Automatic silicon chip insertion equipment with cleaning function

An automatic cleaning and chip insertion technology, applied in conveyor objects, sustainable manufacturing/processing, electrical components, etc., can solve the problems of silicon wafer pollution, silicon wafer damage, low efficiency, etc., to reduce manual participation and improve chip insertion. Quality and efficiency, the effect of convenient subsequent production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

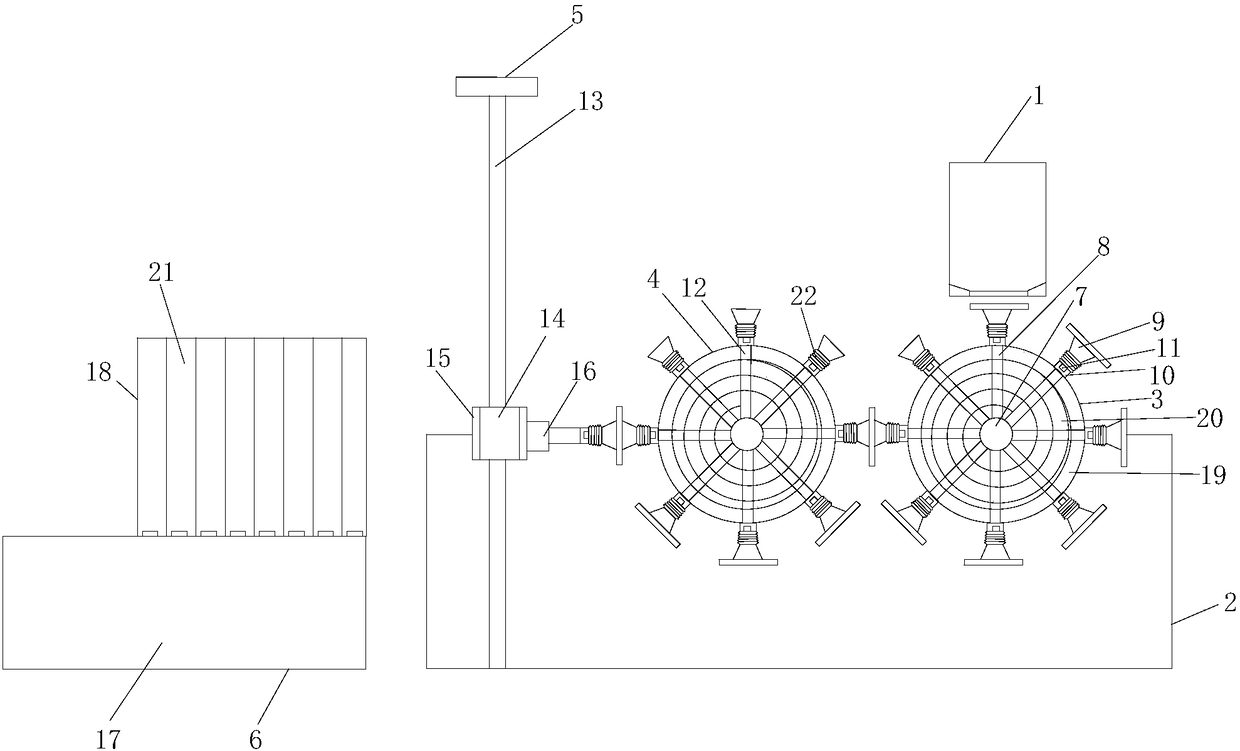

[0013] refer to figure 1 , a silicon chip automatic cleaning inserting device of the present invention, comprising a lower hopper 1, a cleaning tank 2, a material receiving cleaner 3, a turning cleaner 4, a transfer inserter 5, and an inserting rack 6, the lower hopper 1 It is arranged directly above the cleaning tank 2, and a material receiving cleaner 3 is arranged directly below the lower hopper 1, and the material receiving cleaner 3 includes a rotating wheel 7, a material receiving column 8, a material suction cup 9, and a vacuum valve 10 . Material sensor 11, the rotating wheel 7 is arranged in the cleaning tank 2, a number of material receiving columns 8 are evenly arranged around the rotating wheel 7, and a vacuum valve 10 is arranged at the outermost end of the material receiving column 8, The top of the vacuum valve 10 is equipped with a suction cup 9, the bottom of the suction cup 9 is provided with a material sensor 11, and the turning cleaner 4 is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com