Complexing agent special for copper extracting agent and preparation method thereof

A technology for a copper extractant and a complexing agent is applied in the field of a special complexing agent for copper extracting agents and its preparation, which can solve the problems of limited floc removal effect, complex organic composition, low separation efficiency, etc. The effect of improving phase separation efficiency and high phase separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

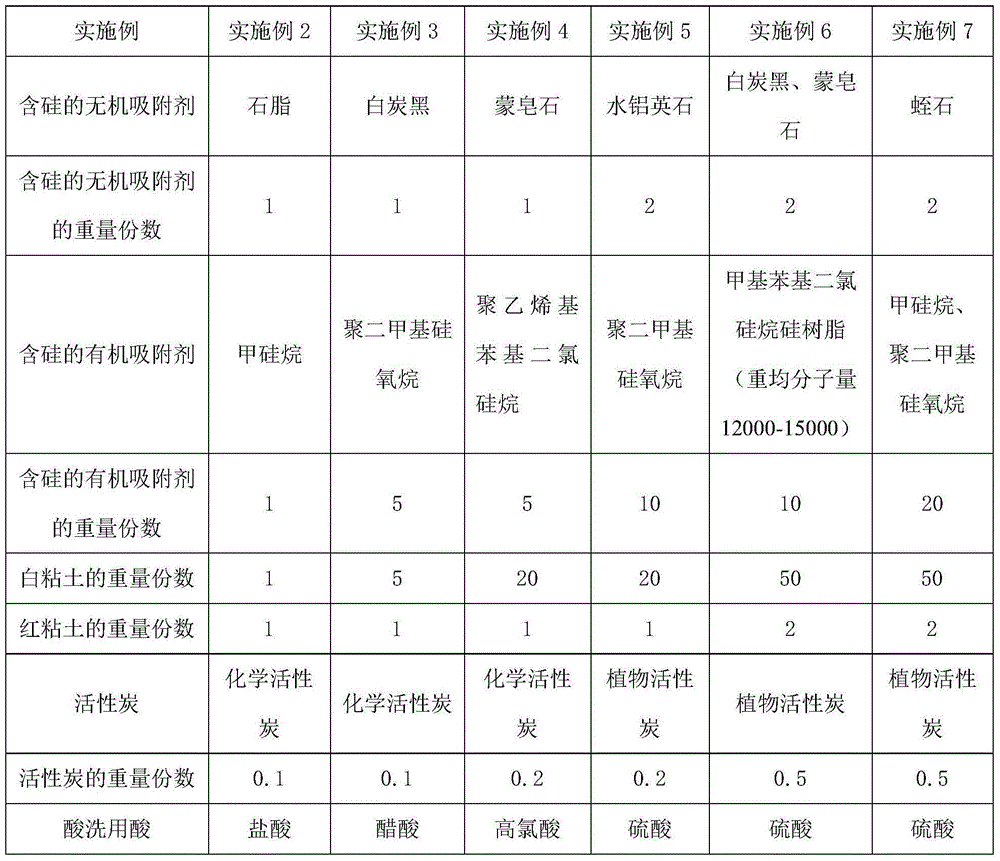

Examples

Embodiment 1

[0021] The special complexing agent for copper extractant in this embodiment includes the following components in parts by weight: 1 part of silicon-containing inorganic adsorbent, 10 parts of silicon-containing organic adsorbent, 10 parts of clay, and 0.5 part of activated carbon. In this embodiment, the silicon-containing inorganic adsorbent is 1 g, the silicon-containing organic adsorbent is 10 g, the clay is 10 g, and the activated carbon is 0.5 g, wherein the silicon-containing inorganic adsorbent is white carbon black, and the silicon-containing organic adsorbent It is monosilane, the clay is a clay mixture obtained by mixing white clay and red clay in a ratio of 1:1 and then drying, and the activated carbon is plant activated carbon.

[0022] The preparation method of above-mentioned complexing agent special for copper extractant comprises the steps:

[0023] 1) After the white carbon black is pulverized, magnetically separated, screened, sulfuric acid pickled and washe...

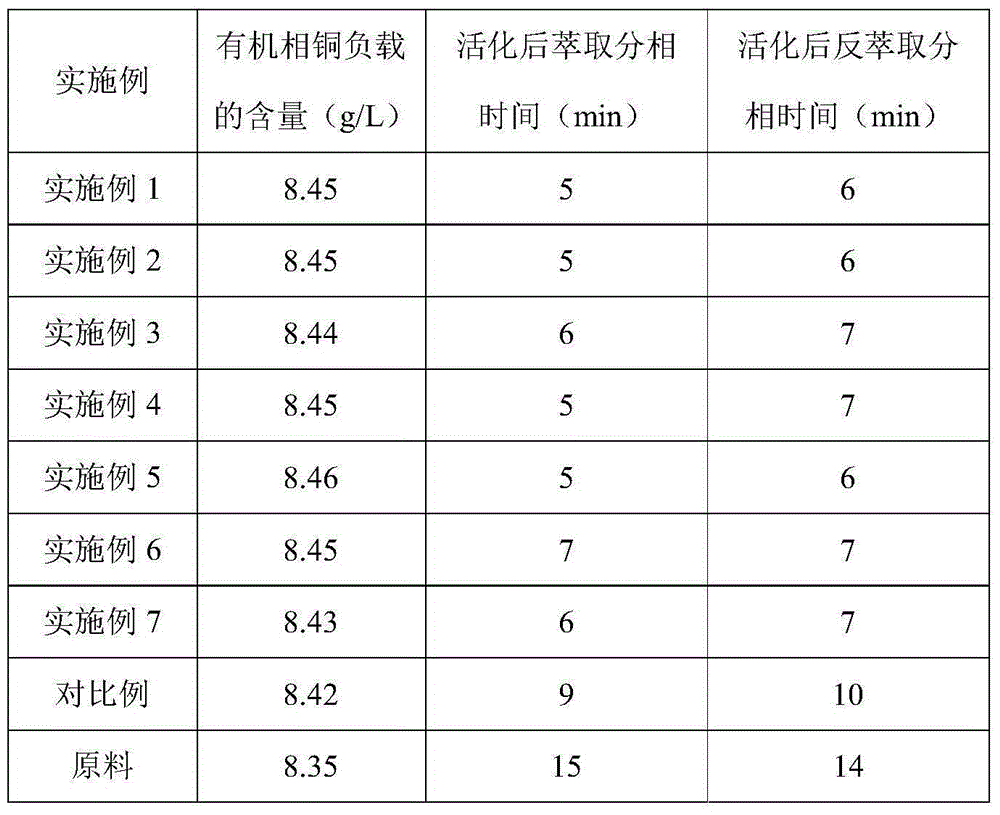

experiment example

[0031] Taking the Lix series copper extractant system used by an enterprise for a certain period of time as the experimental object, the technical indicators of the copper extractant are as follows:

[0032] 1) After nuclear magnetic detection, the content of organic phase components in the copper extractant system is 14.3%. The content of organic phase components refers to the content of pure copper extractant in the copper extractant system, and the remaining components in the system are diluents and degradants. after impurities.

[0033] 2) After titration detection, the content of copper loading in the original organic phase is 8.35g / L, wherein the copper loading content of the organic phase refers to the amount of copper contained in the organic phase of the extraction agent with a unit volume concentration after the copper extraction agent extracts copper. Concentration of extractable metals (g / L).

[0034] 3) The extraction and phase separation time of the copper extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com