Supported platinum group catalyst applied to propane dehydrogenation propylene preparation and preparation method of supported platinum group catalyst

A platinum-based catalyst and propane dehydrogenation technology, applied in the field of propylene, can solve the problems of high energy consumption, long preparation process, increase the difficulty of separation and purification, etc., and achieve the effects of high reaction activity, slow activity decline, and high regeneration stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

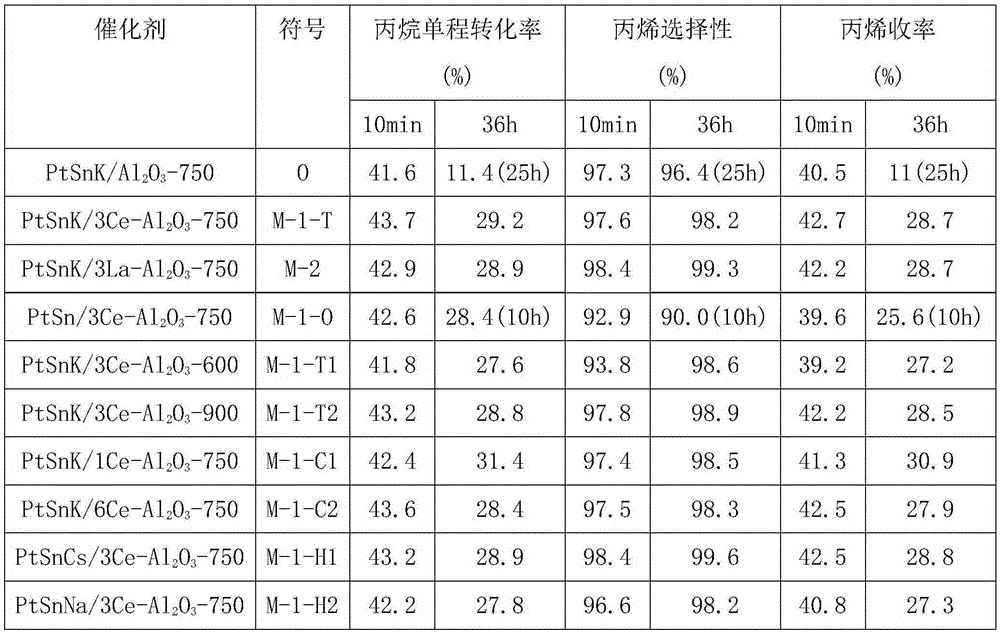

Embodiment 1

[0038](1) Weigh 100g of pseudo-boehmite, add 100g of an aqueous solution containing 9.2967g of cerium nitrate hexahydrate and mix evenly, and follow the rolling ball molding method to obtain spherical particles with a particle size of 1.4-1.5mm. Place it in an oven at 120°C for 6 hours and then bake it at 750°C for 4 hours to obtain the propane dehydrogenation catalyst carrier Ce-Al of the present invention 2 o 3 .

[0039] (2) the preparation method of next catalyst is with step (2) and (3) in comparative example, makes propane dehydrogenation supported catalyst PtSn-K / Ce-Al of the present invention 2 o 3 .

[0040] The obtained catalyst is denoted as M-1-T, and the percentages of its components are: Ce: 3%, Pt: 0.4%, Sn: 0.8%, K: 1.5%, and the balance is Al 2 o 3 .

Embodiment 2

[0045] (1) Weigh 100g of pseudo-boehmite, add 100g of an aqueous solution containing 9.3525g of lanthanum nitrate hexahydrate and mix evenly, and follow the rolling ball forming method to obtain spherical particles with a particle size of 1.4-1.5mm. Place it in an oven at 120°C for 6 hours and then bake it at 750°C for 4 hours to obtain the propane dehydrogenation catalyst carrier La-Al of the present invention 2 o 3 .

[0046] (2) the preparation method of next catalyst is with step (2) and (3) in comparative example 1, obtains propane dehydrogenation supported catalyst PtSn-K / La-Al among the present invention 2 o 3 .

[0047] The obtained catalyst is denoted as M-2, and the percentages of its components are: La: 3%, Pt: 0.4%, Sn: 0.8%, K: 1.5%, and the balance is Al 2 o 3 .

Embodiment 3

[0049] (1) Weigh 100g of pseudo-boehmite, add 100g of an aqueous solution containing 9.2967g of cerium nitrate hexahydrate and mix evenly, and follow the rolling ball molding method to obtain spherical particles with a particle size of 1.4-1.5mm. Place it in an oven at 120°C for 6 hours and then bake it at 600°C for 4 hours to obtain the propane dehydrogenation catalyst carrier Ce-Al of the present invention 2 o 3 .

[0050] (2) the preparation method of next catalyst is with step (2) and (3) in comparative example 1, makes propane dehydrogenation supported catalyst PtSn-K / Ce-Al of the present invention 2 o 3 .

[0051] The obtained catalyst is denoted as M1-T1, and the percentages of its components are: Ce: 3%, Pt: 0.4%, Sn: 0.8%, K: 1.5%, and the balance is Al 2 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com