Catalyst-containing urea for automobiles and preparation method of urea

A technology of urea and catalyst for vehicles, which is applied in the directions of heterogeneous catalyst chemical elements, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low conversion efficiency and poor urea dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

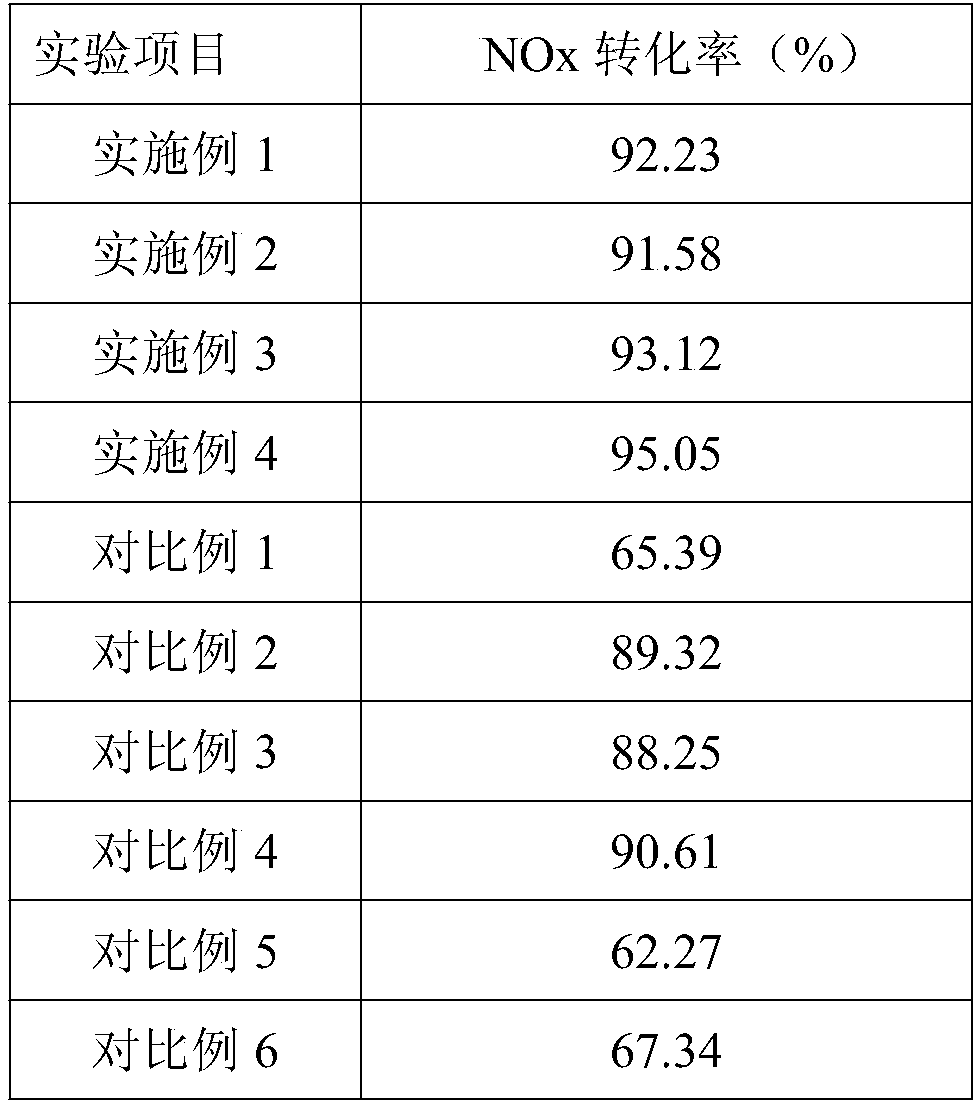

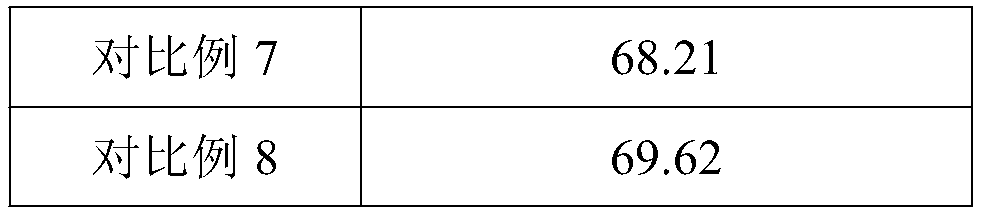

Examples

preparation example Construction

[0027] The preparation method of the described catalyzer-containing urea for vehicles comprises the following steps:

[0028] S1: Take ammonium metavanadate by weight ratio and add deionized water to make a solution, then add nano-WO 3 / MoO 3 -TiO 2 Stir at 60-80°C for 2-3h, put it in an electric furnace and bake at a high temperature of 500-550°C for 0.5-1.5h, then cool naturally to room temperature, put it in an electric furnace again and bake at a high temperature of 550-600°C for 1-1.5 hours h, naturally cool to room temperature to obtain catalyst; the consumption ratio of described ammonium metavanadate and deionized water is 1:20-40;

[0029] S2: Add urea to high-purity water at 25-30°C, stir to dissolve it fully, filter to make a solution with a concentration of 32% and less than 1% insoluble matter, and then add ethanolamine, ethanol, and ethylene glycol in sequence Alcohol, ammonium bicarbonate and secondary alcohol polyoxyethylene ether are fully stirred, and filt...

Embodiment 1

[0032] A catalyst-containing urea for vehicles, comprising the following raw materials: 32 parts of urea, 60 parts of high-purity water, 8 parts of ethanolamine, 8 parts of ethanol, 5 parts of ethylene glycol, 4 parts of ammonium bicarbonate, 2.8 parts of secondary alcohol polyoxyethylene ether, 3.2 parts of ammonium metavanadate, nano WO 3 / MoO 3 -TiO 2 2.3 servings.

[0033] The preparation method of the described catalyzer-containing urea for vehicles comprises the following steps:

[0034] S1: Take ammonium metavanadate by weight ratio and add deionized water to make a solution, then add nano-WO 3 / MoO 3 -TiO 2 Stir at 70°C for 3h, put it into an electric furnace and roast at a high temperature of 500°C for 0.5h, then naturally cool to room temperature, put it into an electric furnace again and roast at a high temperature of 580°C for 1.2h, and naturally cool to room temperature to obtain a catalyst; The dosage ratio of ammonium vanadate to deionized water is 1:20; ...

Embodiment 2

[0038] A catalyst-containing urea for vehicles, comprising the following raw materials: 36 parts of urea, 68 parts of high-purity water, 10 parts of ethanolamine, 2 parts of ethanol, 6 parts of ethylene glycol, 8 parts of ammonium bicarbonate, 3.1 parts of secondary alcohol polyoxyethylene ether, 1.5 parts of ammonium metavanadate, nano WO 3 / MoO 3 -TiO 2 2.6 servings.

[0039] The preparation method of the described catalyzer-containing urea for vehicles comprises the following steps:

[0040] S1: Take ammonium metavanadate by weight ratio and add deionized water to make a solution, then add nano-WO 3 / MoO 3 -TiO 2 Stir at 80°C for 2h, put it into an electric furnace and roast at a high temperature of 530°C for 1.2h, then cool naturally to room temperature, put it into an electric furnace again and roast at a high temperature of 600°C for 1.5h, and naturally cool to room temperature to obtain a catalyst; The dosage ratio of ammonium vanadate to deionized water is 1:30; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com