Spinning enhanced parylene composite film and preparation method thereof

A parylene and composite film technology, applied in textiles and papermaking, medical science, non-woven fabrics, etc., can solve problems affecting device performance, biological tissue damage, shedding, etc., and achieve simple process and good mechanical stretching The effect of low performance and manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

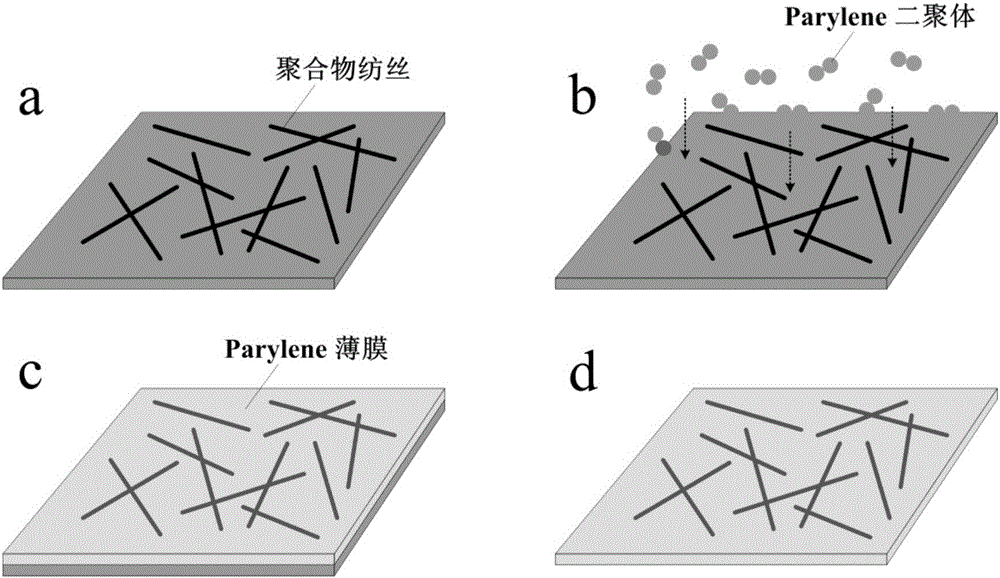

[0027] Such as figure 1 As shown, the present embodiment provides a method for preparing a spinning reinforced parylene composite film, including:

[0028] 1. Dissolve polylactic acid (PLA) in chloroform (chloroform), and fully dissolve the solute by heating and stirring to form a polylactic acid spinning solution;

[0029] 2. Deposit the polylactic acid spinning solution on the stainless steel sheet substrate by electrospinning to form a single spinning structure with a diameter of 10 to 100 nanometers;

[0030] 3. Chemical vapor deposition of a 1 micron ParyleneC film on a stainless steel sheet substrate covered with a spinning structure;

[0031] 4. The film deposited on the stainless steel sheet substrate is released from the substrate to form a polylactic acid spinning reinforced ParyleneC composite film. Compared with the pure parylene ParyleneC film, the bonding force of the prepared polylactic acid spinning enhanced paryleneC composite film on the stainless steel sub...

Embodiment 2

[0033] Such as figure 1 As shown, the present embodiment provides a method for preparing a spinning reinforced parylene composite film, including:

[0034] 1. Dissolve polycaprolactone (PCL) and titanium dioxide nanoparticles in a mixture of chloroform (chloroform) and dimethylformamide (DMF), and fully dissolve the solute by stirring to form polycaprolactone (PCL ) and titanium dioxide nanoparticles mixed spinning solution;

[0035] 2. Deposit the mixed spinning solution of polycaprolactone and titanium dioxide nanoparticles on the glass substrate by electrospinning to form a single spinning structure with a diameter of 400 to 600 nanometers;

[0036] 3. Chemical vapor deposition of a 5 micron ParyleneD film on a glass substrate covered with a spinning structure;

[0037] 4. Peeling and releasing the film deposited on the glass substrate from the substrate to form a ParyleneD composite film enhanced by spinning of polycaprolactone and titanium dioxide nanoparticles. Compared...

Embodiment 3

[0039] Such as figure 1 As shown, the present embodiment provides a method for preparing a spinning reinforced parylene composite film, including:

[0040] 1. Dissolve polylactic acid-glycolic acid (PLGA) and nerve growth factor (NGF) in a mixture of chloroform (chloroform) and dimethylformamide (DMF), and fully dissolve the solute by heating and stirring to form Polylactic-glycolic acid (PLGA) and nerve growth factor (NGF) mixed spinning solution;

[0041] 2. Deposit the mixed spinning solution of polylactic acid-glycolic acid (PLGA) and nerve growth factor (NGF) on the polystyrene substrate by electrospinning to form a single spinning structure with a diameter of 5 to 10 microns;

[0042] 3. Chemical vapor deposition of a 20-micron ParyleneN film on a polystyrene substrate covered with a spinning structure;

[0043] 4. The film deposited on the polystyrene substrate is released from the substrate to form a polylactic-glycolic acid (PLGA) and nerve growth factor (NGF) spinn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com