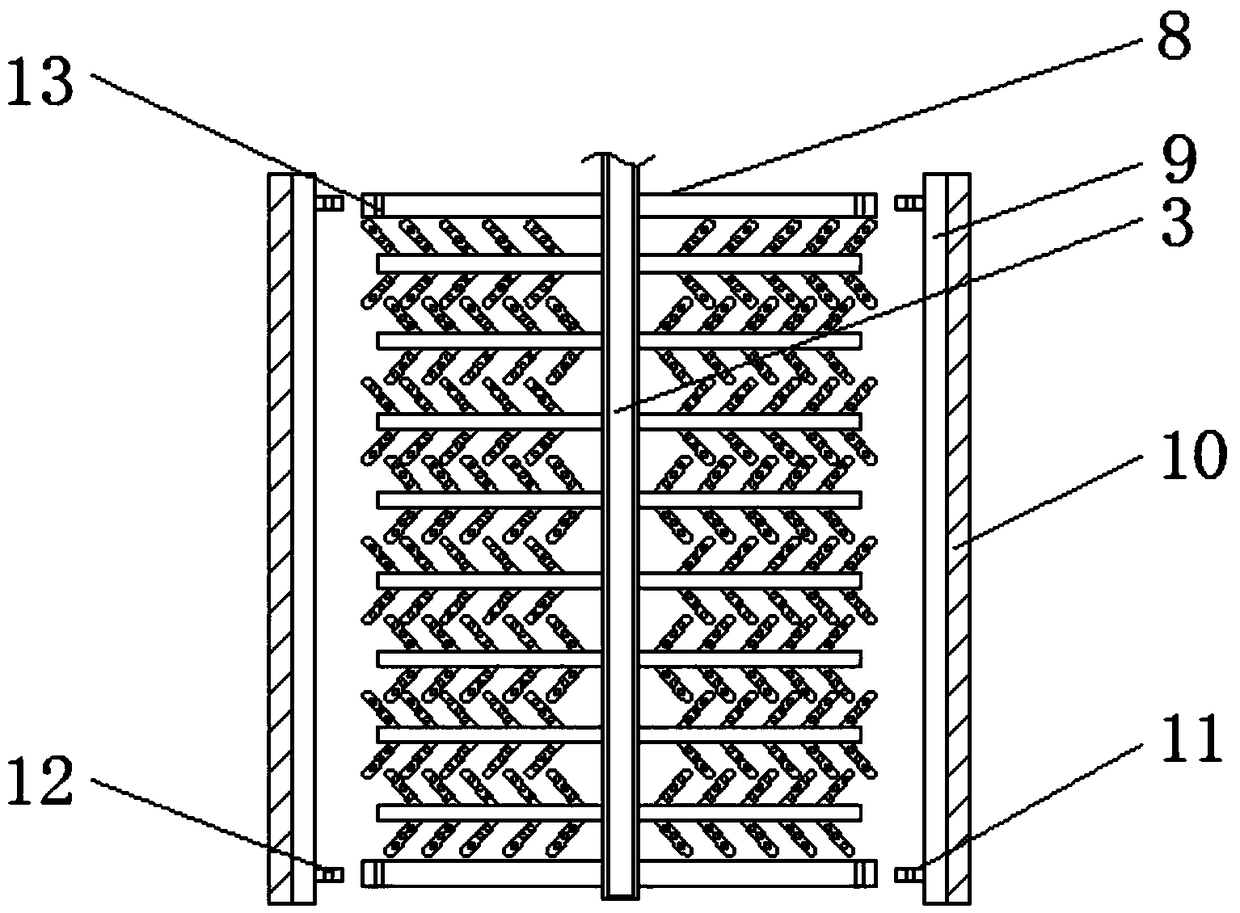

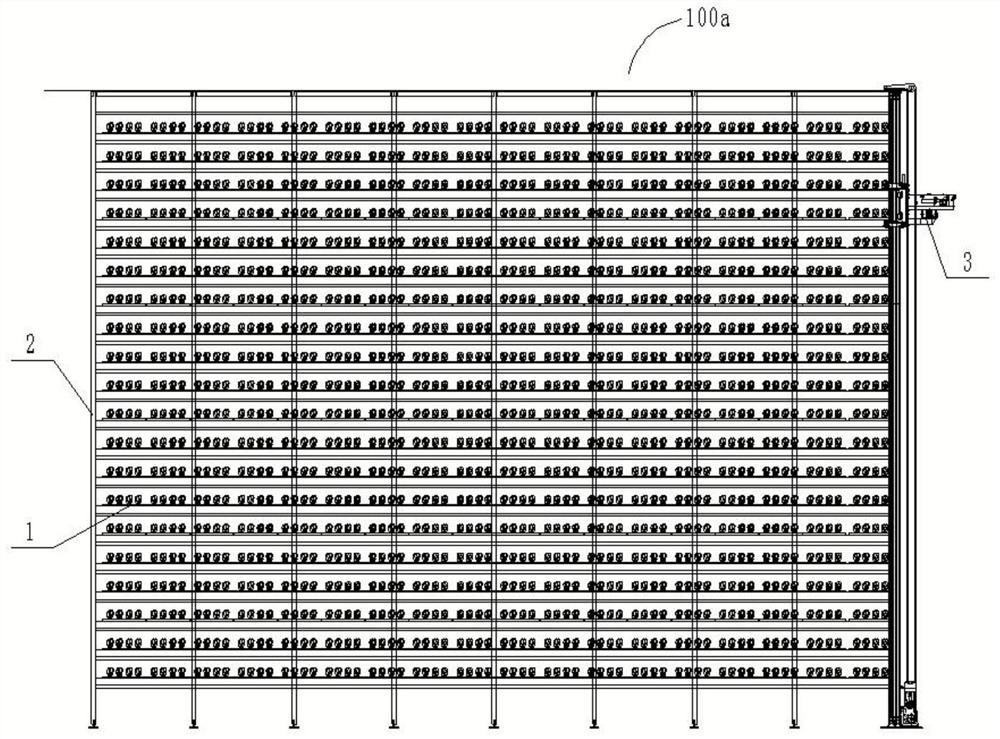

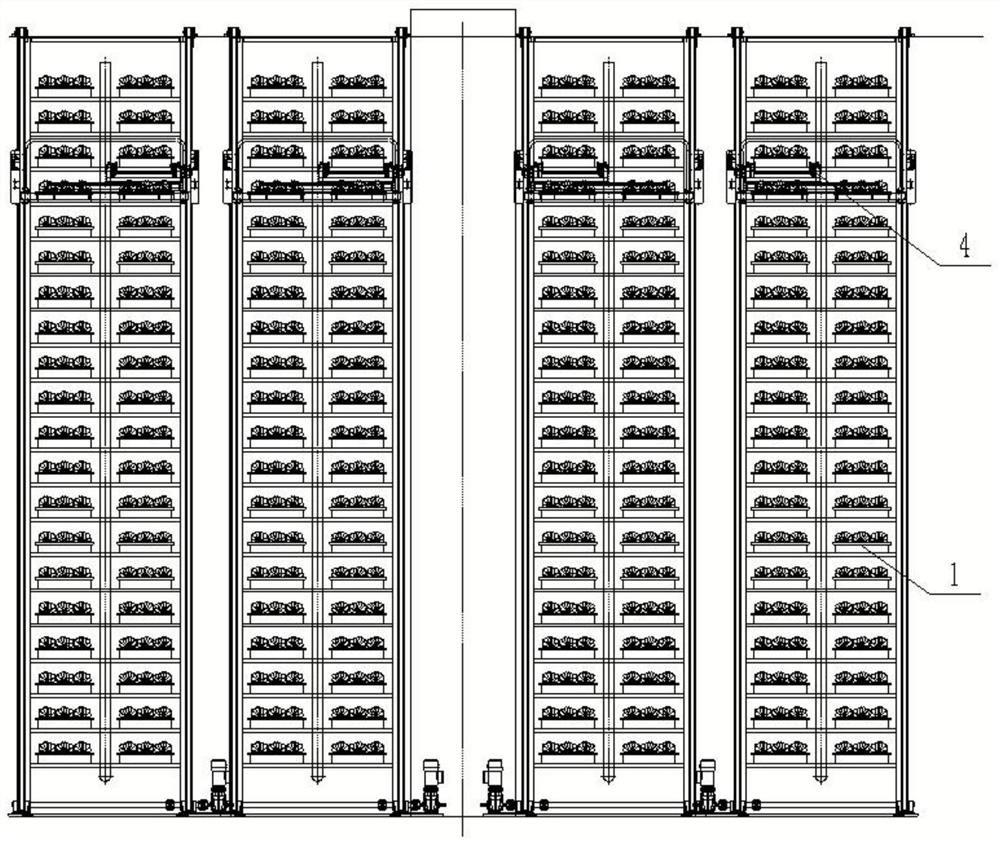

Cultivation plate three-dimensional space automatic transfer vertical plant factory

ActiveCN113479543AGuaranteed stabilityGuaranteed reliabilityAgriculture gas emission reductionCultivating equipmentsPlant factoryAgricultural engineering

The invention discloses a cultivation plate three-dimensional space automatic transfer vertical plant factory. The cultivation plate three-dimensional space automatic transfer vertical plant factory comprises cultivation plates, a cultivation frame, a lifting assembly and a space transfer trolley, the cultivation plates can cultivate plants, the space transfer trolley can support the cultivation plates, and the space transfer trolley can slide along cultivation layers in a reciprocating mode; the cultivation plates planted with seedlings can be conveyed into the cultivation layers through the space transfer trolley, and after the plants grow up, the cultivation plates are lifted up from the cultivation layers and conveyed out through the space transfer trolley again; and meanwhile, the lifting assembly is arranged on the side vertical face of the cultivation frame, and the lifting assembly can drive the space transfer trolley to reciprocate in the height direction of the cultivation frame, so that plant conveying of the multiple cultivation layers is completed. According to the cultivation plate three-dimensional space automatic transfer vertical plant factory, transportation of the cultivation plates is achieved through the lifting assembly and the space transfer trolley, the problem that the space utilization rate is reduced due to the fact that a large operation space is reserved between cultivation frames is solved, meanwhile, the operation efficiency is improved, and in addition, the stability and reliability of frame loading and unloading operation of the cultivation plates are guaranteed.

Owner:INST OF URBAN AGRI CHINESE ACADEMY OF AGRI SCI

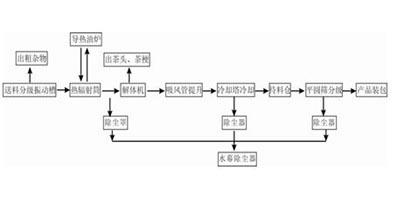

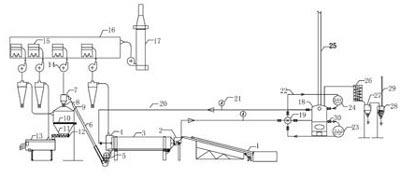

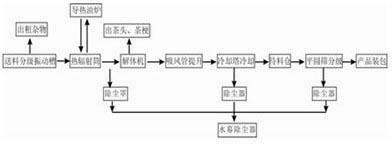

Broken tea refined processing technique

InactiveCN102599281AAvoid cokingStop evaporationPre-extraction tea treatmentProduction lineCooling tower

The invention relates to a broken tea refined processing technique. Equipment used in the broken tea refined processing technique comprises feeding grading vibration grooves, a drying system, a disintegration machine, a suction pipe, a cooling tower, an automatic tapping device and a dust removal system. The broken tea refined processing technique is characterized in that tealeaves enter the disintegration machine to be disintegrated so as to remove tea heads and tea stalks after entering a heat radiation cylinder of the drying system to be dried and dust removed through the feeding grading vibration grooves, then the disintegrated tealeaves enter the cooling tower to be cooled through the suction pipe, and finally the cooled tealeaves enter a flat and round sieve to be graded and packaged. An automatic production line is provided for the tealeaves from impurity removal, drying, dust removal, disintegration, grading to packaging, so that the production efficiency is improved, the working environment is improved, and the grade of the tealeaves is improved.

Owner:HUNAN LONGZHOU TEA IND

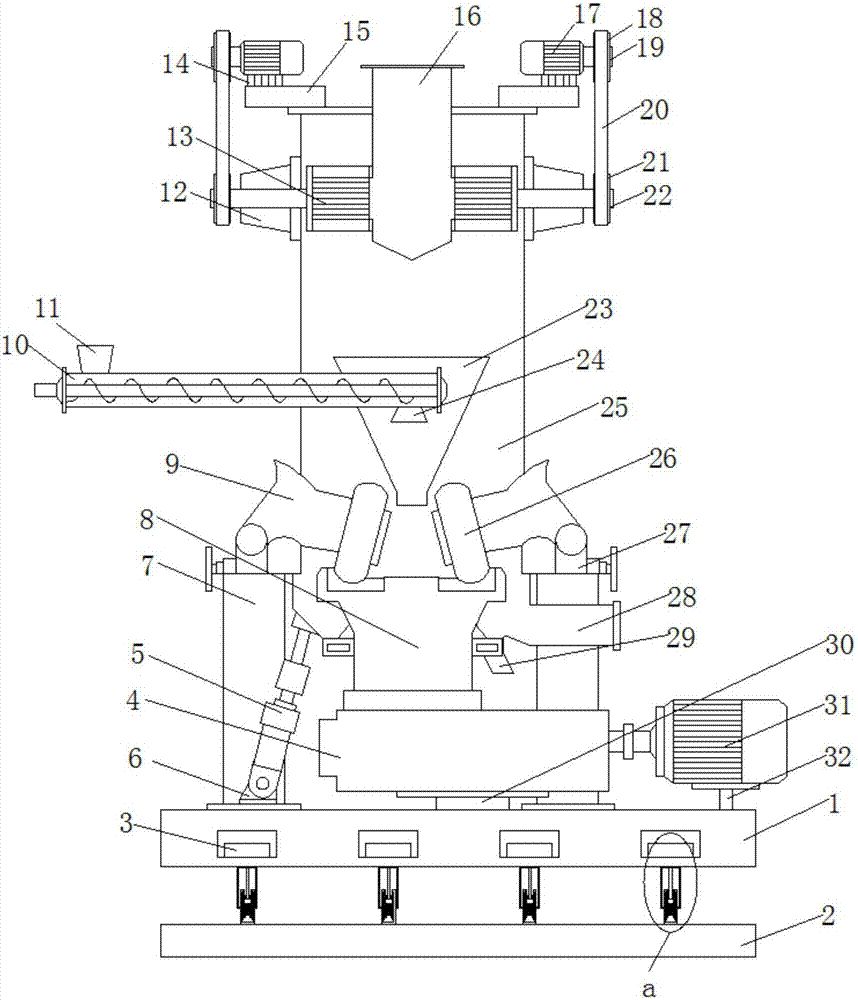

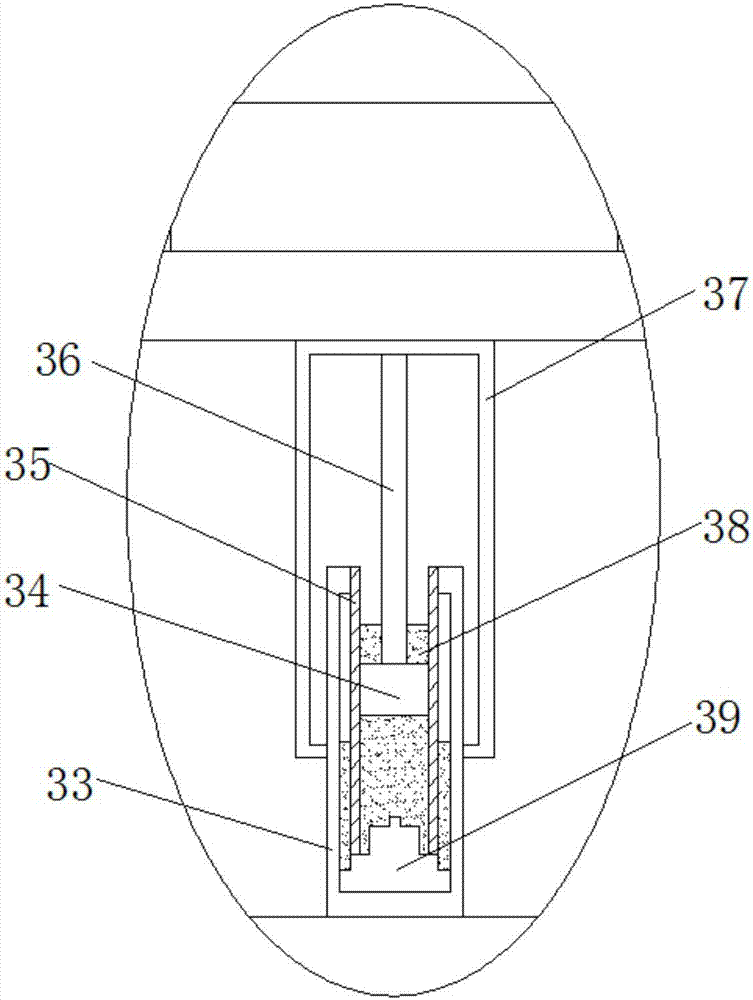

Winnowing machine for cork manufacturing

InactiveCN107398977AIncrease contactTo achieve the purpose of making powderWood working apparatusVibration suppression adjustmentsReducerEngineering

The invention discloses a winnowing machine for cork manufacturing. The winnowing machine comprises a foundation base and a supporting base; a plurality of cavities are uniformly formed in the foundation base; a limiting block is arranged in each cavity; a plurality of oil storage cylinder bodies are uniformly arranged on the upper surface of the supporting base; bottom valves are arranged in the oil storage cylinder bodies; pressure cylinders are arranged on the bottom valves; a plurality of first circular through holes are uniformly formed in the side walls of the pressure cylinders, and the pressure cylinders are internally filled with damping oil; a plurality of protective pipes are uniformly arranged on the lower surface of the fpundation base; piston rods are fixedly connected to the lower ends of the limiting blocks; a first support and a second support are arranged on the foundation base; a main motor is arranged on the first support; a speed reducer is arranged on the second support; and a grinding disc is arranged on the speed reducer. The winnowing machine is ingenious in structure, convenient and rapid to use, fine in crushing and powder grinding and convenient for subsequent production, a damping device is arranged so that the damage to internal parts caused by vibration can be reduced, the service life can be prolonged, and the winnowing machine is worthy of popularization.

Owner:望谟县金腾软木(淀粉)制品有限责任公司

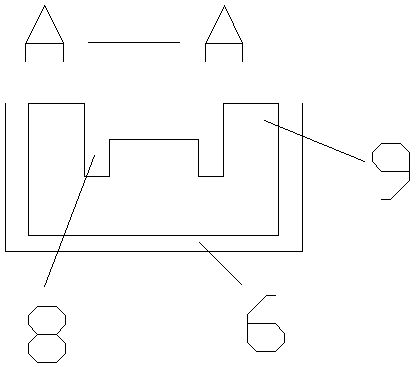

Discharging mechanism of automatic cutting system

InactiveCN111391011ANeatly stackedNot easy to fall overMetal working apparatusControl engineeringElectric machinery

The invention discloses a discharging mechanism of an automatic cutting system. The invention provides the technical scheme points that the discharging mechanism of the automatic cutting system comprises an installation frame, wherein a conveying mechanism is connected onto the installation frame; a pushing mechanism and two stacking mechanisms are arranged at the left end of the installation frame; the installation frame comprises two support frames and two connecting blocks; the conveying mechanism comprises a drive roller and a driven roller rotatably connected between the two support frames; a conveyor belt is tensioned on the drive roller and the driven roller; a drive motor is connected to one end of the drive roller; the pushing mechanism comprises a push rod connected with the connecting block on the left side in a front-and-back sliding way; limiting switches are arranged on the front side and the back side of the push rod; the push rod is connected with the pushing mechanism;a limiting block is fixed to the upper ends of the two support frames; a photoelectric sensor is arranged on the front side of the limiting block; the limiting block is close to the right end of theinstallation frame; a demising groove is formed in the lower end of the push rod; the stacking mechanisms comprise lifting plates connected with the support frames in an up-and-down sliding way; and the lifting plates are connected with a lifting assembly. The discharging mechanism of the automatic cutting system provided by the invention has the functions on flatly staking the cut materials conveniently and providing convenience for post processing.

Owner:宋建华

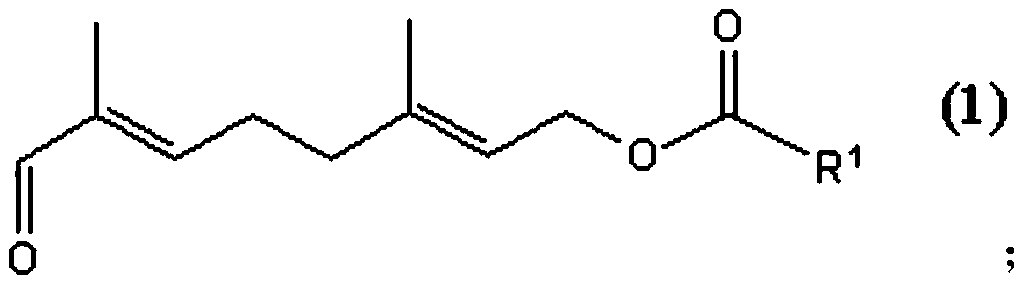

Purification method of 8-oxo-3, 7-dimethyl-octadiene carboxylic ester compound

ActiveCN111269121AConvenience for follow-up productionSimple processOrganic compound preparationCarboxylic acid esters separation/purificationVitamin A AlcoholCombinatorial chemistry

The invention discloses a purification method of a 8-oxo-3, 7-dimethyl-octadiene carboxylic ester compound. The by-products generated in the reaction process of preparing the 8-oxo-3, 7-dimethyl-octadiene carboxylic ester compound and impurities derived from raw materials can be effectively removed; the process is simple under normal pressure, the purity of the 8-oxo-3, 7-dimethyl-octadiene carboxylic ester compound can be effectively improved, the method is suitable for industrial mass production, and subsequent production of vitamin A and carboxylic esters thereof is facilitated.

Owner:广州巨元生化有限公司

Chemical machinery capable of automatically conveying materials and preventing leakage of raw materials

ActiveCN109158021AWell mixedConvenience for follow-up productionRotary stirring mixersTransportation and packagingWater storageWater storage tank

The invention discloses chemical machinery capable of automatically conveying materials and preventing leakage of raw materials. The chemical machinery comprises a chemical raw material storage tank,material feeding ports, connecting pipes, shock absorbing springs and caulking grooves, wherein the upper end of the chemical raw material storage tank is equipped with a driving motor; an output endof the driving motor is connected with a rotating shaft; the outer wall of the rotating shaft is respectively fixed with first stirring rods and second stirring rods; the shock absorbing springs are mounted at the tail ends of second supporting rods; the caulking grooves are formed above the inside of an support base; an anti-collision casing is ranged on an side wall of the chemical raw materialstorage tank; water storage tanks are arranged outside the chemical raw material storage tank; and water pumps are arranged inside the water storage tanks. According to the chemical machinery capableof automatically conveying materials and preventing the leakage of raw materials, since first stirring blades and second stirring blades are arranged in a staggered manner, a stirring effect on chemical raw materials inside the chemical raw material storage tank is achieved, so that the chemical raw materials are uniformly mixed, and the subsequent production of the mixed chemical raw materials for users is facilitated.

Owner:上海瑞迈企业管理咨询有限公司 +1

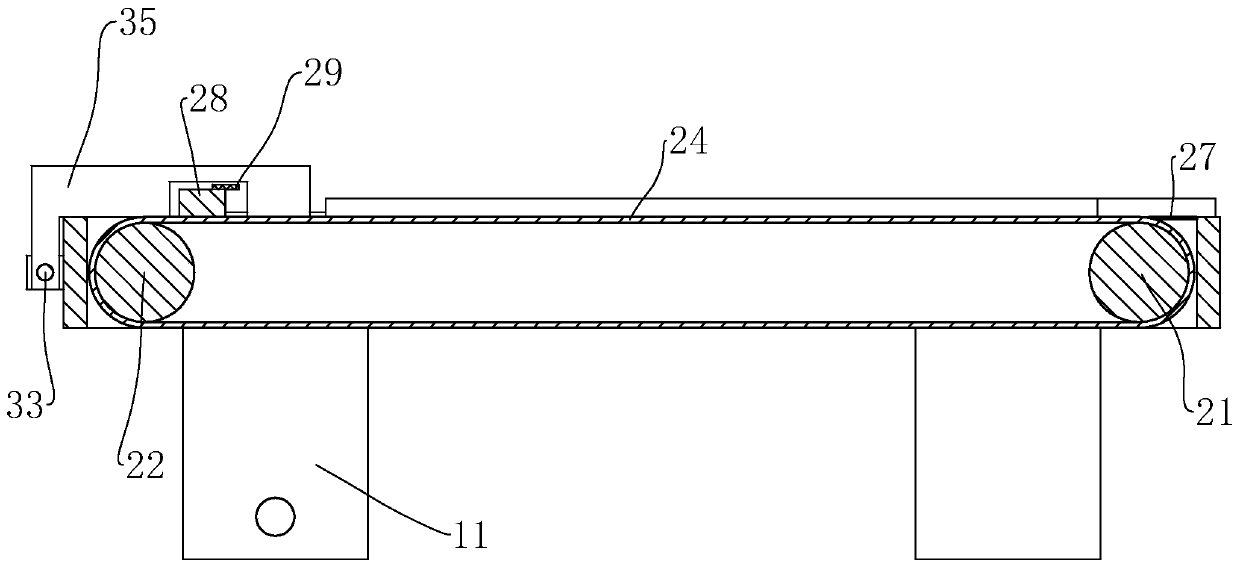

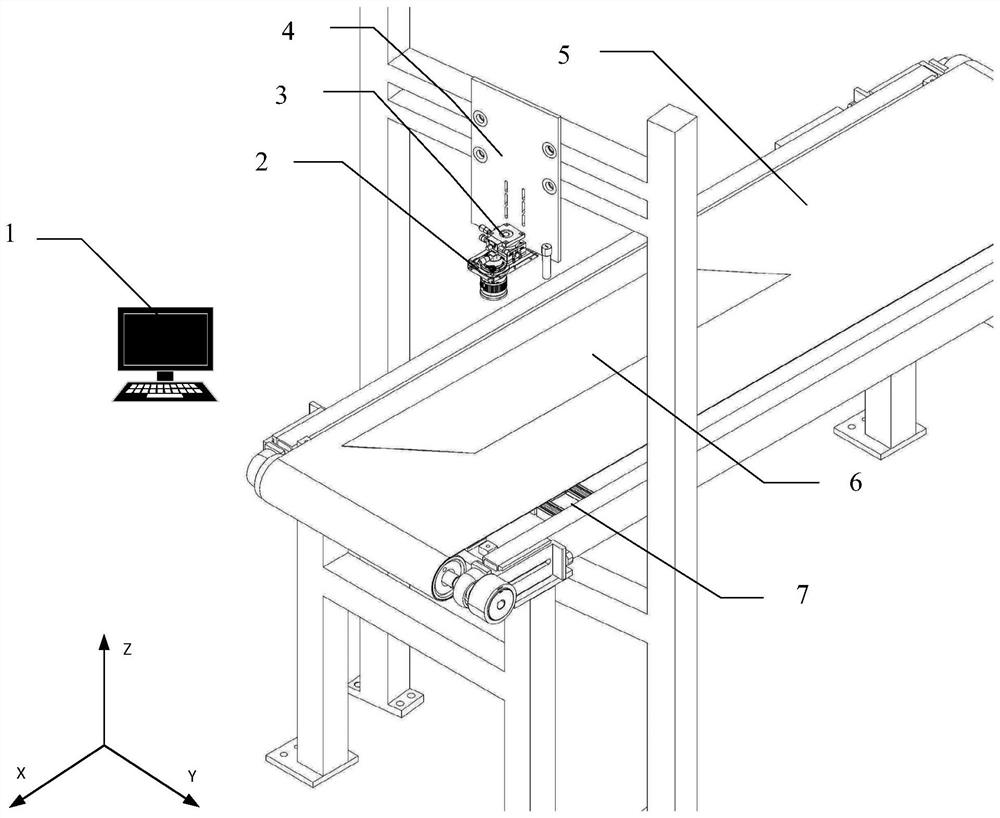

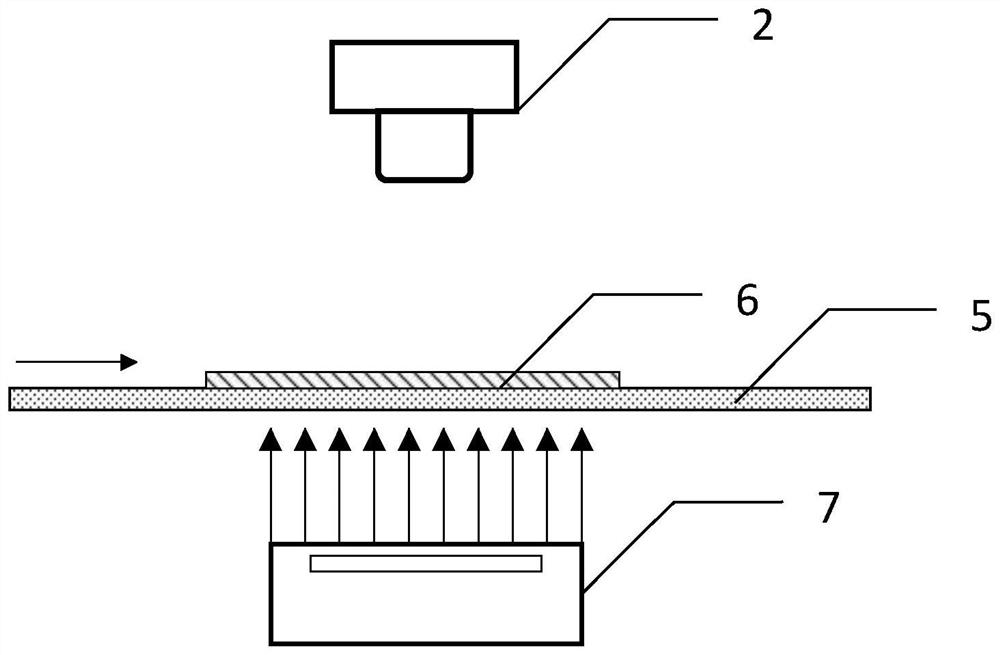

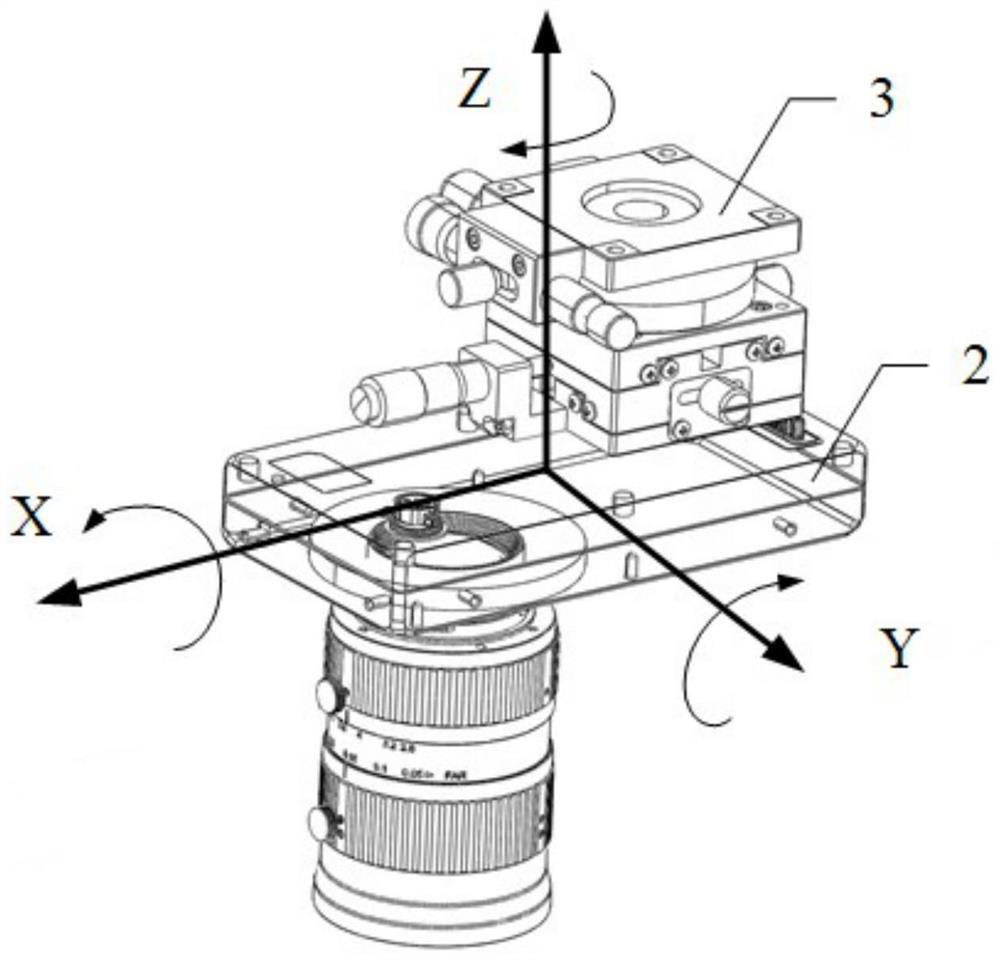

Visual measurement system for size of film on conveying belt and measurement method thereof

PendingCN114152199ARealize the need for real-time measurement of dimensionsRealize the need for real-time measurementUsing optical meansImaging qualityMechanical engineering

The invention provides a visual measurement system and method for the size of a film on a conveying belt, and the system comprises a main frame, a conveying belt assembly, an infrared LED backlight source, a camera, a precise sliding table, and a control device. The conveying belt assembly is installed on the main frame, the infrared LED backlight source is arranged under the conveying face of the conveying belt assembly, the camera is arranged over the conveying face of the conveying belt assembly and connected with the control device, the collecting portion of the camera is arranged right opposite to the conveying face and the infrared LED backlight source, the camera is installed on the precise sliding table, and the precise sliding table is connected with the control device. And the precise sliding table is mounted on the main frame. According to the measuring method, the measuring system is adopted for measurement, the measuring system is high in size measuring precision, more convenient and quicker to use and easy to operate, and the technical problems that in the prior art, the imaging quality of a detected film is poor, the measuring speed is low, and a calibration method is complex can be solved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY +1

Cleaning solution convenient for workpiece cleaning

The invention relates to a cleaning solution convenient for workpiece cleaning. The cleaning solution comprises, by weight, 24.28-25.67% of a cleaning agent, 4.59-5.37% of sodium nitrite, 1.75-2.28% of sodium hydroxide, 0.87-1.14% of thiourea as an oxidizing agent, 1.69-2.36% of trisodium phosphate and 63.18-66.82% of water. The cleaning solution comprising the cleaning agent, sodium nitrite, sodium hydroxide, thiourea as an oxidizing agent, trisodium phosphate and water is used for cleaning a workpiece so that an antirust layer is formed on the surface of the workpiece. Through cooperation of thiourea as an oxidizing agent and sodium hydroxide, oxidation performances in mixing are guaranteed, cleaning efficiency is improved, the workpiece does not fade, use performances and a service life are improved, a chrome plating process on the workpiece is avoided, a production cost is reduced, production efficiency is improved, safety and reliability are obtained, workpiece quality after cleaning is guaranteed and follow-up production processes are convenient.

Owner:湖州卓瑞刀具科技有限公司

Automatic silicon chip insertion equipment with cleaning function

PendingCN108389816AImprove qualityImprove efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingSilicon chipInsertion device

The invention discloses automatic silicon chip insertion equipment with a cleaning function. The automatic silicon chip insertion equipment includes a discharge hopper, a cleaning tank, a material receiving cleaner, a turn-over cleaner, a chip transfer and insertion device and a chip insertion rack. The automatic silicon chip insertion equipment with a cleaning function can enable chip insertion of silicon wafers to be performed automatically, reduces artificial participation, improves chip insertion quality and efficiency, and the silicon chips can be turned over to be cleaned, thereby ensuring cleanliness and tidiness, and facilitating subsequent production.

Owner:浙江岐达科技股份有限公司

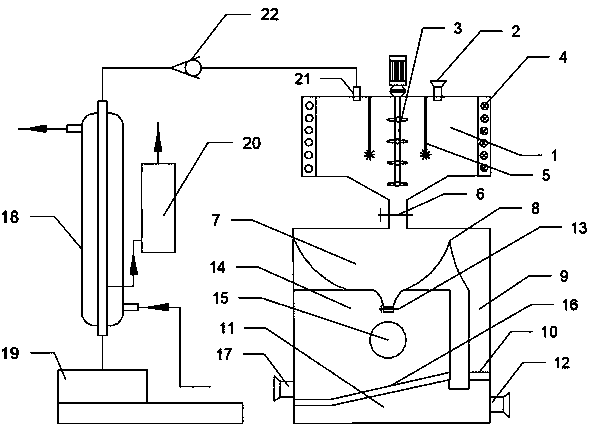

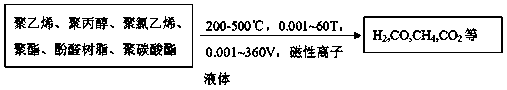

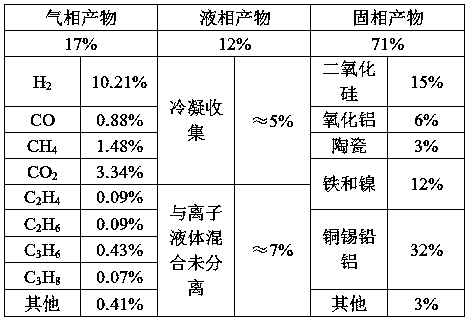

Method and device for recycling waste circuit boards through ion liquid

InactiveCN109967487AOvercome the disadvantages of high energy consumptionWide electrochemical windowTransportation and packagingSolid waste disposalParticulatesCatalytic pyrolysis

The invention discloses a method and a device for recycling waste circuit boards through ion liquid, and belongs to the technical field of solid waste resource development and utilization. The methodcomprises the steps of prilling the waste circuit boards, then mixing the waste circuit board particles and the magnetic ion liquid, heating the mixture, meanwhile, applying voltage on the mixture through an inert electrode or / and applying a magnetic field on the mixture through a magnetic induction loop, carrying out catalytic pyrolysis on the mixture at 200 to 500 DEG C, collecting a gas-phase product, and condensation recycling; and separating solid-phase and liquid-phase products, recycling a liquid phase, and magnetically separating a solid phase. According to the method and the device for recycling the waste circuit boards through the ion liquid provided by the invention, the ion liquid with a high catalytic performance is utilized, electricity or / and magnetism is / are additionally added for producing an electromagnetic coupling liquid phase catalysis effect on an organic matter base plate, the pyrolysis temperature is low, the micromolecule substance yield is high, a catalyst canbe recycled, and a pyrolysis three-phase product is high-value utilized.

Owner:KUNMING UNIV OF SCI & TECH

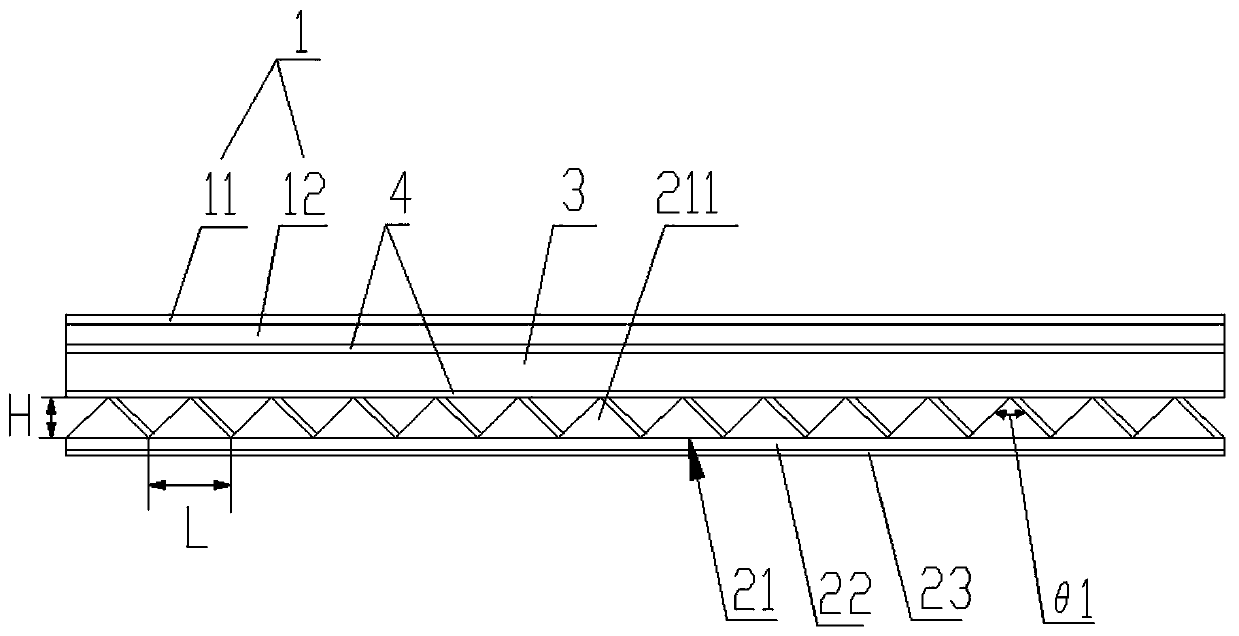

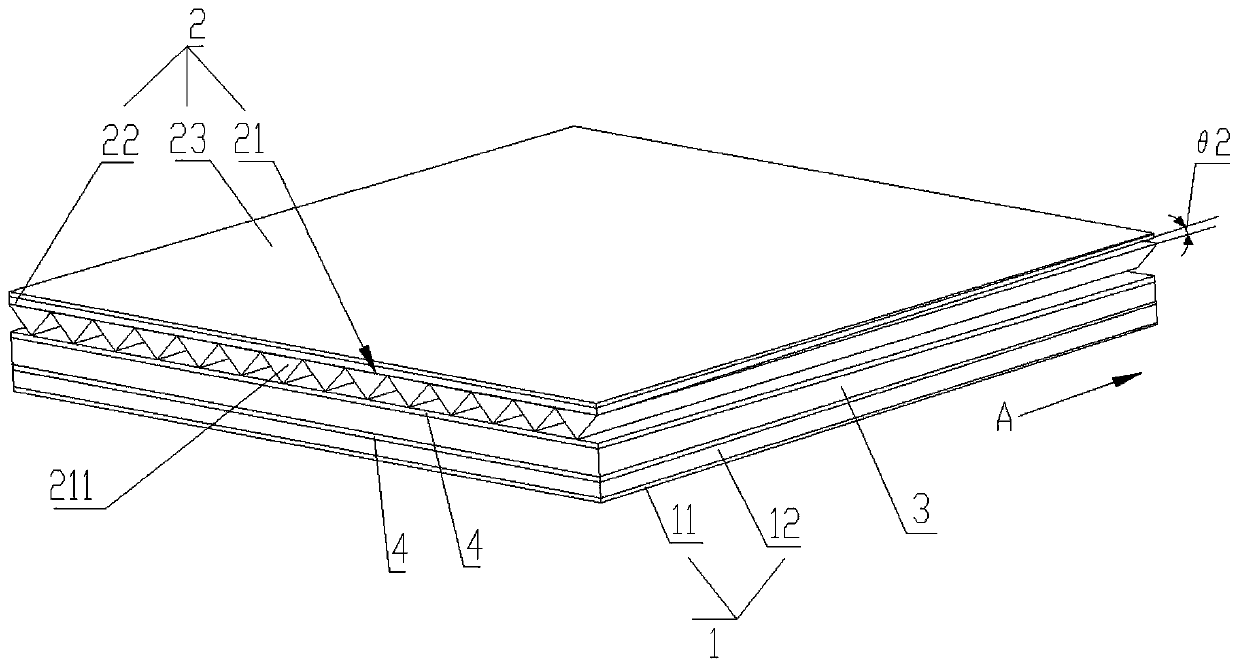

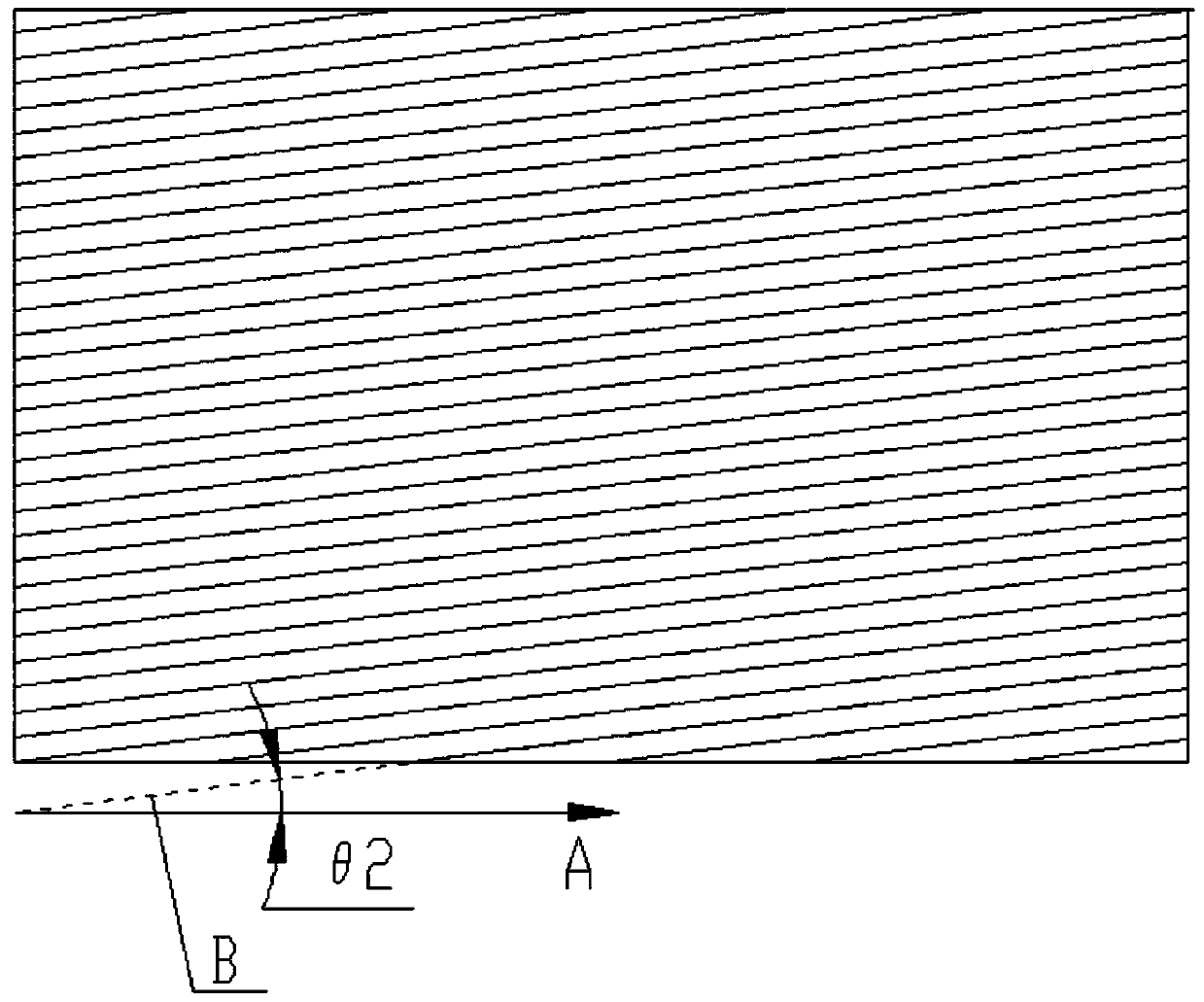

Laminating film for display and display backlight module

PendingCN111580201ANo interferenceNo glarePrismsPolarising elementsLiquid-crystal displayDisplay device

The invention relates to an optical film, and discloses a laminating film for a display. The laminated film comprises an atomization layer film, a base film and a prism layer film which are sequentially arranged from top to bottom. The prism layer film comprises a prism structure layer, the prism structure layer comprises a plurality of continuously-arranged prisms, and the prisms extend in the direction forming an included angle [theta]2 of 6-8 degrees with the reference direction with the production conveying direction of the laminated film production line as the reference direction. The invention further relates to a display backlight module. According to the prism layer film designed by the invention, the problem that lines on the liquid crystal display panel interfere with the laminating film can be solved. The interference-free effect is achieved, the applicability is wider, the interference problem of film layers such as the atomization layer film does not need to be solved by designing a rotating angle, the design complexity is reduced, the design is simpler, the subsequent production is easier and more accurate, and the product percent of pass is increased.

Owner:CCS (SHANGHAI) FUNCTIONAL FILMS IND CO LTD

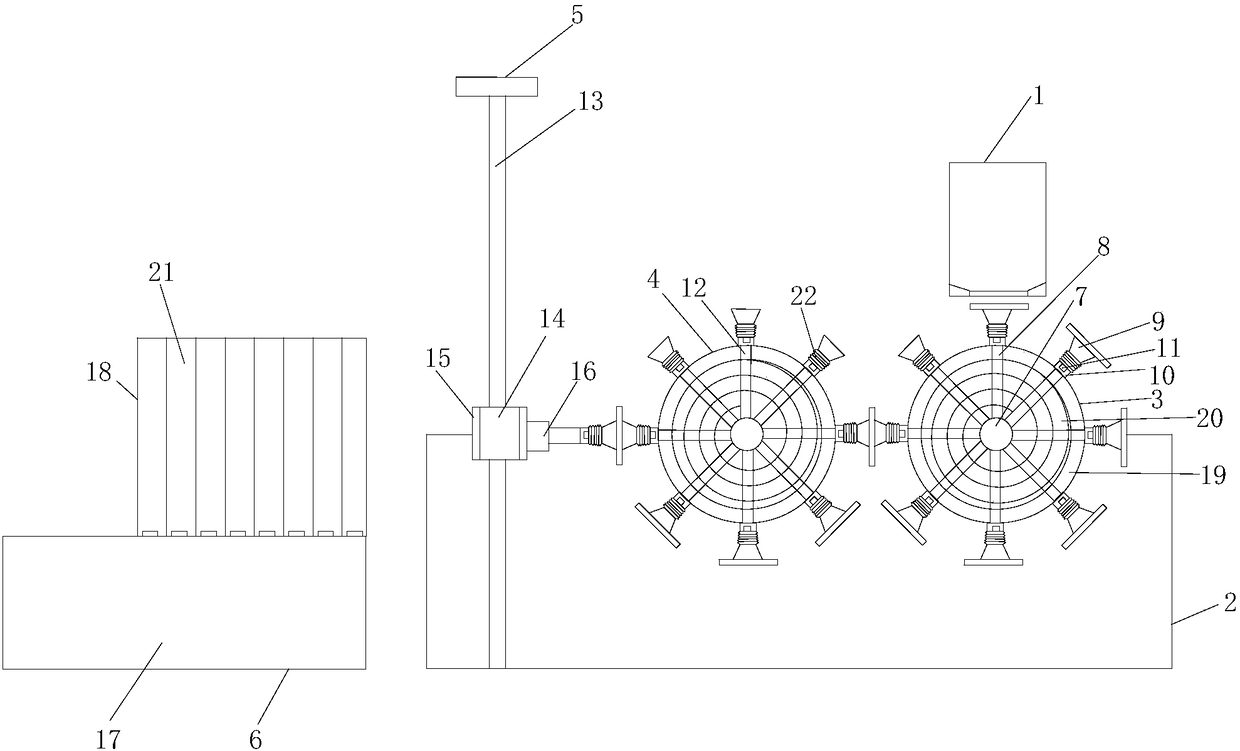

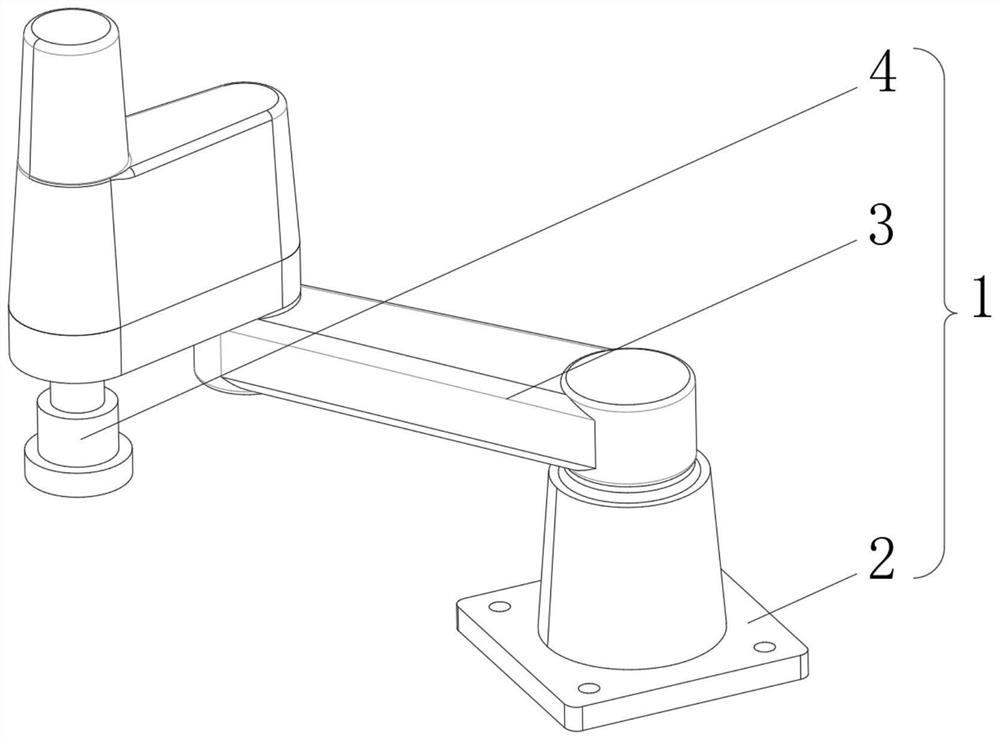

An injection molded sheet picking manipulator

ActiveCN112809659BImprove gripAvoid offsetProgramme-controlled manipulatorGripping headsRobot handRobotic arm

The invention discloses a manipulator for picking up injection molded sheets, which comprises a body of the manipulator for picking up injection molded sheets composed of a base, a manipulator arm and a grabbing mechanism. The top of the base is fixedly connected to the bottom of the manipulator arm, and the left bottom of the manipulator arm is The top of the grabbing mechanism is rotatably connected, and the inside of the mechanical arm is respectively provided with a suction vacuum pump and a micro motor. The grabbing mechanism includes an upper block, and the top of the upper block is rotatably connected to the micro motor through a rotating rod. The interior of the upper bearing block is slidably connected with a touch mechanism. The present invention relates to the technical field of injection molding manipulators. This kind of manipulator for picking up injection molded pieces solves the problem that during the production process of injection molded pieces, the temperature of injection molded pieces is high, the labor intensity of manual picking is high, the efficiency is low, and it is easy to burn; when ordinary manipulators pick up, individual injection molded pieces are squeezed, causing The injection molded sheet is deformed, and it is easy to fall off during the transfer process, causing damage to the injection molded sheet.

Owner:汕头市优必选高德乐科技有限公司

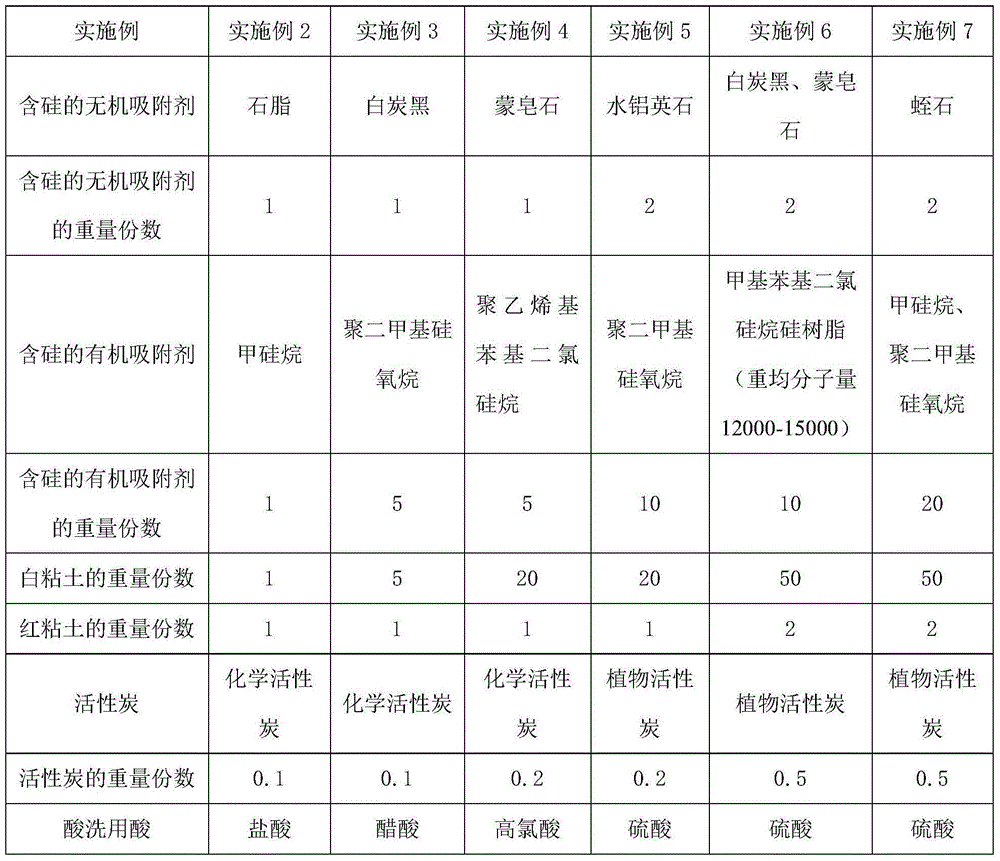

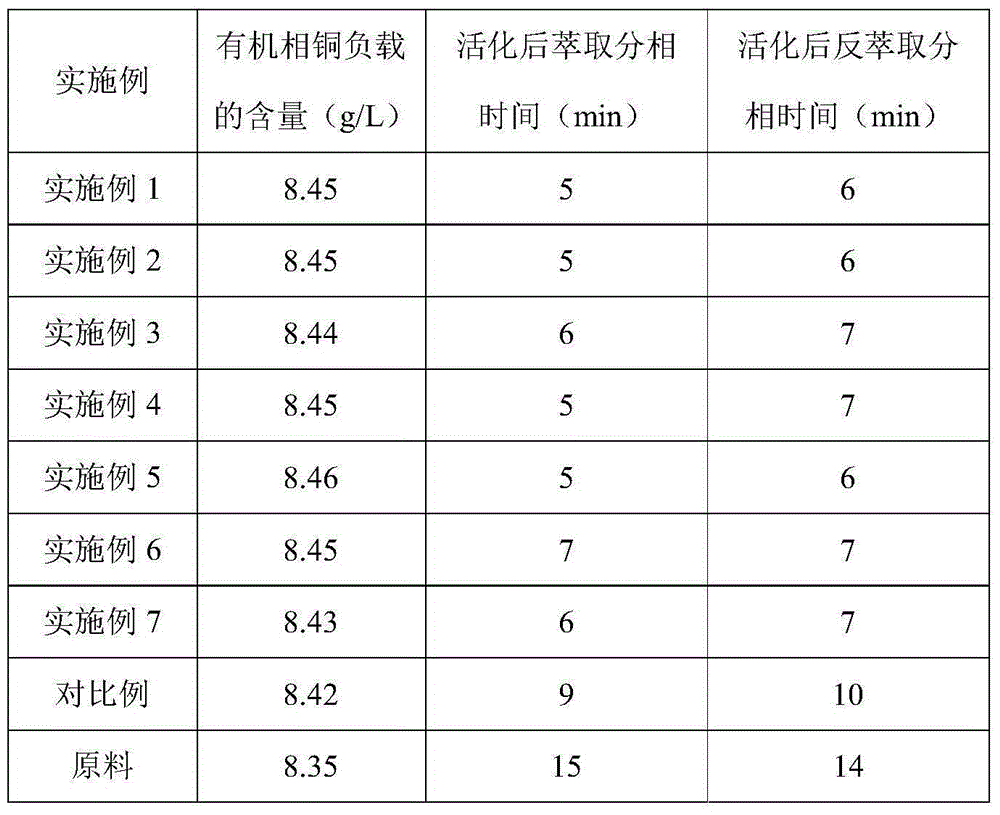

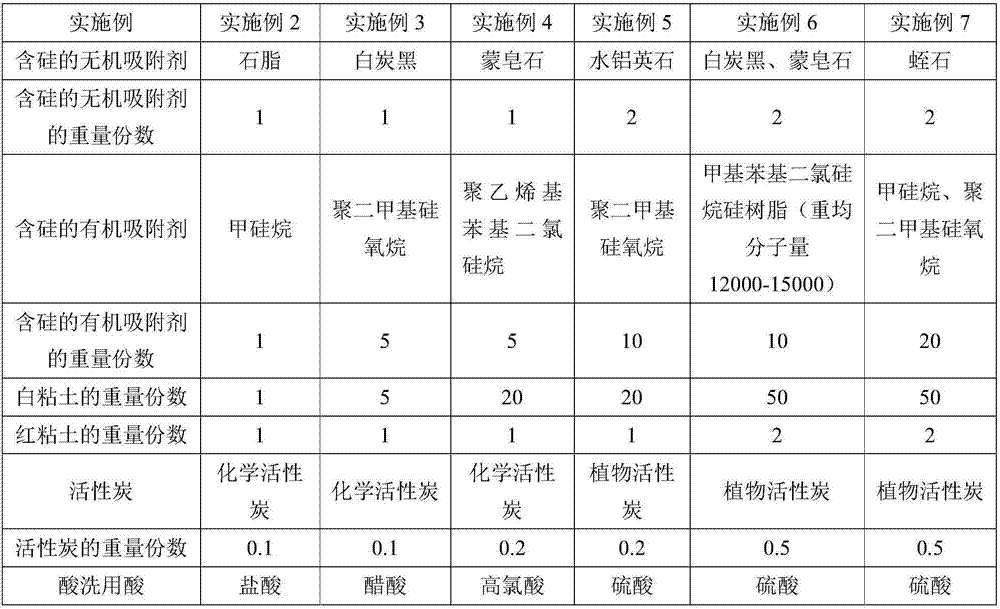

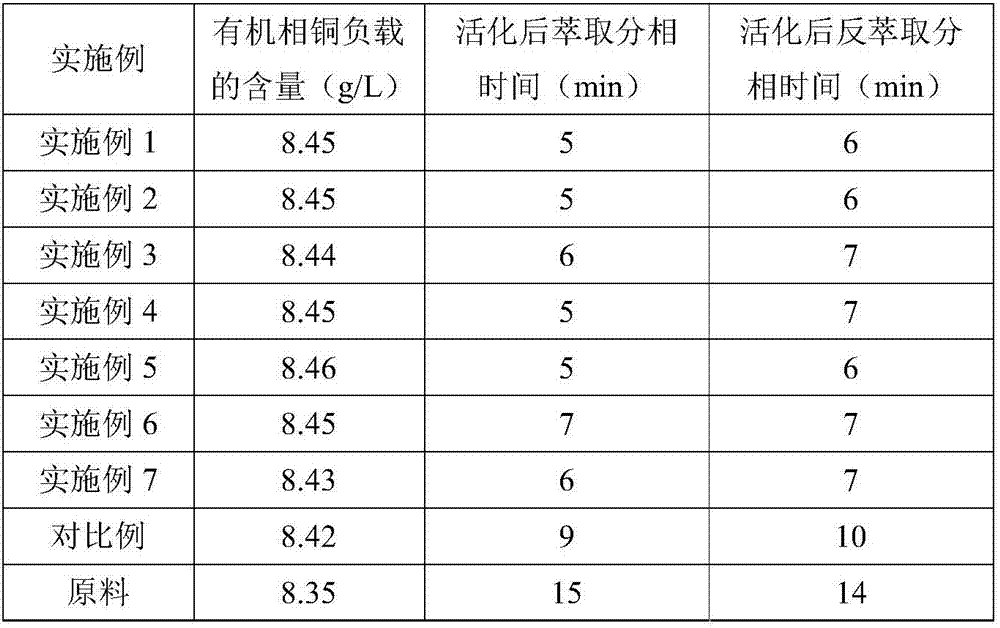

Complexing agent special for copper extracting agent and preparation method thereof

ActiveCN105039696APhase separation effect is goodImprove efficiencyProcess efficiency improvementFlocculationAllophane

The invention relates to a complexing agent special for a copper extracting agent and a preparation method thereof, and belongs to the technical field of wet metallurgy of copper. The complexing agent special for the copper extracting agent comprises, by weight parts, 1-2 parts of silicon-containing inorganic adsorbents, 1-20 parts of silicon-containing organic adsorbents, 1-52 parts of clay and 0.1-0.5 part of activated carbon. The silicon-containing inorganic adsorbents are one or more of gedanite, white carbon black, smectite, allophane and vermiculite. The silicon-containing organic adsorbents are one or more of silane, polysiloxane, polysilane and silicon resin. According to the complexing agent special for the copper extracting agent, the elimination rate of flocculation dirt in the copper extracting agent reaches over 90%, the extraction phase splitting efficiency is improved over 50%, and the use cycle of the copper extracting agent is obviously prolonged.

Owner:平顶山德源精细化学品有限公司

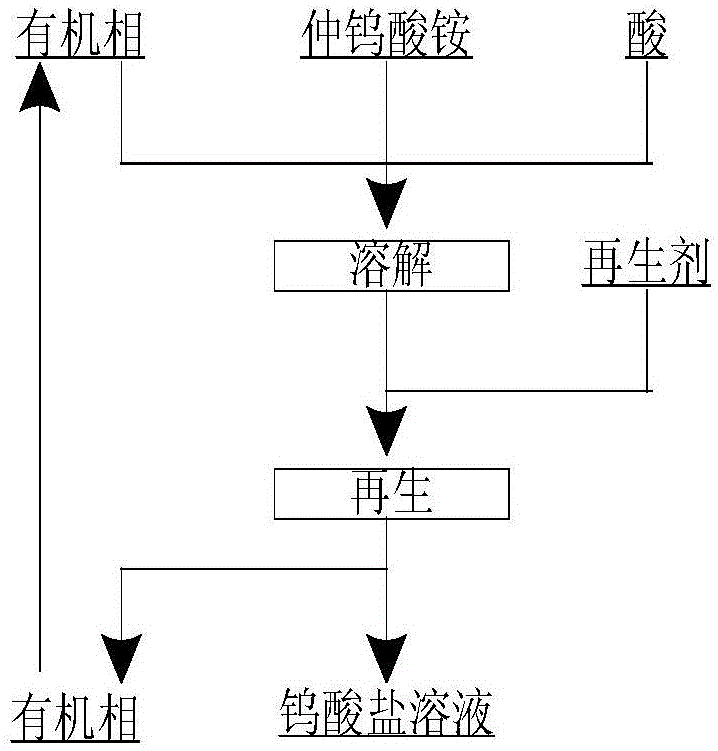

Fast dissolving method for ammonium paratungstate/tungsten trioxide

ActiveCN106555061AReduce the temperatureReduce energy consumptionProcess efficiency improvementPhosphoric Acid EstersTungstate

The invention discloses a fast dissolving method for ammonium paratungstate / tungsten trioxide. Ammonium paratungstate / tungsten trioxide solids are added to one or more extraction agents of acid and amines, quaternary ammonium salts, phosphoric acid esters, alcohols and ketones and are mixed with a regulator and solvent oil, and the ammonium paratungstate / tungsten trioxide is completely dissolved with the obtained organic phase; ammonia water and a sodium hydroxide solution are poured into the organic phase and mixed, and organic phase regeneration is completed; and finally the organic phase and a tungstate solution are separated, the organic phase is reused, the tungstate solution is obtained, and the dissolving process of the ammonium paratungstate / tungsten trioxide is completed. According to the fast dissolving method, the amines, quaternary ammonium salts, phosphoric acid esters, alcohols and ketones are used as a reagent and mixed with a solvent, the organic phase is obtained for promoting decomposition of the ammonium paratungstate / tungsten trioxide, the process temperature is low, the reaction speed is high, the concentration of the obtained tungstate is high, the residual alkali concentration is low, no waste gas is generated, and energy conservation and environmental protection are achieved.

Owner:湖南瑞友有色科技有限公司

Special complexing agent for copper extractant and preparation method thereof

ActiveCN105039696BPhase separation effect is goodImprove efficiencyOther chemical processesProcess efficiency improvementAllophaneActivated carbon

The invention relates to a complexing agent special for a copper extracting agent and a preparation method thereof, and belongs to the technical field of wet metallurgy of copper. The complexing agent special for the copper extracting agent comprises, by weight parts, 1-2 parts of silicon-containing inorganic adsorbents, 1-20 parts of silicon-containing organic adsorbents, 1-52 parts of clay and 0.1-0.5 part of activated carbon. The silicon-containing inorganic adsorbents are one or more of gedanite, white carbon black, smectite, allophane and vermiculite. The silicon-containing organic adsorbents are one or more of silane, polysiloxane, polysilane and silicon resin. According to the complexing agent special for the copper extracting agent, the elimination rate of flocculation dirt in the copper extracting agent reaches over 90%, the extraction phase splitting efficiency is improved over 50%, and the use cycle of the copper extracting agent is obviously prolonged.

Owner:平顶山德源精细化学品有限公司

A vertical plant factory with three-dimensional automatic transfer of cultivation plates

ActiveCN113479543BConvenient space transfer vehicle operationConvenience for follow-up productionAgriculture gas emission reductionCultivating equipmentsPlant factoryAgricultural engineering

The invention discloses a vertical plant factory for automatic three-dimensional space transfer of cultivation boards, comprising a cultivation board, a cultivation rack, a lifting component and a space running car. The cultivation layer slides back and forth, and the cultivation board with seedlings can be sent to the cultivation layer by using the space running vehicle. A lifting assembly is arranged on the side elevation of the cultivation rack, and the lifting assembly can drive the space running vehicle to reciprocate along the height direction of the cultivation rack, so as to complete the transportation of plants in multi-layer cultivation layers. The invention utilizes the lifting component and the space running vehicle to realize the transportation of the cultivation board, avoids the problem of reserving a large working space between the cultivation racks to reduce the space utilization rate, at the same time, the work efficiency is improved, and in addition, the upper and lower parts of the cultivation board are ensured. Stability and reliability of unloading operations.

Owner:INST OF URBAN AGRI CHINESE ACADEMY OF AGRI SCI

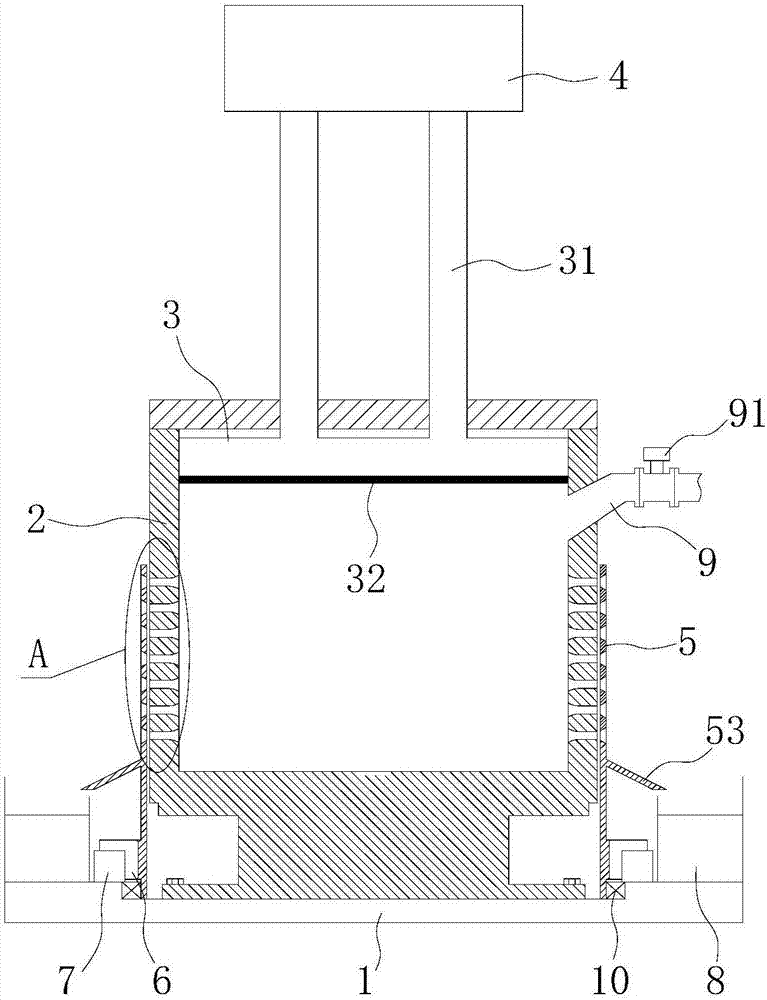

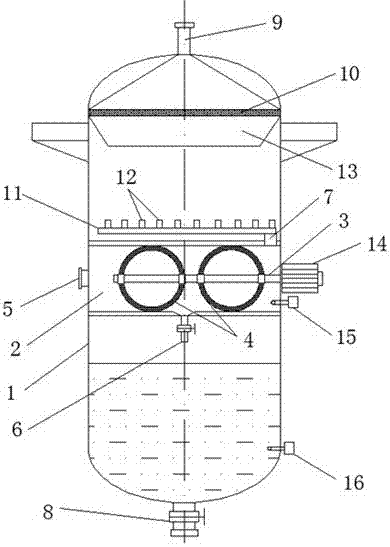

Refrigeration and separation tank for producing liquefied natural gas

InactiveCN107469482AStable jobConvenience for follow-up productionDispersed particle filtrationTransportation and packagingEngineeringControl valves

The invention discloses a refrigeration and separation tank for producing liquefied natural gas. The refrigeration and separation tank is a cylindrical shell body, wherein a sealed cylindrical separation groove is formed in the middle of the shell body; a rotary shaft, which is horizontally mounted, is arranged in the separation groove; the rotary shaft is provided with a plurality of spherical liquid filtering screen meshes; the diameter of the liquid filtering screen meshes is the same as the inner diameter of the separation groove; a feeding hole is formed in the shell body at one side of the separation groove and a rotary motor is arranged on the shell body at the other side of the separation groove; the rotary motor is connected onto the rotary shaft; a gas outlet is formed in the top of the separation groove in one side of the rotary motor; a liquid discharging opening is formed in the bottom of the separation groove; a tank body exhausting opening is formed in the top of the shell body; a tank body liquid discharging opening is formed in the bottom of the shell body; the liquid discharging opening is provided with an electromagnetic control valve. The refrigeration and separation tank is improved and a gas product which only contains less liquid and is generated in a liquefied natural gas production process is treated; the device has the advantages of simple structure, convenience for operation, accuracy in controlling and good gas-liquid separation effect and is convenient for subsequent production of the liquefied natural gas.

Owner:JIANGSU ZHUODA INFORMATION TECH CO LTD

Production mechanism for producing plastic raw material

InactiveCN108656389AConvenience for follow-up productionEasy to collectEngineeringMechanical engineering

The invention provides a production mechanism for producing a plastic raw material. The production mechanism comprises an extruding apparatus; the body of the production mechanism is arranged out of the extruding apparatus; the extruding apparatus is composed of extruding rods symmetrically arranged in the body; the upper ends of the extruding rods are provided with a blanking port; a blanking chamber is arranged above the blanking port; a flatly spread screen mesh is arranged in the blanking chamber and is fixed in the blanking chamber through welding; a pulling plate is arranged below the extruding apparatus and fixed in a pulling groove; the pulling plate moves back and forth in the pulling groove; and a motor is arranged on the motor and drives the extruding apparatus to rotate.

Owner:江苏斯瑞达塑业有限公司

Novel chemical production device

InactiveCN110801799AImprove controllabilityConvenience for follow-up productionCleaning using toolsChemical/physical/physico-chemical stationary reactorsProcess engineeringPipe

The invention discloses a novel chemical production device, relates to the technical field of chemical production devices, and aims to solve that problem of low production efficiency; the novel chemical production device specifically comprises a solid chamber and a liquid chamber, wherein a solid feed inlet is welded on the outer wall at one side of the solid chamber; a feed door is connected withthe outer wall at one side of the solid chamber through a shaft and a bearing; a material guide pipe is welded on the inner wall at one side of the solid chamber; and a crushing box is welded on theouter wall at one side of the material guide pipe. By arrange sieve holes, small particle material entering the crushing box and small particle materials generated in the crushing process can be sieved through the sieve holes, convenience is provided for subsequent production; by setting a feeding switch, the staff can feed or stop solid materials according to the actual situation, convenience isprovided for production, and safety is enhanced at the same time. By setting a regulating valve, workers can adjust the rate of liquid raw materials flowing through the regulating valve according to the actual situation, thus realizing the controllability of liquid supply.

Owner:LEIYANG JINYUE SCI & TECH DEV

Uniformly distributed separating conveyor belt

PendingCN109592295AEvenly arrangedReasonable structural designConveyorsConveyor partsEngineeringConveyor belt

The invention relates to a uniformly distributed separating conveyor belt, wherein the concrete structure of the separating conveyor belt is that the middle part of a conveyor passage is a rising slope structure, the input section and the output section of the conveyor passage are both made into horizontal sections, the input section is used for receiving the falling materials screened by a separating roller, and the output section is used for connecting the inlet of equipment of the next process; a one-way transmission network is driven in the conveyor passage, the one-way transmission network specifically comprises shaft rods and screen plates, the plurality of shaft rods are uniformly arranged in the same axial direction, and a plurality of mesh plates which are arranged in a transverseand longitudinal staggered array are pierced on the shaft rods to form a continuous mesh surface structure, and the mesh plates are provided with convex unidirectional limit angles, and metal sheetsslide on the mesh surface to be uniformly arranged in a single layer under the action of gravity in the conveying process. The invention has the advantages of reasonable structure design, simple operation, automatic conveying of recovered waste, uniform arrangement of materials in the conveying process, convenience for subsequent production, continuous automatic processing and high production efficiency.

Owner:天津市曙光金属网有限公司

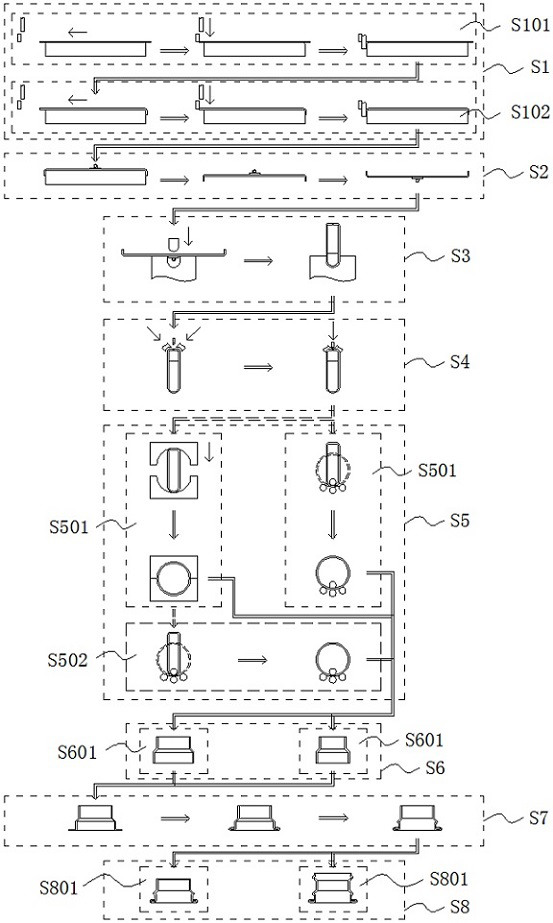

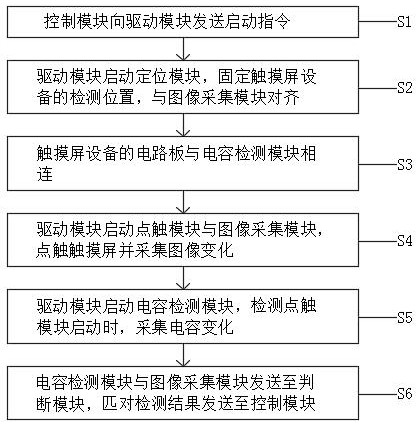

Function detection method of touch screen

PendingCN113049894AHigh precisionEasy to operateElectrical testingTesting optical propertiesComputer hardwareEngineering

The invention discloses a function detection method of a touch screen. The detection method comprises the following steps of S1, using a control module to send a starting instruction to a driving module; S2, starting a positioning module by the driving module, fixing a detection position of the touch screen device, and aligning the detection position with an image acquisition module; S3, connecting a circuit board of the touch screen driving device with a capacitance detection module; S4, using the driving module to start a point contact module and the image acquisition module, using the touch screen, and acquiring the image change; S5, using the driving module to start the capacitance detection module, and acquiring the capacitance change when the detection point touch module is started; and S6, using the capacitance detection module and the image acquisition module to send the detection results to a judgment module, pairing the detection results and sending to a control module. According to the function detection method of the touch screen, the process is simple, detection is carried out in a mode of matching the image real-time acquisition and the point contact capacitance change, and compared with the traditional capacitance detection, the precision is higher, and the number of times of repeated detection is reduced.

Owner:苏州伟之佳光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com