Catalyst for preparing dichloroaniline through hydrogenization for dichloronitrobenzene, and preparation method

A technology of dichloronitrobenzene and dichloroaniline, which is applied in the preparation of amino compounds, chemical instruments and methods, catalysts for physical/chemical processes, etc., can solve the problems of few times of applying catalysts, adding dehalogenation inhibitors, and high content of precious metals , to achieve the effect of many times of application, inhibition of dechlorination phenomenon, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Grind the activated carbon into powder in a ball mill, screen 80-120 mesh activated carbon in 2mol.L -1 HNO 3 Soak in water for 24 hours, then filter out the activated carbon, wash it repeatedly with water until neutral, add water to make a slurry with a concentration of 5ml water / g activated carbon;

[0039] 0.083ml concentration is the PdCl of 80g / L 2 Aqueous solution, with a concentration of 10g / L Na 2 CO 3 The aqueous solution was adjusted to pH 5.

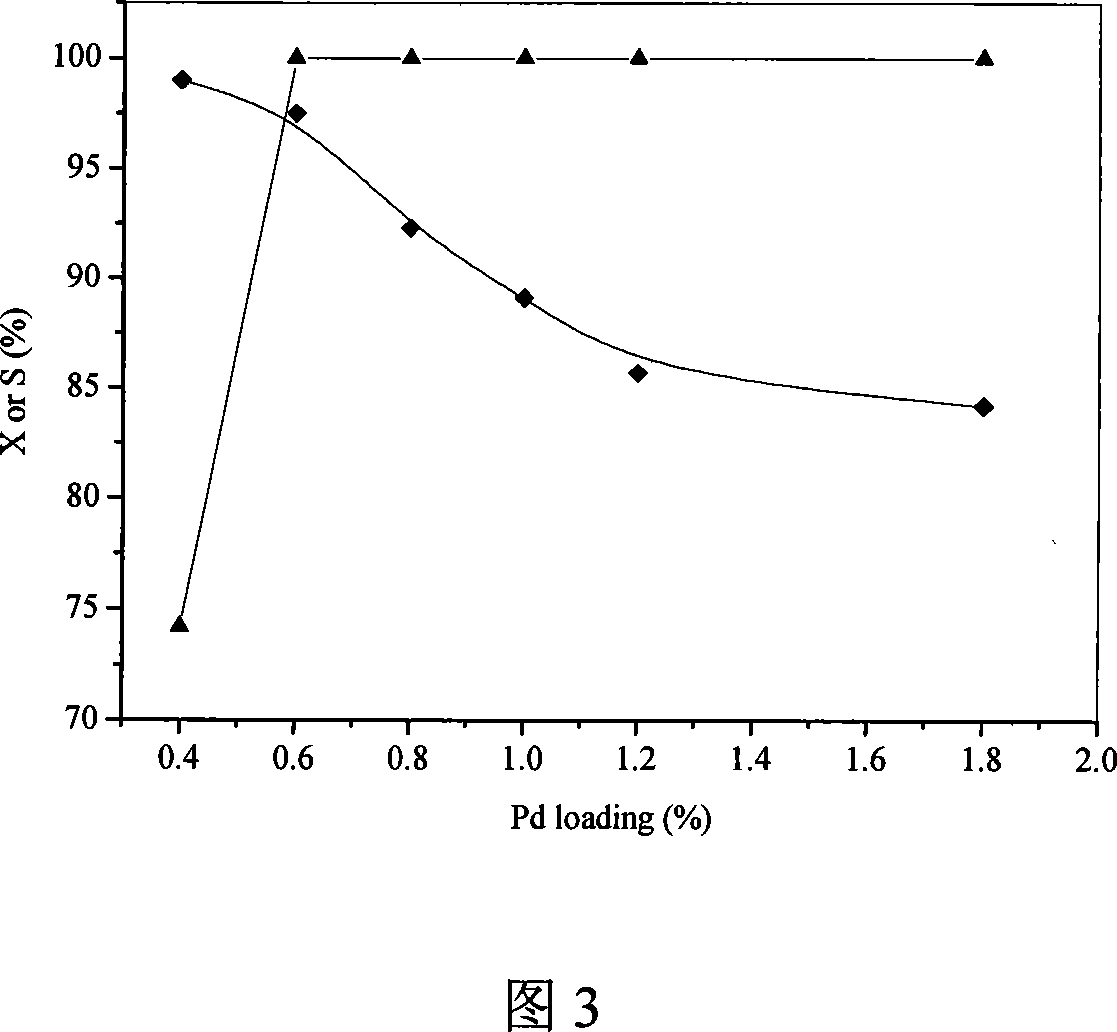

[0040] Add the above PdCl dropwise to 6g of activated carbon slurry 2 The aqueous solution was magnetically stirred in a water bath at 70°C for 3 hours, then filtered, and the filter cake was dried in an oven at 110°C for 3 hours to obtain a Pd / activated carbon catalyst with a loading capacity of 0.4%.

Embodiment 2~6

[0042] Adopt the same preparation method as Example 1, wherein, PdCl 2 The addition amount of aqueous solution is 0.125, 0.167, 0.208, 0.250, 0.375ml respectively, can obtain the Pd / activated carbon catalyst of loading capacity as 0.6%, 0.8%, 1.0%, 1.2%, 1.8%.

Embodiment 7

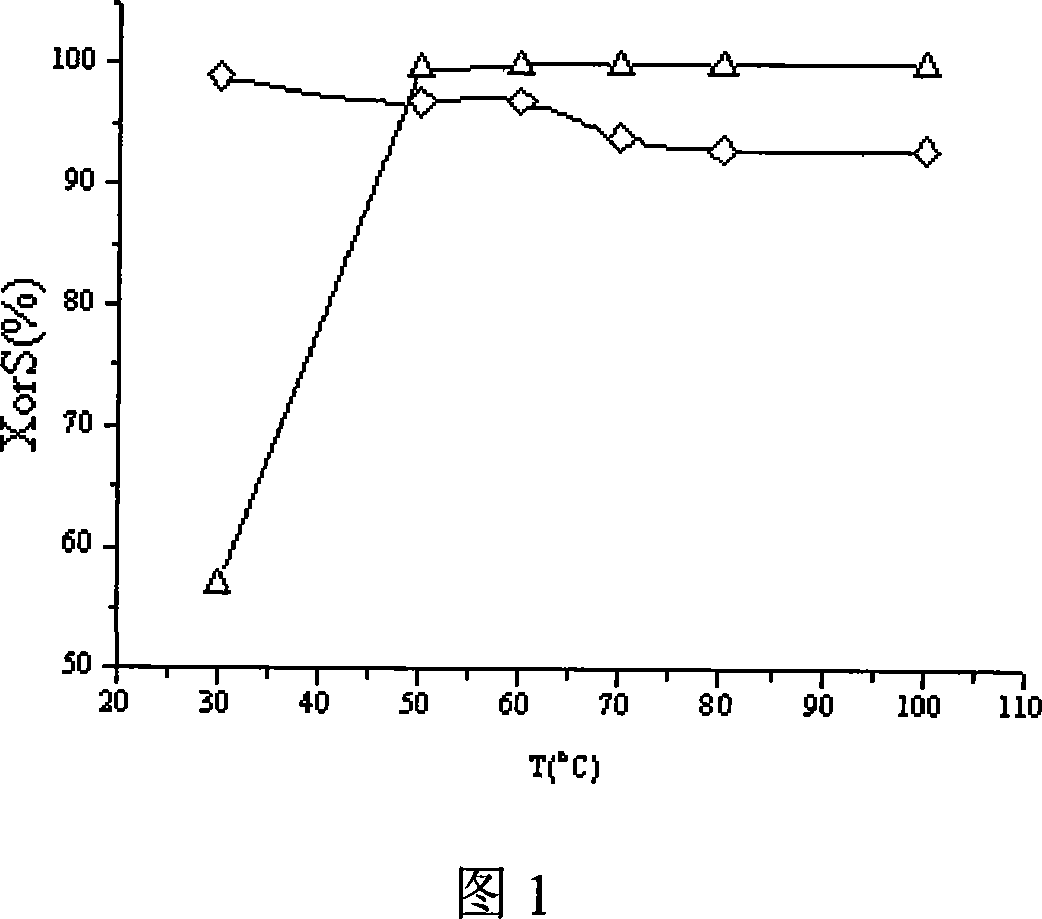

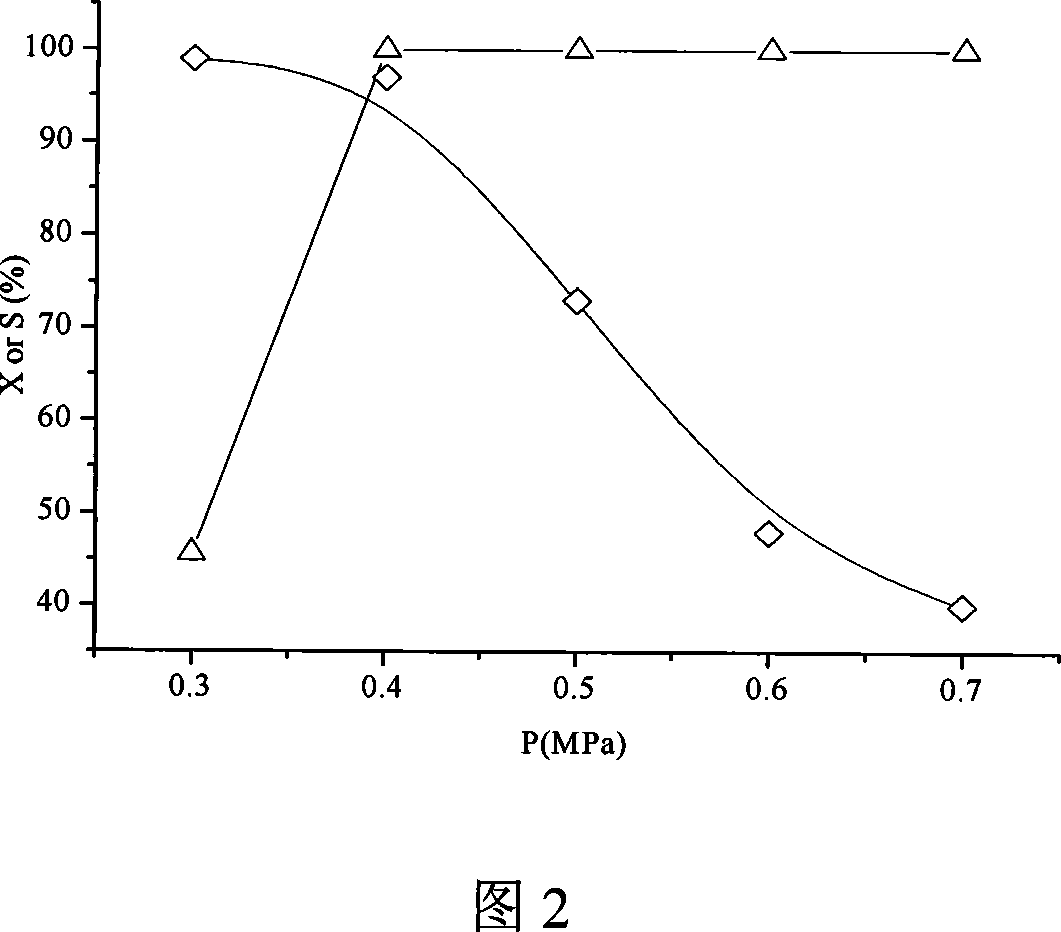

[0044] 3g 3,4-dichloronitrobenzene, 25ml methanol solvent and the 0.6%Pd / activated carbon catalyst prepared in 0.05g embodiment 1 were added in a stainless steel autoclave, the autoclave was closed, and the air in the autoclave was replaced with nitrogen for 3 times , and then replace the nitrogen in the kettle with hydrogen for 3 times and maintain a certain pressure in the kettle. Under stirring, raise the temperature of the autoclave to 60°C, maintain the reaction pressure at 0.4 MPa, and react at a constant temperature until the pressure in the autoclave remains constant, unload the autoclave, discharge the material, filter out the catalyst, and analyze the filtrate with a capillary gas chromatograph, 3,4 - The conversion rate of dichloronitrobenzene is 100.0%, and the selectivity of 3,4-dichloroaniline is 97.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com