Ultraviolet-proof nano-fiber yarn and preparation method thereof

A nanofiber and anti-ultraviolet technology, which is applied in the direction of fiber treatment, yarn, filament/thread forming, etc., can solve the problems of fabric comfort and hand feeling, high processing cost, high technical requirements, etc., achieve long-lasting anti-ultraviolet performance and save energy Cost and energy, the effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

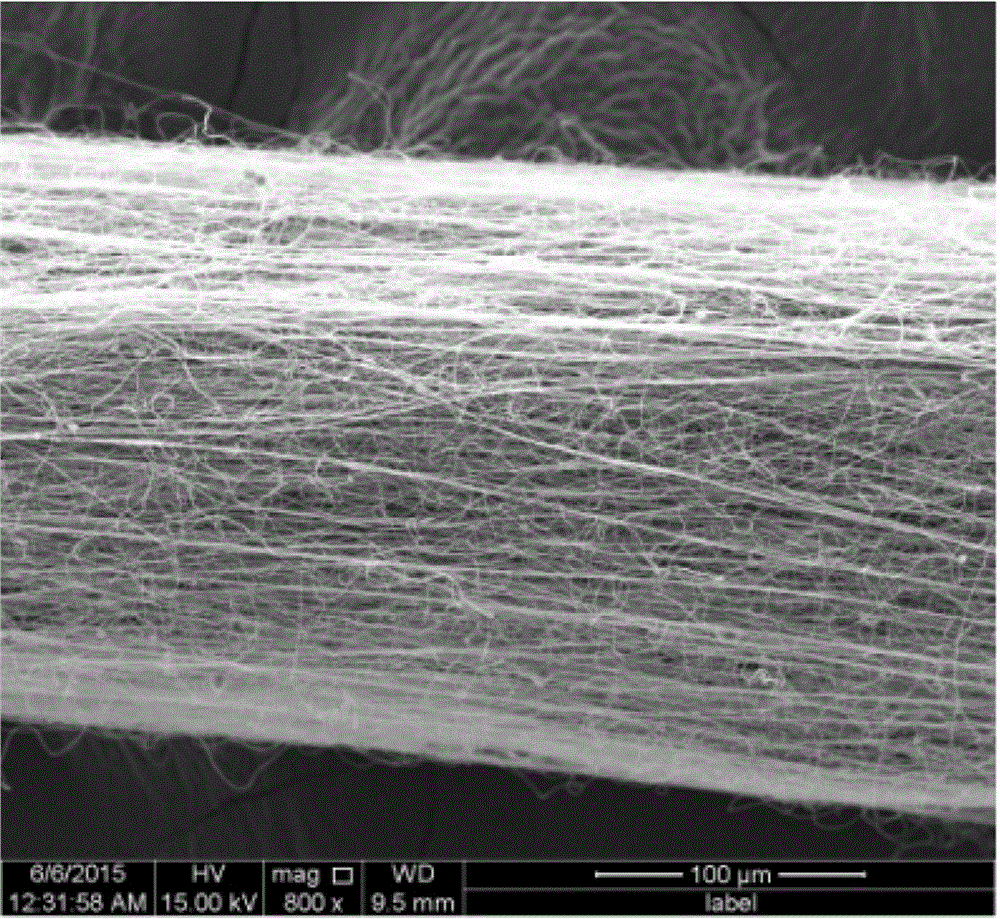

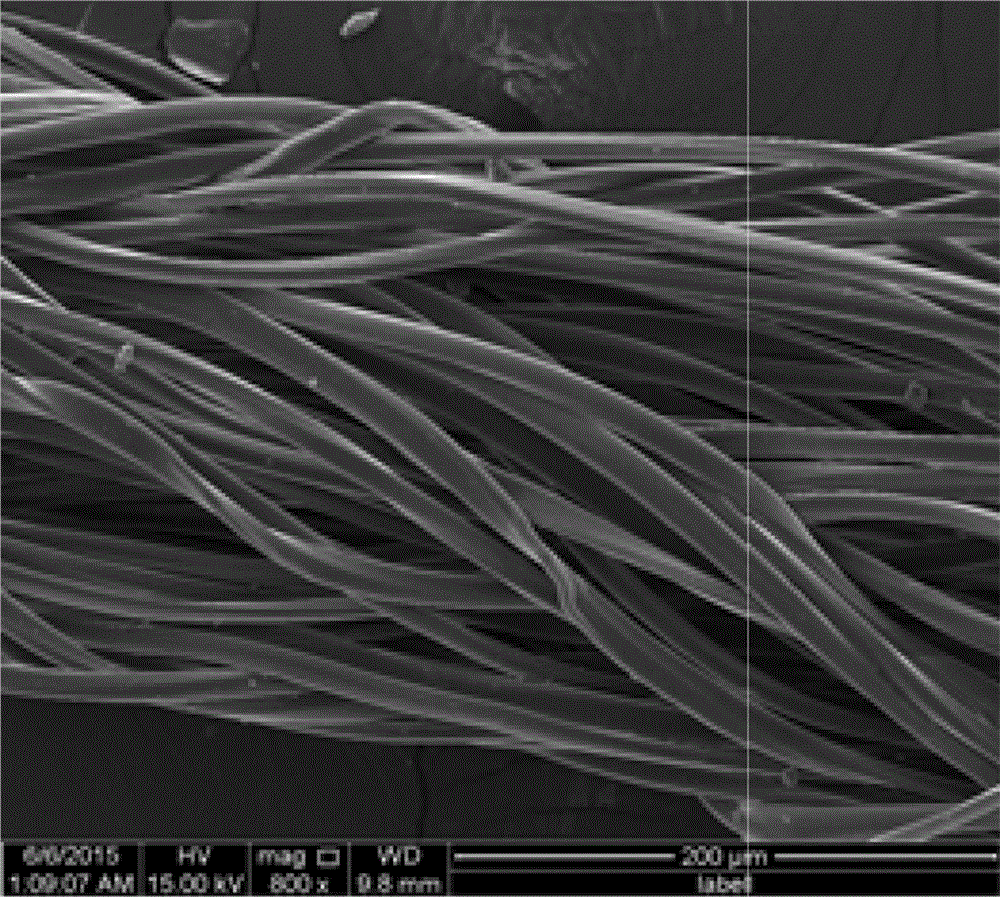

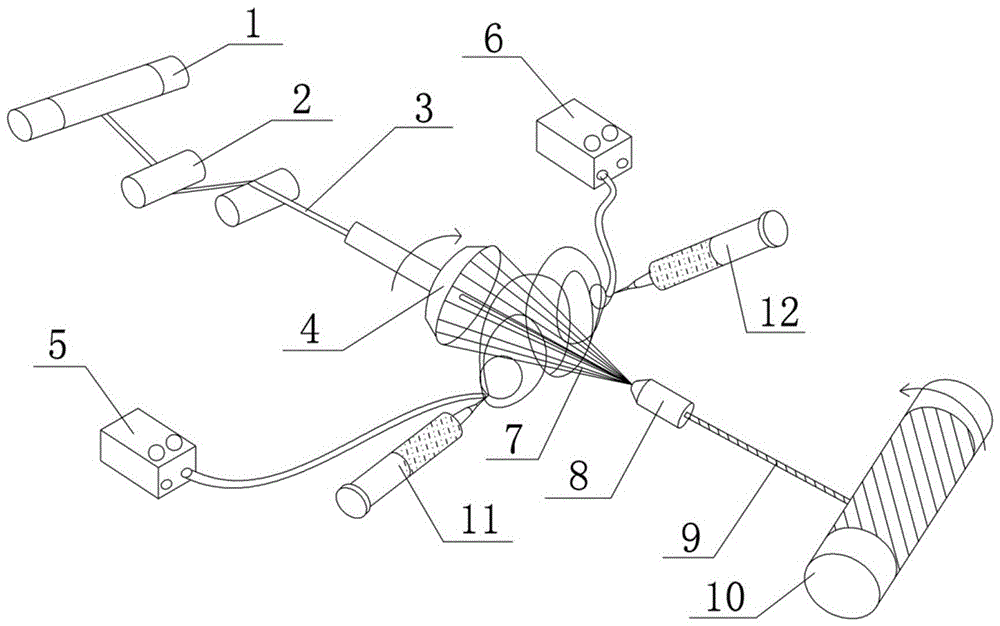

[0031] Embodiment 1: a kind of anti-ultraviolet nanofiber yarn, such as figure 1 As shown, it includes the core and the skin that completely and uniformly covers the outer surface of the core; the core is polyester filaments, and the skin is polyacrylonitrile (PAN) nanofibers, which are evenly distributed inside the polyacrylonitrile (PAN) nanofibers. Distributed with TiO 2 UV screener. see figure 1 The longitudinal SEM picture of the anti-ultraviolet nanofiber yarn of the present invention in, and figure 2 The comparison of the SEM pictures of ordinary polyester filaments in the above shows that polyacrylonitrile / TiO with UV protection function 2 The nanofiber is completely covered on the surface of the polyester filament, so that the anti-ultraviolet nanofiber yarn has good anti-ultraviolet performance. Moreover, the diameter of the nanofiber is much smaller than that of the polyester filament, and has a very large specific surface area, large porosity and wicking perf...

Embodiment 2

[0037] Example 2: A UV-resistant nanofiber yarn, the difference from Example 1 is that the core is nylon filaments, and the skin is polypropylene (PP) nanofibers, inside the polypropylene (PP) nanofibers Evenly distributed with ZnO UV shielding agent.

Embodiment 3

[0038] Embodiment 3: A UV-resistant nanofiber yarn, the difference from Embodiment 1 is that the core is an acrylic filament, and the cortex is a polyurethane (PU) nanofiber, uniformly inside the polyurethane (PU) nanofiber Distributed with MgO UV shielding agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com