Novel chemical production device

A new type of chemical production technology, applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as low production efficiency and slow reaction speed, and achieve improved production efficiency, block reaction speed, increase The effect of crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

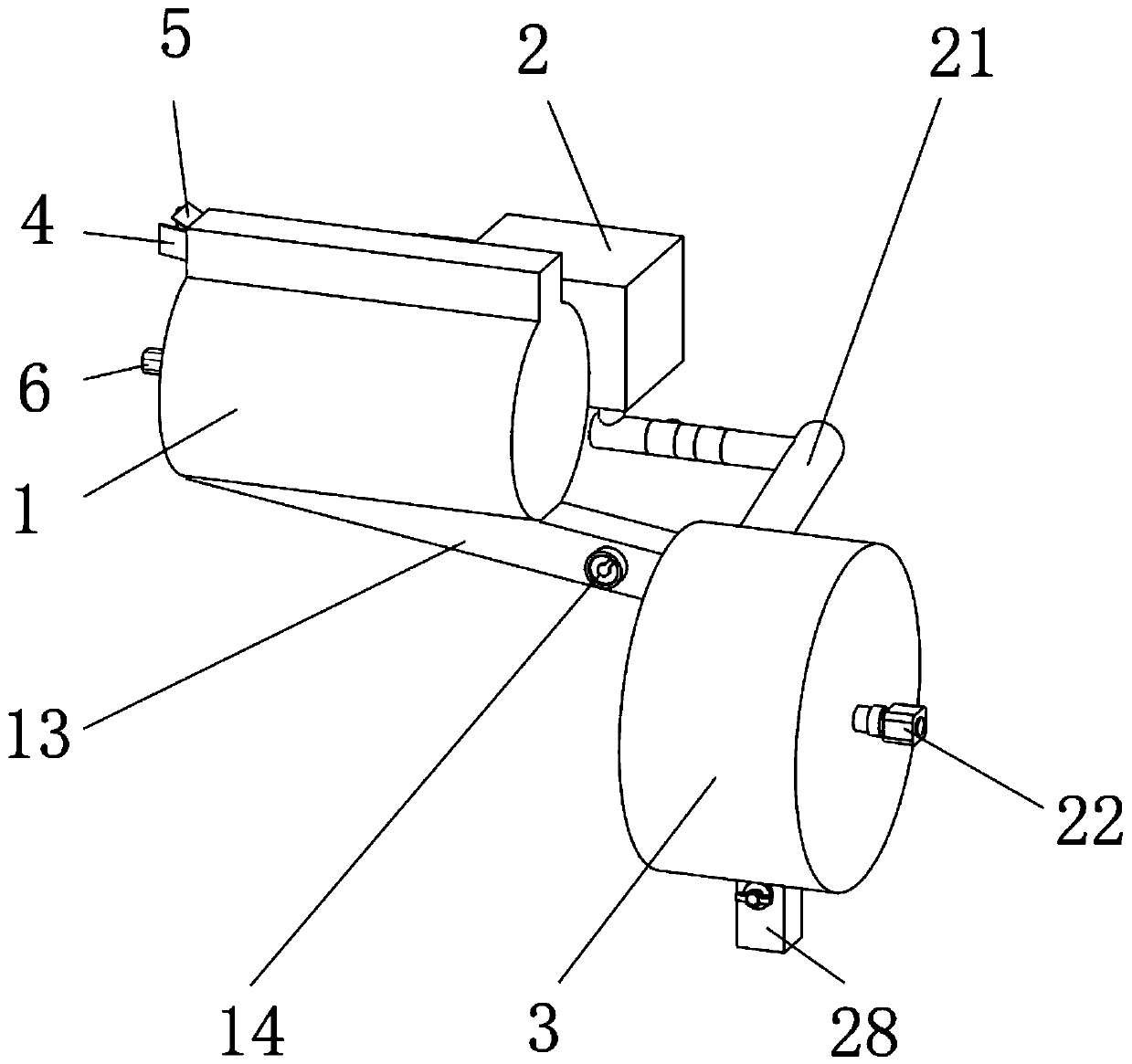

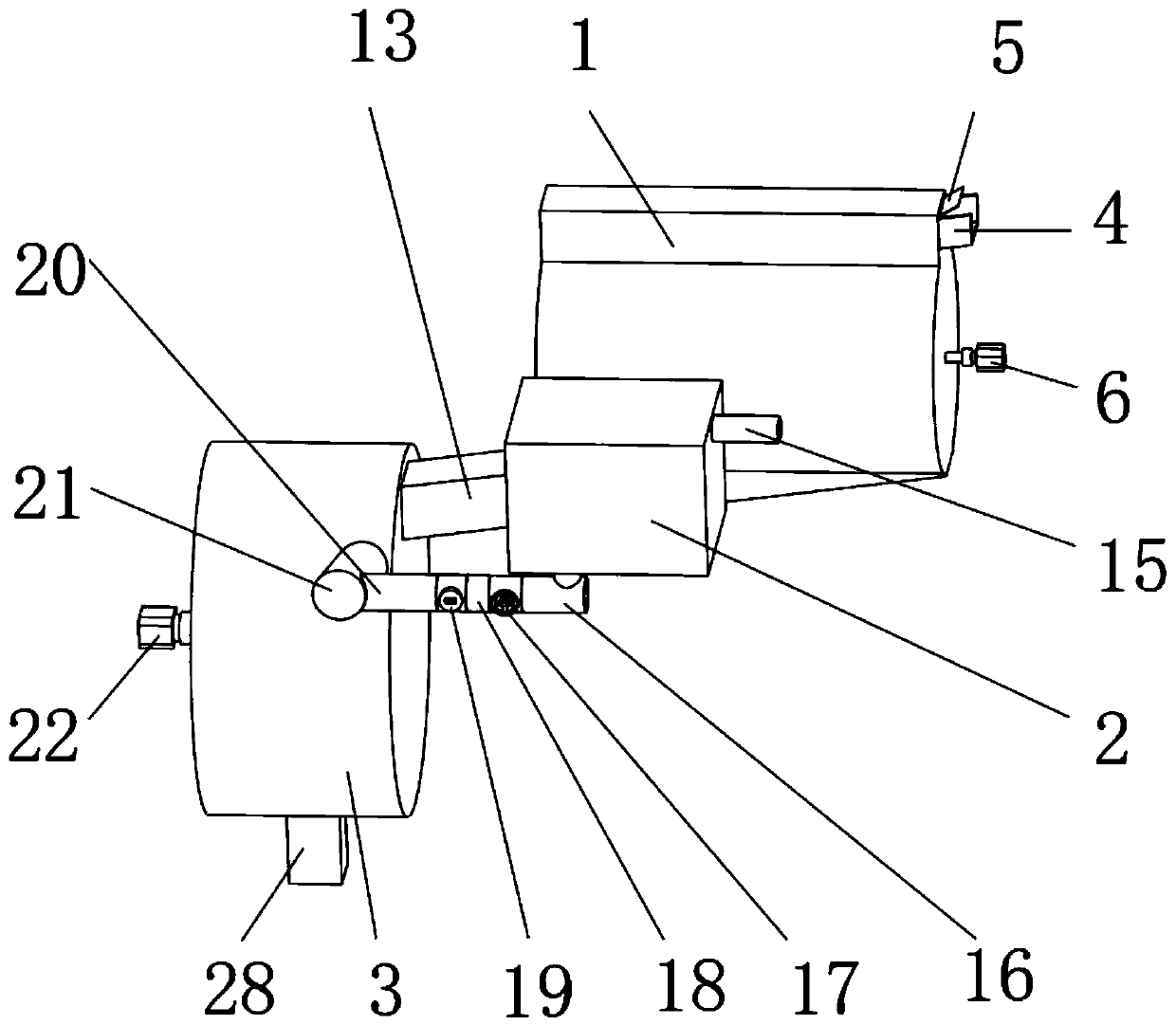

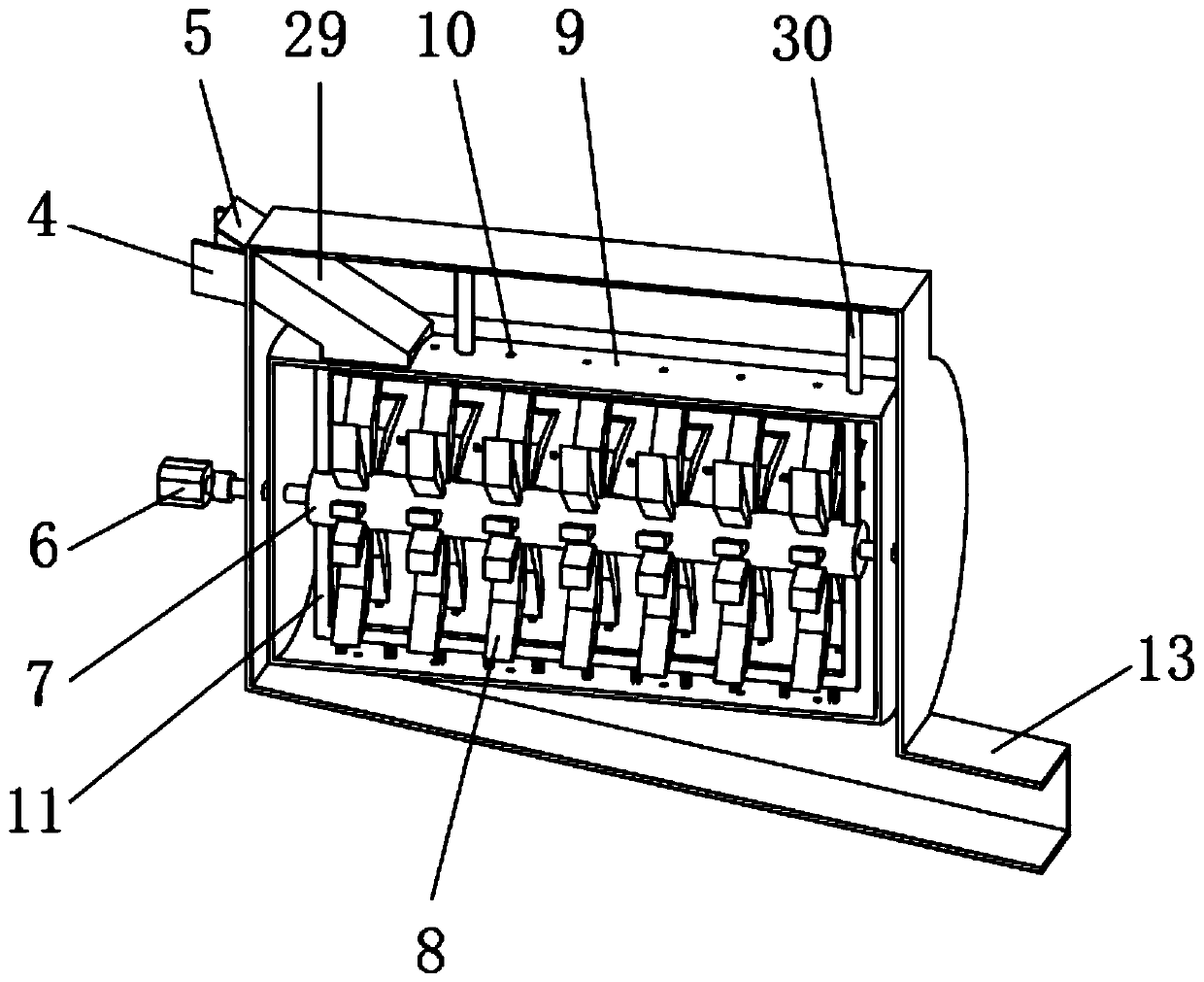

[0033] A new type of chemical production device, such as figure 1 , image 3 As shown, it includes a solid chamber 1 and a liquid chamber 2, the outer wall of the solid chamber 1 is welded with a solid feed port 4, and the outer wall of the solid chamber 1 is connected with a feed gate 5 through a shaft and a bearing. A feed pipe 29 is welded on the inner wall of one side of the chamber 1, and a crushing box 9 is welded on the outer wall of one side of the feed pipe 29. When the solid feed port 4 is put into the material, it can be discharged through the feed pipe 29 to the inside of the crushing box 9. , the top outer wall of the crushing box 9 is welded with a support column 30, the support column 30 is welded to the top inner wall of the solid chamber 1, and the outer wall of one side of the solid chamber 1 is equipped with a crushing motor 6 through the first motor seat, and the crushing box 9 The inner walls of both sides are equipped with the same crushing main shaft 7 ...

Embodiment 2

[0044] A new type of chemical production device, such as Figure 4 As shown, in order to solve the problem of imprecise crushing; this embodiment makes the following improvements on the basis of embodiment 1: the outer wall of the crushing main shaft 7 is welded with a brush head frame 11, and the outer walls of both sides of the brush head frame 11 pass through the brush head holder Evenly distributed brush heads 12 are installed. When the crushing main shaft 7 rotates, it can drive the brush head frame 11 to rotate, and then drive the brush head 12 to work. By setting the brush head frame 11 and the brush head 12, the crushing teeth 8 can be crushed while The brushing and stripping of the solid materials stuck to the inner wall of the crushing box 9 and the cleaning of the large particles accumulated in the sieve holes 10 effectively increase the crushing efficiency and avoid the blockage of the sieve holes 10 at the same time.

[0045] When the present embodiment is in use,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com