Patents

Literature

141results about How to "Facilitate phase transition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

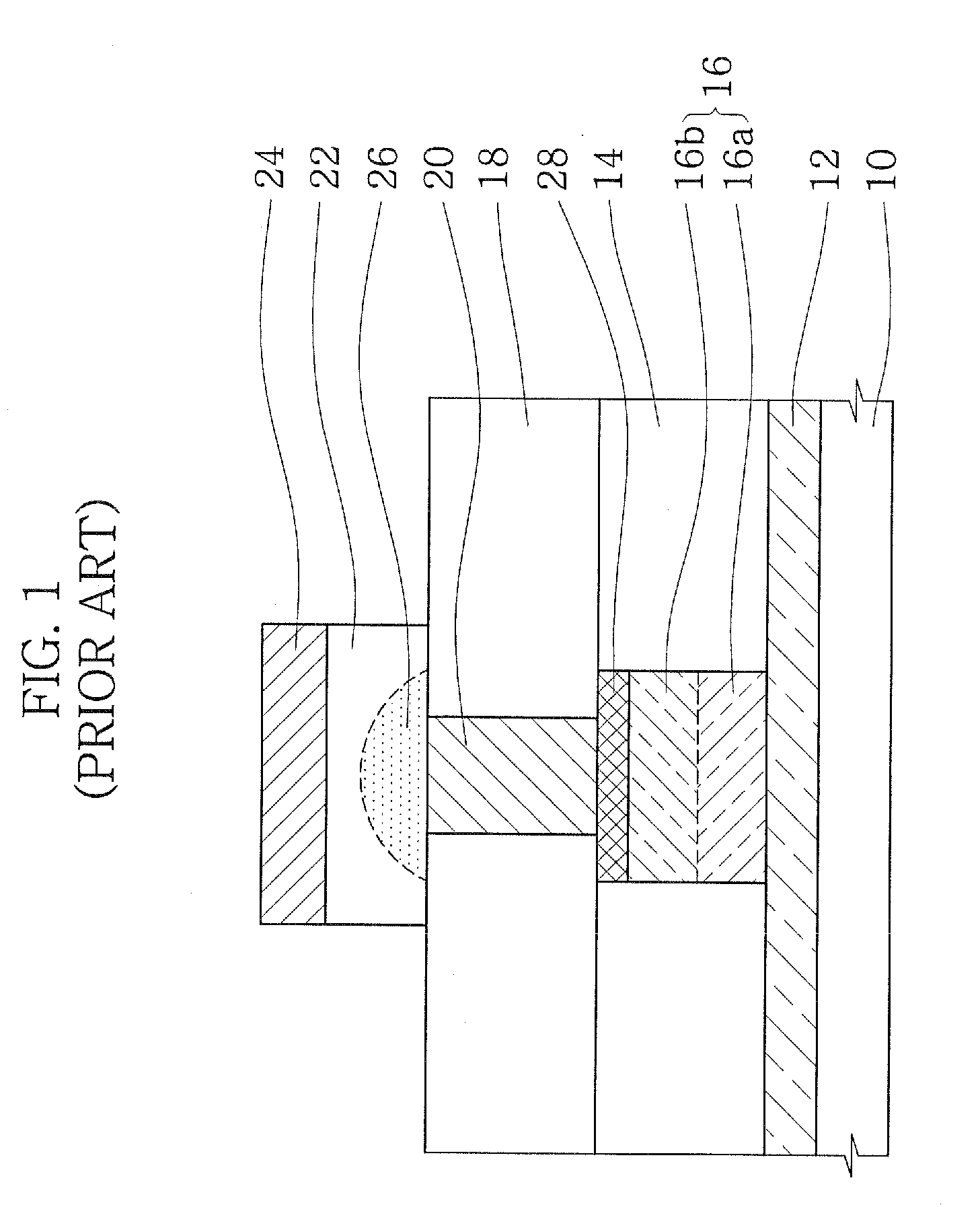

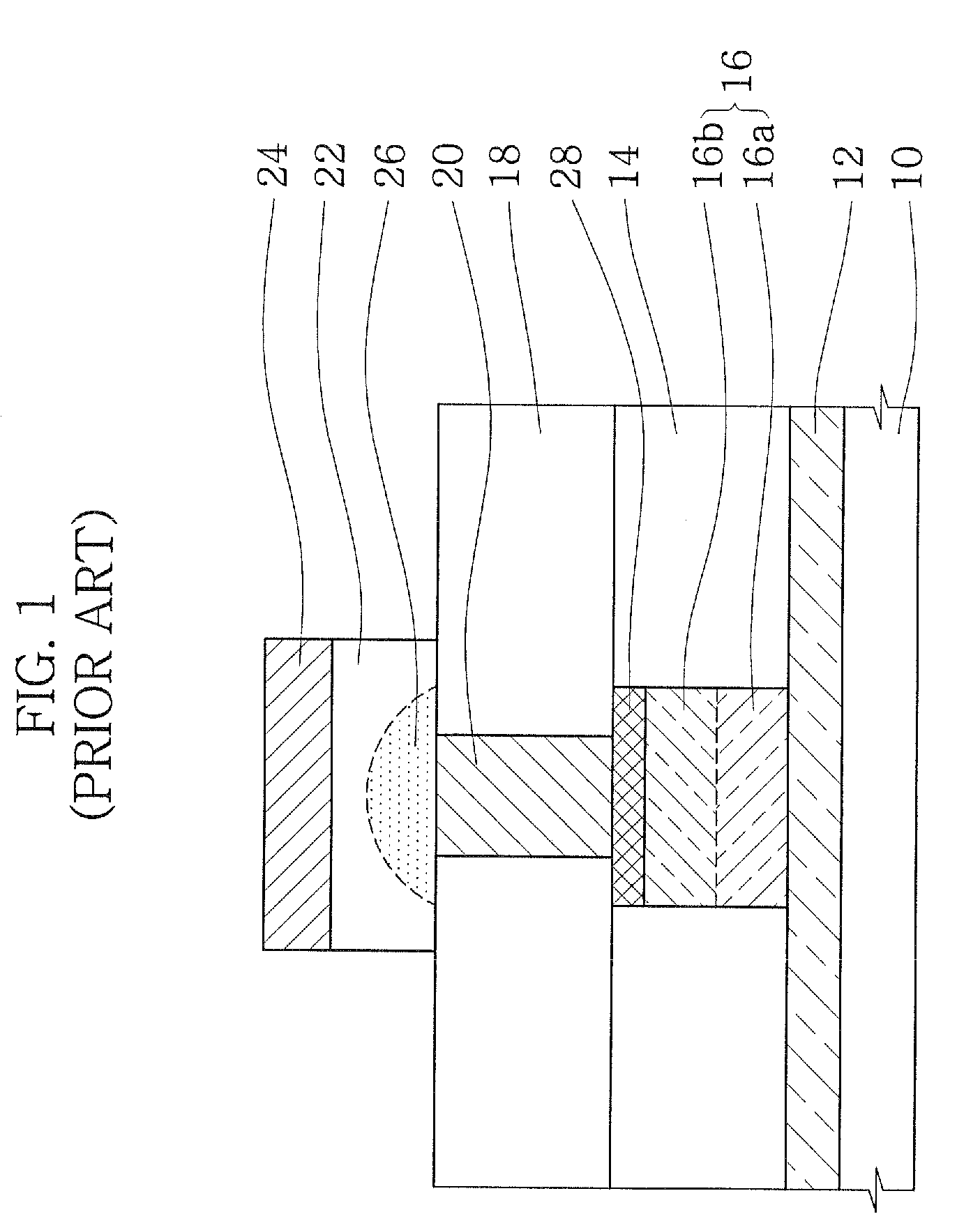

Phase change memory devices having dual lower electrodes and methods of fabricating the same

ActiveUS20080099753A1Facilitate phase transitionSemiconductor/solid-state device manufacturingDigital storagePhase-change memoryPhase-change material

A semiconductor device includes a semiconductor substrate and a lower interlayer insulating layer disposed on the substrate. An opening passing through the lower interlayer insulating layer and exposing the substrate is included. A buried insulating pattern is disposed in the opening. First and second conductive layer patterns are sequentially stacked to surround the sidewall and bottom of the buried insulating pattern. A phase change material pattern is included, which is disposed on the lower interlayer insulating layer in contact with a top surface of the second conductive layer pattern, and spaced apart from the first conductive layer pattern. An upper interlayer insulating layer covering the lower interlayer insulating layer and the phase change material pattern is included. A conductive plug is included, which passes through the upper interlayer insulating layer and is electrically connected to the phase change material pattern. A method of fabricating the semiconductor device is also provided.

Owner:SAMSUNG ELECTRONICS CO LTD

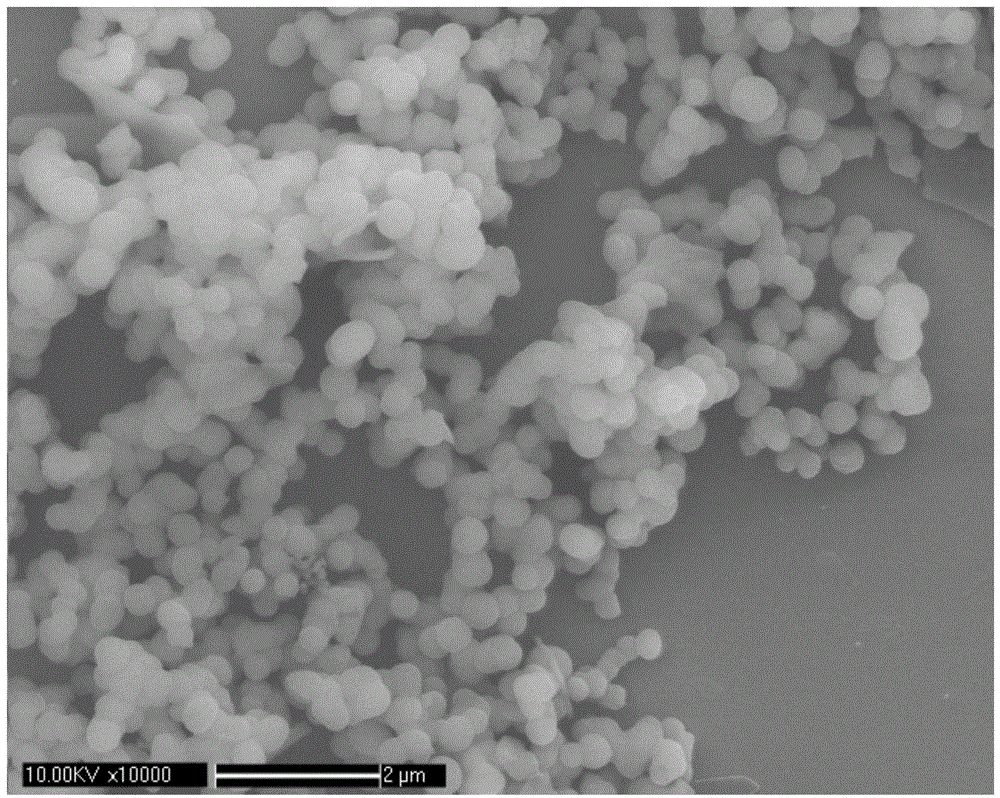

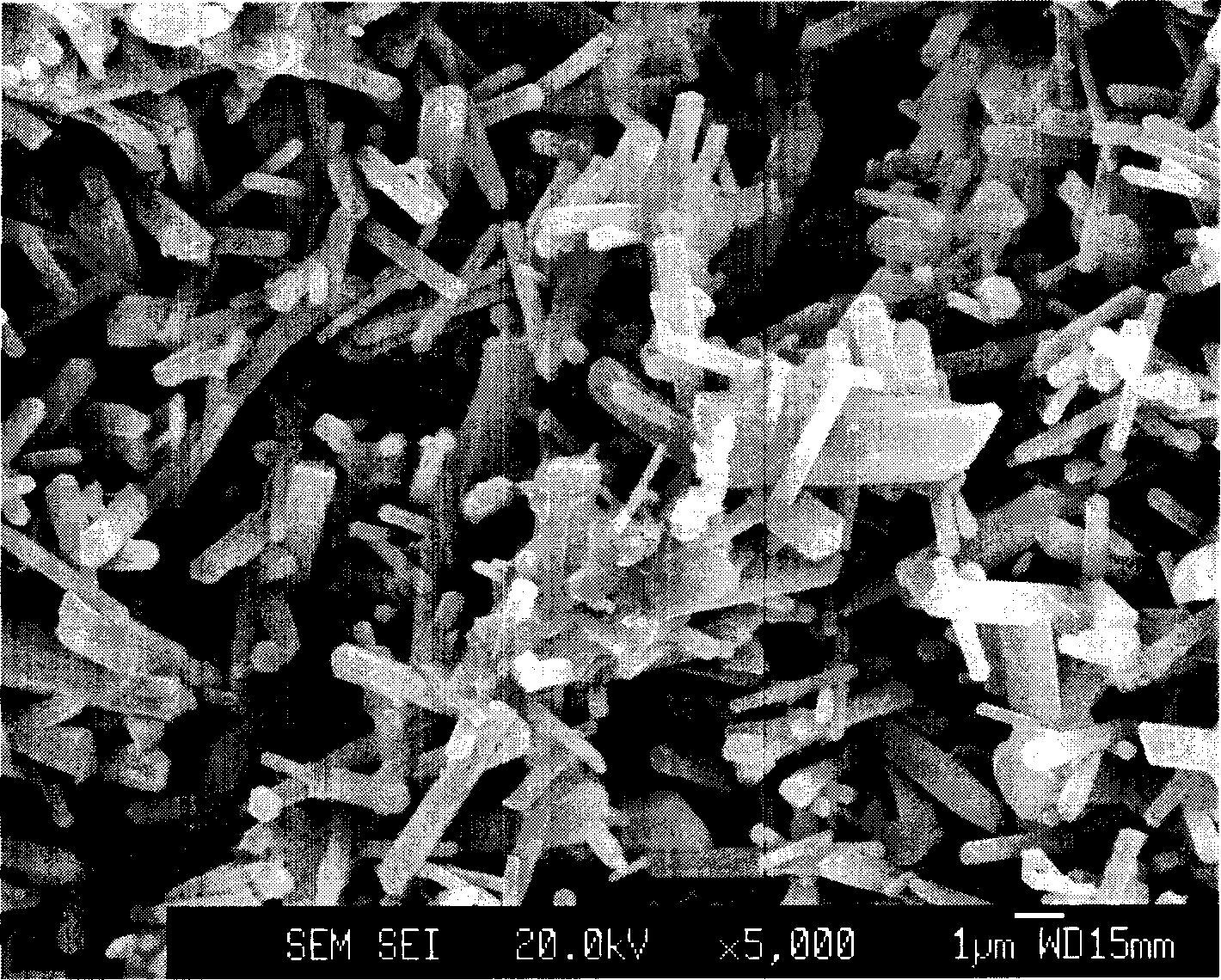

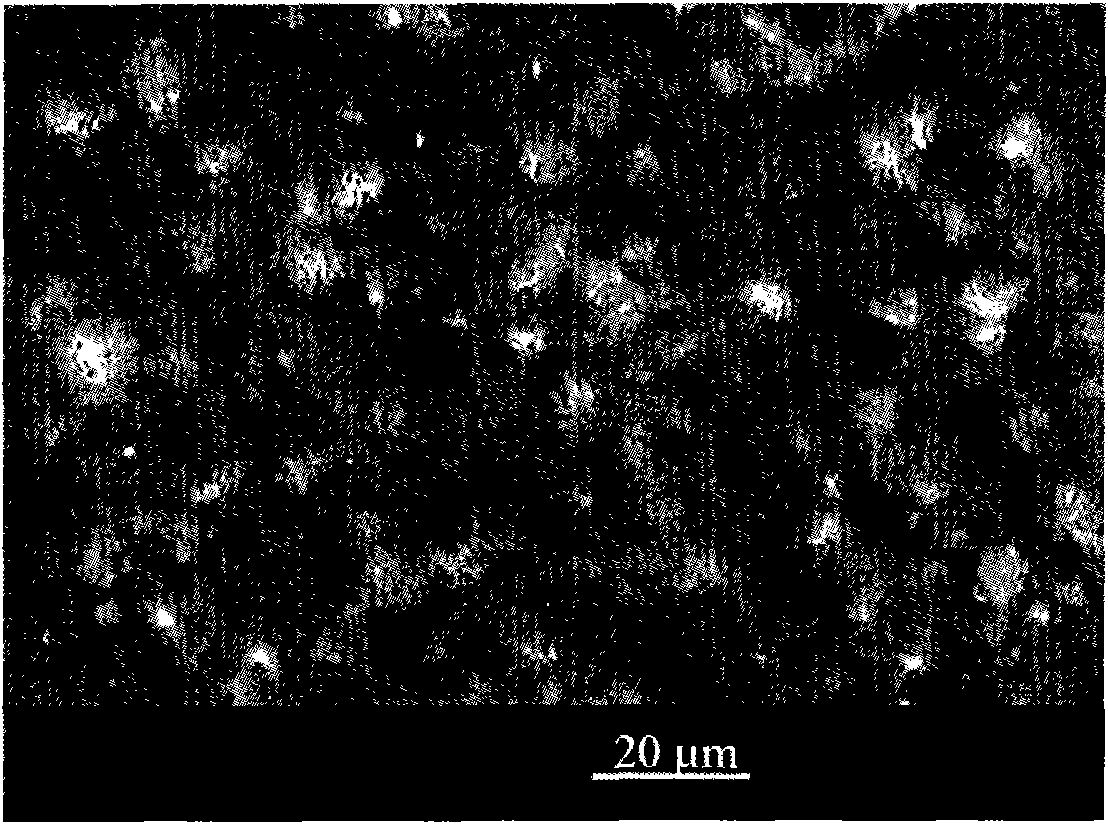

Phase-change energy-storage material nanocapsule and preparation method thereof

ActiveCN104449590ASmall sizeImprove stabilityHeat-exchange elementsMicroballoon preparationTetraethyl orthosilicateNanocapsules

The invention discloses a phase-change energy-storage material nanocapsule and a preparation method thereof and particularly relates to a phase-change energy-storage material capsule using an inorganic material as a shell layer and a preparation method of the capsule. By dispersing an oil phase formed by mixing the phase-change energy-storage material and tetraethyl orthosilicate in an aqueous phase formed by water and ethanol in a shape of nanoscale droplets, carrying out hydrolysis-condensation reaction on tetraethyl orthosilicate in the presence of a basic catalyst, and forming a silicon oxide shell layer on the surface of each of oil phase droplet to coat the phase-change energy-storage material, thus obtaining the phase-change energy-storage material nanocapsule of which the particle size is less than 1mu m. The nanocapsule has the advantages of uniform particle size distribution, large surface area and high enthalpy of phase change. The preparation method is simple and feasible, is high in preparation yield and is conductive to prepration of the phase-change energy-storage material having high heat storage / release efficiency in a large scale.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

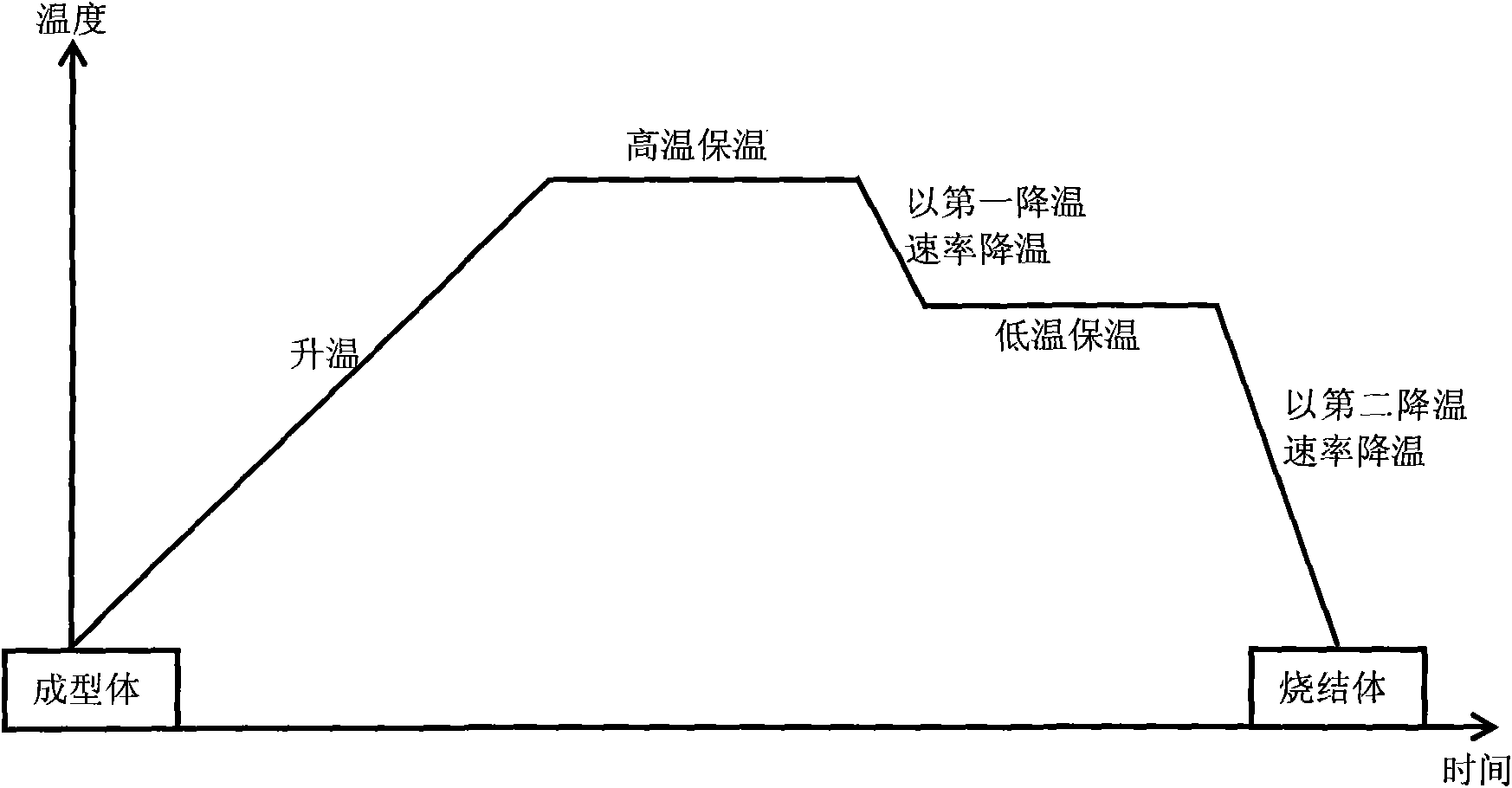

Recipe and preparation method of high-voltage gradient zinc oxide resistance card

The invention discloses a recipe and a preparation method of a high-voltage gradient zinc oxide resistance card. The recipe of the zinc oxide resistance card of the invention reasonably and preferably adopts the ingredients and the contents of the zinc oxide resistance card, the zinc oxide resistance card prepared by the recipe has the high-voltage gradient as high as 350 to 600v / mm, and at the same time, under the high-voltage gradient, the zinc oxide resistance card can maintain good nonlinear characteristic, electrical property and ageing-resistant characteristic to meet the miniaturization requirement of electronic components such as lightning protectors in practical application. In the preparation method of the zinc oxide resistance card of the invention, the accessory ingredients and trace ingredients in the zinc oxide resistance card have fine granularity, are matched, and are uniformly mixed, the impurity mixing quantity is reduced, at the same time, because the low-temperature heat-insulation process is added in the sintering process, the zinc oxide resistance card forms a stable crystal boundary structure which is favorable for improving the stability of the zinc oxide resistance card and the phase change of the bismuth oxide in the secondary heat treatment process, so the electrical property of the zinc oxide bismuth oxide can be improved.

Owner:NINGBO ZHENHAI GUOCHUANG HIGH VOLTAGE ELECTRIC APP

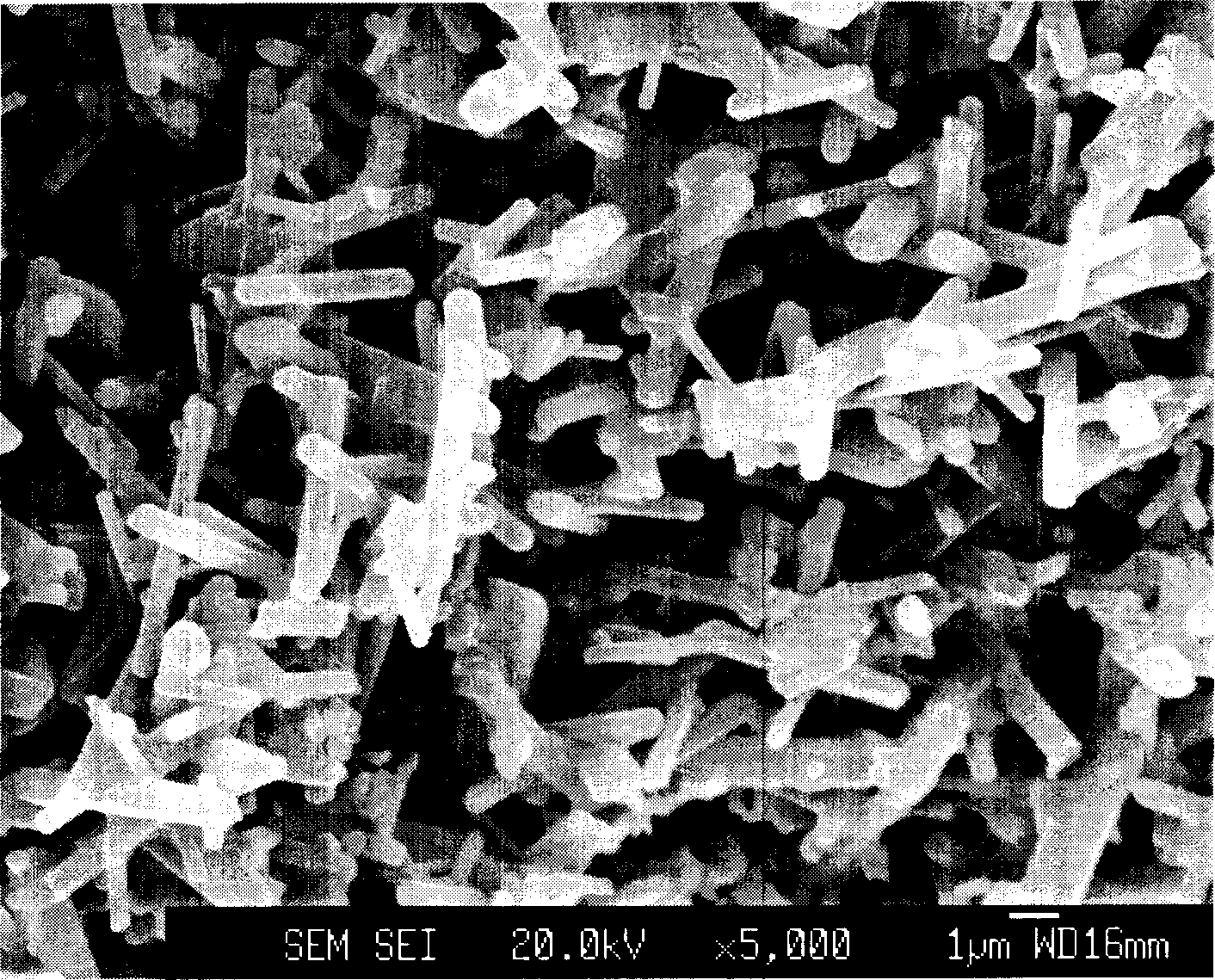

Silicon nitride porous ceramics and its preparing method

The porous silicon nitride ceramic is prepared with C and CO2 in 75-95 wt%, silicon nitride 1-10 wt%, and sintering assistant 2-20 wt%. The C / CO2 weight ratio is 0.4-0.6; and the sintering assistant is at least one the metal oxides Y2O3, Al2O3 and MgO. The preparation process includes the following steps: ball milling the materials, drying and sieving to obtain mixture powder; pressure forming in mold; and sintering in a nitrogen atmosphere furnace through raising temperature at the rate of 600deg.c / hr to 1500deg.c, further raising temperature at the rate of 180deg.c / hr to 1700-1800deg.c, and maintaining at nitrogen pressure of 6-10 atm for 2-8 hr to obtain the sintered body. The porous silicon nitride ceramic may be used as base filter material for separating gas in high temperature and corrosive atmosphere, heat resisting material and reinforcing material in gas turbine, engine, space shuttle, etc.

Owner:XI AN JIAOTONG UNIV

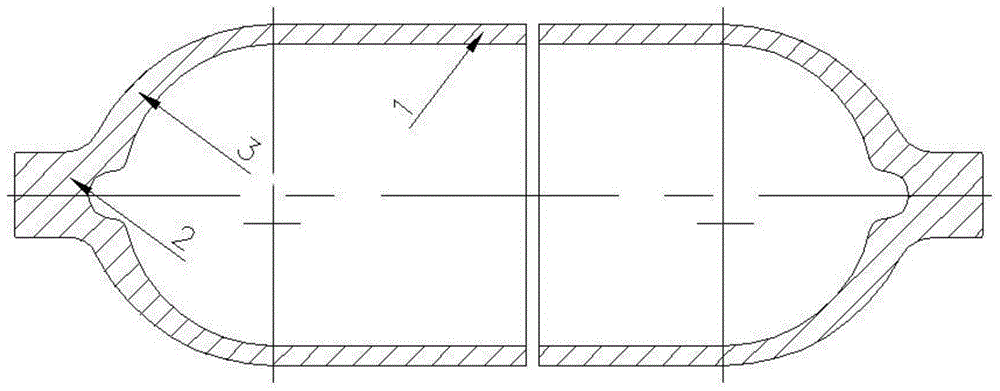

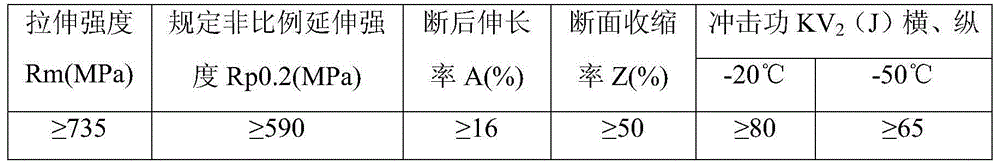

High-pressure seamless 10CrNi3MoV steel cylinder and manufacturing process thereof

ActiveCN104451419AImprove toughnessAvoid brittlenessFurnace typesHeat treatment furnacesHigh probabilityHigh pressure

The invention belongs to the field of machinery manufacturing, particularly relates to a high-pressure seamless 10CrNi3MoV steel cylinder and a manufacturing process thereof, and aims to solve the technical problems of difficulty in manufacturing process determination, poor low-temperature toughness of materials, high probability of deformation and cracking and the like of the current welded type high-pressure seamless 10CrNi3MoV steel cylinder. The scheme is that the high-pressure seamless 10CrNi3MoV steel cylinder adopting seamless 10CrNi3MoV steel pipes as raw materials is provided. The invention further provides a manufacturing process of the high-pressure seamless 10CrNi3MoV steel cylinder. A cylinder body and a seal head of the high-pressure seamless 10CrNi3MoV steel cylinder are seamlessly connected, so that the welding defect is overcome, and meanwhile, with the adoption of the manufacturing process, the low-temperature toughness of steel is further improved.

Owner:CHENGDU GREAT HIGH PRESSURE VESSEL

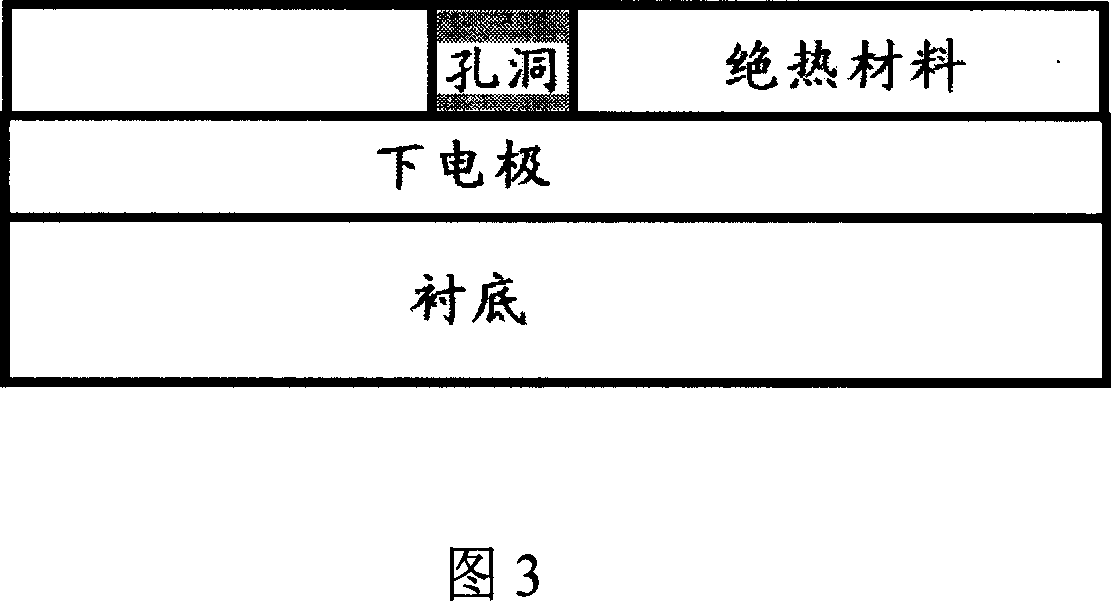

Phase transformation memory storing unit and producing method thereof

ActiveCN1933207AReduce contact areaFacilitate phase transitionSolid-state devicesDigital storageInsulation layerElectrical impulse

This invention relates to a phase-transformation storage unit and its preparation method charactering in covering a lower electrode layer on the substrate, covering a heat insulation material layer with holes on the lower electrode layer, and the holes contain a hollow column heating electrode material structure conducting to the lower electrode, a heat insulation material layer covers the column heating electrode and contains holes matched to the heating electrode and an inverse phase-transformation material layer covered by a heat insulation material layer with holes is contained in the electrode holes and the holes of the insulation material layer, and the upper electrode material is filled in the holes of the heat insulation layer conducting to the phase-transformation material, which limits the phase-transformation material in the holes in the hollow post and the insulation material to keep the phase-transformation material to be transformed first at the environment high temperature and high pressure when electric pulse operates a storage unit.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

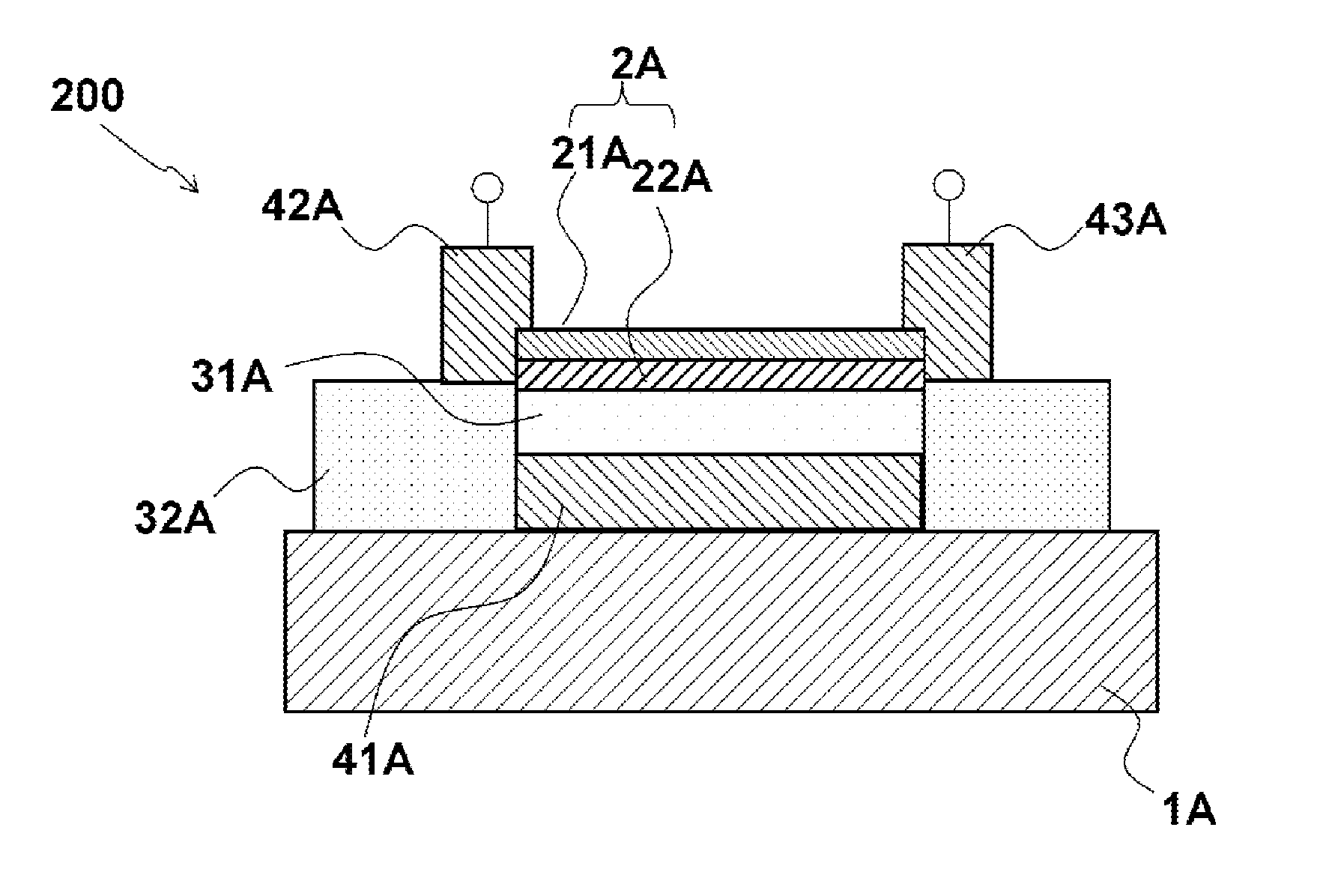

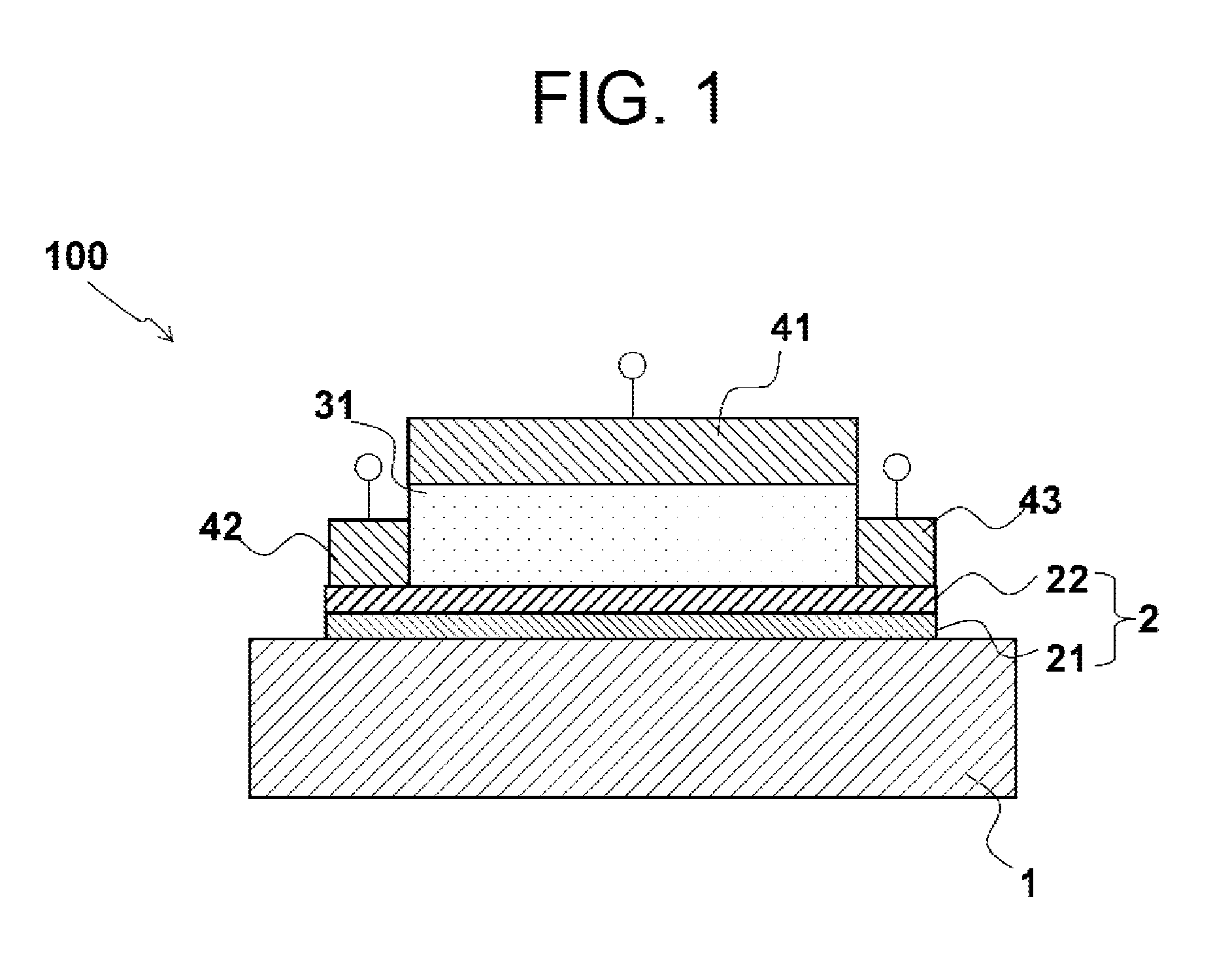

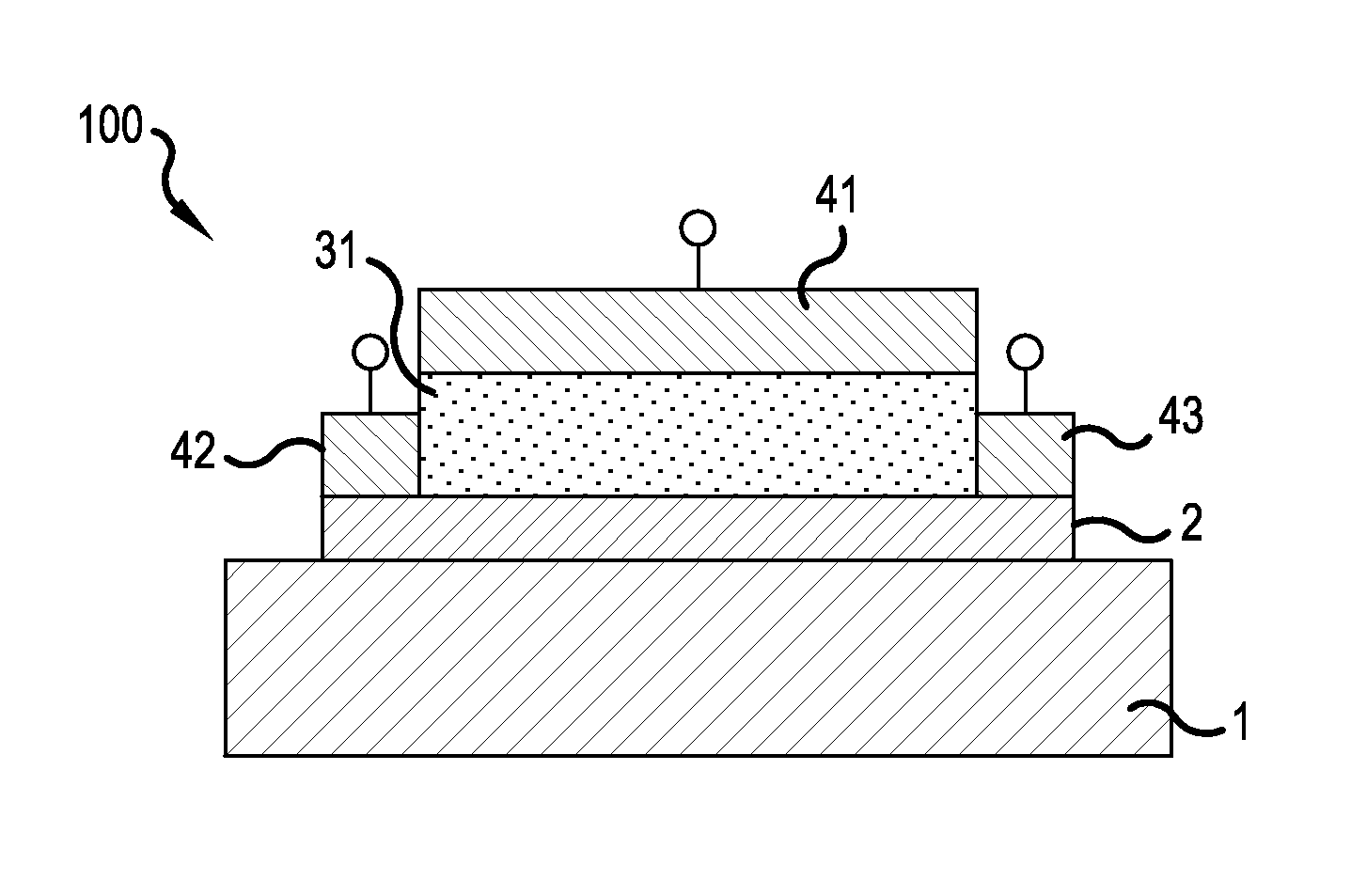

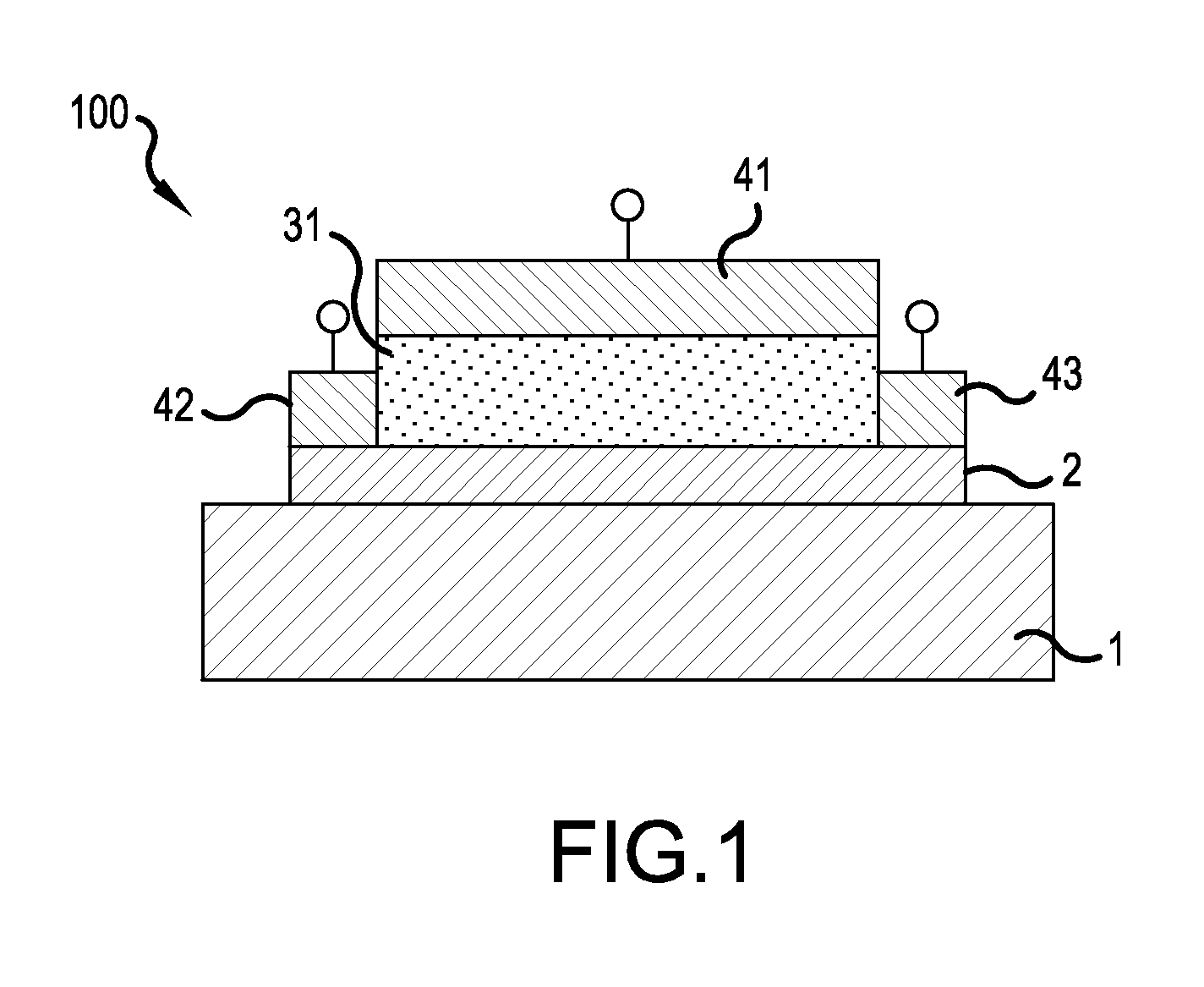

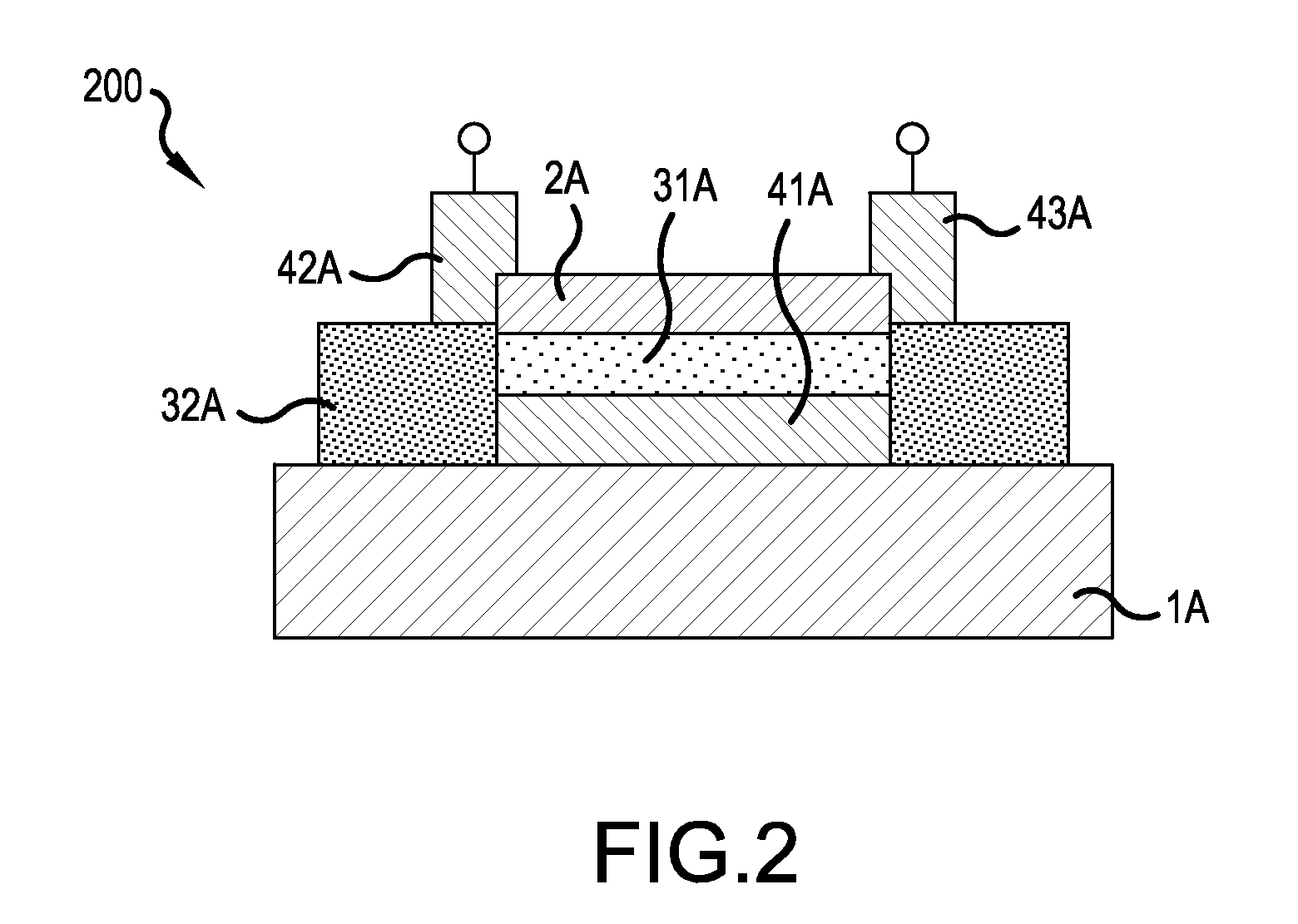

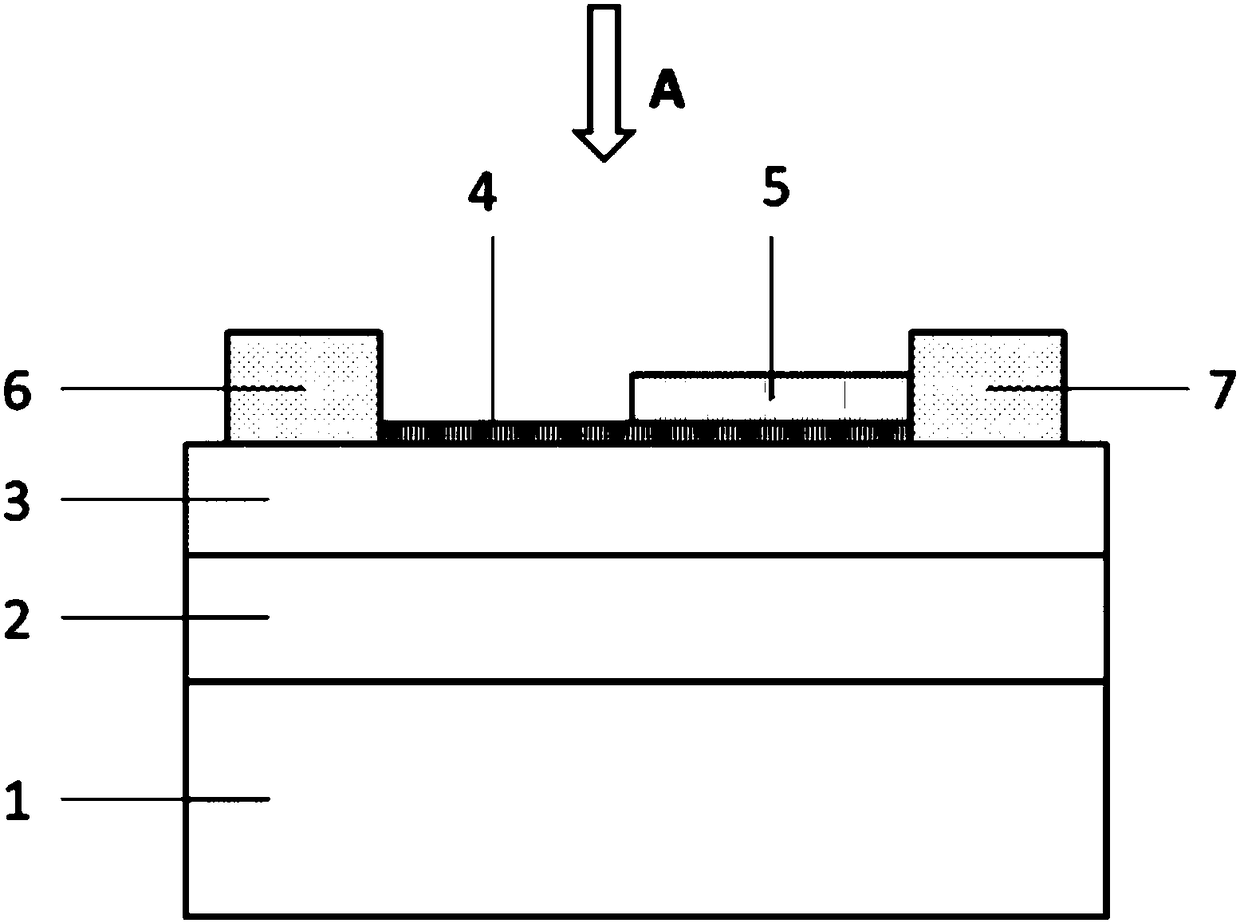

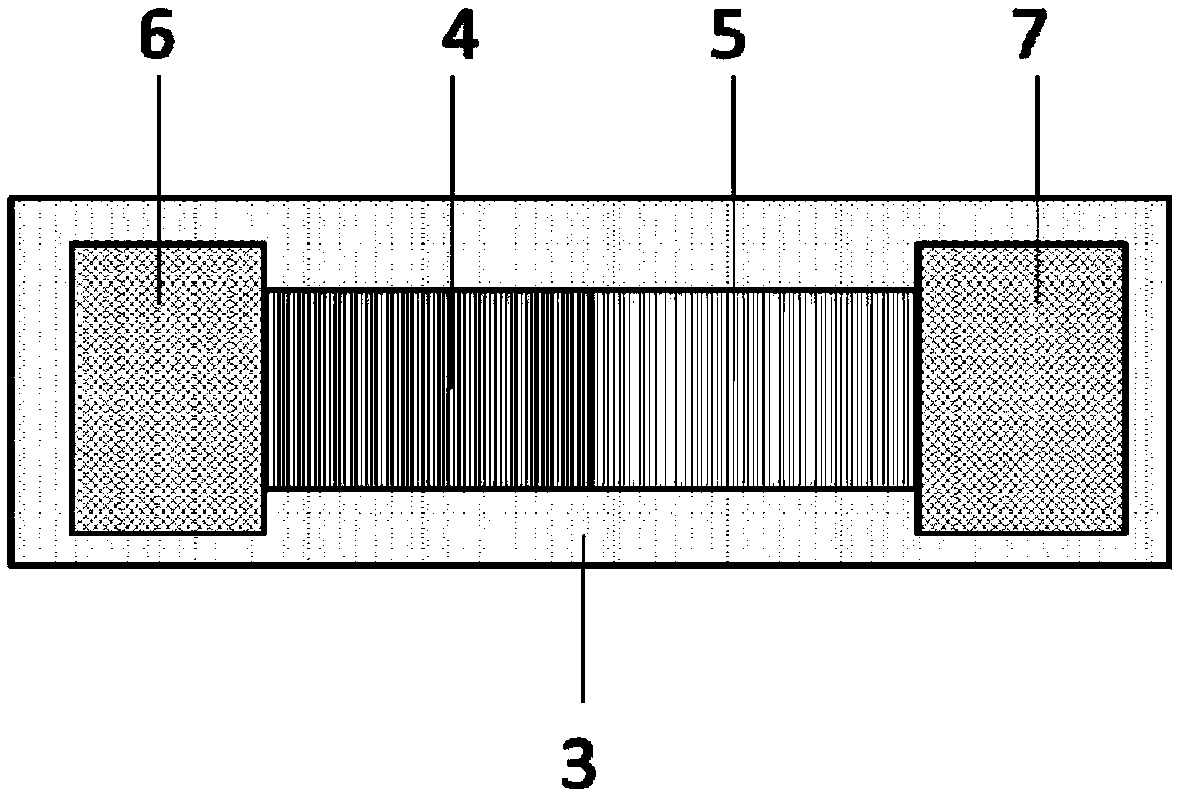

Strongly correlated oxide field effect element

InactiveUS20130200457A1Reduce thicknessGuaranteed functionSolid-state devicesSemiconductor/solid-state device manufacturingCritical thicknessTransition layer

Provided is a strongly correlated oxide field effect element demonstrating a phase transition and a switching function induced by electrical means. The strongly correlated oxide field effect element is a strongly correlated oxide field effect element 100 including a channel layer 2 constituted by a strongly correlated oxide film, a gate electrode 14, a gate insulating layer 31, a source electrode 42, and a drain electrode 43. The channel layer 2 includes an insulator-metal transition layer 22 of a strongly correlated oxide and a metallic state layer 21 of a strongly correlated oxide that are stacked on each other. The thickness t of the channel layer 2, the thickness t1 of the insulator-metal transition layer 22, and the thickness t2 of the metallic state layer 21 satisfy the following relationship with critical thicknesses t1c and t2c for respective metallic phases of the layers: t=t1+t2≧t1c>t2c, where t1<t1c and t2<t2c.

Owner:FUJI ELECTRIC CO LTD

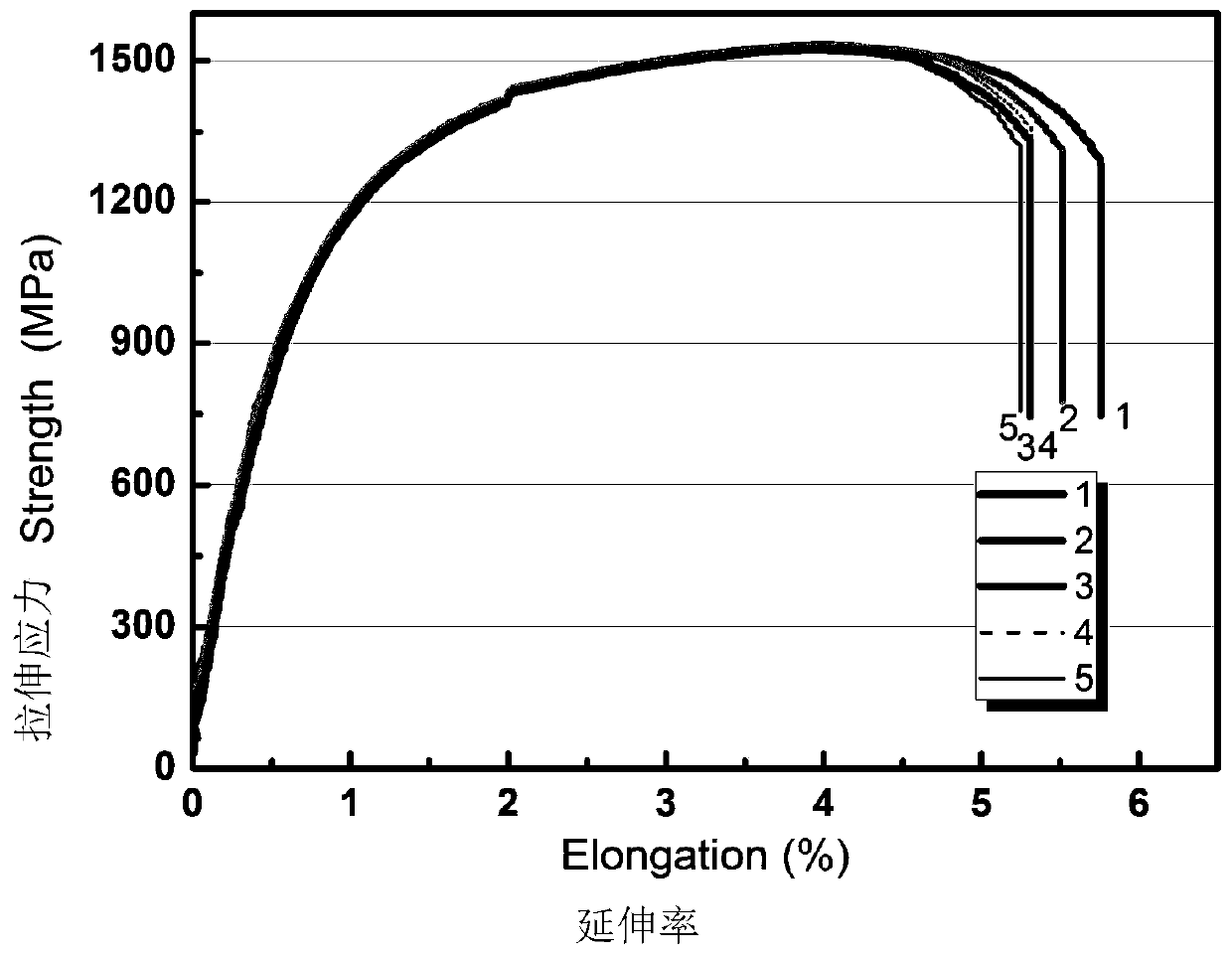

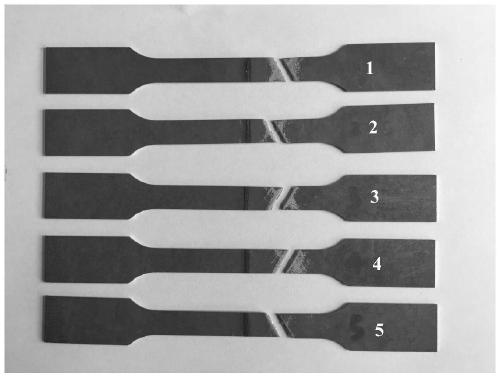

Method for manufacturing steel thin-wall welding equal-strength components with aluminum or aluminum alloy coatings

ActiveCN111230301APromote homogenizationImprove hardenabilityArc welding apparatusWelding/cutting media/materialsHot stampingMetal alloy

Provided is a method for manufacturing steel thin-wall welding equal-strength components with aluminum or aluminum alloy coatings. A steel plate to be welded comprises a base body and at least one coating on the surface of the base body. Each coating comprises an intermetallic compound alloy layer in contact with the base body and a metal alloy layer on the intermetallic compound alloy layer. Thecoatings do not need to be removed or thinned before welding or in the welding process; by presetting the welding gap and using a carbon manganese steel welding wire, a welding process and protectivegas for welding, after a welding component is subjected to hot stamping treatment, the tensile strength of a weld joint is greater than the tensile strength of a base material, the extension rate of the weld joint is greater than 4%, and the application requirement of the equal-strength welding components in the hot stamping field is met.

Owner:BAOSHAN IRON & STEEL CO LTD

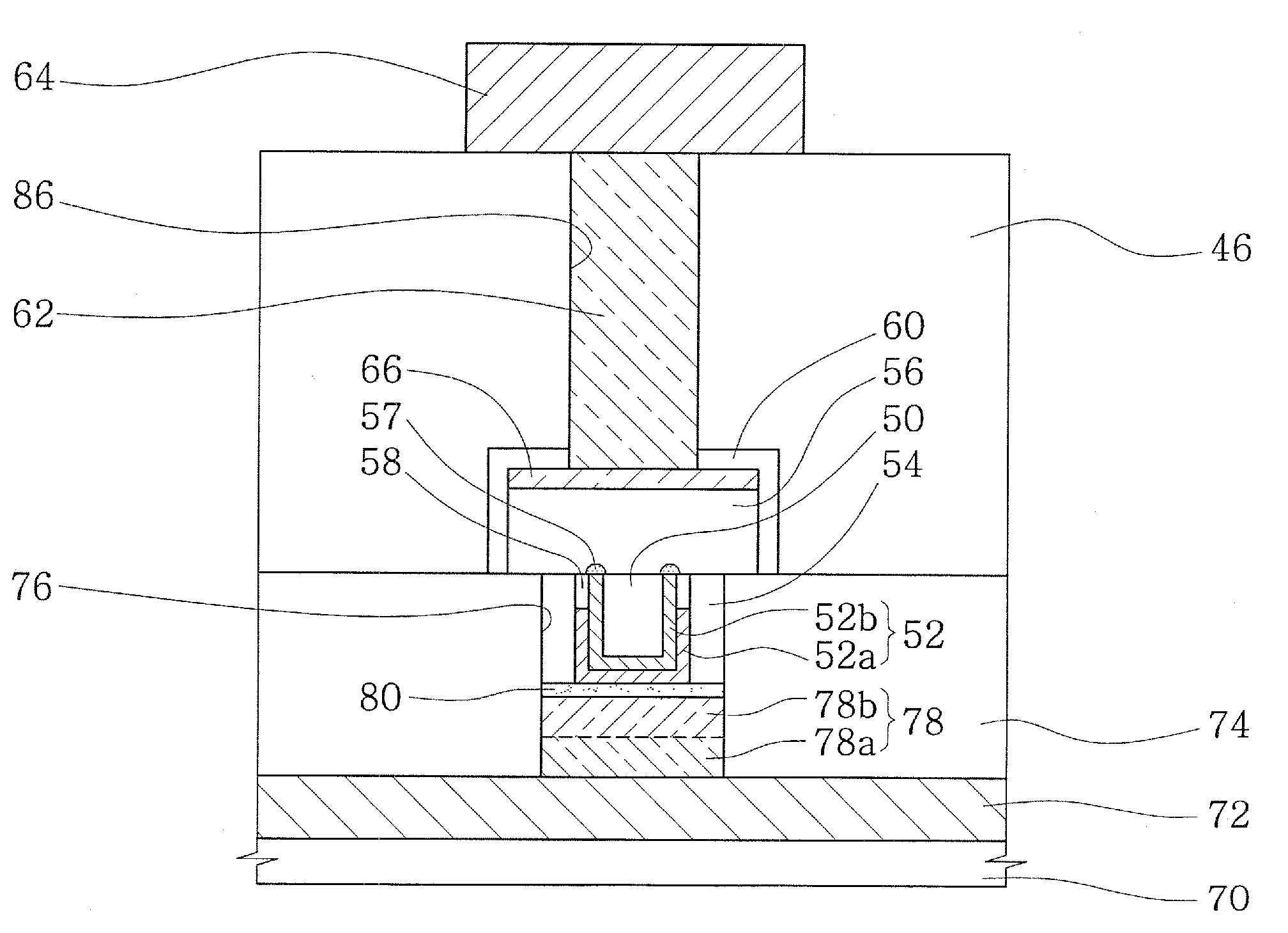

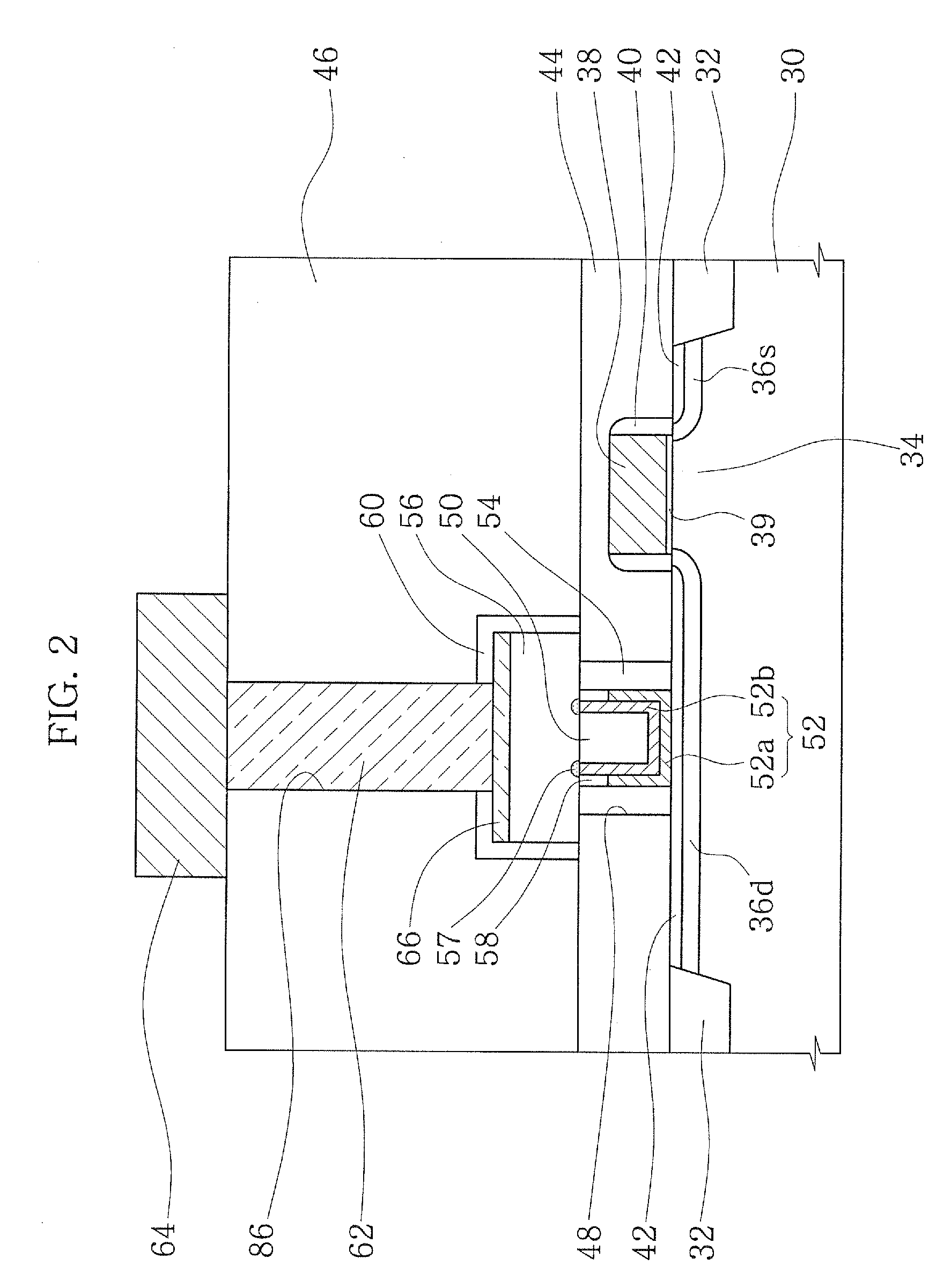

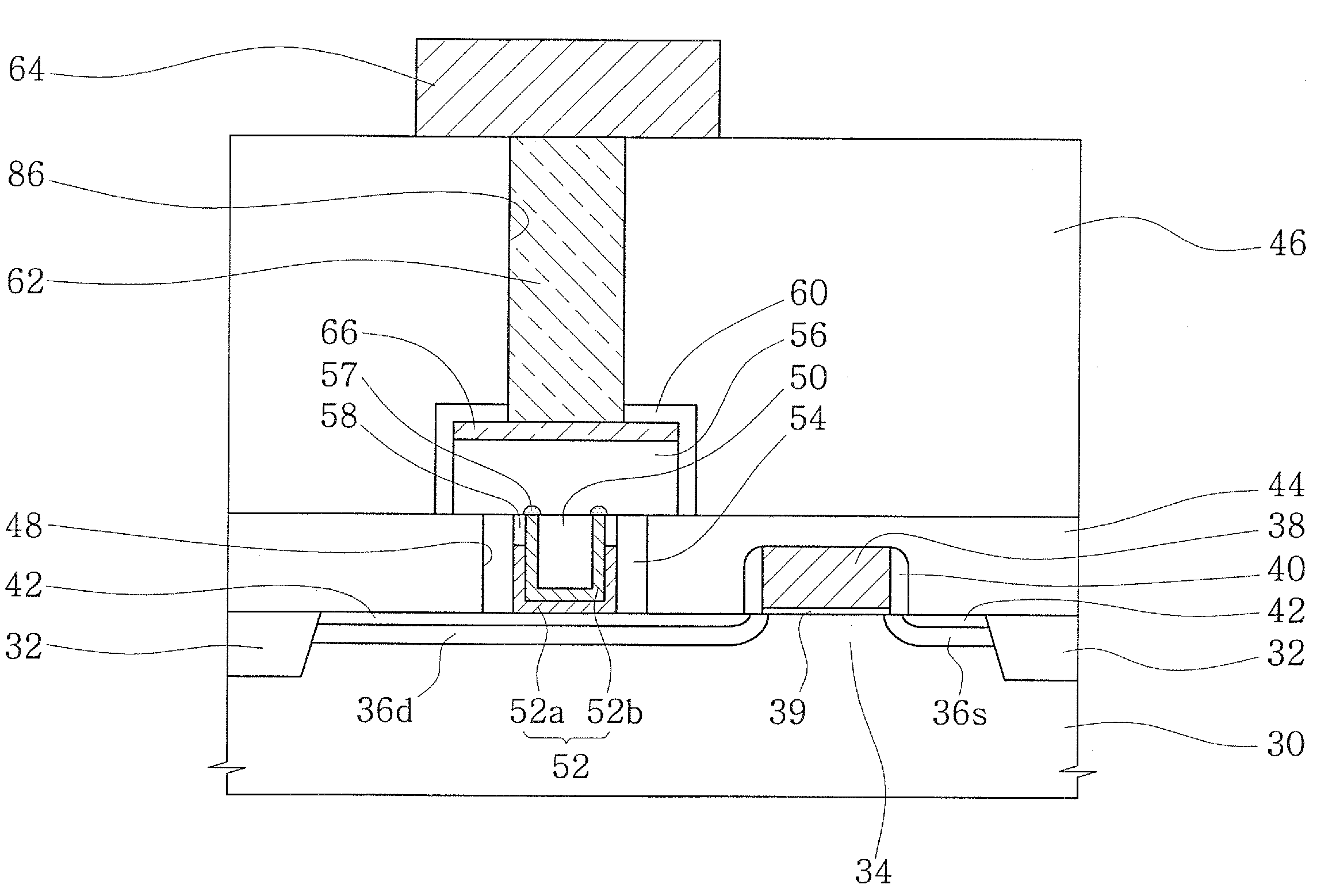

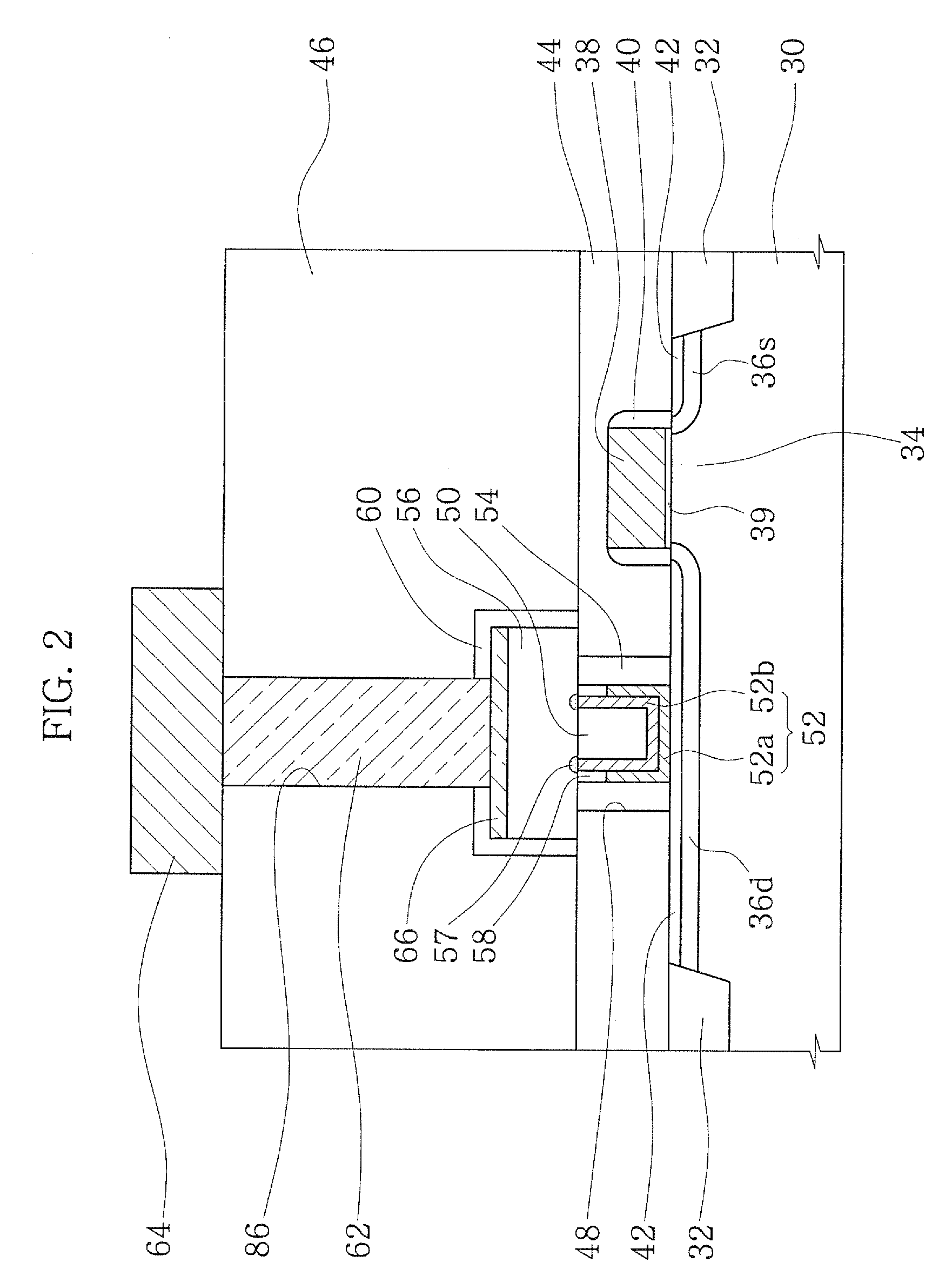

Phase change memory devices having dual lower electrodes

ActiveUS7696508B2Facilitate phase transitionSolid-state devicesDigital storagePhase-change memoryPhase-change material

A semiconductor device includes a semiconductor substrate and a lower interlayer insulating layer disposed on the substrate. An opening passing through the lower interlayer insulating layer and exposing the substrate is included. A buried insulating pattern is disposed in the opening. First and second conductive layer patterns are sequentially stacked to surround the sidewall and bottom of the buried insulating pattern. A phase change material pattern is included, which is disposed on the lower interlayer insulating layer in contact with a top surface of the second conductive layer pattern, and spaced apart from the first conductive layer pattern. An upper interlayer insulating layer covering the lower interlayer insulating layer and the phase change material pattern is included. A conductive plug is included, which passes through the upper interlayer insulating layer and is electrically connected to the phase change material pattern. A method of fabricating the semiconductor device is also provided.

Owner:SAMSUNG ELECTRONICS CO LTD

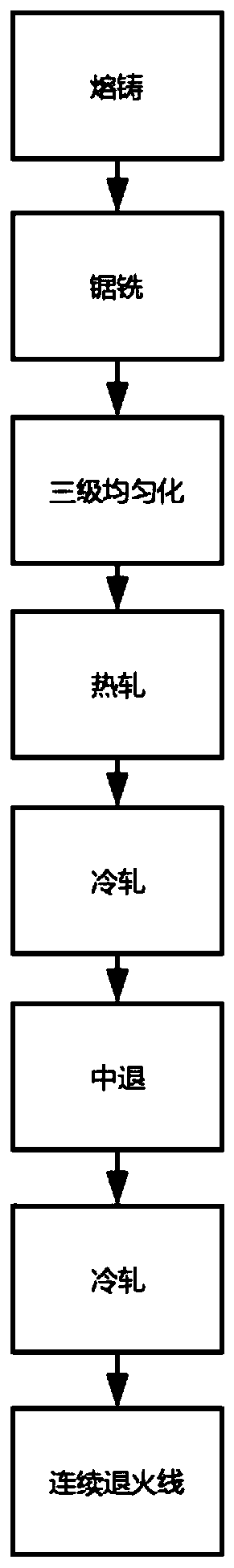

5182-0 aluminum alloy sheet preparation method for automobiles

The invention belongs to the technical field of aluminum alloy manufacturing, and relates to a 5182-0 aluminum alloy sheet preparation method for automobiles. Aluminum alloy raw materials are preparedfrom the components in percentage by mass: namely 0.01-0.08% of Si, 0.15-0.30% of Fe, 0.01-0.1% of Cu, 0.10-0.30% of Mn, 4.5-5.0% of Mg, less than or equal to 0.1% of Cr, less than or equal to 0.05%of Zn, less than or equal to 0.1% of Ti, less than or equal to 0.1% of Ni, less than or equal to 0.05% of a single impurity, less than or equal to 0.15% of total, and the balance of Al. Aluminum alloycoils cold rolled to intermediate pass in cold rolling process are annealed and insulated at 320 DEG C for 2 h, wherein the annealing process of finished aluminum alloy coils is passed in a single layer mode in a continuous air cushion annealing furnace, the coils are blown to suspend in the furnace through hot air, and the problems that most parts of the local deformation of aluminum alloy sheets are cracked during the stamping deformation due to the uneven inner grain structure of aluminum alloy sheets prepared by existing aluminum alloy sheet preparation process are solved.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

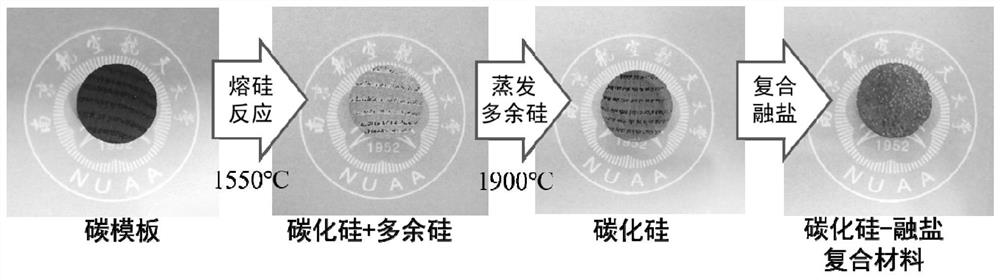

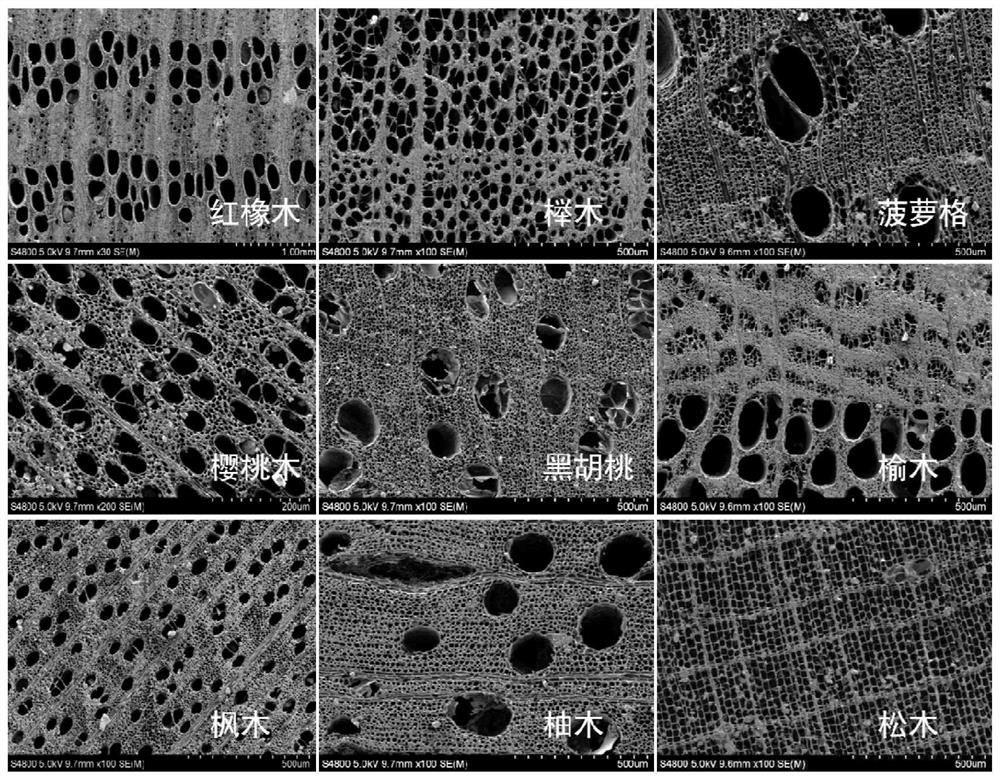

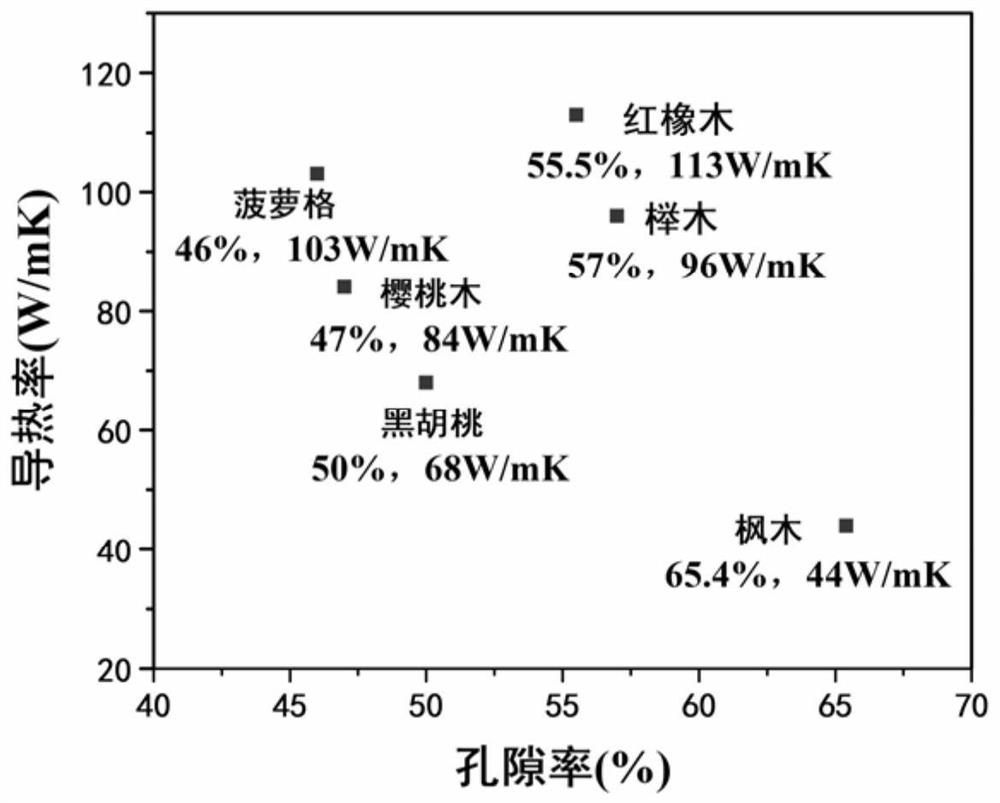

Biomorphic silicon carbide ceramic high-temperature photo-thermal storage material

ActiveCN112521153AImprove thermal conductivityImprove spectral absorption capacityHeat-exchange elementsCeramicwareMolten siliconPhase-change material

The invention provides a biomorphic silicon carbide ceramic high-temperature photo-thermal storage material and a preparation method thereof. The heat storage material is prepared by compounding a biomorphic silicon carbide ceramic framework and chlorate. The biomorphic silicon carbide ceramic is a ceramic material generated by high-temperature reaction of molten silicon and a charcoal porous precursor, and silicon carbide ceramic frameworks with different porosities can be obtained by different wood precursors. The phase-change heat storage material is prepared by fully and uniformly mixing sodium chloride and potassium chloride in a ball mill and drying to obtain the sodium-potassium chloride eutectic salt. The biomorphic silicon carbide ceramic framework is coated with the phase changeheat storage material by adopting a vacuum impregnation method, so that pores of the ceramic framework are filled with the phase change material, thereby obtaining the biomorphic silicon carbide ceramic high-temperature photo-thermal storage material. The composite material prepared by the invention has the excellent characteristics of high thermal conductivity (116 W / mK), high spectral absorptionperformance (92%) and high heat storage density (453 kg / kJ), and is expected to promote the development of constructing a clean, low-carbon, efficient and safe energy system.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

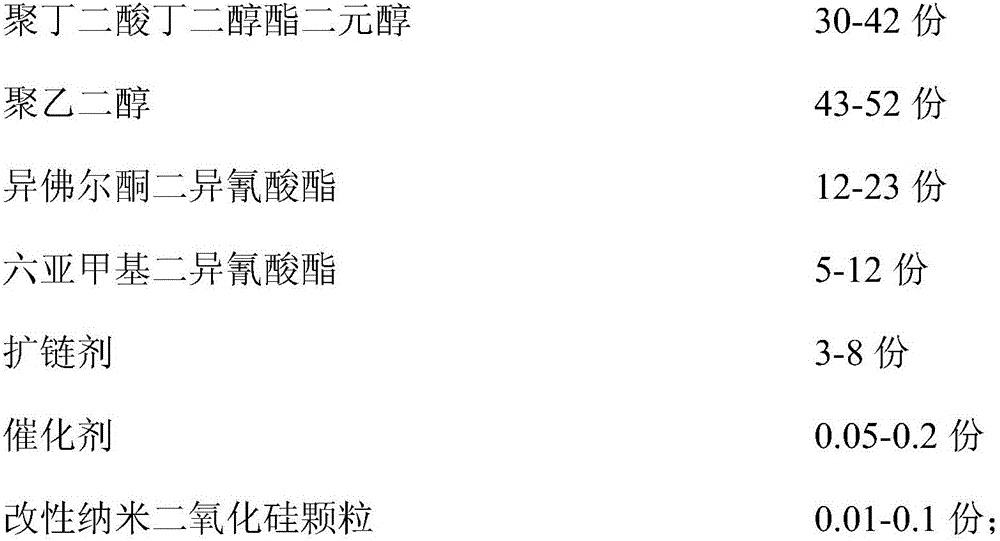

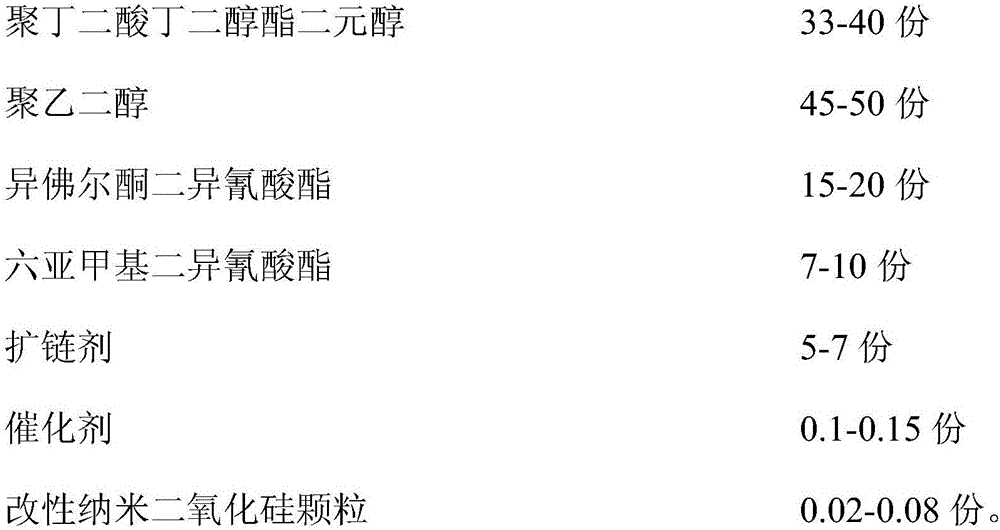

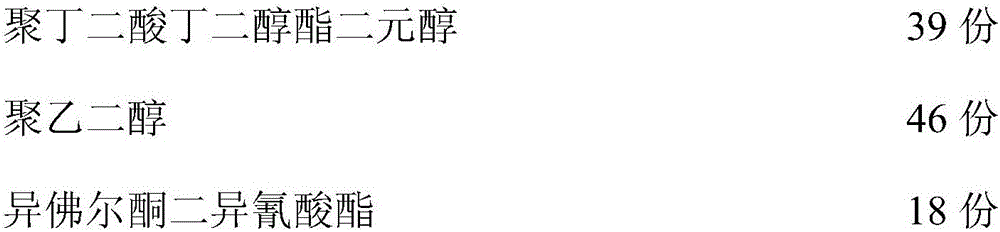

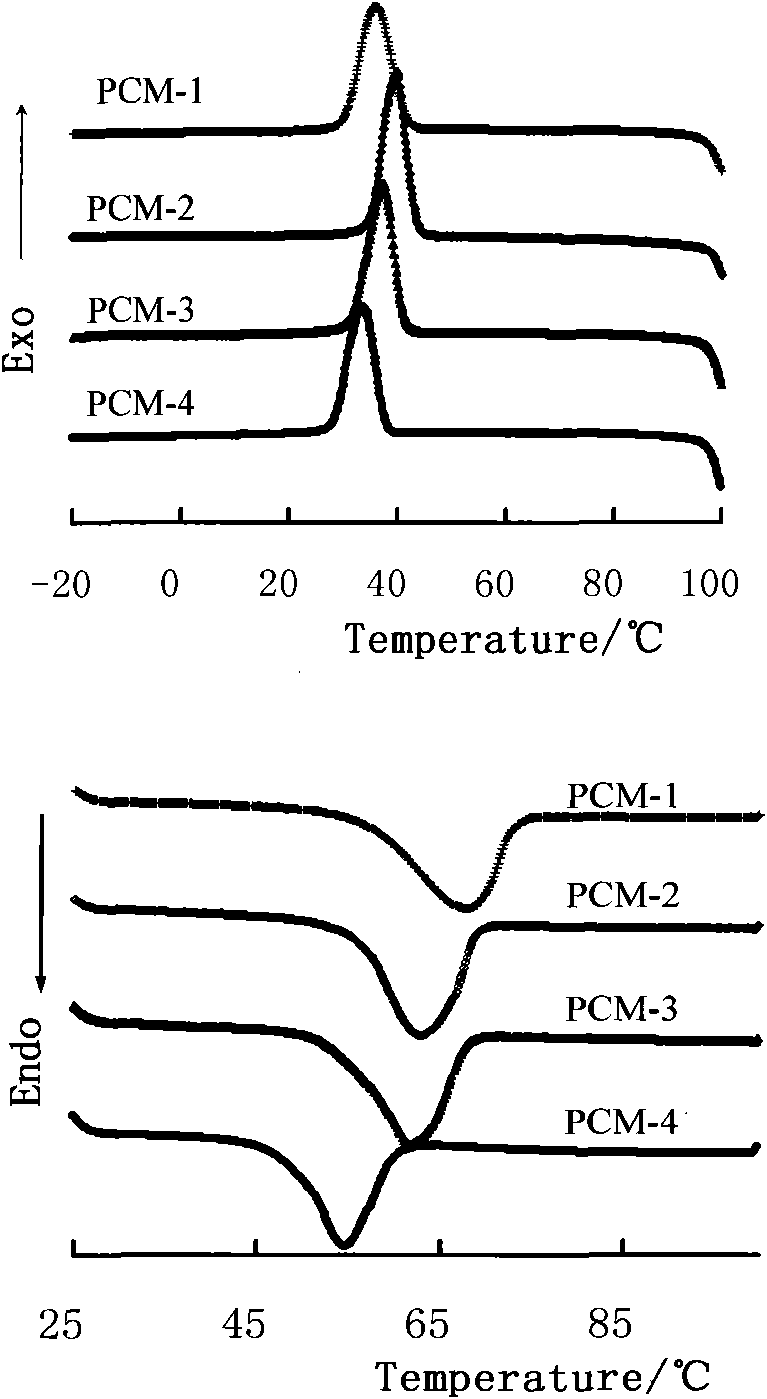

High strength thermoplastic polyurethane solid-solid phase change energy storage material and preparation method thereof

InactiveCN106084179AGood mechanical propertiesHigh phase change enthalpyHeat-exchange elementsSolid phasesChemistry

The invention provides a high strength thermoplastic polyurethane solid-solid phase change energy storage material and a preparation method thereof. The high strength thermoplastic polyurethane solid-solid phase change energy storage material is prepared from 30-42 parts by weight of polybutylene succinate diol, 43-52 parts by weight of polyethylene glycol, 12-23 parts by weight of isophorone diisocyanate, 5-12 parts by weight of hexamethylene diisocyanate, 3-8 parts by weight of a chain extender, 0.05-0.2 parts by weight of a catalyst and 0.01-0.1 parts by weight of modified nanometer silica particles. The number-average molecular weight of the polybutylene succinate diol is in a range of 7000-8500 and the number-average molecular weight of polyethylene glycol is in a range of 6000-8000. Ingredients of the phase change energy storage material produce synergism so that the phase change energy storage material has good mechanical properties, material tensile strength greater than 36MPa and a fracture percentage elongation greater than 921%. The preparation method has simple processes and a wide application range.

Owner:DONGGUAN JIXIN POLYMER SCI & TECH

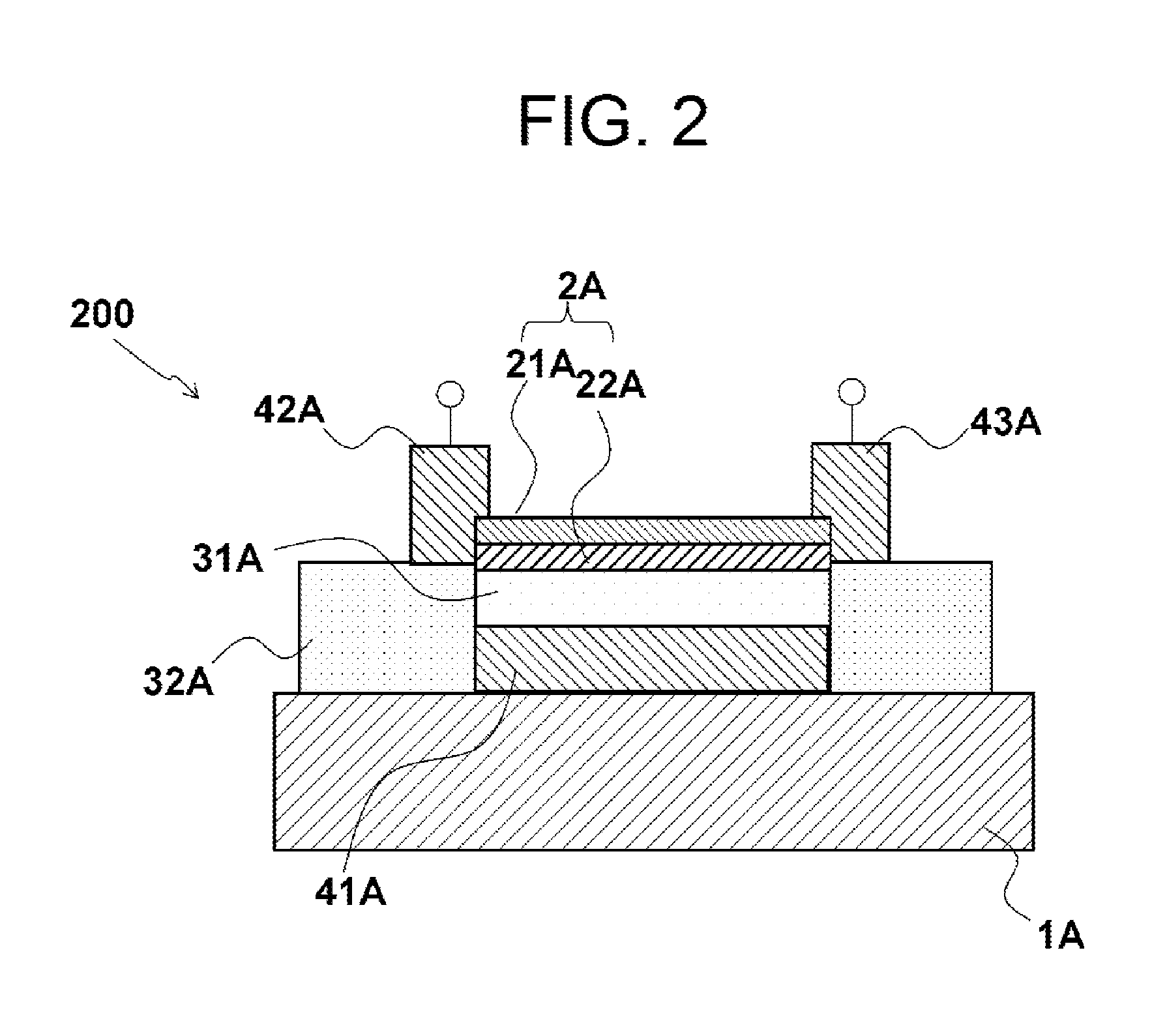

Strongly correlated nonvolatile memory element

InactiveUS20140209850A1Giant resistance changeIncrease carrier densitySolid-state devicesDigital storagePhysicsEngineering

In aspects of the invention, a strongly correlated nonvolatile memory element is provided which exhibits phase transitions and nonvolatile switching functions through electrical means. In an aspect of the invention, a strongly correlated nonvolatile memory element is provided including, on a substrate, a channel layer, a gate electrode, a gate insulator, a source electrode, and a drain electrode. The channel layer includes a strongly correlated oxide thin film, and is formed of a perovskite type manganite which exhibits a charge-ordered phase or an orbital-ordered phase; the gate insulator is formed in contact with at least a portion of a surface or interface of the channel layer and is sandwiched between the channel layer and the gate electrode, and the source electrode and drain electrode are formed in contact with at least a portion of the channel layer.

Owner:FUJI ELECTRIC CO LTD

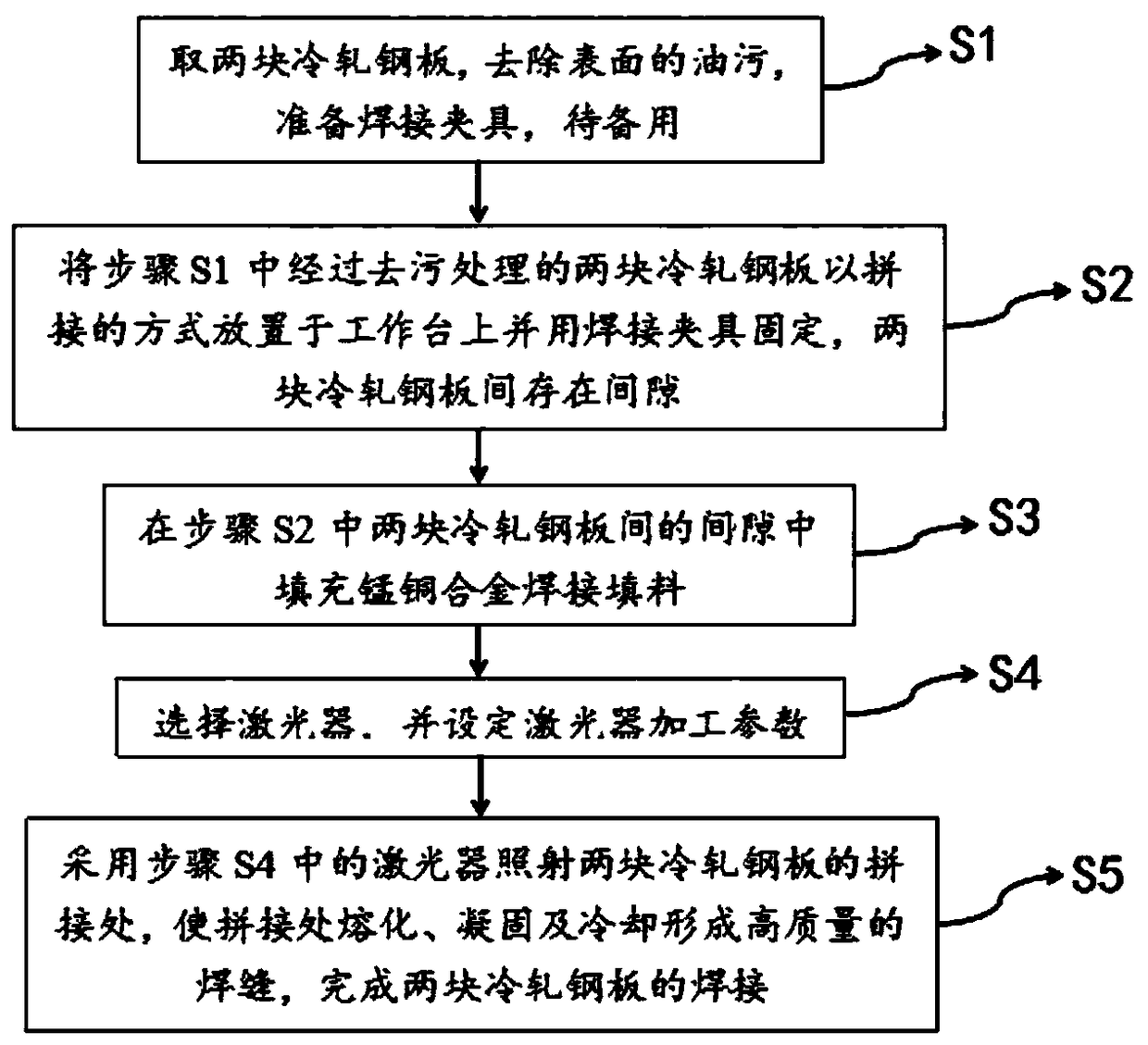

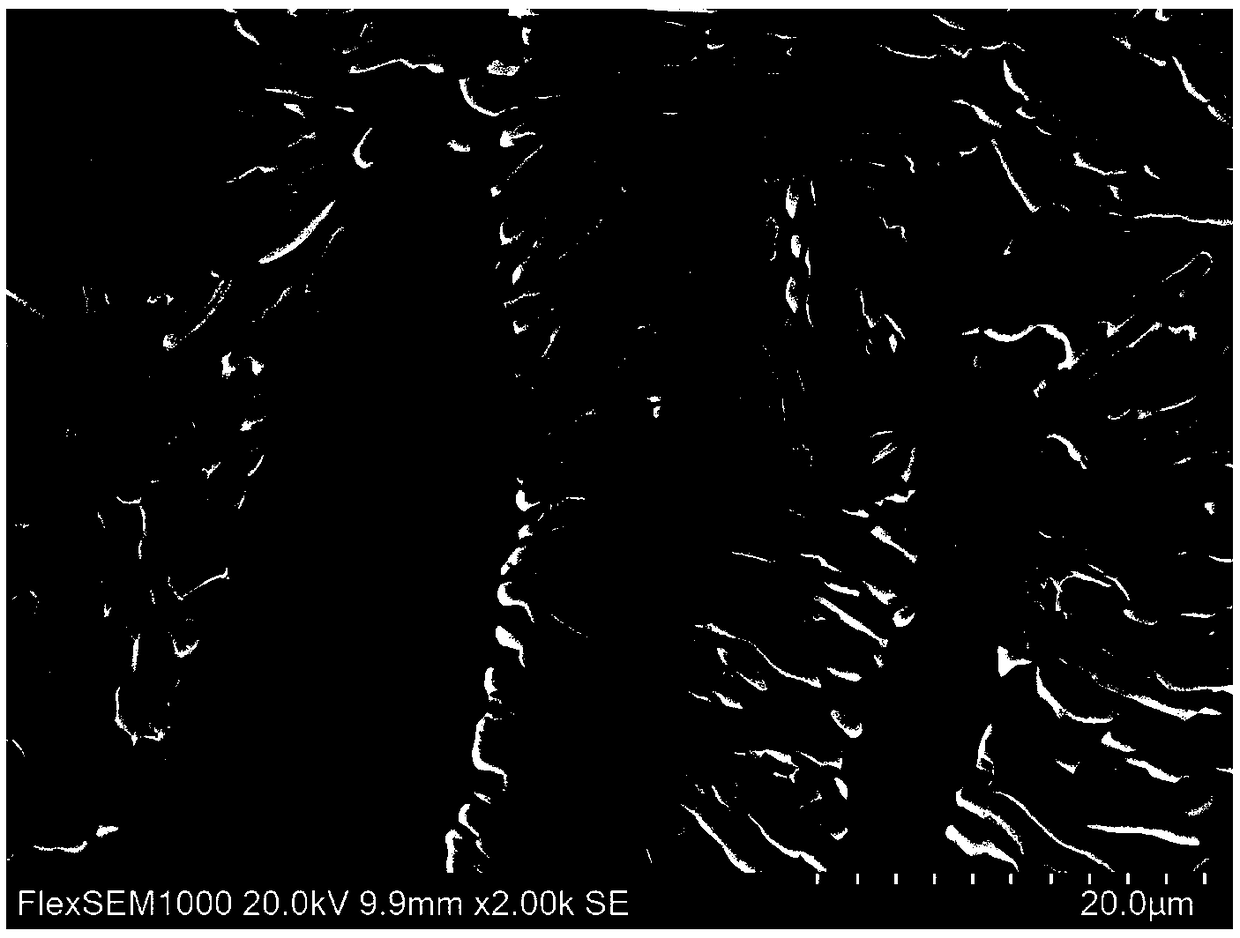

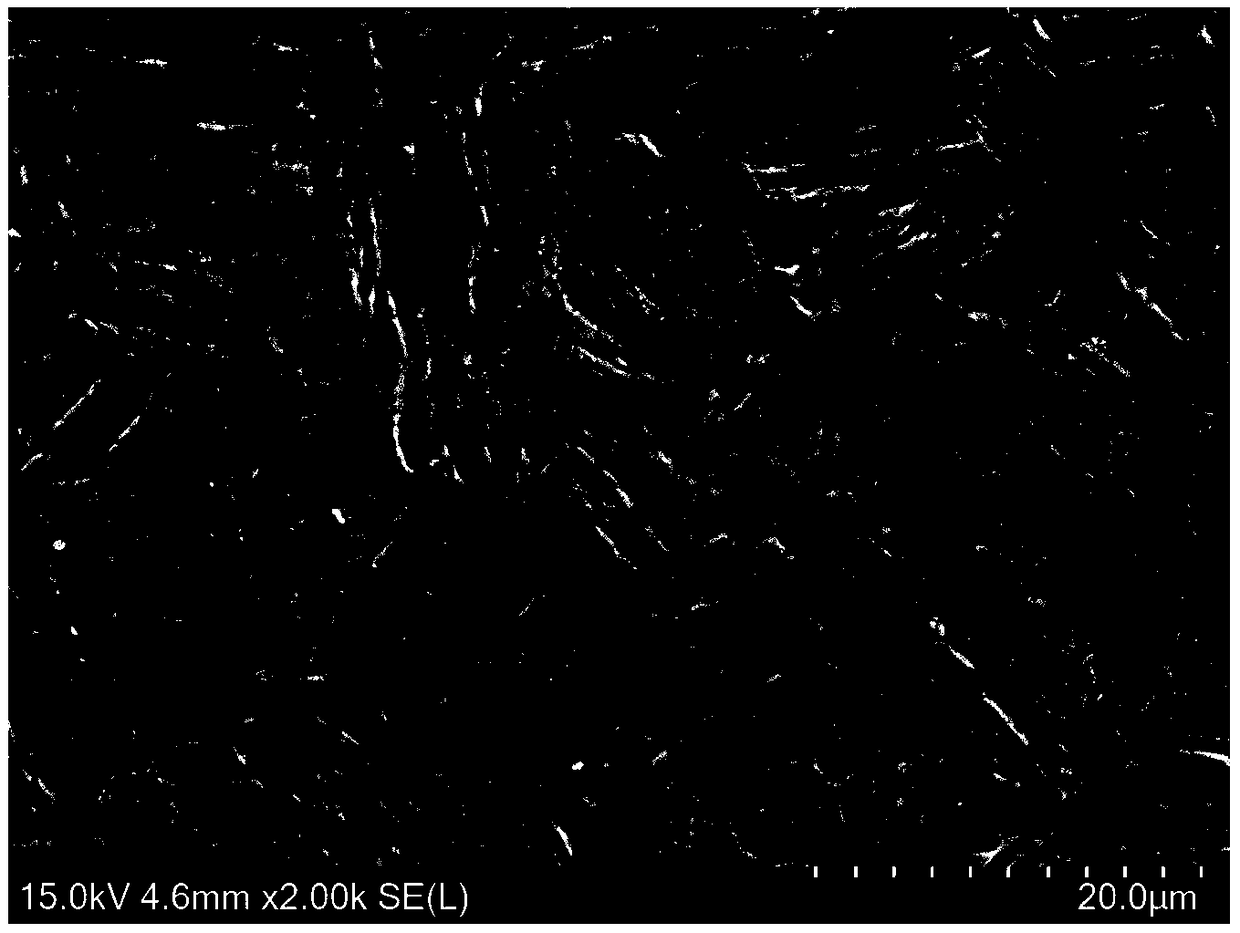

Laser welding method for cold-rolled steel plates for car and welding joint thereof

ActiveCN108838541APrevent precipitationAchieve full martensiticWelding/cutting auxillary devicesAuxillary welding devicesSheet steelManganese

The invention provides a laser welding method for cold-rolled steel plates for a car. The method comprises the following specific steps that 1, two cold-rolled steel plates are taken, oil dirt on thesurfaces is removed, and a welding clamp is prepared for standby application; 2, the two cold-rolled steel plates subjected to dirt removal treatment in the step 1 are placed on a working table in a spliced manner and fixed through the welding clamp, and a gap exists between the two cold-rolled steel plates; 3, the gap between the two cold-rolled steel plates in the step 2 is filled with manganesecopper alloy welding filler; 4, a laser device is selected, and laser device machining parameters are set; and 5, the laser device in the step 4 is adopted for irradiating the spliced portion of thetwo cold-rolled steel plates, the spliced portion is fused, solidified and cooled to form a high-quality weld seam, and welding of the two cold-rolled steel plates is completed. According to the method, the problem existing in the prior art can be solved fully, meanwhile, the mechanical property of the welding joint can be improved, and the alloying degree and the production cost of the weld seamare reduced.

Owner:SUZHOU UNIV

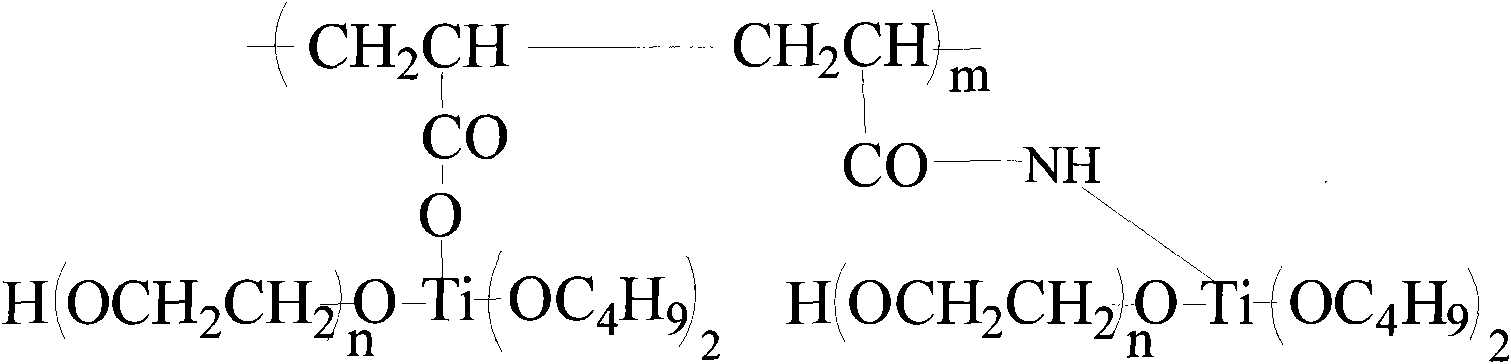

Method for preparing shape-stabilized phase change material by using acrylic fiber waste silks

The invention relates to a method for preparing a shape-stabilized phase change material by using acrylic fiber waste silks. The method comprises the following steps of: hydrolyzing the acrylic fiber waste silks into alkali liquid, obtaining an acrylic fiber hydrolysis product through ethanol precipitation, and then swelling and dissolving the acrylic fiber hydrolysis product; and mixing and reacting the acrylic fiber hydrolysis product and a mixture of polyethylene glycol, chain extender, catalyst and solvent to obtain a graft copolymer of the acrylic fiber hydrolysis product and the polyethylene glycol, wherein the graft copolymer has the solid-solid phase change characteristic. The shape-stabilized phase change material prepared by the method has the advantages of high heat enthalpy value, excellent thermal stability, simple preparation method, low cost, reclamation and recycle of the solvent and the like; and the method is a technique capable of realizing resource reutilization, energy conservation and environmental protection, and has broad market application space.

Owner:DALIAN POLYTECHNIC UNIVERSITY

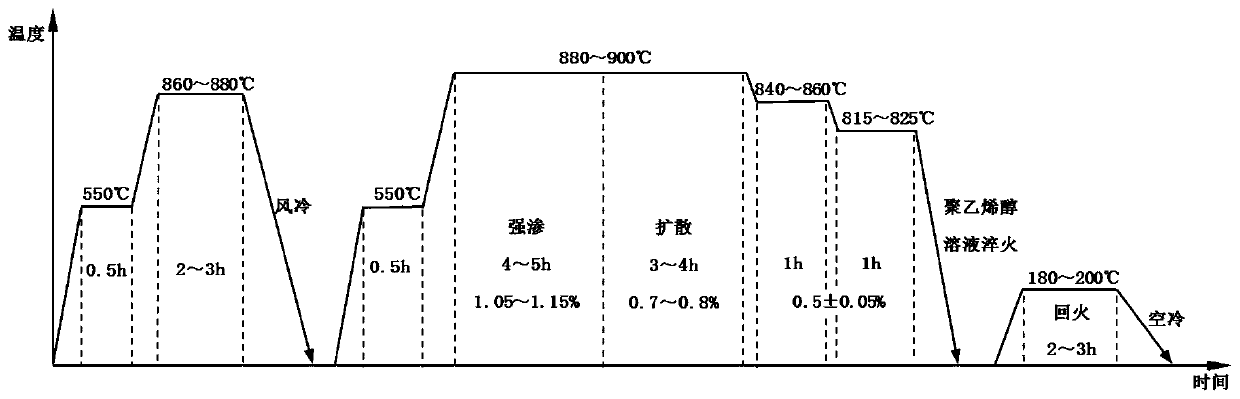

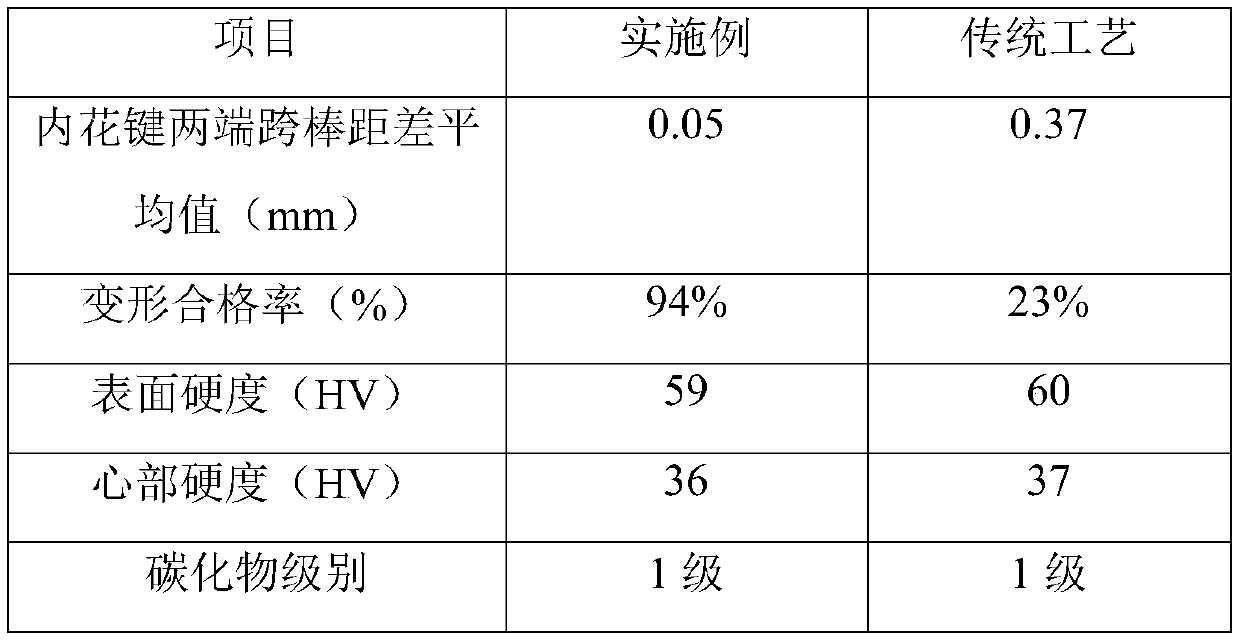

Sub-temperature carburizing heat treatment method for reducing heat treatment deformation of thin-wall gear

ActiveCN111020455AReduce the impact of uniformityIncreased speed of penetration into gear surfacesSolid state diffusion coatingFurnace typesCarbon potentialTempering

The invention relates to a sub-temperature carburizing heat treatment method for reducing heat treatment deformation of a thin-wall gear. The method comprises the following steps of S1, pre-sub-temperature normalizing; S2, slow speed shot blasting; S3, sub-temperature carburization, specifically, gradient heating is adopted to a sub-temperature carburizing temperature, a two-stage carburizing method is adopted in the sub-temperature carburizing process, the first stage is a strong carburizing stage, and the second stage is a diffusion stage; S4, gradient slow cooling quenching, specifically, firstly, gradient slow cooling is carried out on a carburized thin-wall gear forging to 840-860 DEG C, heat preservation is carried out for about 1h, then the slow cooling is continuously carried out to 815-825 DEG C, the heat preservation is carried out for about 1h, the carbon potential in the furnace is controlled to be 0.5-0.05%, and then quenching is carried out in a polyvinyl alcohol solution; and S5, low-temperature tempering. According to the method, the deformation degree of a gear workpiece can be greatly reduced, the production qualification rate can be obviously improved, meanwhile,crystal grains can be effectively refined, the hardness and strength of a gear can be improved, the service life of the gear can be obviously prolonged, and in addition, the refined crystal grains can obviously improve the carburizing speed, reduce the process time and reduce the energy consumption.

Owner:WUHAN UNIV OF TECH

Electric field controllable 2D material Schottky diode

ActiveCN108493255AThin materialSmall footprintSemiconductor devicesSemiconductor materialsMetal electrodes

The invention relates to an electric field controllable 2D material Schottky diode. The diode comprises a substrate layer, the substrate layer is provided with a metal layer, a high-dielectric-constant material layer and a single 2D semiconductor material layer from bottom to top successively, the two ends of the single 2D semiconductor material layer are provided with a metal electrode A and a metal electrode B, part of the rear of the upper portion of the single 2D semiconductor material layer is provided with a multilayer 2D semiconductor material layer, and the multilayer 2D semiconductormaterial layer makes contact with the metal electrode B. Compared with the prior art, the Schottky diode saves the occupation space of a unit device, and is helpful for development towards high density of the device; a polarized electric field of an applied electric field induction ferroelectric material excites a lot of carriers and enables phase change of the 2D material, and a phase change induction method is simple, controllable and low in cost; when the electric field is applied, the phase of the single layer 2D material changes from a semiconductor to metal, and contact between the metalelectrode and the single layer 2D semiconductor material is changed into ohmic contact, and the parasitic resistance of the Schottky diode is reduced.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Rolling process of improving 38CrMoAl steel rolling state structure

InactiveCN110180893AImprove uniformityRefined grain sizeTemperature control deviceMetal rolling arrangementsMetallurgyNucleation

The invention discloses a rolling process of improving a 38CrMoAl steel rolling state structure. The rolling process is characterized by comprising the following steps of 38CrMoAl steel blank selection, steel blank heating, steel blank rough rolling, steel blank medium rolling, steel blank finish rolling and steel cooling. The rolling process of improving the 38CrMoAl steel rolling state structurehas the following advantages that a relatively low final rolling temperature is controlled, so that the surface temperature of a rolled piece is lower than a temperature of a core portion in the process, the steel core portion obtains a relatively large compressive stress in the rolling process, the structure uniformity is greatly improved, and crystal grains are further refined; the final rolling temperature is lowered to be close to the actual critical phase change point Ar3, a phase change from gamma to alpha is promoted, and a nucleation site of ferrite is increased, so that a structure morphology of a product is ferrite and pearlite structures in a balanced state; and the rolling process is green and environmentally friendly, does not pollute the environment, is capable of lowering the cost and increasing the benefit and particularly has important significance of controlling the online structure and the performance of medium-low carbon alloy structural steel.

Owner:XINING SPECIAL STEEL +1

High-carbon high-chromium martensitic stainless steel for cutter and preparation method thereof

ActiveCN112522635APromotes even distributionPurified smelting inclusion contentFurnace typesHeat treatment furnacesMartensitic stainless steelChromium

The invention relates to high-carbon high-chromium martensitic stainless steel for a cutter and a preparation method thereof, and belongs to the technical field of materials. The high-carbon high-chromium martensitic stainless steel comprises the following chemical components of, in percentage by weight, 0.90%-1.20% of C, 14.0%-16.0% of Cr, 1.0%-2.0% of Co, 0.5%-1.5% of Mo, 0.20%-0.40% of V, 0.2%-0.6% of Mn, 0.001%-0.01% of La, less than 0.01% of P, less than 0.01% of S and the balance iron. The preparation method of the high-carbon high-chromium martensitic stainless steel comprises the following steps of burdening, smelting, casting molding, forging and hot working, cold working and heat treatment. According to the high-carbon high-chromium martensitic stainless steel for cutter and thepreparation method thereof, the rare earth element content in the material is optimized, primary carbide coarsening is inhibited, carbide uniform distribution is promoted, the heat treatment process is improved, the martensite content and the austenite content in a matrix are controlled, and the optimal matching of the strength and the toughness of the material is obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

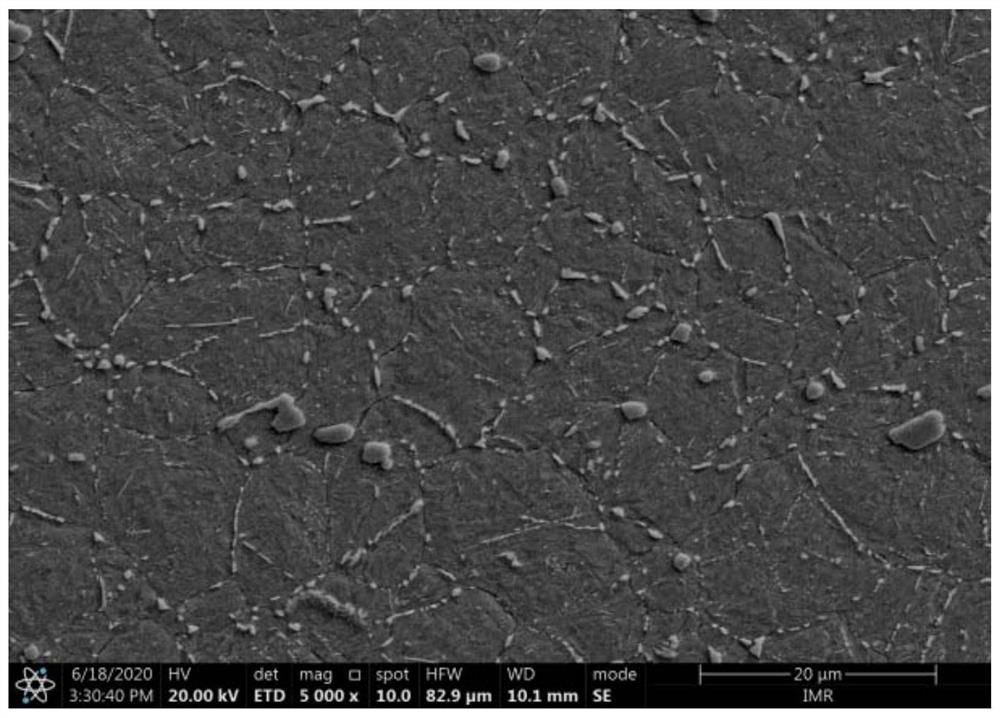

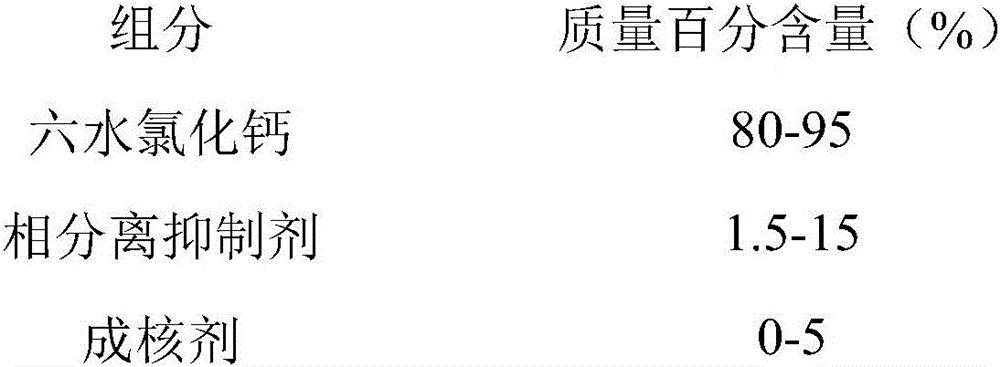

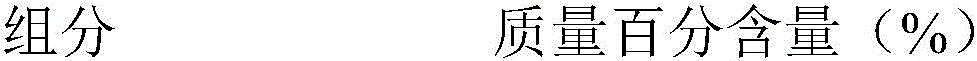

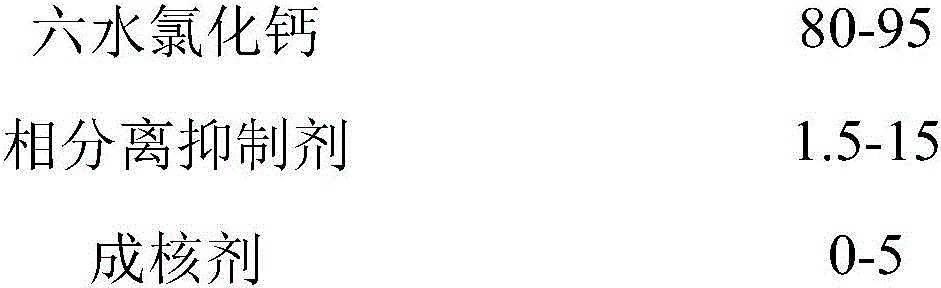

Composite phase-change energy storage material, and preparation method and application thereof

ActiveCN106634858AExtended service lifeIncrease energy storageHeat-exchange elementsHigh energyCalcium Chloride Hexahydrate

The invention relates to a composite phase-change energy storage material and a preparation method thereof. The composite phase-change energy storage material is composed of the following components in percentage by mass: 80-95% of calcium chloride hexahydrate, 1.5-15% of phase separation inhibitor and 0-5% of nucleator. The preparation method of the composite phase-change energy storage material comprises the following steps: weighing equal mass of anhydrous calcium chloride and water, and stirring until the anhydrous calcium chloride is completely dissolved, thereby obtaining a first solution; adding the nucleator into the first solution, and stirring to obtain a second solution; and adding the phase separation inhibitor into the second solution, and stirring to obtain the liquid composite phase-change energy storage material. By using the calcium chloride hexahydrate as the phase-change material, the energy storage material has low degree of supercooling, can still keep the phase change complete after repeated circulations, has high energy storage rate, and is more suitable for practical application.

Owner:CHINA BUILDING MATERIALS ACAD

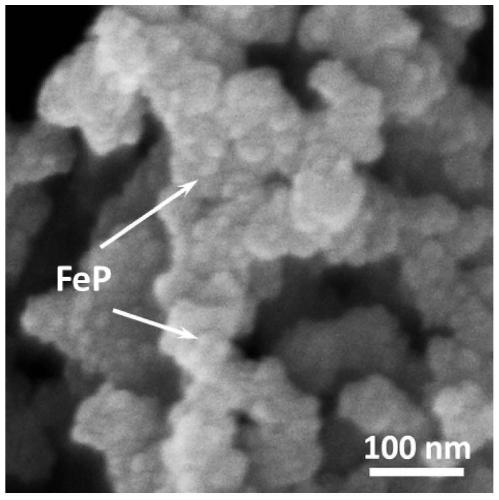

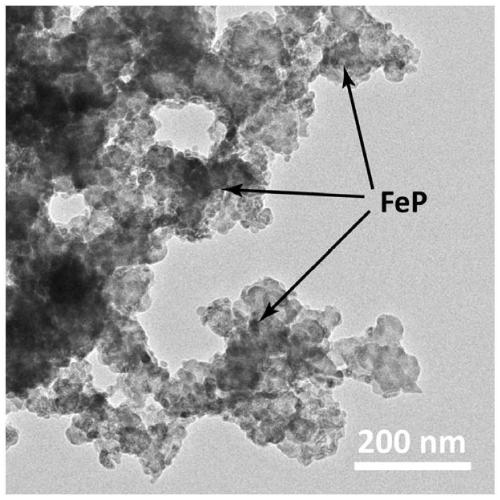

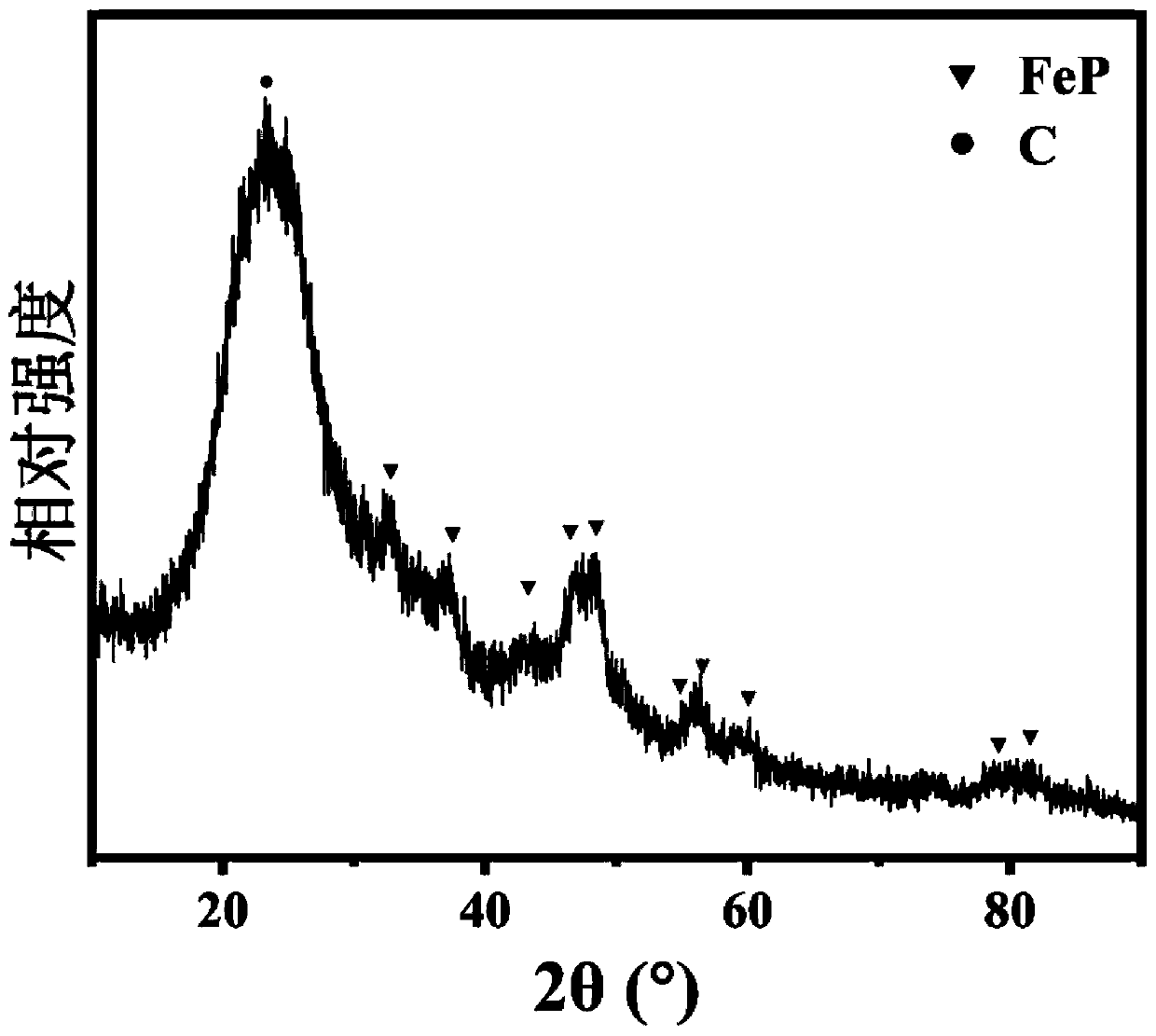

Lithium-sulfur battery conductive agent based on nano transition metal phosphide/carbon composite material as well as preparation method and application of lithium-sulfur battery conductive agent

InactiveCN111477873AImprove stabilityConductiveMaterial nanotechnologyCell electrodesCarbon compositesLithium–sulfur battery

The invention relates to the technical field of lithium-sulfur battery conductive agents, and in particular relates to a lithium-sulfur battery conductive agent based on a nano transition metal phosphide / carbon composite material as well as a preparation method and application of the lithium-sulfur battery conductive agent. The conductive agent comprises a conductive agent body and nano transitionmetal phosphide particles growing on the conductive agent body in situ, and the conductive agent body is a conductive carbon material. According to the invention, the conductive nano transition metalphosphide is compounded on the conductive carbon material to form the lithium-sulfur battery conductive agent with a new structure; the conductive performance of the lithium-sulfur battery conductiveagent is superior to that of a traditional conductive agent, shuttling of polysulfide can be effectively prevented, and a certain catalytic effect is generated; due to the existence of the catalyticaction of the transition metal phosphide, the reaction time of converting soluble lithium polysulfide into a liquid state in the charging and discharging process can be effectively shortened, and nucleation of lithium polysulfide is accelerated; the charging and discharging rate of a positive electrode material is increased; the utilization rate of active substances of the positive electrode material is increased; and the specific capacity and the cycling stability of the lithium-sulfur battery are improved.

Owner:SHANDONG UNIV

2.3 GPa strength grade Co-Ni-Cr-based alloy and preparation method thereof

The invention discloses a 2.3 GPa strength grade Co-Ni-Cr-based alloy and a preparation method thereof. The alloy comprises the following components of, in percentage by mass, 42%-45% of Co, 30%-33% of Ni, 18%-21% of Cr, 0.8%-1.2% of W, 1.8%-2.2% of Mo, 0.3%-0.7% of V and 0.15%-0.3% of C. The preparation method of the alloy comprises the steps of casting, homogenization treatment, solution treatment, cold deformation treatment and aging heat treatment. The tensile strength of the alloy can reach 2.30 GPa or above, the alloy has certain plasticity, the preparation process is simple, and the alloy can be produced through conventional casting and cold and hot machining processes.

Owner:SHENYANG AEROSPACE UNIVERSITY

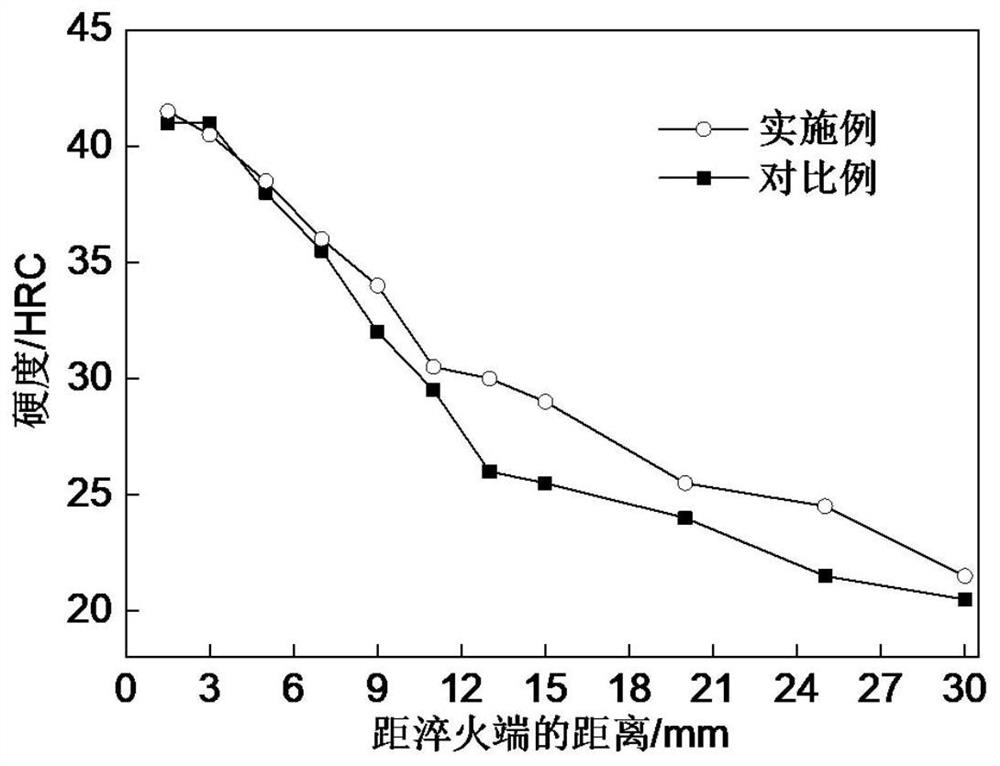

Rolling method capable of reducing as-rolled hardness of 42CrMo steel

ActiveCN106424158AIncrease compressive stressImprove tissue uniformityTemperature control deviceMetal rolling arrangementsMetallurgyPhase change

The invention relates to a rolling method capable of reducing an as-rolled hardness of 42CrMo steel. The rolling method comprises the following steps: (1) carrying out heating treatment on a blank of the 42CrMo steel; and (2) sequentially carrying out rough rolling, medium rolling and finish rolling on the treated blank of the 42CrMo steel to obtain the 42CrMo steel with a low as-rolled hardness. The rolling method capable of reducing the as-rolled hardness of the 42CrMo steel, which is disclosed by the invention, has the following beneficial effects: 1. a low finish rolling temperature is controlled, a high pressure stress on the core part of the steel is achieved during a rolling process, structure uniformity is greatly improved, and grains are further refined; and 2. the finish rolling temperature is lowered to be approximate to an actual critical phase change point (Ar3), thus phase change of the 42CrMo steel from phase gamma to phase alpha is promoted, finally an as-rolled structure is a balanced ferrite and pearlite structure, and then the as-rolled hardness is reduced to HB230-250 from HB300.

Owner:XINING SPECIAL STEEL

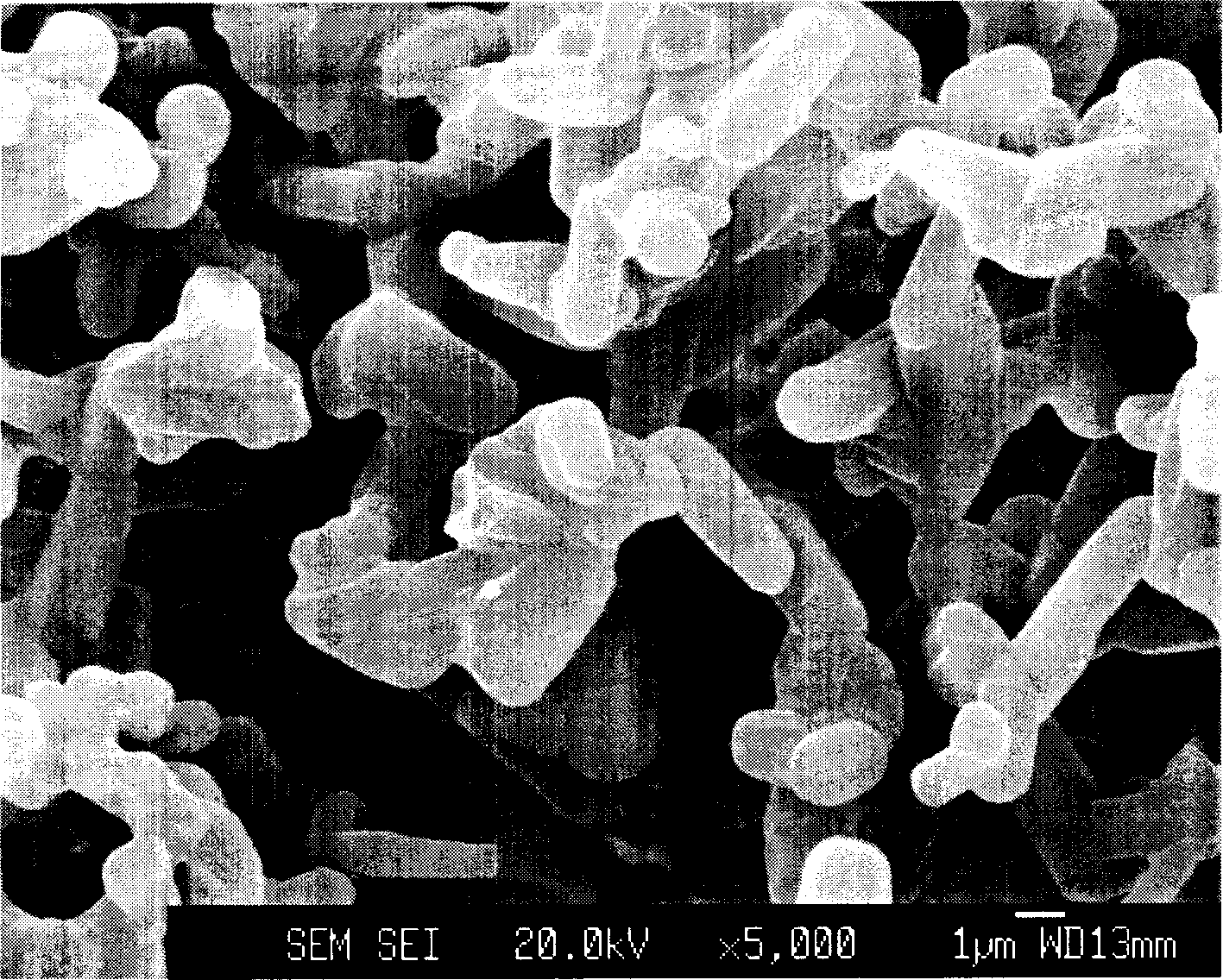

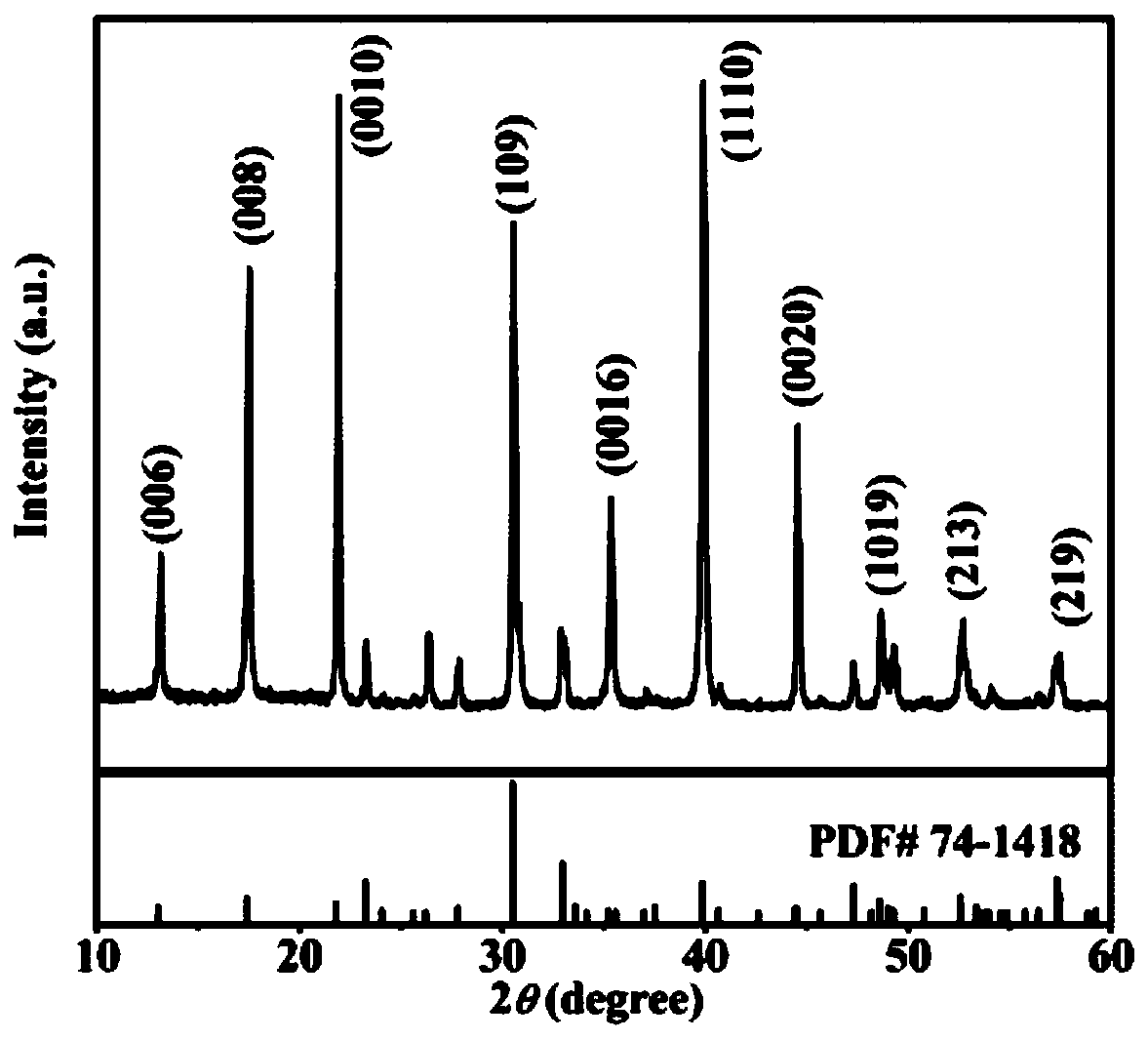

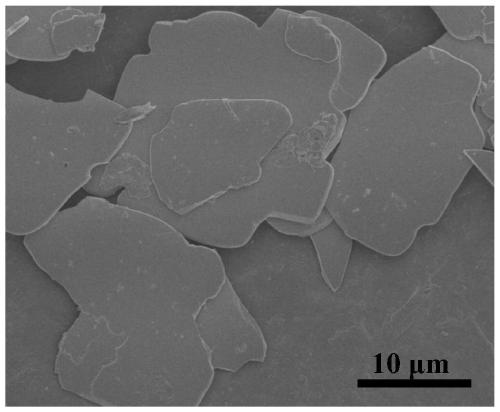

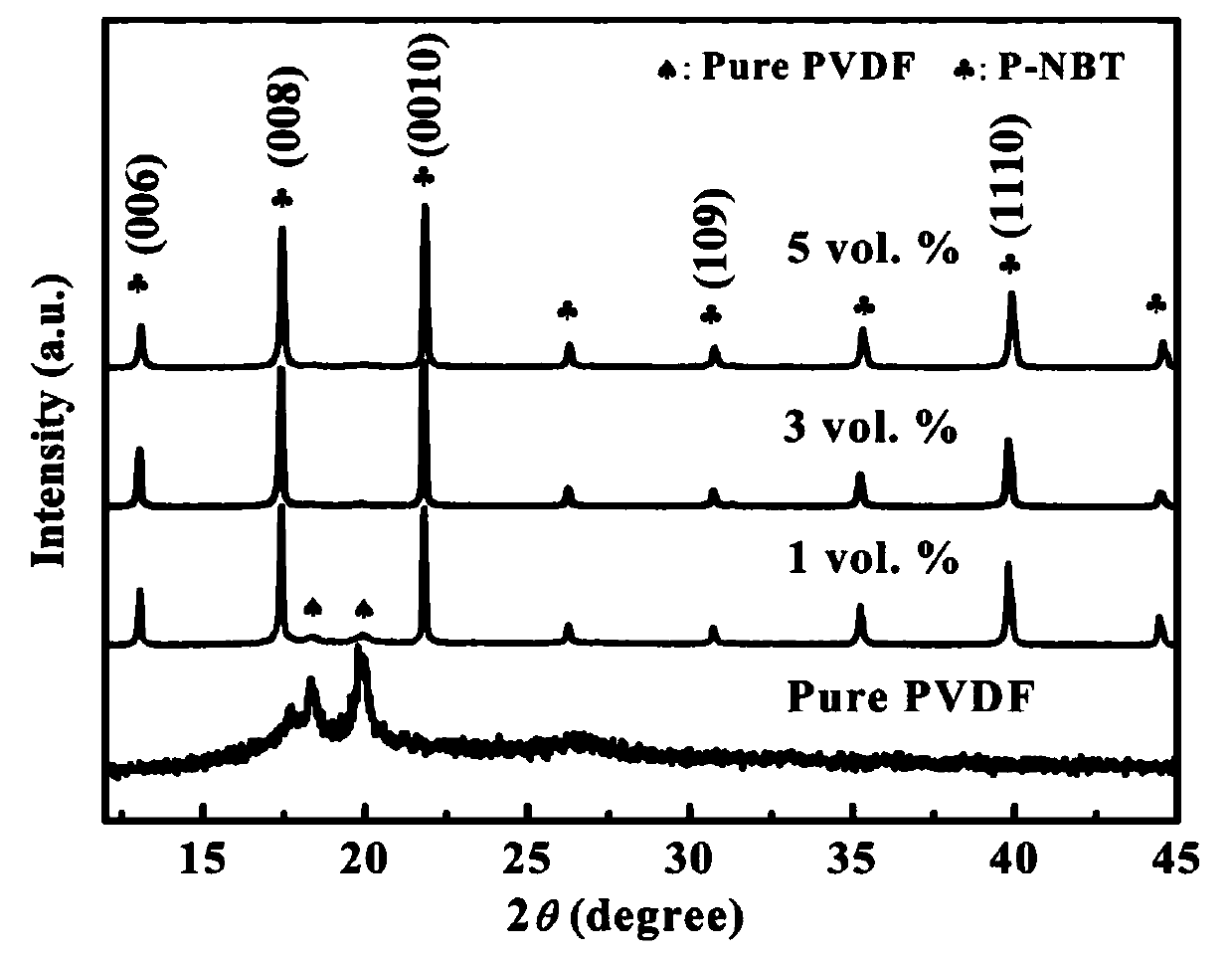

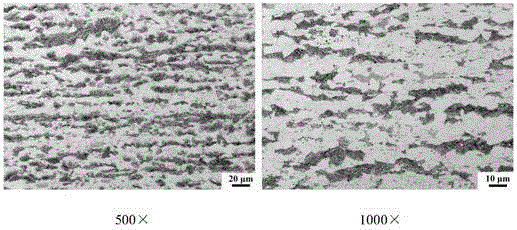

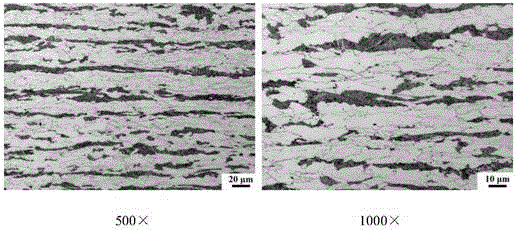

Tabular sodium bismuth titanate/polyvinylidene fluoride composite material and preparation method thereof

InactiveCN110183798AReduce failure rateReduced polarizationTitanatesCompound aPolyvinylidene difluoride

The invention relates to a tabular sodium bismuth titanate / polyvinylidene fluoride composite material and a preparation method thereof. The method comprises the following steps: step 1, calcining Na2CO3, Bi2O3, TiO2 and NaCl at 900-1100 DEG C for 2-8 h; step 2, removing Cl- in an obtained mixture A, drying and then grinding uniformly; step 3, adding an ethanol solution, then drying, adding dopamine hydrochloride and hydrochloric acid, reacting and then drying a product to obtain dopamine-coated tabular sodium bismuth titanate powder; step 4, adding the dopamine-coated tabular sodium bismuth titanate powder into a solution prepared from polyvinylidene fluoride, preparing a compound of the tabular sodium bismuth titanate powder and polyvinylidene fluoride through a tape casting method, and drying to obtain a compound A; step 5, drying the compound A and then quenching; the composite material is maintained at relatively high breakdown field strength, and has large energy density under thesame breakdown field strength compared with pure polyvinylidene fluoride.

Owner:SHAANXI UNIV OF SCI & TECH

Economic air-cooled dual-phase low yield ratio steel plate and production process thereof

ActiveCN103981452AImprove low temperature toughnessFacilitate phase transitionChemical compositionMetallurgy

The invention relates to an economic air-cooled dual-phase low yield ratio steel plate and a production process thereof. The steel plate comprises the following chemical components in percentage by weight: 0.07-0.09% of C, 0.70-0.90% of Si, 1.90-2.10% of Mn, less than or equal to 0.015% of P, less than or equal to 0.008% of S, 0.90-1.10% of Cr, and the balance of Fe and inevitable impurities. By controlling a Mn / C ratio at 21-25, Si+Mn+Cr content is 3.5-3.7%; through a low-temperature rolling process and by air cooling after cooling, a ferrite+martensite dual-phase structure is obtained; according to the prepared steel plate product, thickness is more than or equal to 15mm, yield strength Rp0.2 is less than or equal to 440MPa, tensile strength Rm is more than or equal to 690Mpa, percentage elongation after fracture is more than or equal to 14%, yield ratio (Rp0.2 / Rm) is less than or equal to 0.64 and impact energy at minus 20 DEG C is more than or equal to 60J.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

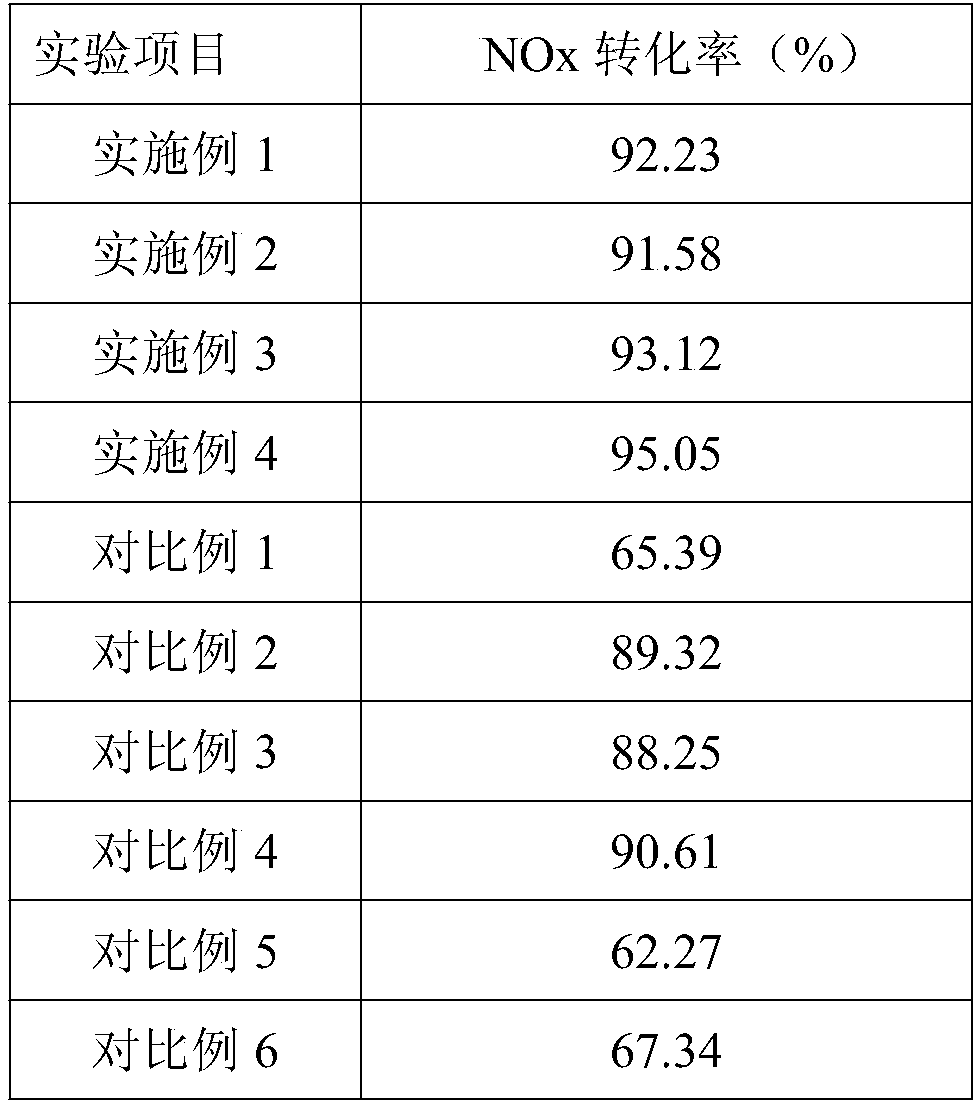

Catalyst-containing urea for automobiles and preparation method of urea

InactiveCN108499360AHigh NOx conversion ratePlay a synergistic roleGas treatmentHeterogenous catalyst chemical elementsAlcoholAmmonium metavanadate

The invention discloses catalyst-containing urea for automobiles and a preparation method of the urea and belongs to the technical field of automobile exhaust treatment. The catalyst-containing urea for automobiles is prepared from raw materials as follows: urea, high-purity water, ethanolamine, ethanol, ethylene glycol, ammonium bicarbonate, secondary alcohol ethoxylate, ammonium metavanadate, nano WO3 / MoO3-TiO2 through preparation of a catalyst, preparation of a urea solution, mixing, stirring and other steps. A reinforcing system formed by secondary alcohol ethoxylate, ammonium metavanadateand nano WO3 / MoO3-TiO2 is applied to the urea for the automobiles, and the NOx conversion rate is increased.

Owner:长沙小新新能源科技有限公司

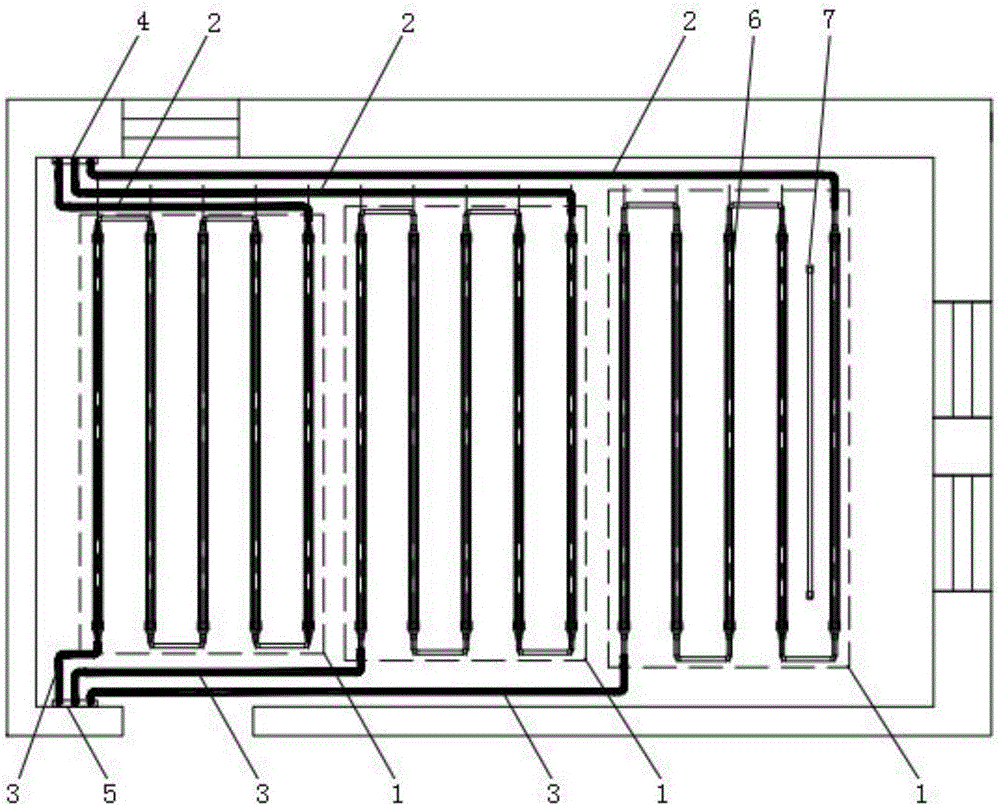

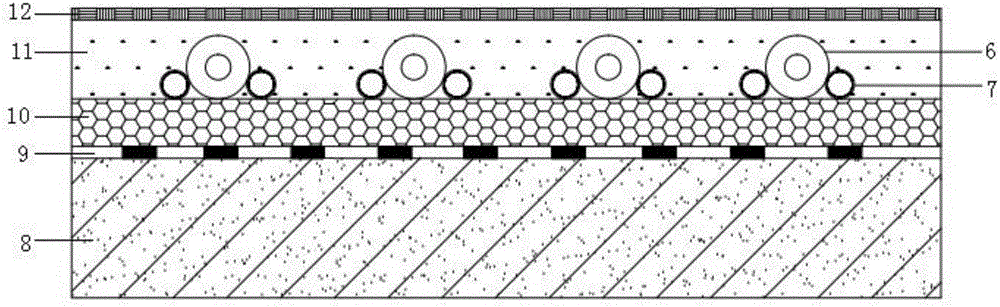

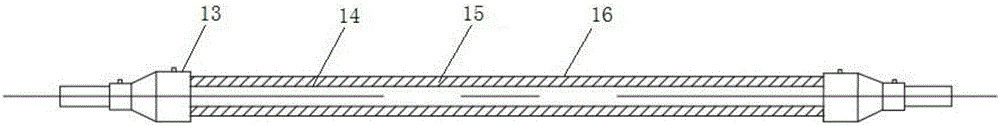

Adjustable phase change heat storage floor based on heat storage heating pipes

InactiveCN106594853AHeating evenlyIncrease profitElectric heating systemHeat storage plantsEngineeringPeak load

The invention discloses an adjustable phase change heat storage floor based on heat storage heating pipes. The adjustable phase change heat storage floor comprises a structural layer, a damp-roof layer, a thermal insulating layer, a packing layer and a decoration surface layer. A plurality of heating pipe modules are laid in the packing layer, connected in parallel in an equal pipe road mode, and arranged between a water distributing device and a water collecting device located on the two sides of a room. A water inlet of each heating pipe module is connected to the water distributing device through a water supply pipe of the module. A water outlet of each heating pipe module is connected to the water collecting device through a water return pipe of the module. Each heating pipe module is a loop composed of the multiple heat storage heating pipes connected in series. The packing layer is further internally provided with heat storage bars. By adoption of the adjustable phase change heat storage floor, efficient and diversified utilization of solar energy in building heating in winter can be achieved, and the problem that coal-fired heating is adopted in rural areas in northern China and the environment is polluted is relieved; and meanwhile, the problem of peak power shortage can be solved, peak-load shifting is achieved, and development of coal-to-electricity projects is facilitated.

Owner:TIANJIN UNIV

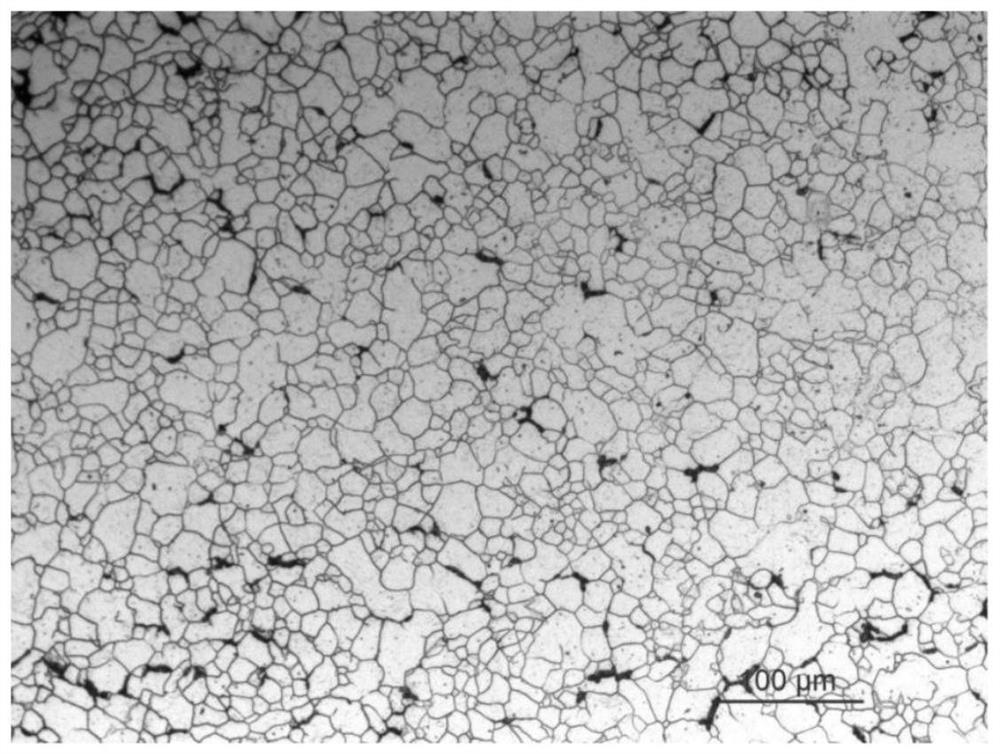

Cold forging gear steel and preparation method thereof

The invention belongs to the technical field of steel, and particularly relates to cold forging gear steel and a preparation method thereof. The gear steel is prepared from the following chemical components in percentage by mass: 0.15%-0.25% of C, 0.05%-0.40% of Si, 0.30%-1.40% of Mn, 0-0.03% of P, 0-0.035% of S, 0.80%-1.50% of Cr, 0-0.05% of Ti, 0-0.045% of Al, 0-0.15% of Cu, 0-0.0150% of N and the balance Fe and inevitable impurities. The metallographic structure of the gear steel comprises austenite, and the grain size of the austenite is 6-7 grades. The gear steel meets gear performance, and has low hardness in a hot rolling state, and the problem of large cold deformation resistance of conventional gear steel is solved; through reduction of the contents of Si and Mn elements, and the cold deformation resistance of a gear steel blank is reduced, and meanwhile the problem of local coarse grains is solved.

Owner:SHOUGANG CORPORATION

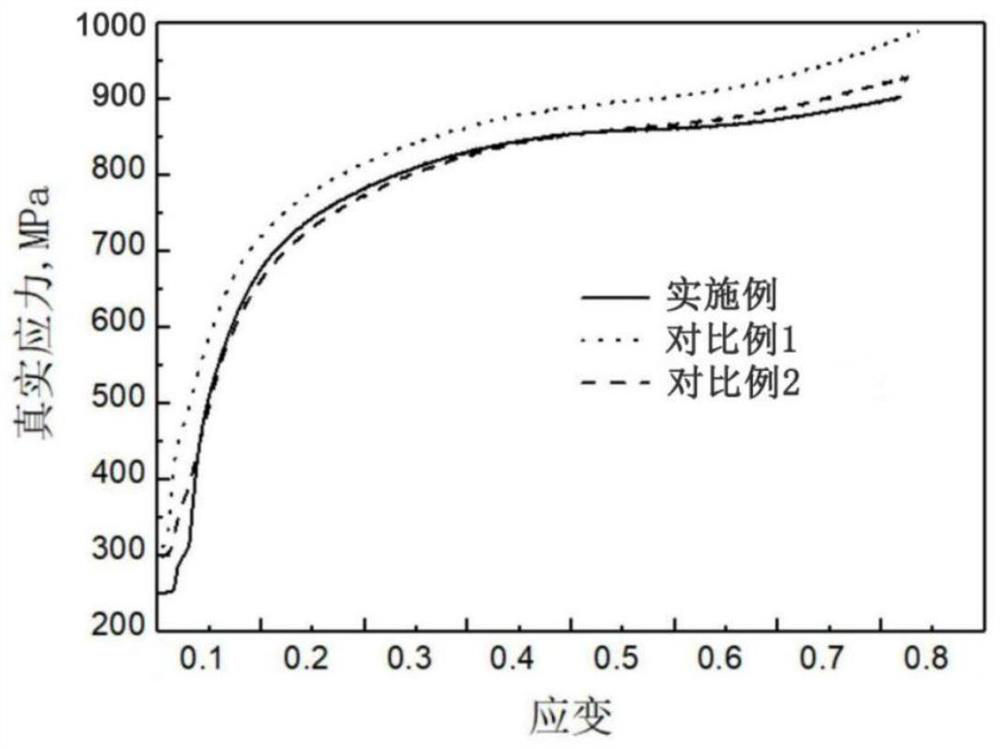

High-performance low-carbon Mo-containing bainite steel and preparation method thereof

The invention relates to high-performance low-carbon Mo-containing bainite steel and a preparation method thereof. According to the technical scheme, the preparation method comprises the following steps of adding Mo into smelting components of Fe-C-Mn-Si low-carbon steel, smelting in vacuum, casting into a steel billet, and rolling the steel billet into a plate; heating the rolled plate to 880-900 DEG C at the heating speed of 5-10 DEG C / s, and keeping the temperature for 10-20 minutes; cooling to 410-420 DEG C by water, cooling to 340-350 DEG C by air, and keeping the temperature for 30-40 minutes; cooling to room temperature by water to prepare the high-performance low-carbon Mo-containing bainite steel. The high-performance low-carbon Mo-containing bainite steel comprises the following chemical components: 0.15wt%-0.22wt% of C, 1.48wt%-1.55wt% of Si, 1.95wt%-2.04wt% of Mn, 0.14wt%-0.15wt% of Mo, less than 0.008wt% of P, less than 0.002wt% of S, less than 0.004wt% of N and the balance of Fe and inevitable impurities. The preparation method has the characteristics of low cost, short cycle and simple process; the prepared high-performance low-carbon Mo-containing bainite steel is excellent in comprehensive performance.

Owner:WUHAN UNIV OF SCI & TECH

Preparation method of two-dimensional porous hexagonal metal oxide nanosheet composite material and application of the composite material in potassium ion battery

ActiveCN110492076AEasy to makeMild reaction conditionsMaterial nanotechnologySecondary cellsOxygen vacancyPotassium

The invention discloses a preparation method of a two-dimensional porous hexagonal metal oxide nanosheet composite material and application of the composite material in a potassium ion battery, and belongs to the technical field of preparation of potassium ion battery composite negative electrode materials. Key points of the technical scheme of the method are as follows: MnO is taken as an examplefor explanation; a MnCO3 NHSs precursor is firstly prepared by utilizing a hydrothermal method; then, a hydrolysis method is used for obtaining a MnCO3@a-TiO2 NHSs intermediate product; then, calcination is performed in a weak reducing atmosphere to introduce oxygen vacancy defects into the nanometer crystals to finally prepare the MnO@a-TiO2-Vo NHSs composite material. The composite material prepared by the method shows excellent rate capability and cycle performance when being used as a negative electrode material of a potassium ion battery, so that the composite material has a relatively good application prospect in the potassium ion battery.

Owner:HENAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com