Ammonium bisulfate poisoning prevention wide-temperature-range SCR (Selective Catalytic Reduction) catalyst taking fly ash as matrix as well as preparation method and application thereof

An SCR catalyst, ammonium hydrogen sulfate technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Industrial waste gas treatment conditions, difficult commercialization in the field of coal combustion, etc., to achieve high water resistance, sulfur resistance and denitration activity, solve catalyst poisoning, and improve the effect of flue gas denitration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

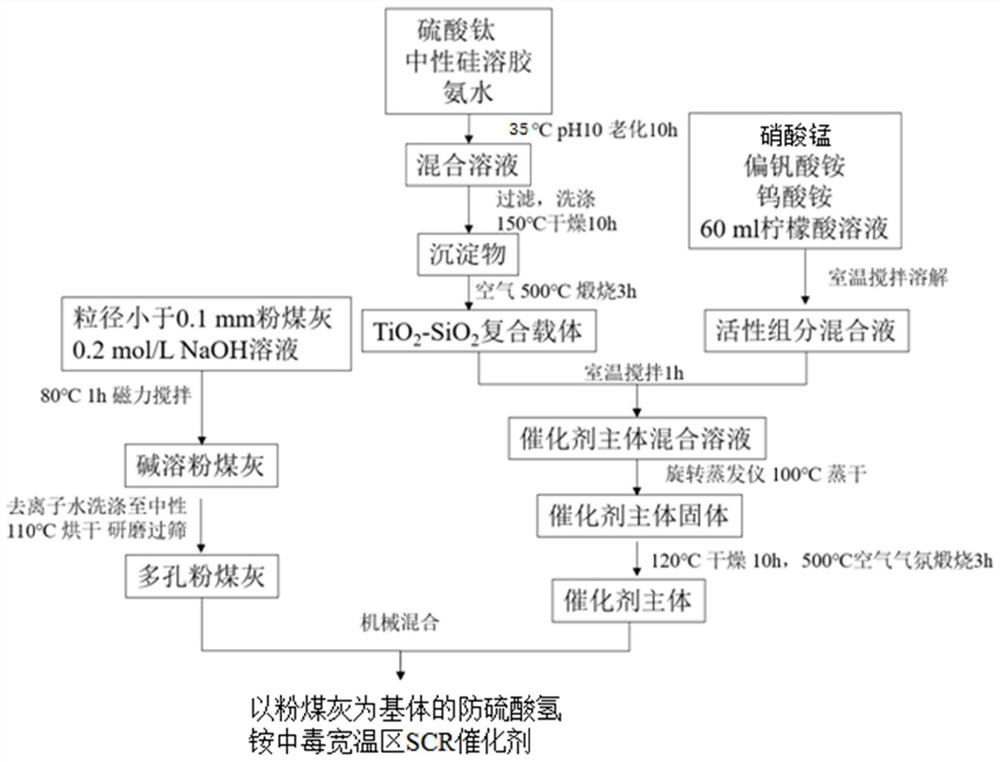

Method used

Image

Examples

Embodiment 1

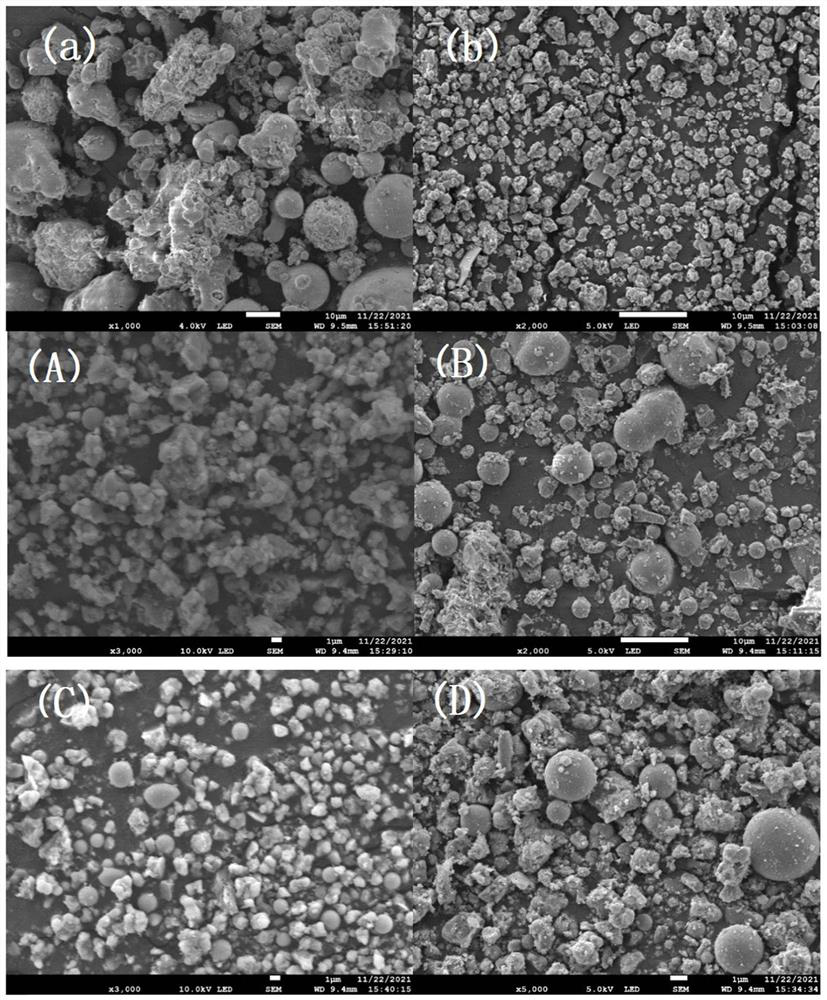

[0037] A wide temperature zone SCR catalyst for preventing ammonium bisulfate poisoning with fly ash as a substrate, the porous fly ash as a substrate, and a wide temperature zone SCR catalyst attached to the surface of the porous fly ash.

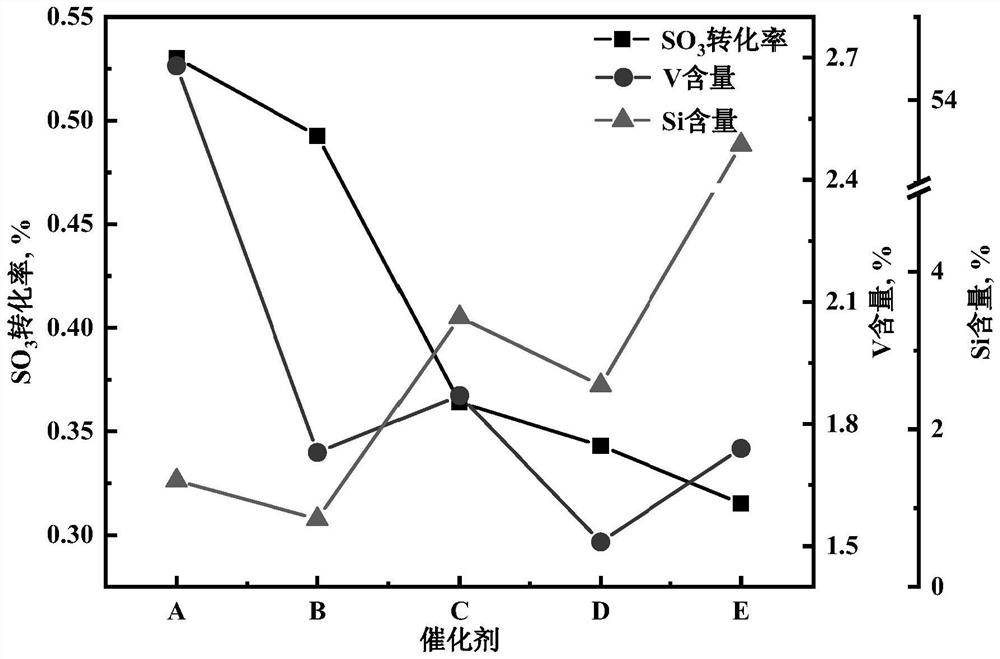

[0038] In this example, the wide temperature zone SCR catalyst is V-W-Mn / TiO 2 -SiO 2 catalyst. The V-W-Mn / TiO 2 -SiO 2 The catalyst is TiO 2 -SiO 2 Composite oxide as carrier, TiO 2 -SiO 2 The composite oxide is loaded with active component V, active component Mn and coagent W, wherein the active component V is V 2 o 5 , the active component Mn is MnO 2 , coagent W is WO 3 ; The V-W-Mn / TiO 2 -SiO 2 The mass fraction of the active component V in the catalyst is 1.096%, the mass fraction of the active component Mn is 5.019%, the mass fraction of the coagent W is 6.29%, and the rest is TiO 2 -SiO 2 Composite oxides; TiO 2 -SiO 2 SiO in composite oxide 2 The mole fraction is 20%.

[0039] A kind of preparation method of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com