A kind of environment-friendly phosphorus-free washing powder and its preparation process

A kind of washing powder, environmental protection technology, applied in the direction of detergent powder/flake/sheet, inorganic/element washing composition, detergent compounding agent, etc., can solve the problems of fabric damage, hard water resistance, etc., and achieve the goal of reducing moisture absorption Possibility, improvement of phase separation, effect of increasing washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] The materials used in this example were all routinely purchased from the market.

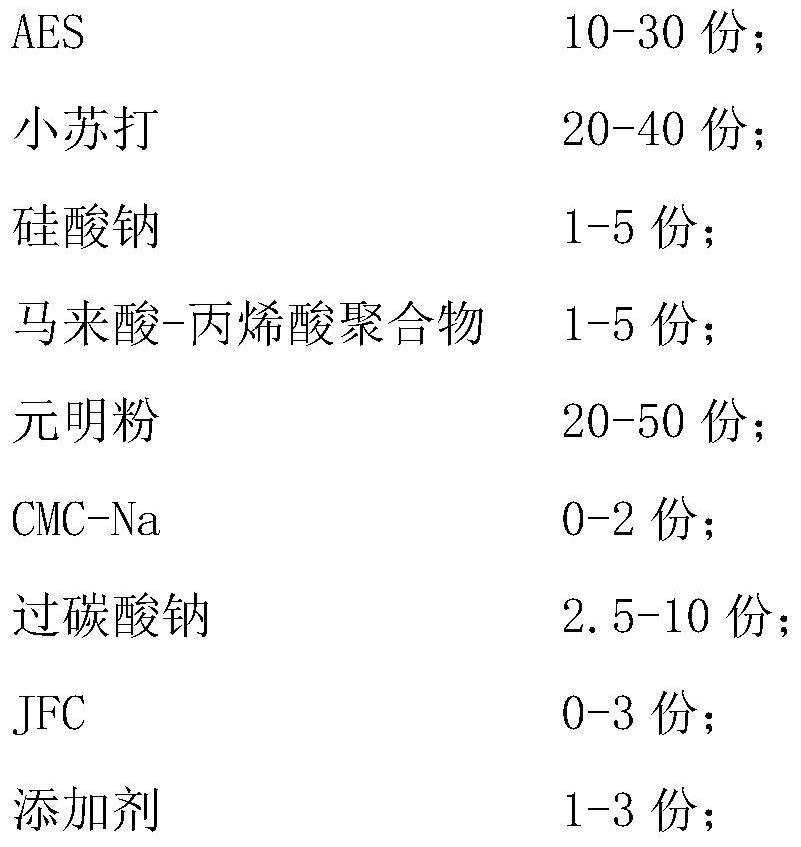

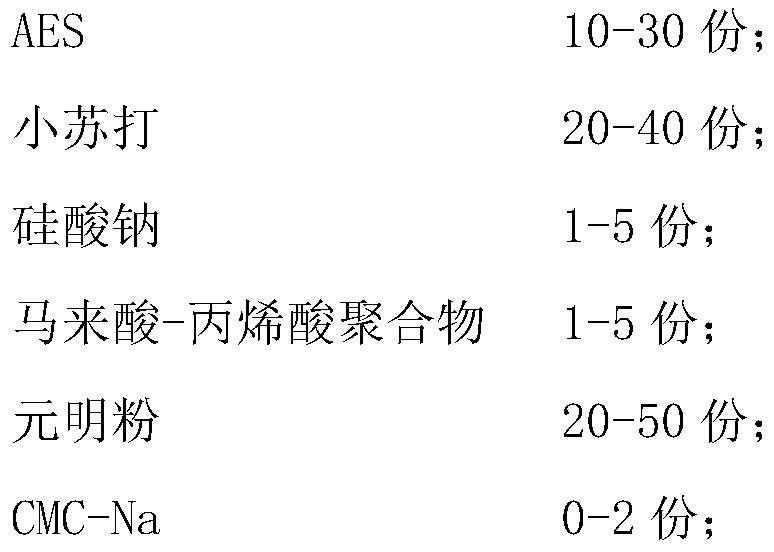

[0079] The invention discloses an environmentally friendly and phosphorus-free washing powder, which comprises the following components by weight and number:

[0080]

[0081] Wherein, the sodium percarbonate is coated with a stabilizer for improving its stability, and according to the weight ratio, sodium percarbonate:stabilizer=1:1. The stabilizer is composed of 3wt% polyacrylamide gel and citric acid monohydrate, and according to the weight ratio, 3wt% polyacrylamide gel: citric acid monohydrate=100:3.

[0082] The technique that stabilizer is coated on the sodium percarbonate specifically comprises the following process steps:

[0083] S1. Spray polyacrylamide gel onto sodium percarbonate in a fluidized bed at a spraying temperature of 60°C, and dry for 2 minutes after spraying to obtain a semi-finished product A;

[0084] S2. Spray solid citric acid monohydrate powder into the f...

Embodiment 2

[0112] The difference between Example 2 and Example 1 is that the sodium percarbonate is not coated with a stabilizer, but is directly added to the washing powder.

[0113] The difference between embodiment 3-6 and embodiment 1 is that the weight and number ratio of each component in the washing powder is calculated as the following table:

[0114]

Embodiment 7

[0115] The difference between embodiment 7 and embodiment 1 is that no CMC-Na is added in the washing powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com