Patents

Literature

94results about How to "Low unsaturation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

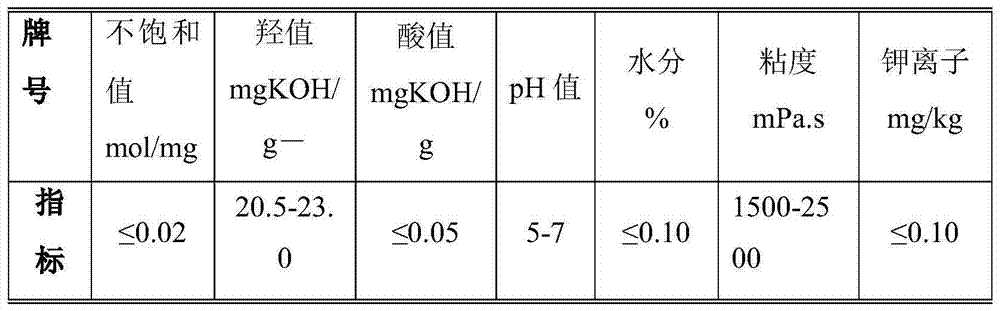

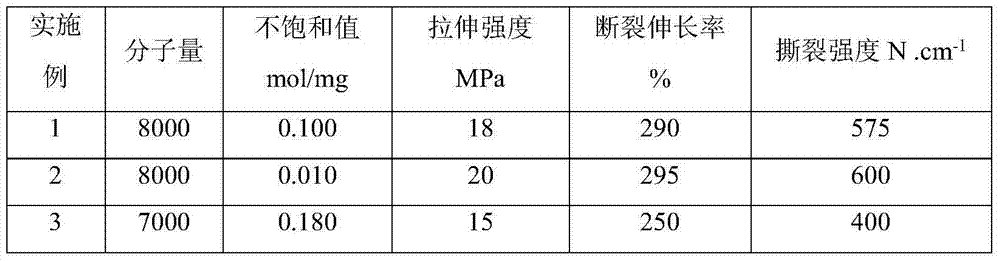

Method for synthesis of low-unsaturation degree, high-molecular weight and high-activity polyether polyol

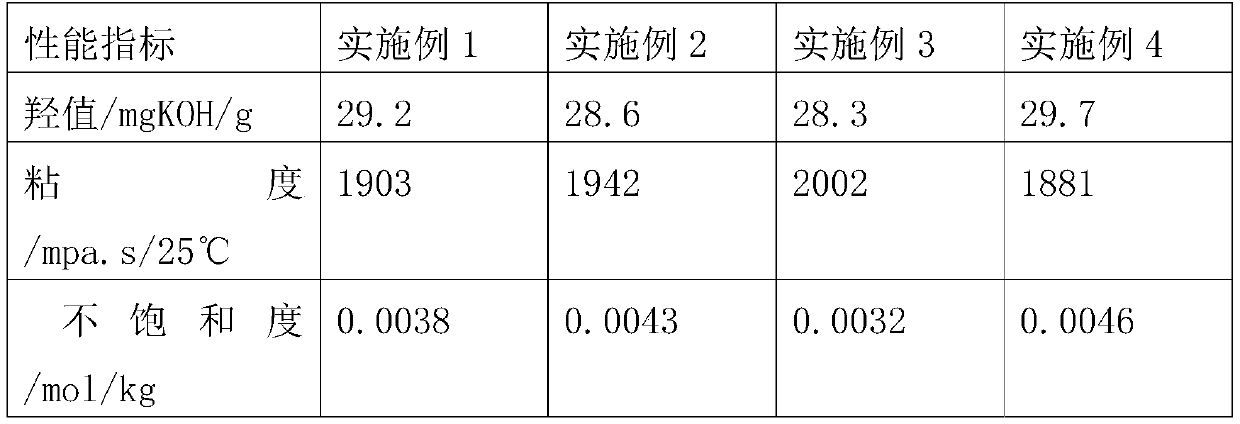

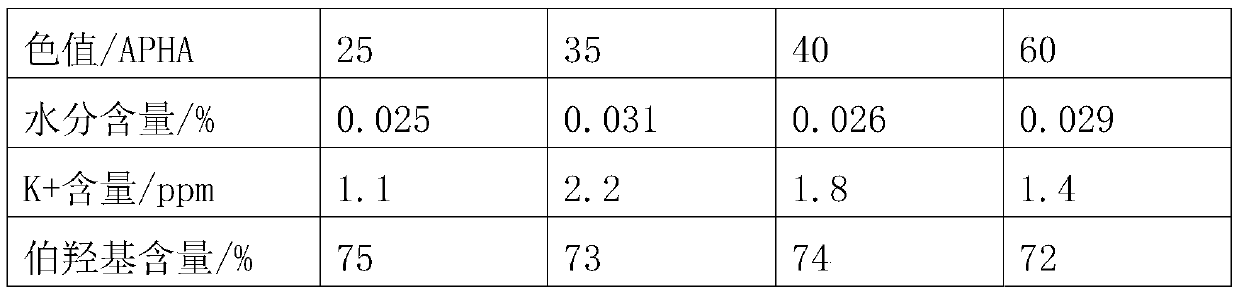

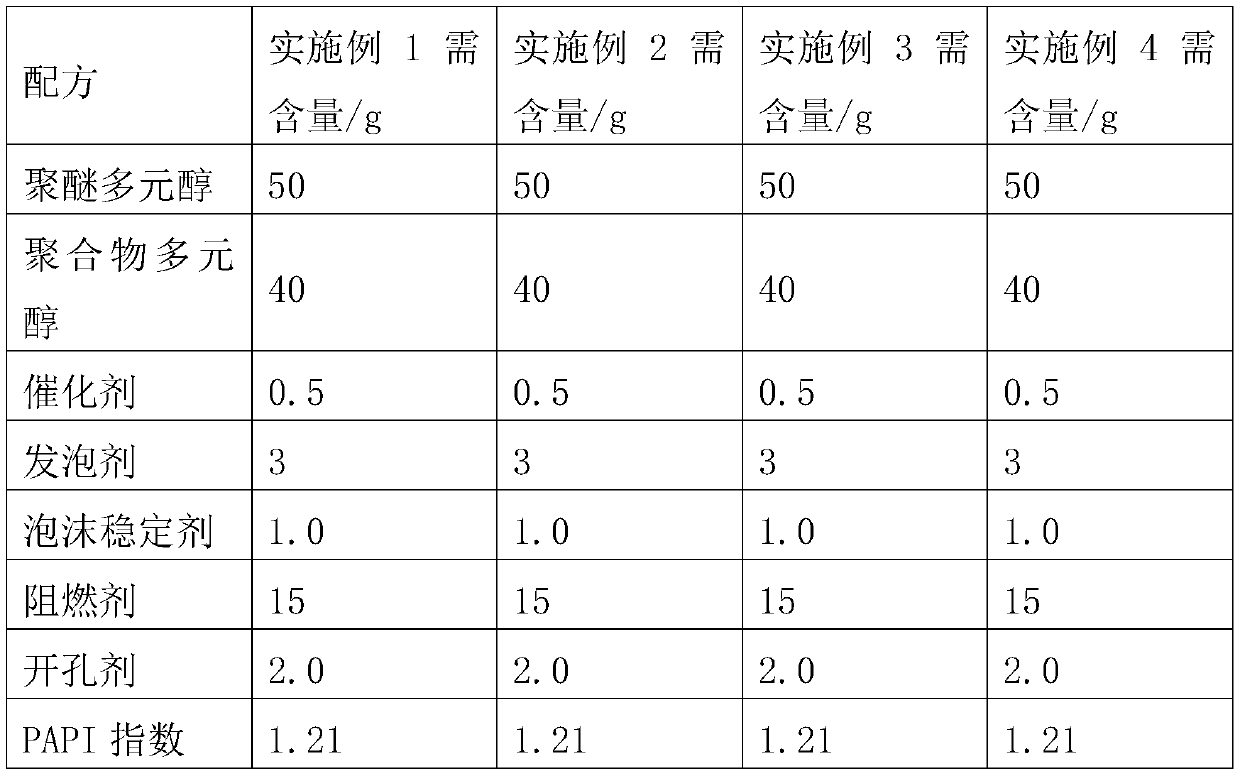

The invention relates to a method for synthesis of low-unsaturation degree, high-molecular weight and high-activity polyether polyol and belongs to the field of chemical engineering. An initiator and an epoxy compound undergo a polymerization reaction in the presence of a catalyst to produce the low-unsaturation degree, high-molecular weight and high-activity polyether polyol. In the polymerization reaction process, the epoxy compound and the catalyst are added into the reaction system by three steps and through the polymerization reaction, the low-unsaturation degree, high-molecular weight and high-activity polyether polyol is obtained. The low-unsaturation degree, high-molecular weight and high-activity polyether polyol has regular molecular weight distribution, low viscosity, a low unsaturation value and high activity. Compared with the universal soft-foam polyether polyol in the market, the low-unsaturation degree, high-molecular weight and high-activity polyether polyol can effectively improve foam resilience. The low-unsaturation degree, high-molecular weight and high-activity polyether polyol can be used for preparation of various molding foam and has the characteristics of high activity and short demolding time.

Owner:SHANDONG BLUSR DONGDA CHEM

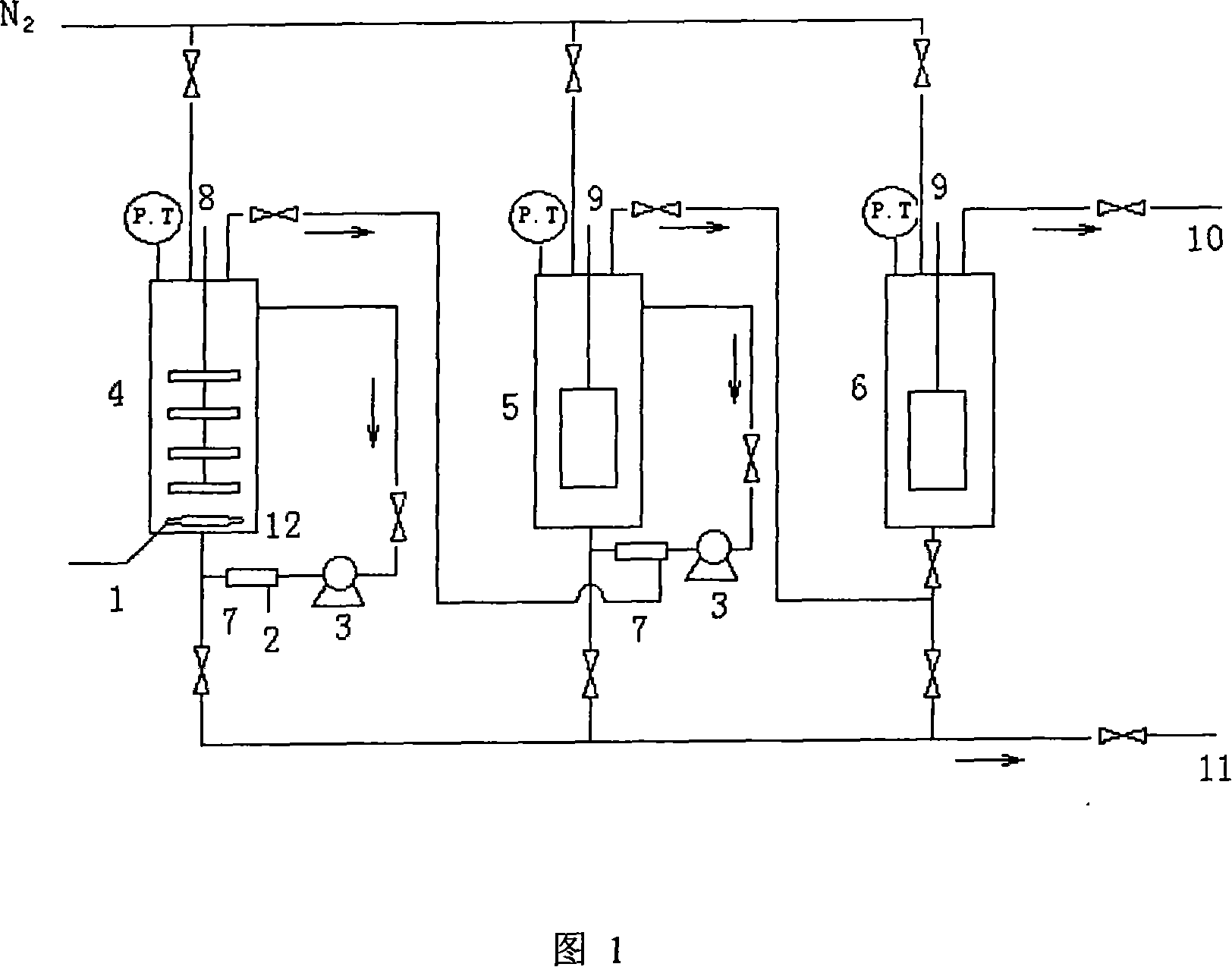

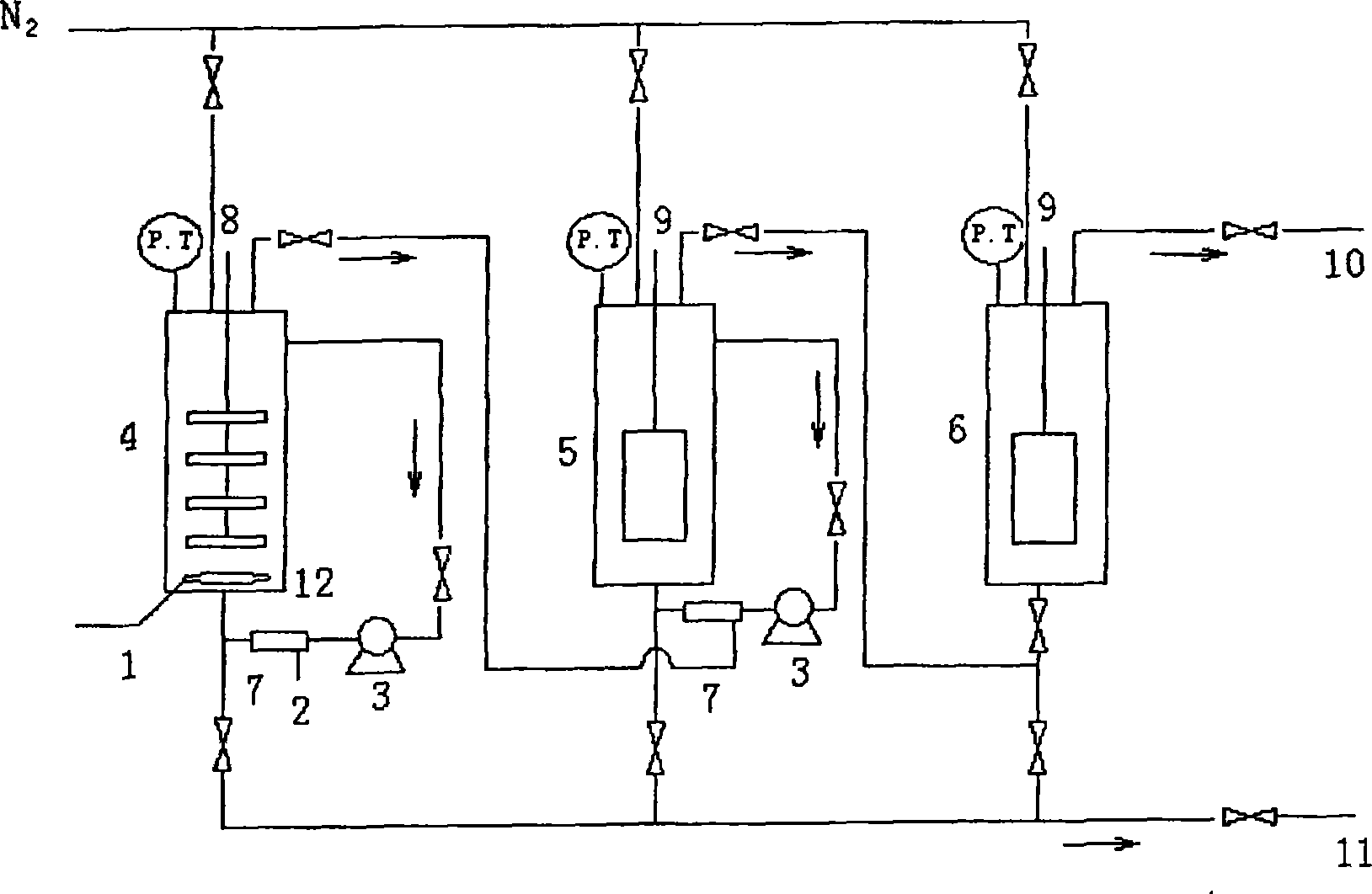

Continuous preparation method for polyether glycol

ActiveCN101121786ASimplified reaction systemNarrow molecular weight distributionDegree of unsaturationNitrogen gas

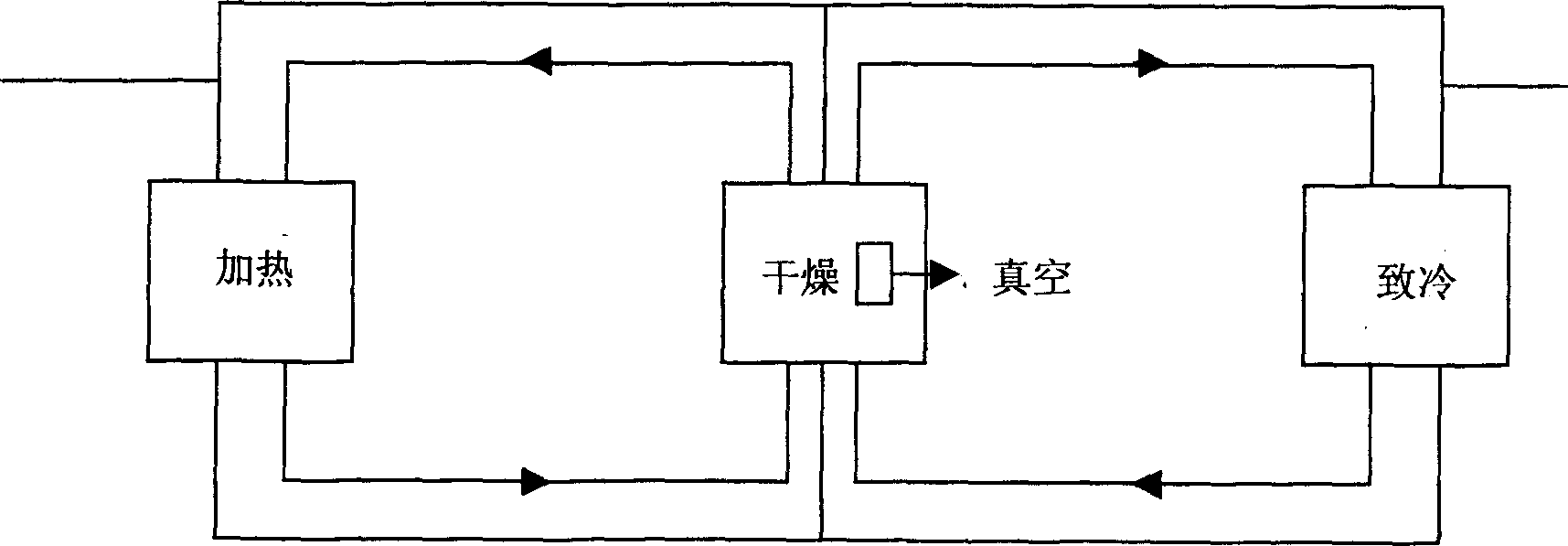

The invention is a continuous preparation method of the polyether polyol; the starting reagent containing the DMC catalyst is added into the reaction kettle; the air is removed with nitrogen; the method is to vacuum, stir, raise the temperature, and the epoxy compound is continuously added into the reaction kettle to make the reaction kettle have the inducing pressure; when the temperature is raised and the pressure is lowered in the reaction kettle, the epoxy compound is continued to to be added into the reaction kettle; the temperature is kept in the reaction between 90 and 200 Celsius system, the pressure between minus 0.05 and 1.0 MPa. Then the starting reagent containing the bimetallic cyanide catalyst and the epoxy compound are added into the reaction kettle according to the proportion at the same time. When the reaction kettle is full, the reaction materials flow into the aging kettle to continue to react; the temperature of the aging kettle is kept between 100 and 180 Celsius system. The polyether polyol product enters the product storage tank after being discharged out of the aging kettle. The polyether polyol produced in the method of the invention has the narrow molecular weight distribution, the low non-saturation degree and the stable quality; the method can use the polyether polyol of the low molecular weight as the starting reagent, and can also directly use the small-molecule polyol as the starting reagent.

Owner:江苏钟山新材料有限公司

Polyester ether polylol and its preparing method

The invention relates to a polyether ester polyhydric alcohol and the manufacturing method. The molecular main chain structure has ester group and ether linkage, and end radical or side radical is hydroxyl. And everage relative molecular weight is 500-9000, and average hydroxyl functionality is bwteen 1 and 4. The methdon includes the following steps: adding polyester polyhydric alcohol, bimetal cyanide complex compound catalyst into reaction kettle, heating to 60-130 degree centigrade, vaporizing to depriving water and other volatile constituents, taking mixture in ultrasonic mixer; adding part of oxyalkylene into the reaction kettle under condition of whisking, protecting by nitrogen gas and at 80-150 degree centigrade; depriving unreacted oxyalkylene to gain polyether ester polyhydric alcohol. The compound is mainly used to make polyurethane material.

Owner:QINGDAO UNIV OF SCI & TECH +1

Polyetherols produced using aluminium phosphonate catalysts

InactiveUS6919486B2Low unsaturationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsArylPolyol

A method for the production of polyetherols using aluminum phosphonate catalysts is disclosed. Reaction products of the process include various polyetherols including very low unsaturation polyether polyols. The aluminum phosphonate catalyst preferably has a general structure of RPO-(OAlR′R″)2, wherein O represents oxygen, P represents pentavalent phosphorous, Al represents aluminum, R comprises a hydrogen, an alkyl group, or an aryl group, and R′ and R″ independently comprise a halide, an alkyl group, an alkoxy group, an aryl group, or an aryloxy group. Polyols produced according to the disclosed procedure have properties very similar to or more beneficial than those produced utilizing the typical base catalysts.

Owner:BASF CORP

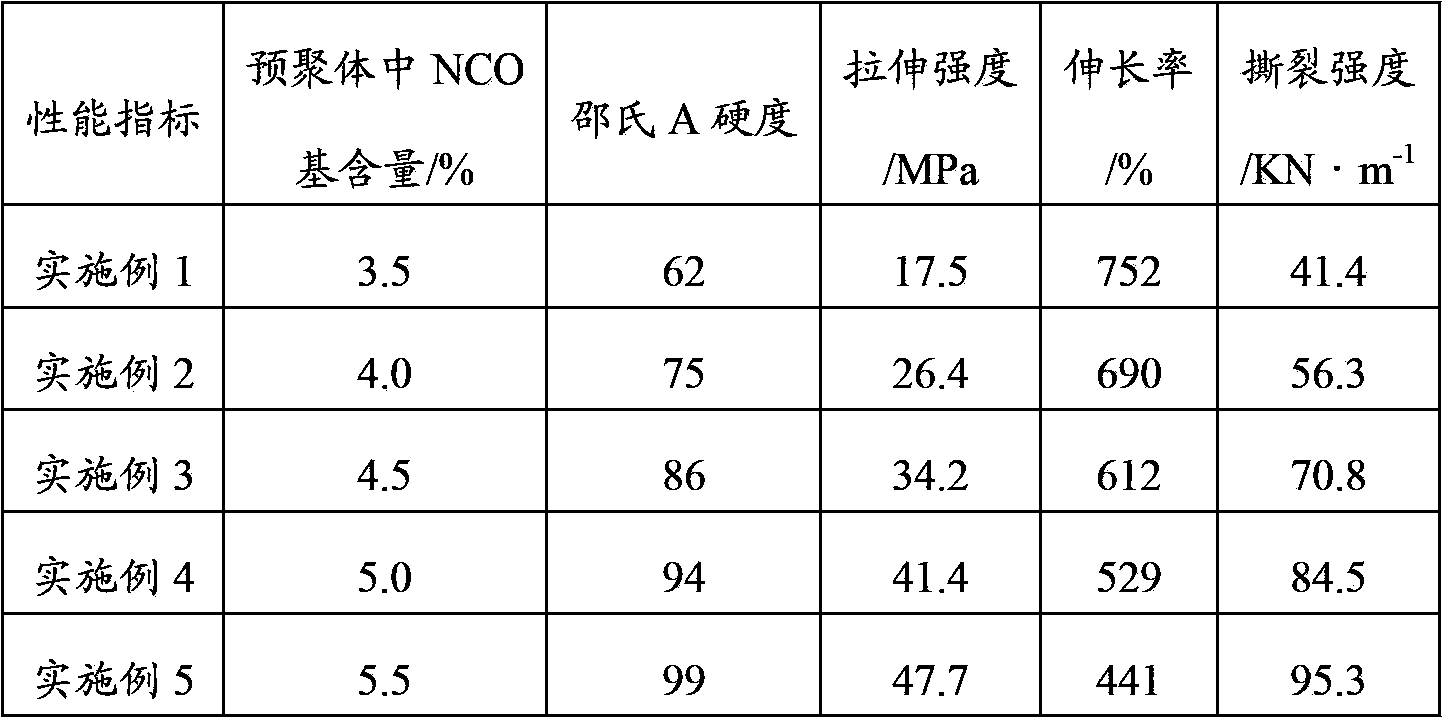

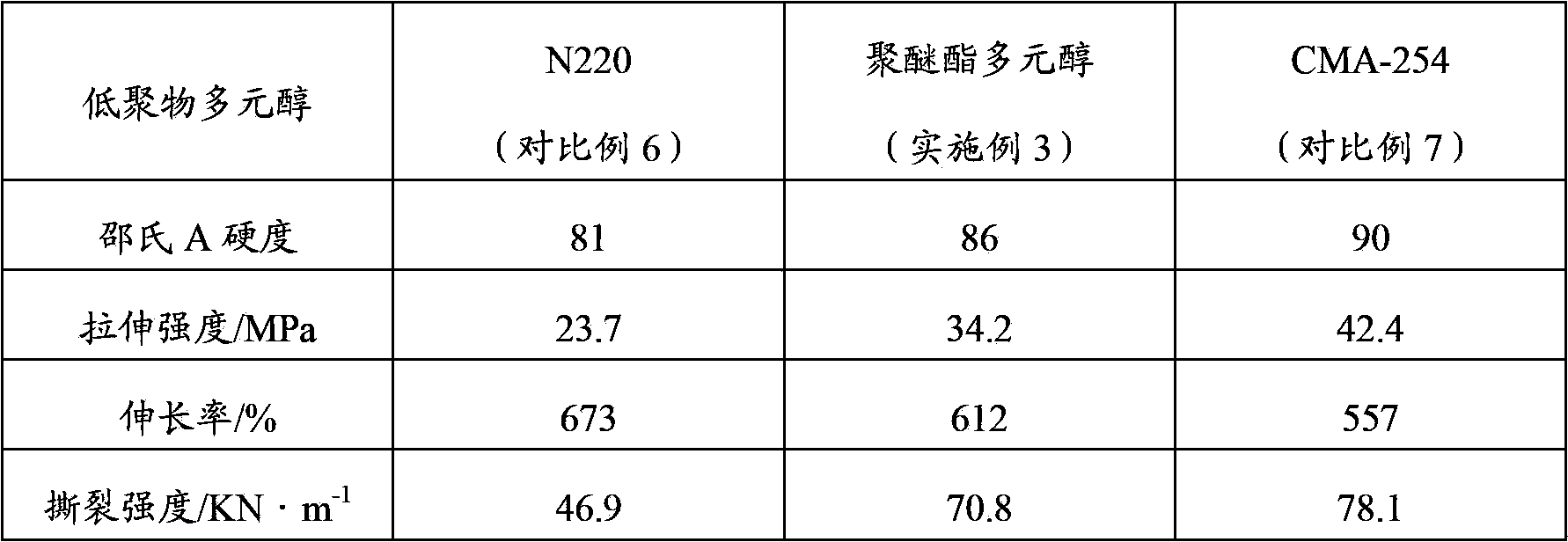

Polyether ester polyurethane elastomer and preparation method thereof

The present invention discloses a polyether ester polyurethane elastomer, which is prepared from the following components, by weight: 100 parts of polyether ester polyol, 8.5-13 parts of diisocyanate, and 10-19 parts of a chain extender. The invention further discloses a preparation method for the polyether ester polyurethane elastomer. According to the present invention, the novel polyether ester polyol is adopted as the raw material, and the polyether ester polyol has characteristics of low unsaturation degree, relatively narrow molecular weight distribution and the like, such that the prepared polyether ester polyurethane elastomer has better mechanical property compared with the polyether type PUE, has substantially increased hydrolysis resistance compared with the polyester type PUE, and further has excellent comprehensive performance and good application prospects.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Preparation method of polyether polyol

The invention relates to a preparation method of polyether polyol, which is mainly used for solving the problems that in the prior art, a polyether polyol product contains metallic elements and a catalyst is complicated to prepare. The preparation method of polyether polyol comprises the following steps: with a phosphine oxide compound as a catalyst, an epoxy compound as a raw material and an activated hydrogen compound as an initiator, reacting the catalyst with the epoxy compound under the conditions that a reaction temperature is 10-180 DEG C, a reaction pressure is not higher than 3.0 MPa and a reaction time is 0.1-50 hours to generate polyether polyol. The technical scheme is adopted to well solving the problem, and the preparation method can be used in the production of polyether polyol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Single reactors synthesis of KOH-capped polyols based on DMC-synthesized intermediates

ActiveCN1636989ALow unsaturationIncrease contentOrganic chemistryOther chemical processesElastomerEndcapping

The present invention relates to a process for the preparation of ethylene oxide (EO) capped polyanols in which it is not necessary to remove catalyst residues or salts formed by neutralization of base catalysts before discharging the polyol from the reactor, which is This is because the neutralization occurs during or after the starter filling of the next batch. The method of the present invention may allow the preparation of DMC-catalyzed intermediates and their base-catalyzed EO capping in the same reactor. The polyols prepared by the method of the present invention have a high content of primary hydroxyl groups, and they can be used to prepare polyurethane foams, elastomers, sealants, coatings, adhesives and the like.

Owner:BAYER MATERIALSCIENCE AG

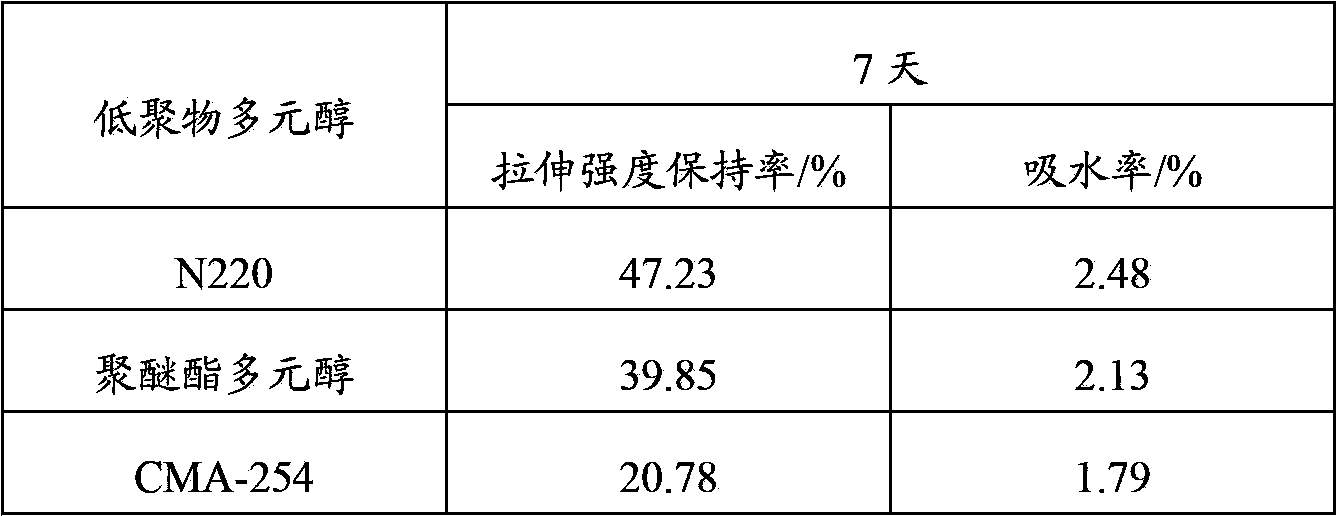

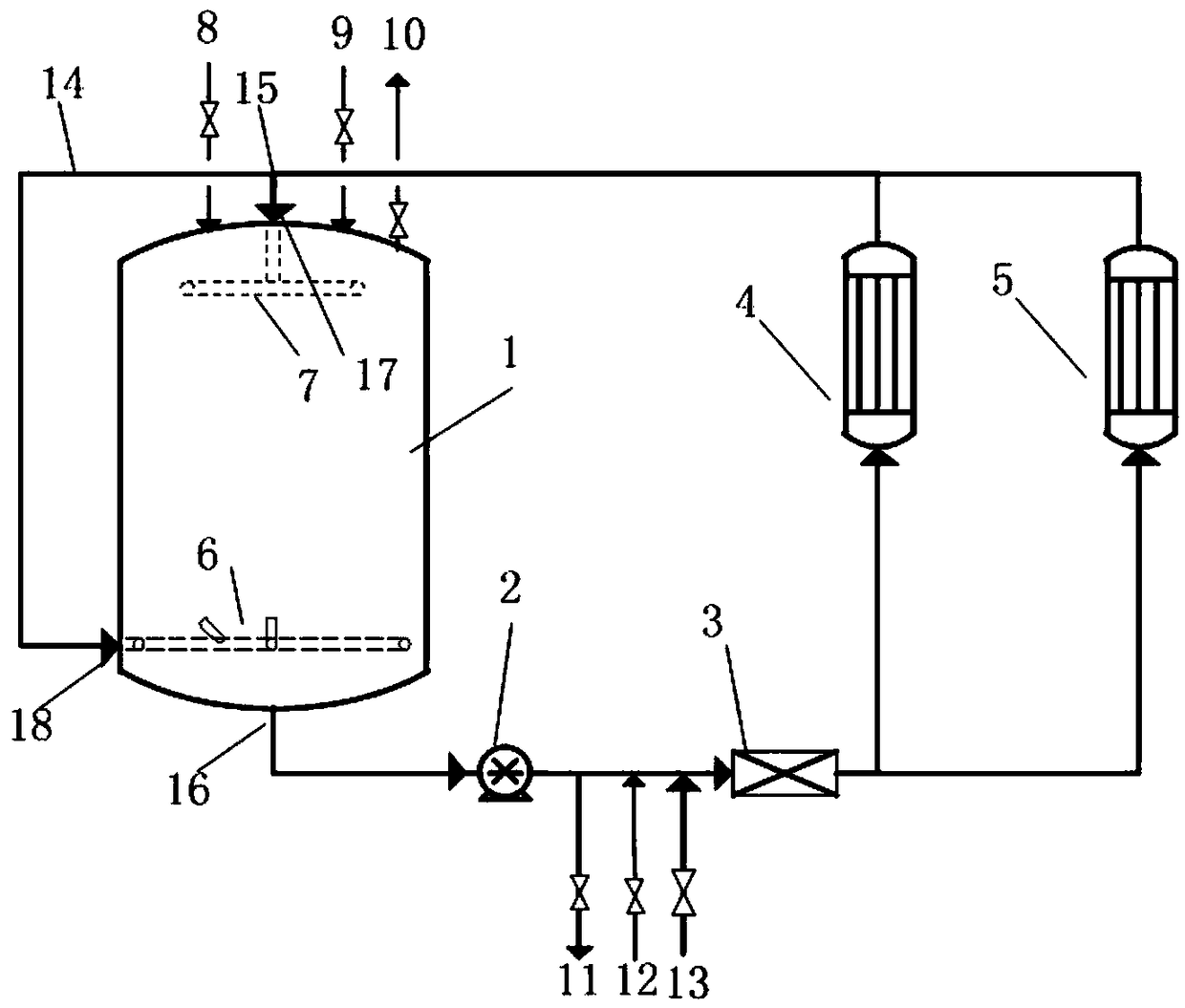

Reaction system and method for preparing polyether polyol

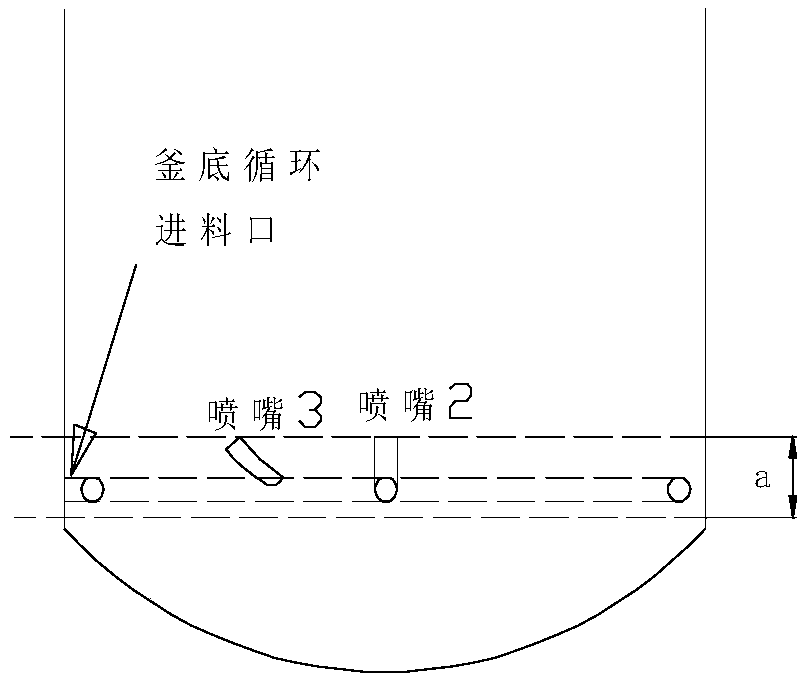

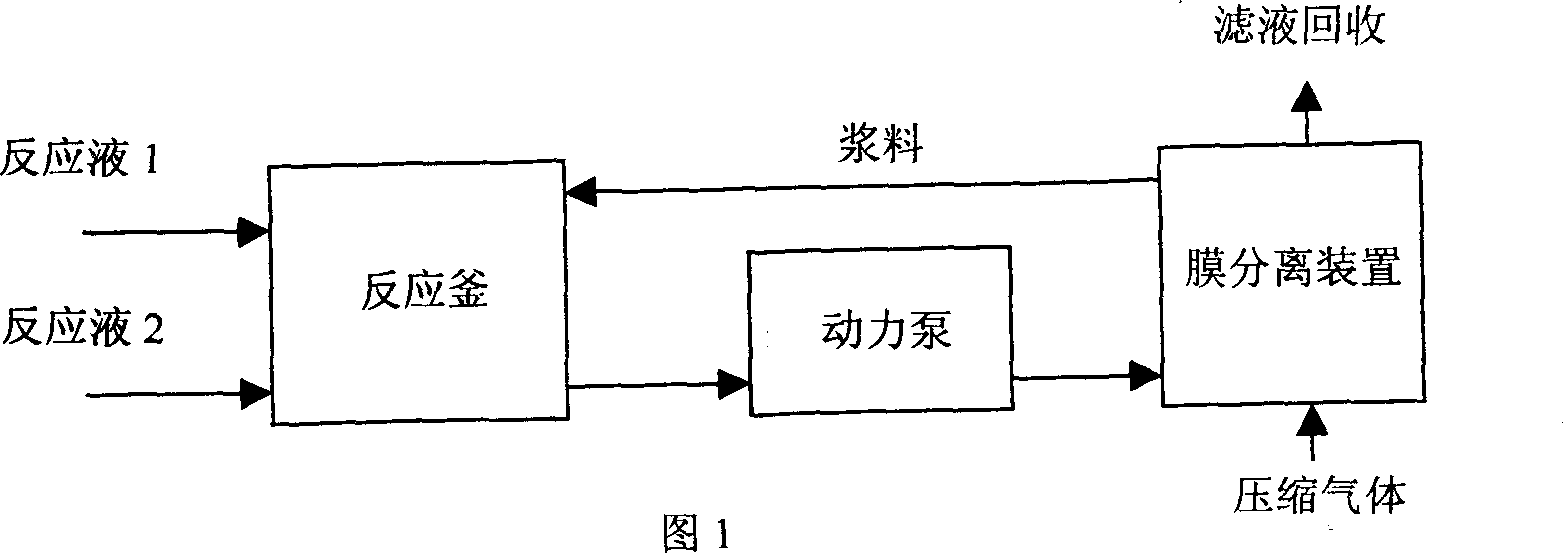

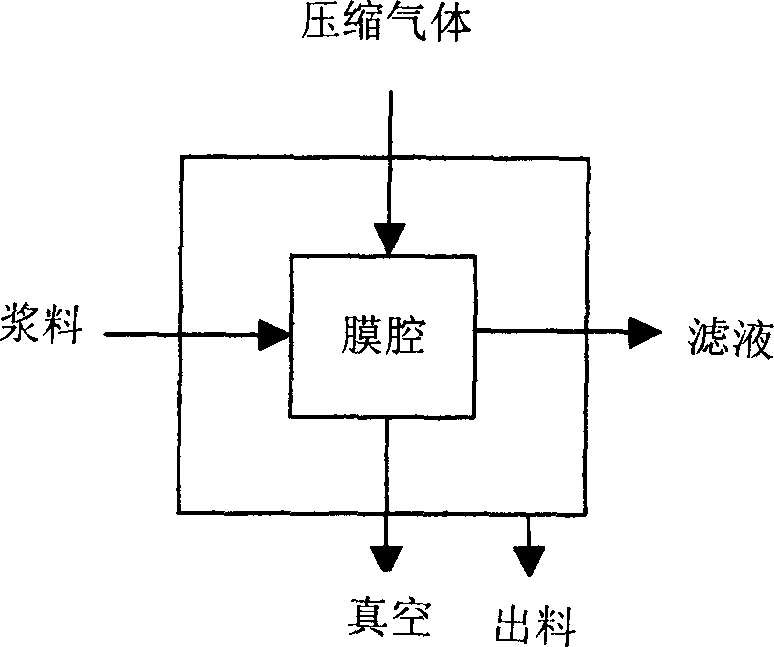

The invention discloses a reaction system and method for preparing polyether polyol. The reaction system comprises a reaction kettle main body and a static mixer, wherein a kettle top distributor anda kettle bottom liquid-phase jet mixer are mounted in a reaction kettle; preferably, the inner surface of the static mixer is sprayed with a Monel alloy doped with 1 to 1000 ppm of cerium oxide. A flow ratio of the kettle top distributor and the kettle bottom liquid-phase jet mixer in a reaction process is controlled, so that the gas-liquid mixing effect is enhanced, the impurity removal efficiency is improved and the reaction speed is increased; the problems of a current process of catalytically synthesizing the polyether polyol through alkali that the reaction period is long, the conversionrate of raw materials is low, more small molecular substances are remained in a product, the unsaturation degree is high and the molecular weight distribution is wide are solved; the production safetyis improved.

Owner:WANHUA CHEM GRP

Polyether polyol used for polyurethane single-component grouting materials and preparation method and application thereof

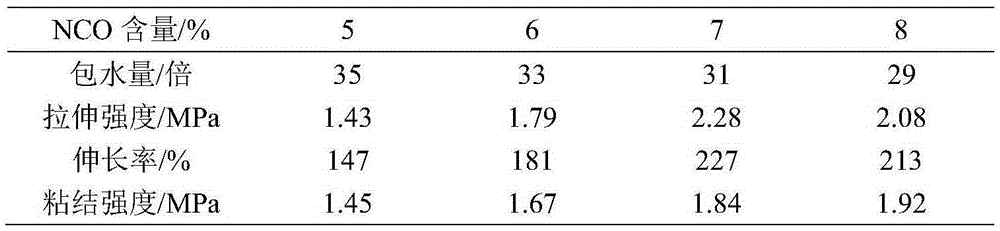

The invention relates to polyether polyol used for polyurethane single-component grouting materials and a preparation method and application thereof. The method mainly overcomes the defects that the water covering amount of polyether for original polyether grouting is small, and the strength of solidified bodies formed through reaction between polyether and water is low. The method includes the following steps that initiating agents and solid catalysts are input and mixed and are heated and dewatered after being evenly stirred, EO / PO is introduced, and aging is performed after material introduction ends; cooling is performed, water and neutralizers of phosphoric acid are added, neutralizing and stirring are performed, aluminum silicate adsorbents are added, low boiling matter and water in crude ether are removed through temperature raising vacuumizing, and finished products are obtained through press filtration after water content is analyzed to be qualified by central control analysis.

Owner:JIANGSU ZHONGSHAN CHEM

Process for continuously preparing double metal cyanide complex catalyst

InactiveCN1457928AHigh yieldThe process takes a short timeOrganic-compounds/hydrides/coordination-complexes catalystsCyanidePolyol

The continuous process of preparing double metal cyanide catalyst includes the steps of: mixing reaction of the materials, filtering and washing, replacement of water, concentration and addition of functional polymer. The catalyst is used in synthesis of polyether polyol and has high reaction activity and short inducing period. The prepared polyether polyol has very low unsaturation degree. The present invention has a technological period within 36 hr.

Owner:SINOPEC JINLING PETROCHEMICAL CO LTD

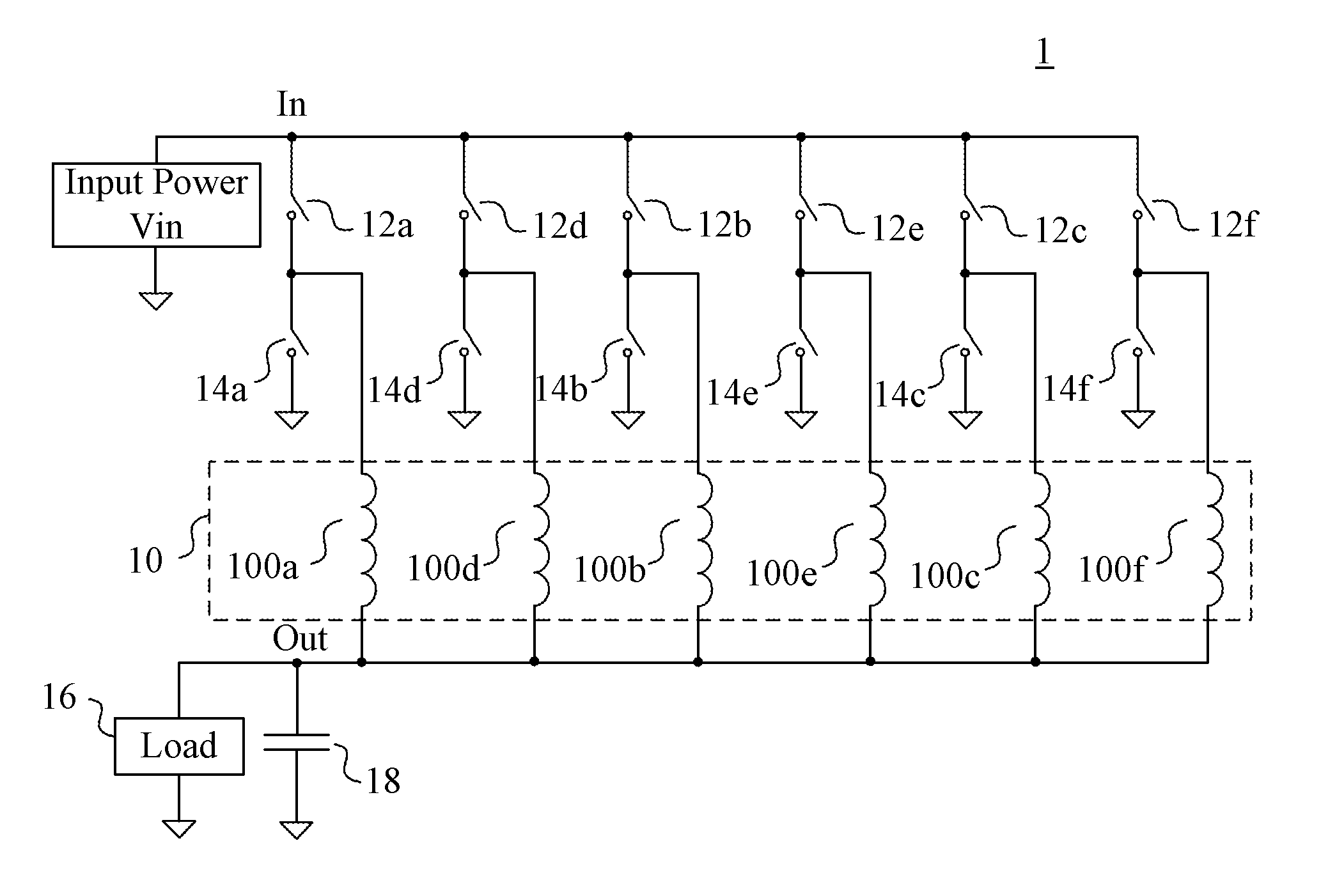

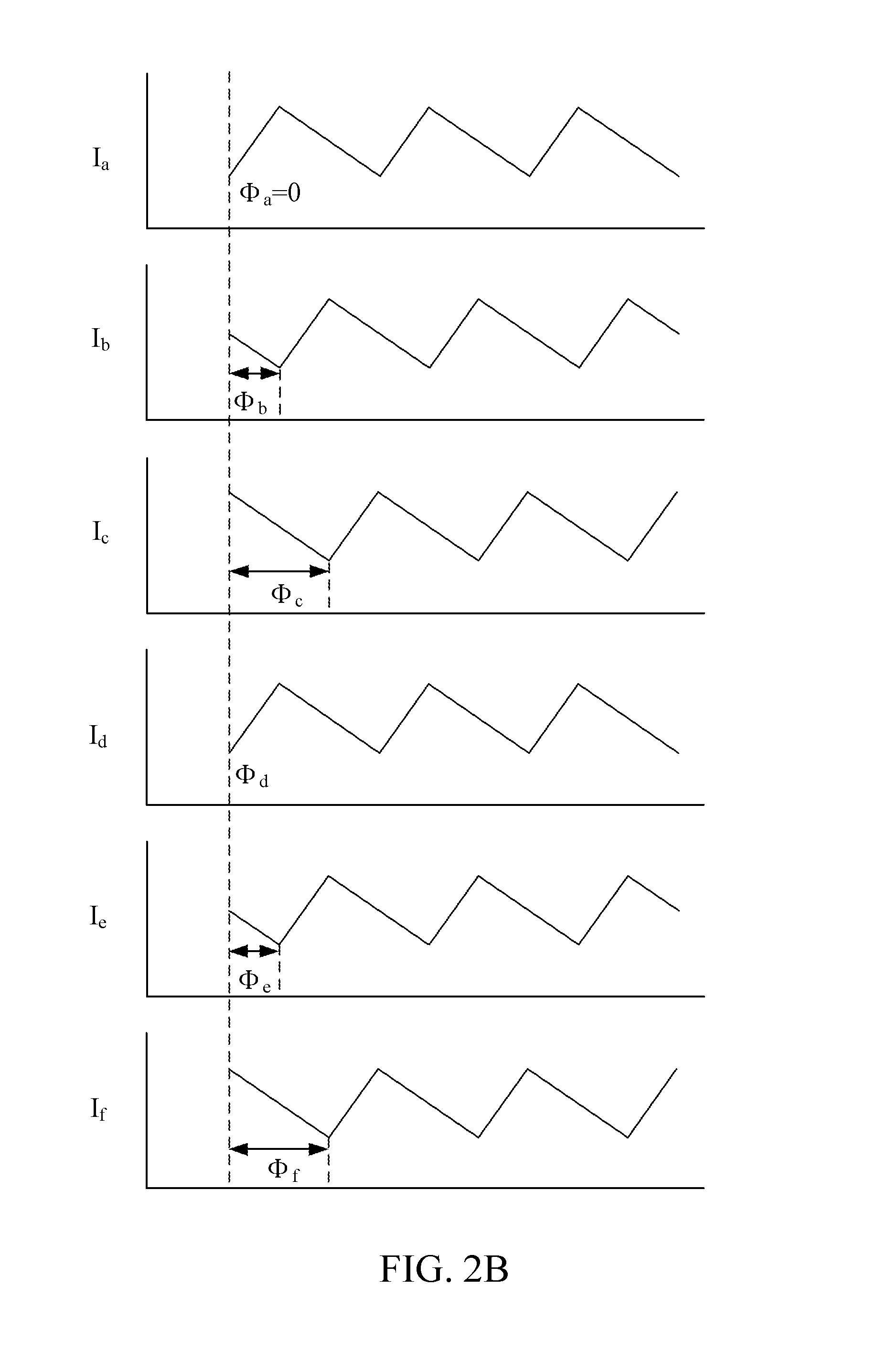

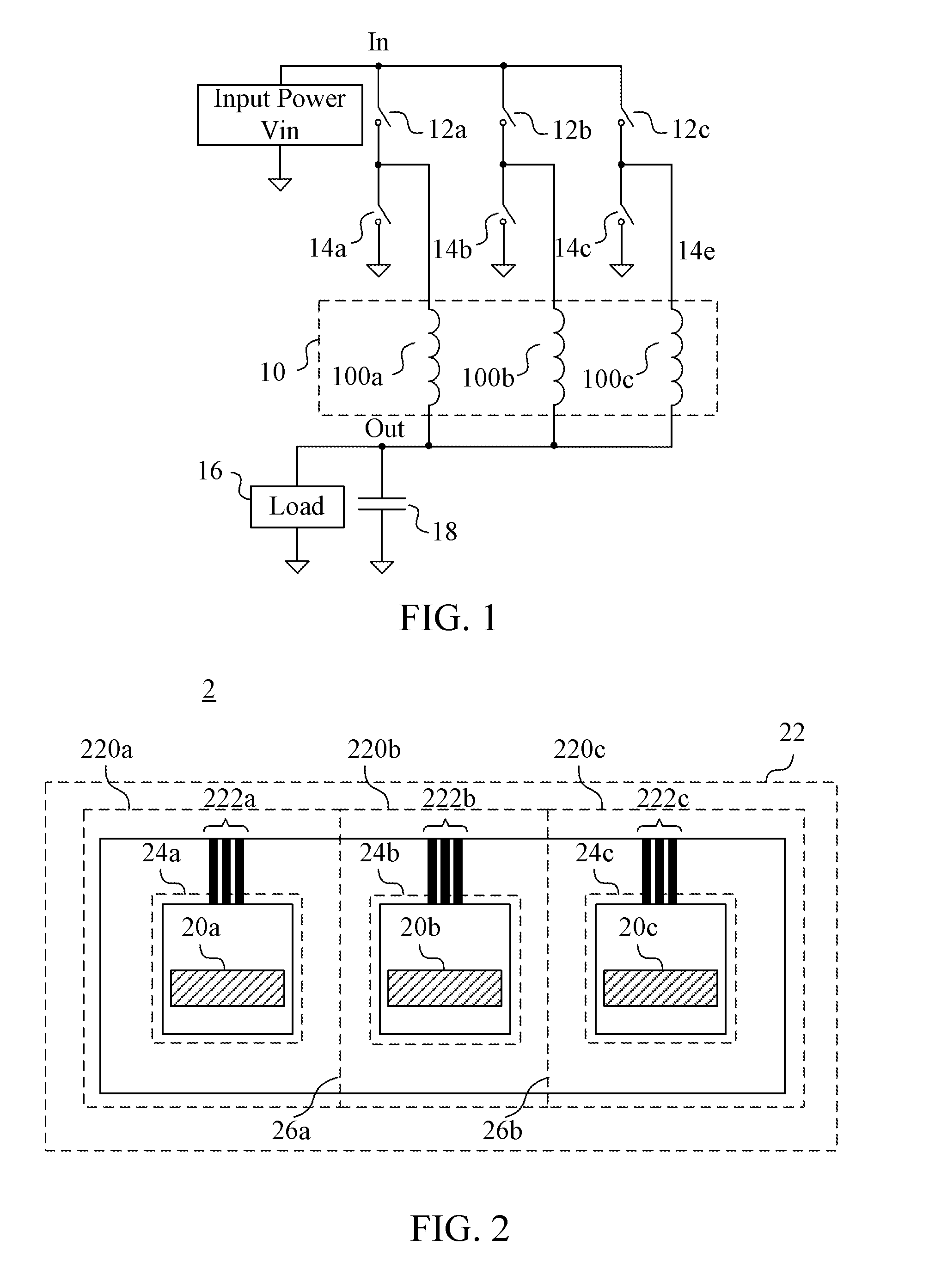

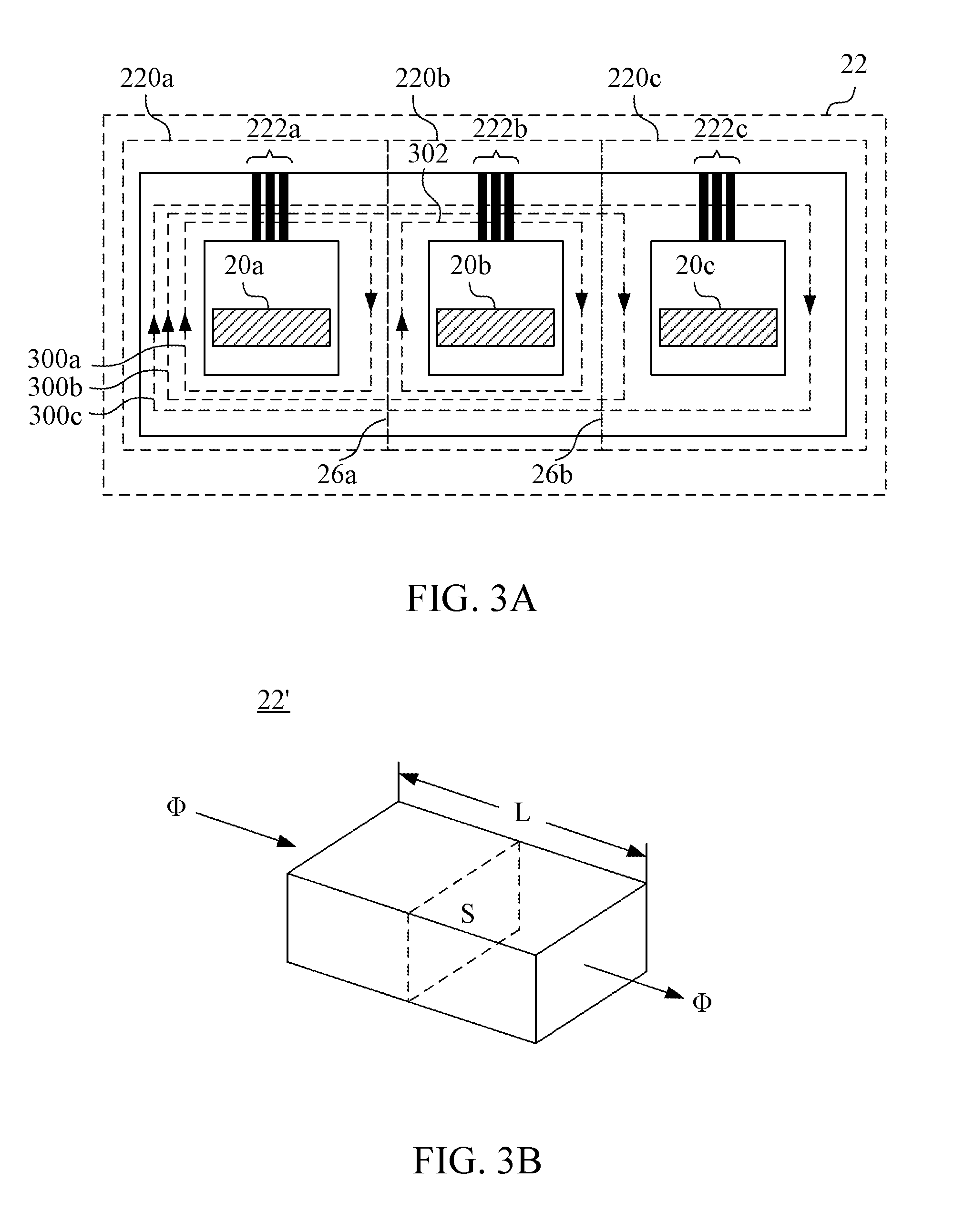

Power converter and device integrating inductors in parallel of the same

ActiveUS20160300658A1Reduce generationReduce lossTransformers/inductances coils/windings/connectionsApparatus without intermediate ac conversionInductorMagnetic core

A device is provided that integrates a plurality of inductors in parallel. The device includes a plurality of windings and a magnetic core structure. A number of the windings corresponds to a number of the inductors. The magnetic core structure includes a plurality of windows, wherein each window includes at least two windings coupled with each other. When a phase difference of the voltage phases is smaller than a predetermined value, voltage phases of two terminals of any two of the windings within the same window are substantially the same.

Owner:DELTA ELECTRONICS INC

Continuous preparation method for polyether glycol

The invention is a continuous preparation method of the polyether polyol; the starting reagent containing the DMC catalyst is added into the reaction kettle; the air is removed with nitrogen; the method is to vacuum, stir, raise the temperature, and the epoxy compound is continuously added into the reaction kettle to make the reaction kettle have the inducing pressure; when the temperature is raised and the pressure is lowered in the reaction kettle, the epoxy compound is continued to to be added into the reaction kettle; the temperature is kept in the reaction between 90 and 200 Celsius system, the pressure between minus 0.05 and 1.0 MPa. Then the starting reagent containing the bimetallic cyanide catalyst and the epoxy compound are added into the reaction kettle according to the proportion at the same time. When the reaction kettle is full, the reaction materials flow into the aging kettle to continue to react; the temperature of the aging kettle is kept between 100 and 180 Celsius system. The polyether polyol product enters the product storage tank after being discharged out of the aging kettle. The polyether polyol produced in the method of the invention has the narrow molecular weight distribution, the low non-saturation degree and the stable quality; the method can use the polyether polyol of the low molecular weight as the starting reagent, and can also directly use the small-molecule polyol as the starting reagent.

Owner:江苏钟山新材料有限公司

Preparation method of polyether polyol used for water-soluble polyurethane grouting materials

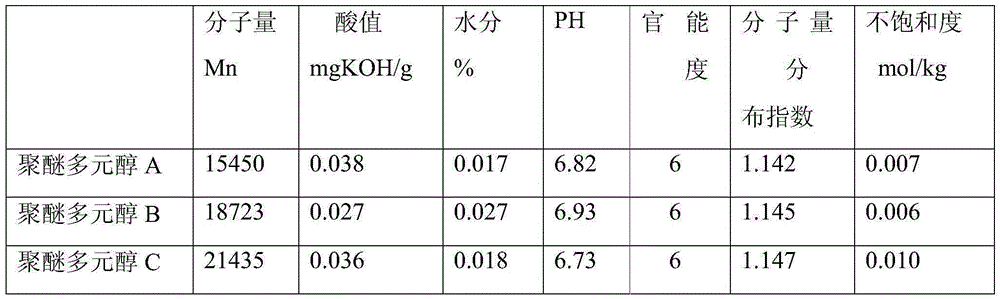

The invention belongs to the technical field of polyether polyol synthesis and particularly relates to a preparation method of polyether polyol used for water-soluble polyurethane grouting materials. A front-segment polymerization reaction includes the steps that firstly, neosorb, an alkali metal catalyst and solvent are added into a reaction kettle, and a midbody polyether polyol is obtained; a rear-segment polymerization reaction includes the steps that the midbody polyether polyol is taken and placed into a reaction kettle, epoxide is dropwise added to the midbody polyether polyol continuously, and the polyether polyol is obtained. The degree of functionality of the obtained polyether is 6, and the molecular weight is 15000-22000. After the polyether which is high in degree of functionality, super high in molecular weight and low in degree of unsaturation is made into the water-soluble polyurethane grouting materials, higher water efficiency and strength are achieved. In an overall polymerization reaction, the ethylene oxide accounts for 50-90% of total epoxide, the activity of the polyether can be improved, and a higher solid water speed is achieved in the obtained water-soluble polyurethane grouting materials.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Continuous process for preparation of polyether polyols

A continuous process for preparation of a polyether polyol in a reactor includes introducing an initial starter / catalyst mixture into the reactor. The initial starter / catalyst mixture comprises an initial starter and a catalyst with the catalyst selected from aluminum phosphate catalysts and / or aluminum phosphonate catalysts and / or residues of these catalysts. In this continuous process, one or more alkylene oxide is continuously introduced into the reactor. Additional amounts of the catalyst and a continuous starter are also continuously introduced into the reactor. The polyether polyol prepared herein is continuously withdrawn from the reactor.

Owner:BASF CORP

Process for rapid activation of double metal cyanide catalysts

The invention discloses a method for activating double metal cyanide catalysts. The polyol feedstock or polyol feedstock / catalyst mixture is heated under vacuum under conditions effective to achieve improved stripping over that achievable by conventional vacuum stripping methods. Combining vacuum stripping with an inert gas purge or stripping in the presence of an organic solvent results in a feedstock / catalyst mixture that is usually rapidly activated in epoxide polymerization. Rapid activation results in more reliable starts and reduces cycle times. The polyols obtained by this process have lower viscosity, lower polydispersity and lower unsaturation for better polyurethanes.

Owner:科思创股份有限公司

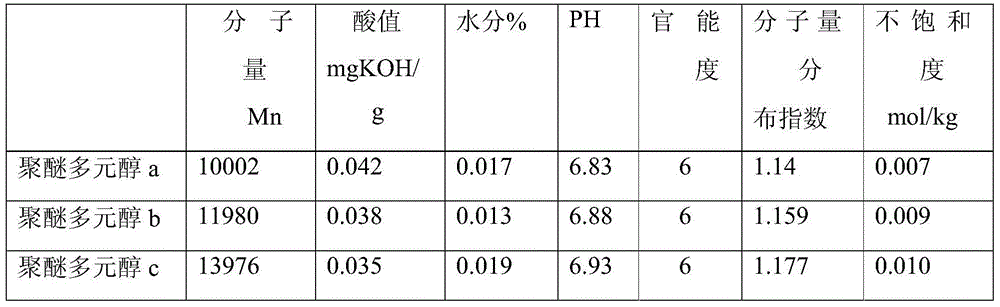

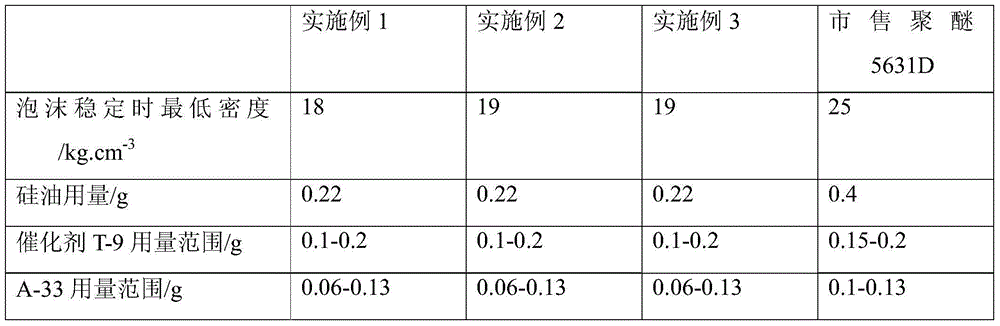

Preparation method for flexible foam polyether polyol for low-density sponge

InactiveCN104403095AOvercoming the problem of inactivation at the late stage of the reactionExcellent operating latitudePolyol synthesisLow density

The invention belongs to the field of polyether polyol synthesis technologies, and particularly relates to a preparation method for flexible foam polyether polyol for low-density sponge. Only neosorb is used as an initiator, and the polyether polyol is prepared through the two-stage polymerization technique. The preparation method provided by the invention has the advantages that the degree of functionality of the prepared polyether polyol reaches 6, the molecular weight of the prepared polyether polyol can reach between 10,000 and 14,000, and the prepared polyether polyol has the characteristics of low degree of unsaturation and narrow molecular weight distribution, so as to solve the problem of subsequent reaction inactivation of conventional catalysts; moreover, compared with the traditional polyether polyol used for low-density sponge products, the polyether polyol prepared through the invention achieves a lower density as well as higher operation tolerance, dimensional stability, flexibility and the like, so that the application range is wider, and the application requirement for high-quality low-density sponge is met.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

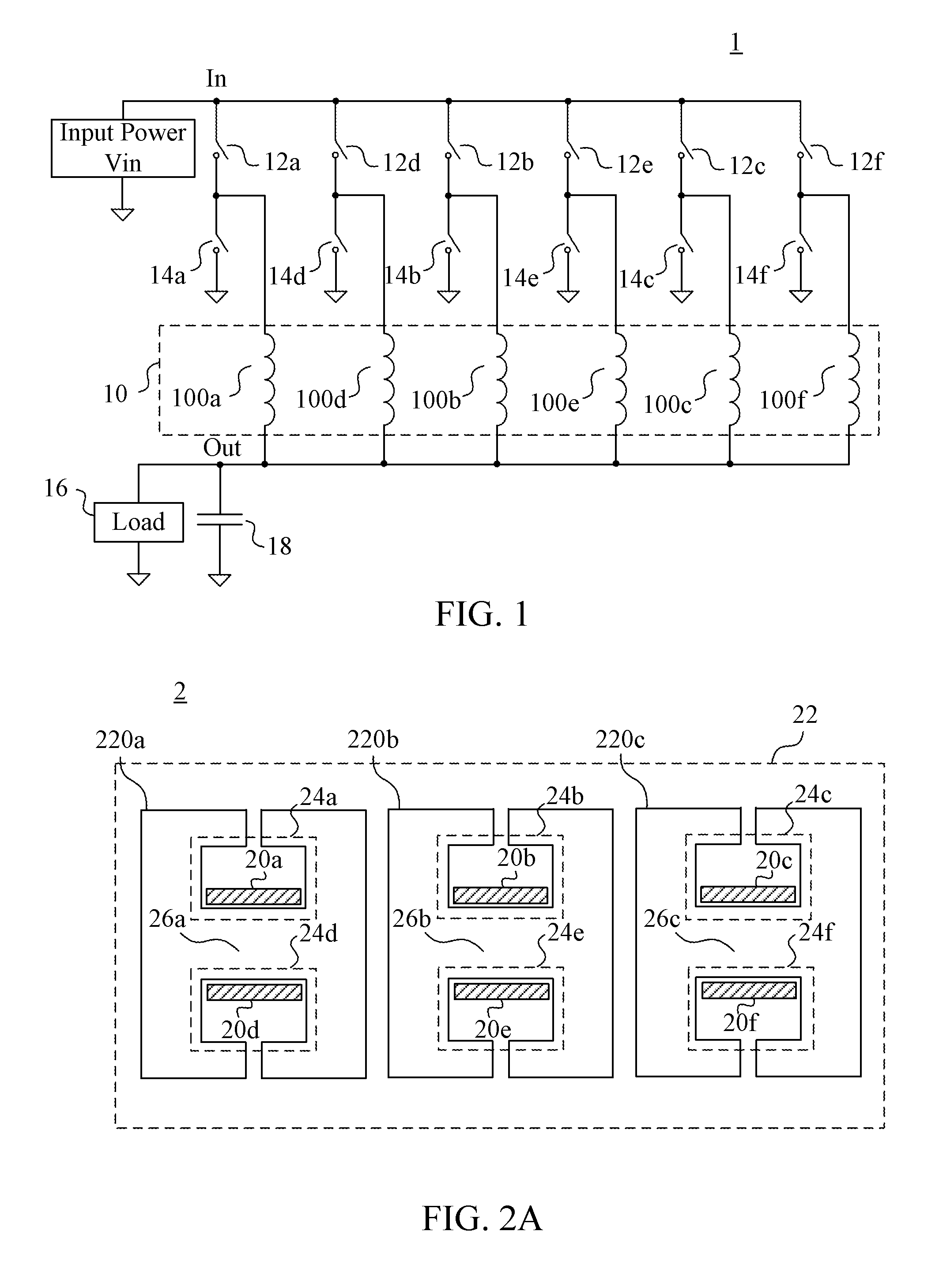

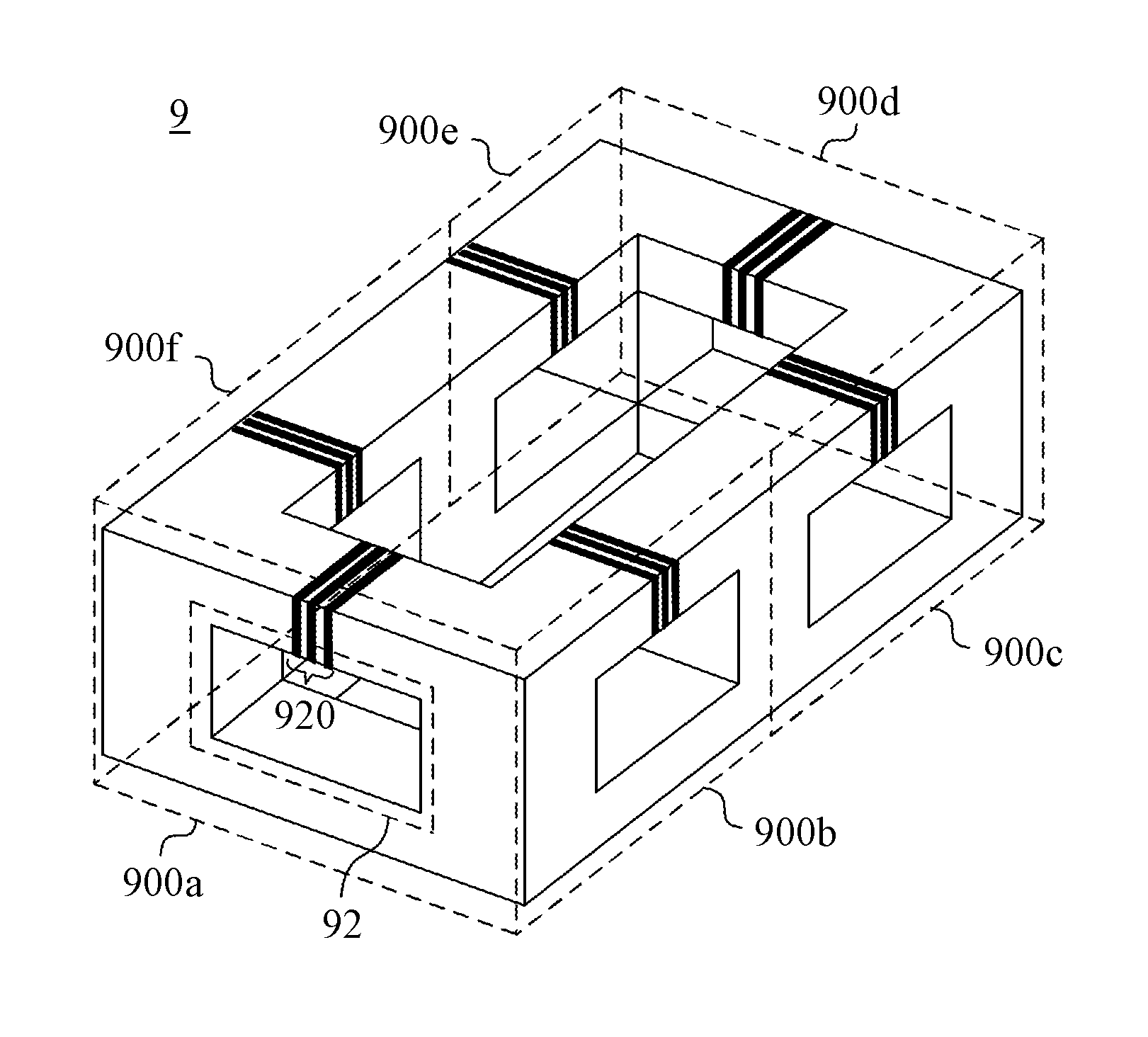

Integrated inductor and integrated inductor magnetic core of the same

ActiveUS20160300657A1Reduce generationReduce lossTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresInductor windingsMagnetic reluctance

An integrated inductor apparatus integrated to be a plurality of inductors is provided. The integrated inductor apparatus includes inductor windings to form inductors and includes at least two windows each having at least one of the inductor windings disposed therein and magnetic core units, each having a closed geometrical structure to form one of the at least two windows, wherein two of the neighboring magnetic core units have a shared magnetic core part. The magnetic core units comprise at least two kinds of material having different magnetic permeability corresponding to different sections of the magnetic core units, wherein the reluctance of the shared magnetic core part is smaller than the reluctance of a non-shared magnetic core part of the magnetic core units.

Owner:DELTA ELECTRONICS INC

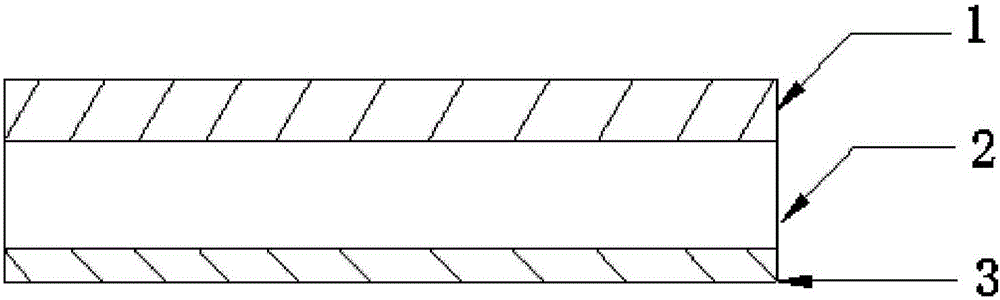

Disposable hygroscopic article

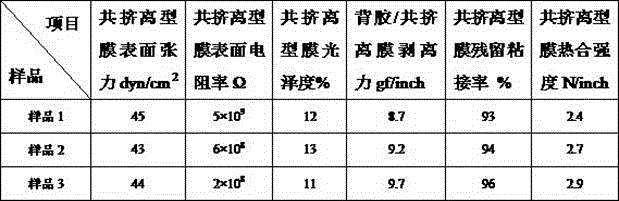

ActiveCN106832538AWith mattingAntistaticPersonal careSynthetic resin layered productsPolyolefinAdhesive

The invention discloses a disposable hygroscopic article, which comprises a liquid-permeable top layer, an absorption core body, a liquid-impermeable bottom layer and a multi-layer coextruded composite release film from top to bottom, wherein the multi-layer coextruded composite release film comprises a surface layer (1), a core layer (2) and a release layer (3). The disposable hygroscopic article is characterized in that the surface layer (1) is prepared from matting resin and polyolefin resin A; the core layer (2) is prepared from a filling material, polyolefin resin B and a thermoplastic elastomer; the release layer (3) is prepared from alpha-olefin polymer resin produced by metallocene, C4 to C14 polyolefin resin produced by a Z-N catalyst and fluorosilicon resin. The surface layer (1) of the multi-layer coextruded composite release film has the surface wetting tension not less than 38dyn / cm<2>, the surface electrical resistivity not less than 10<10>omega and the glossiness less than 15 percent; the release layer has the stripping force of 8.0gf / inch to 18gf / inch, the release residual adhesion rate not less than 90 percent and the heat bonding strength not less than 1.5N / inch. Compared with the prior art, the multi-layer coextruded composite release film has matting, antistatic and release anti-adhesion effects; further, the viscosity loss or the adhesive transfer of a back adhesive of a hygienic article can be effectively prevented.

Owner:FUJIAN HENGAN HLDG CO LTD +2

Catalyst of manganese cobalt hexacyanide complex, its preparation and usage

InactiveCN1631540AReduce smearingLow viscosityOrganic-compounds/hydrides/coordination-complexes catalystsManganeseEther

The invention concerns the catalyst using 6-H-Gu-Mn as the framework, and its producing way and application in gathering ether. The catalyst is synthesized by water dissolved Mn salt, 6H-Gu acid (salt), organic match thing, organic functions compound and polymer. The gathering ether made by this way , has the features of fewer high numerator tail, low glue degree, the gathering ether compounded at high temperature has low degree of not saturation, narrow distributing of numerator.

Owner:LIMING RES INST OF CHEM IND

Cyanide complex catalyst, and its preparing method and use

InactiveCN1640544AImprove performanceThe synthesis process is stableOrganic-compounds/hydrides/coordination-complexes catalystsKetoneCarboxylic acid

The present invention relates to a cyanide complex compound catalyst, its preparation method and application in polyether. Said catalyst is made up by means of common coordination of three ligands of organics small molecule, functional compound and functional polymer which are introduced into cyanide complex compound. Said organic small molecule ligand is one or several kinds of alcohol, ether, aldehyde, ketone, ester or acidamine, its molecular weight is less than 200; the functional compound is aromatic carboxylic acid ester compound, its molecular weight is less than 500, and the functional polymer is macromolecular compound containing oxygen, nitrogen, phosphorus and sulfur, and its molecular weight is greater than 500.

Owner:LIMING RES INST OF CHEM IND

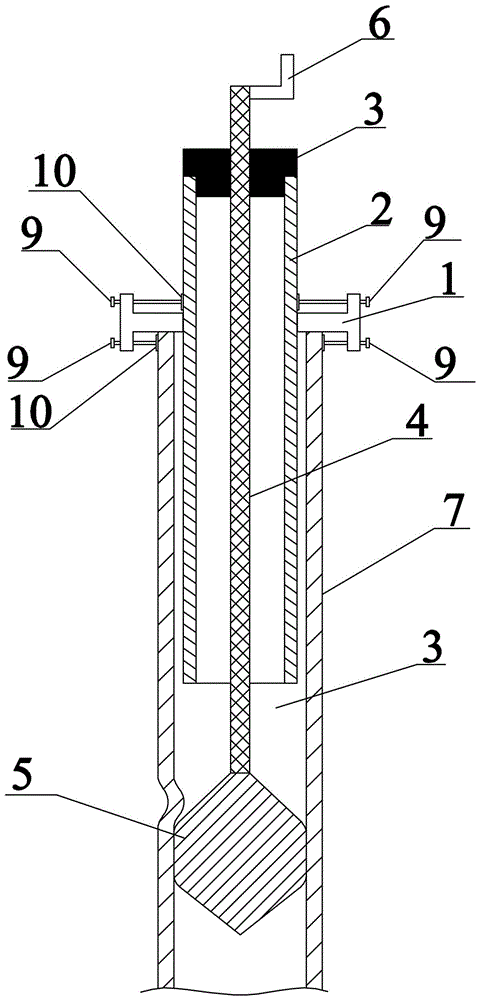

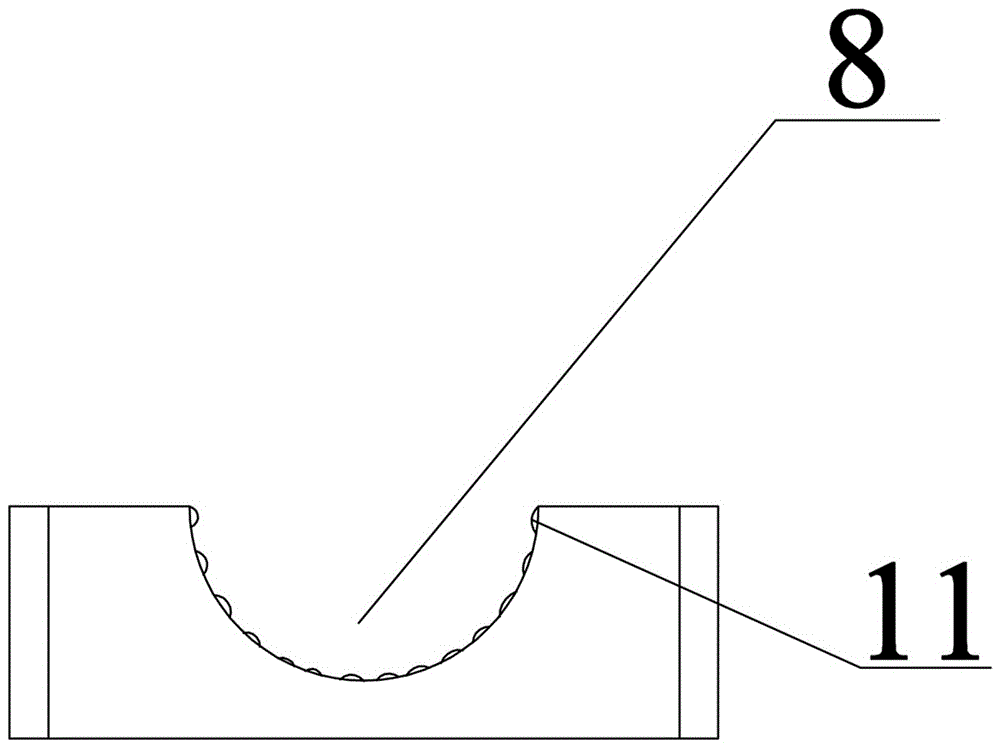

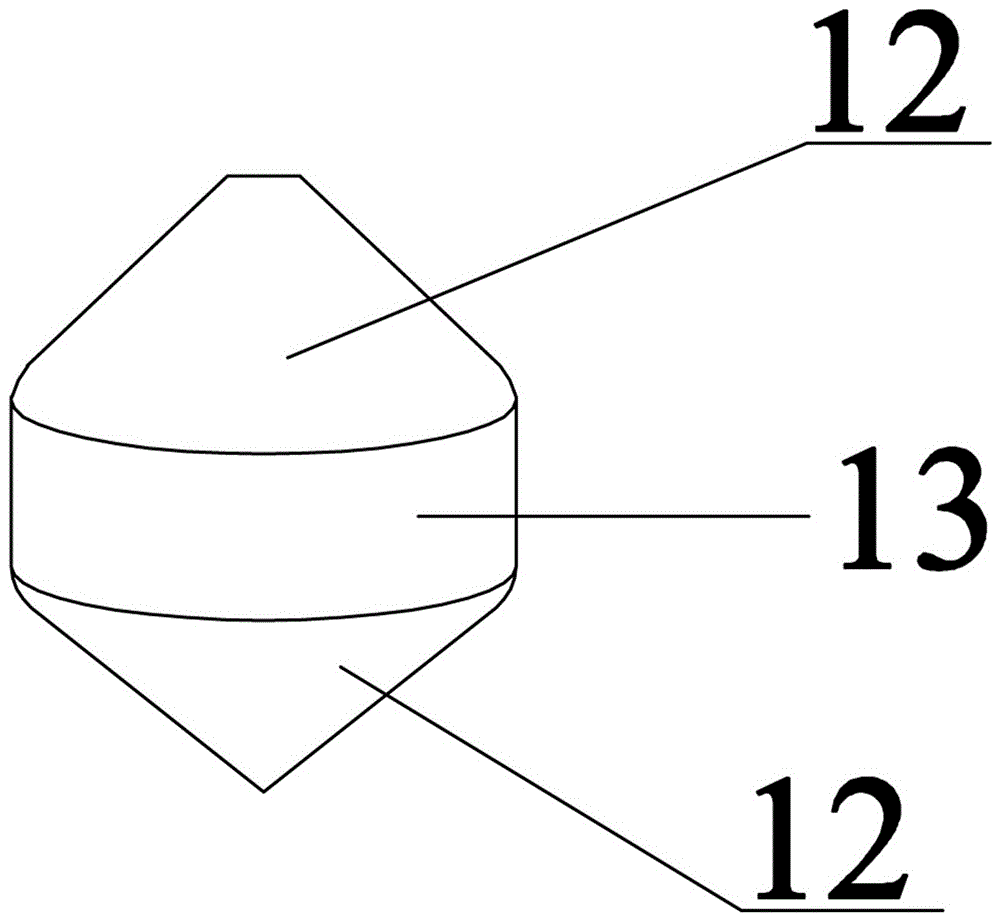

Squashed cable duct repairing device

The invention discloses a squashed cable duct repairing device. The squashed cable duct repairing device comprises a fixed seat, a support pipe, a seal cover, a rotary rod, a repairing head and a shaking handle. The fixed seat is arranged outside a cable duct. One side face of the fixed seat makes contact with a port of the cable duct. The upper end face of the fixed seat is in the shape of an I. The middle of the upper end face of the fixed seat is provided with a semicircular groove matched with the support pipe. The two sides of the fixed seat are each provided with two radial jacking wires. Tooth plates are arranged at the ends of the jacking wires correspondingly. The support pipe is located in the cable duct, and the center lines of the support pipe and the cable duct coincide. The seal cover is arranged at one end of the support pipe. The center of the seal cover is provided with a threaded hole. The rotary rod is provided with an outer thread matched with the threaded hole. The rotary rod penetrates through the seal cover and is coaxial with the support pipe. The shaking handle is arranged at the end, provided with the thread, of the rotary rod. The repairing head matched with the cable duct is arranged at the other end of the rotary rod. The squashed cable duct repairing device is simple in structure, simple, convenient and flexible to operate, deformation is not liable to occur to the cable duct, the impact resistance is good, and repairing is easy to be conduct after squashing.

Owner:NANYANG POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

Double metal cyanide catalysts for producing polyether polyols

The invention relates to a double metal cyanide catalysts for producing polyether polyols, wherein the catalyst composition comprises bimetallic cyanide mixture, C4-C10 organic alcohol having a tertiary alcohol structure and selected from silicon acid esters, the catalyst can be applied into the industrial production of polyether polyols.

Owner:CHINA PETROLEUM & CHEM CORP +1

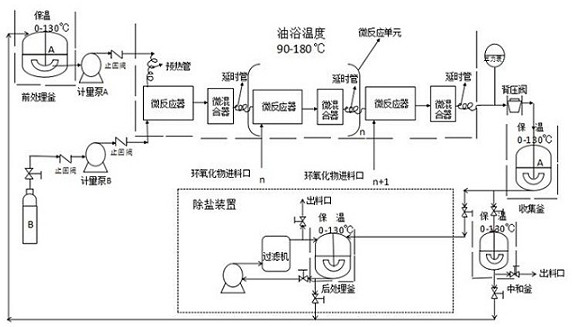

Method for continuously producing high-molecular-weight polyether by adopting micro-channel reactor

InactiveCN111925514AImprove securitySolve heat transferChemical/physical/physico-chemical microreactorsMicroreactorReactor system

The invention relates to a method for producing high-molecular-weight polyether by adopting a micro-channel reactor. The method adopts a micro-reactor, a micro-mixer, a pretreatment kettle, a preheating pipe, a delay pipe, a metering pump A, a metering pump B, an epoxy compound storage tank B, a collection kettle, a neutralization kettle, a desalting device, a post-treatment kettle, a back pressure valve and a pressure gauge. The micro-reactor is provided with a plurality of micro-channels, two micro-reactor feed ports and a micro-reactor discharge port; the micro-reactor, the micro-mixer andthe delay pipe form a micro-reaction unit; the desalting device comprises a post-treatment kettle and a filtering machine; and the pressure gauge is arranged between the micro-mixer and the back pressure valve. The method is advanced and scientific, the micro-reactor system adopted in the method is rapid and uniform in mixing, the over-temperature phenomenon is avoided, side reactions are reduced,low-unsaturation-degree and high-molecular-weight polyether can be continuously produced, direct large-scale production can be achieved, and the method has high safety performance and is suitable forindustrial production.

Owner:XIHUA UNIV

Multi-metal cyanide complex catalyst

The invention relates to a polymetallic cyanide complex catalyst for ring opening polymerization of oxyalkylene, mainly aiming at resolving the problems existing in the prior technique that the activity of a catalyst is not enough and the catalyst needs relatively long induction period to acquire higher activity. In the invention, the technical proposal which better resolves the problems is as follows: the catalyst comprises one or a plurality of metallic cyanide complexes, a C4 to C10 organic alcohol with an tertiary alcohol structure and an organic ligand selected from aliphatic ester, aromatic monoester or aromatic diester and a mixture of the aromatic monoester and the aromatic diester. The catalyst has the advantages of no induction period and high activity, and is applied to the industrial preparation of unsaturated polyether polyols by the ring opening polymerization of the oxyalkylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of low-odor polyether polyol

ActiveCN110790916AReduce the content of metal ionsLow monoalcohol contentPolymer adsorptionEpoxide Compound

The invention relates to a preparation method of low-odor polyether polyol, which comprises the following steps: 1) adding an initiator and a catalyst into a reaction kettle, adding an azeotropic solvent, removing water in the system in an azeotropy manner, and continuing heating to remove the azeotropic solvent in the system; 2) introducing an epoxy compound, preferably propylene oxide or ethylene oxide, at the temperature of 80-140 DEG C, preferably 90-120 DEG C, firstly adding 5%-10% of the total amount of the epoxy compound at a time for prepolymerization, and reacting to generate polyether polyol a; 3) when the reaction gauge pressure is lower than 0.05 MPa, adding a radical initiator under the protection of nitrogen, and uniformly stirring; 4) continuing to introduce the epoxy compound, and continuing to perform polymerization reaction to obtain crude polyether. The preparation method provided by the invention can effectively reduce the unsaturation degree of polyether, adopts astrongly acidic polymer to adsorb alkali metal ions, avoids conventionally used acid neutralization and filtration processes, can obtain an extremely low metal content, reduces odor, and is low in production cost.

Owner:WANHUA CHEM GRP +1

Double metal cyanide catalysts

InactiveCN1500554AShort induction periodHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsCyanide compoundAlcohol

The present invention relates to one kind of double-metal cyanide catalyst and aims at solving the problem of catalyst with longer induction period. The catalyst includes double-metal cyanide mixture, organic C4-C10 alcohol with tertiary alcohol structure and organic ester selected from fatty ester, aromatic monoester, aromatic biester and their mixture. It may be used in the industrial production of low unsaturation degree polyether polyol.

Owner:CHINA PETROLEUM & CHEM CORP +1

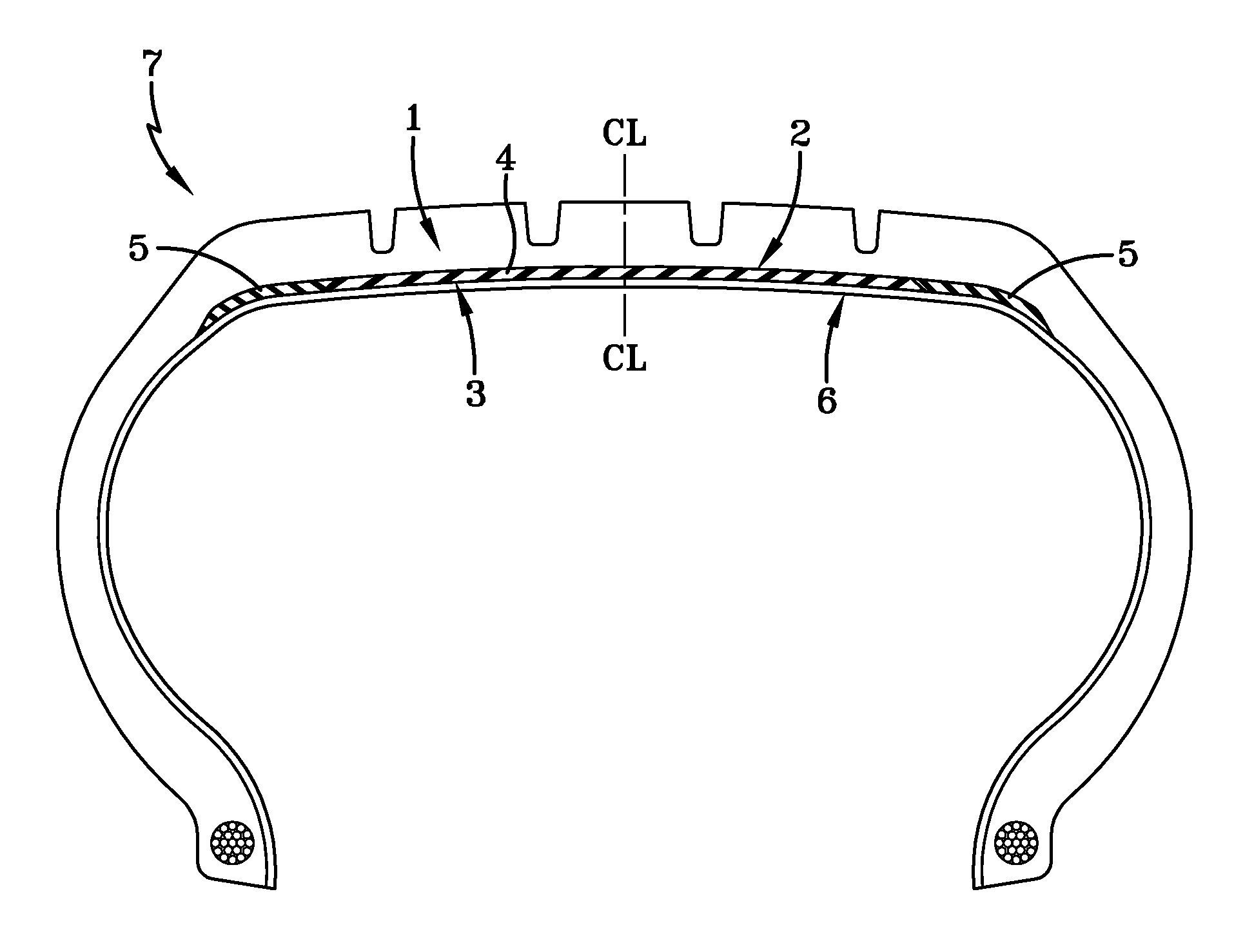

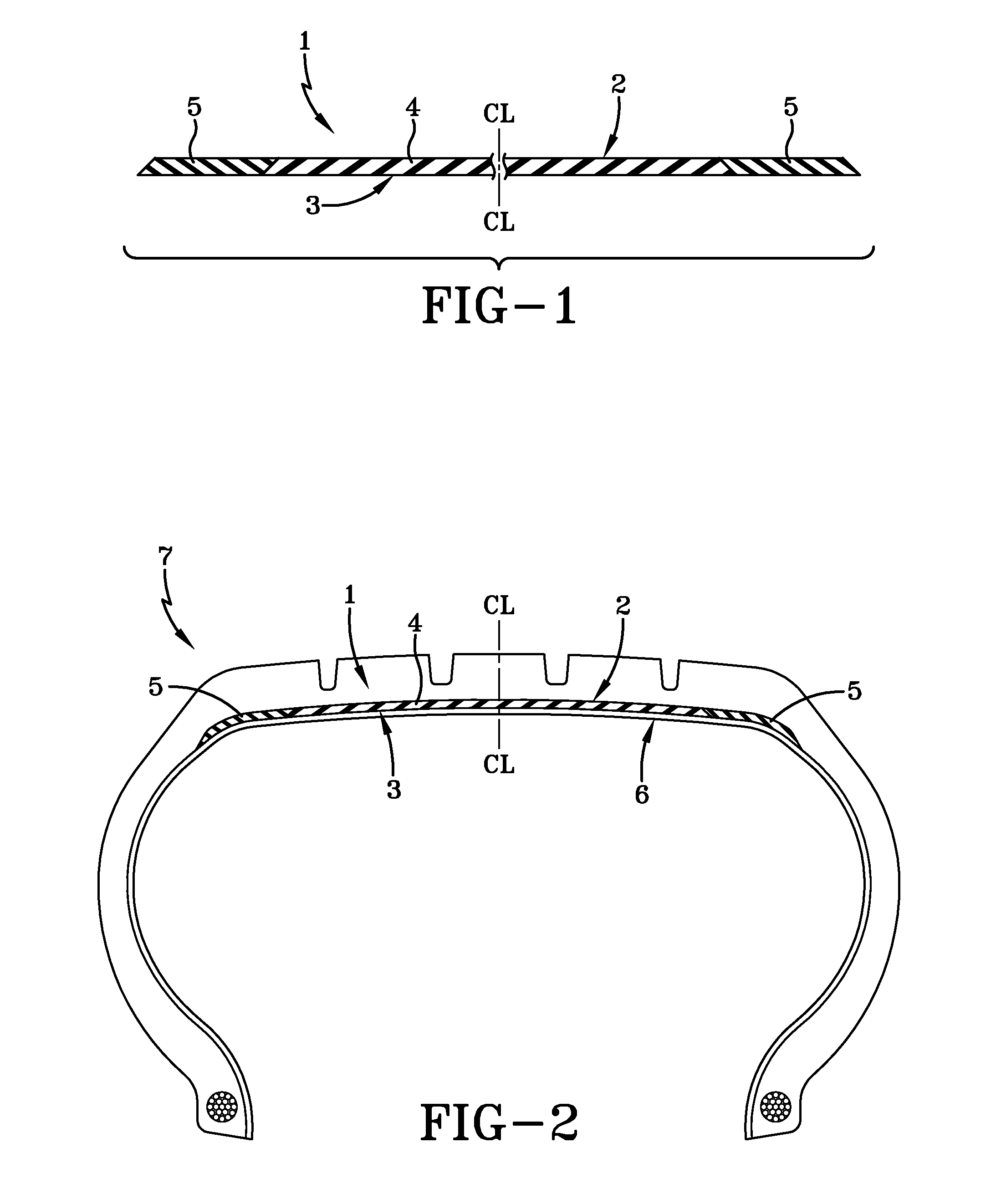

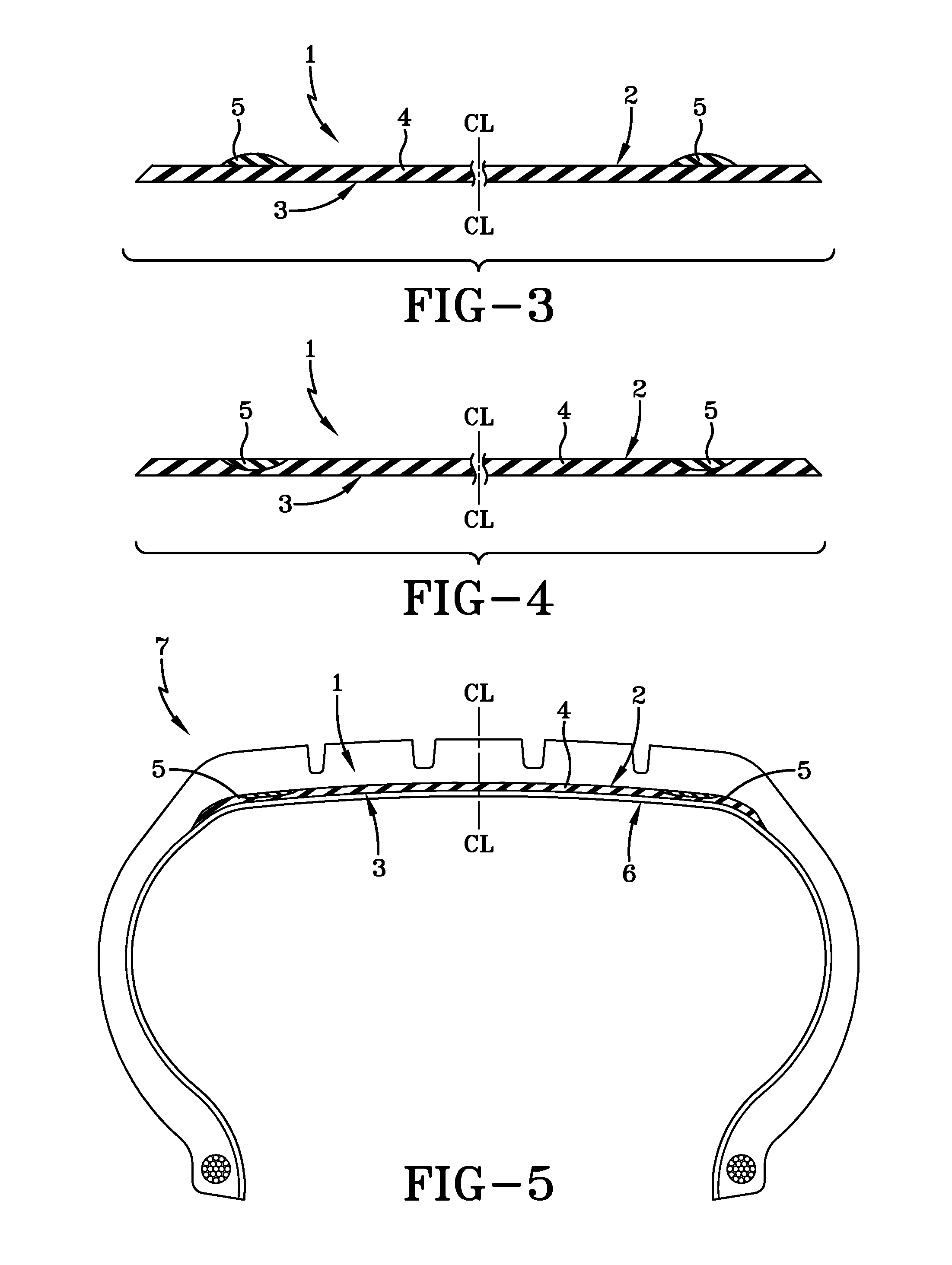

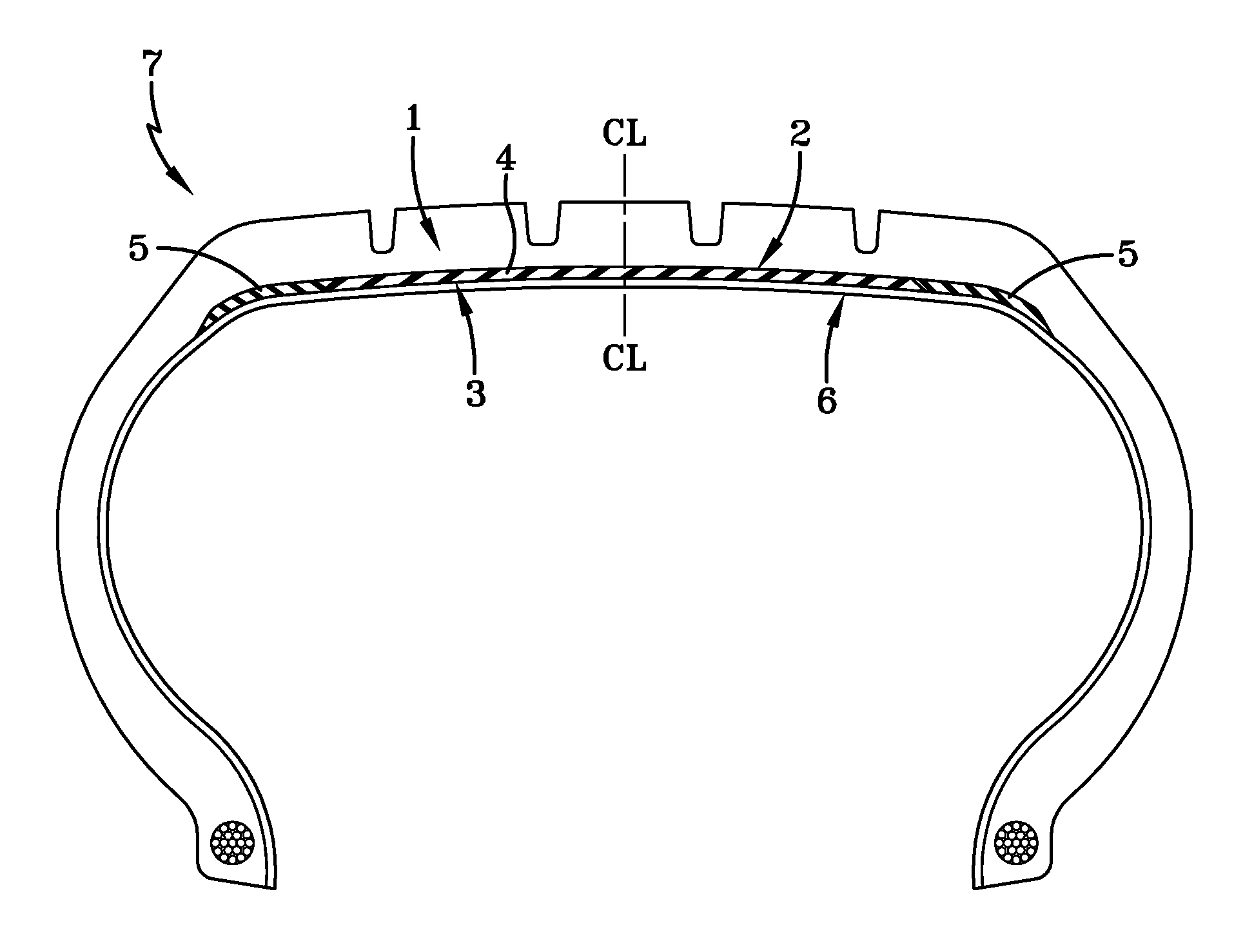

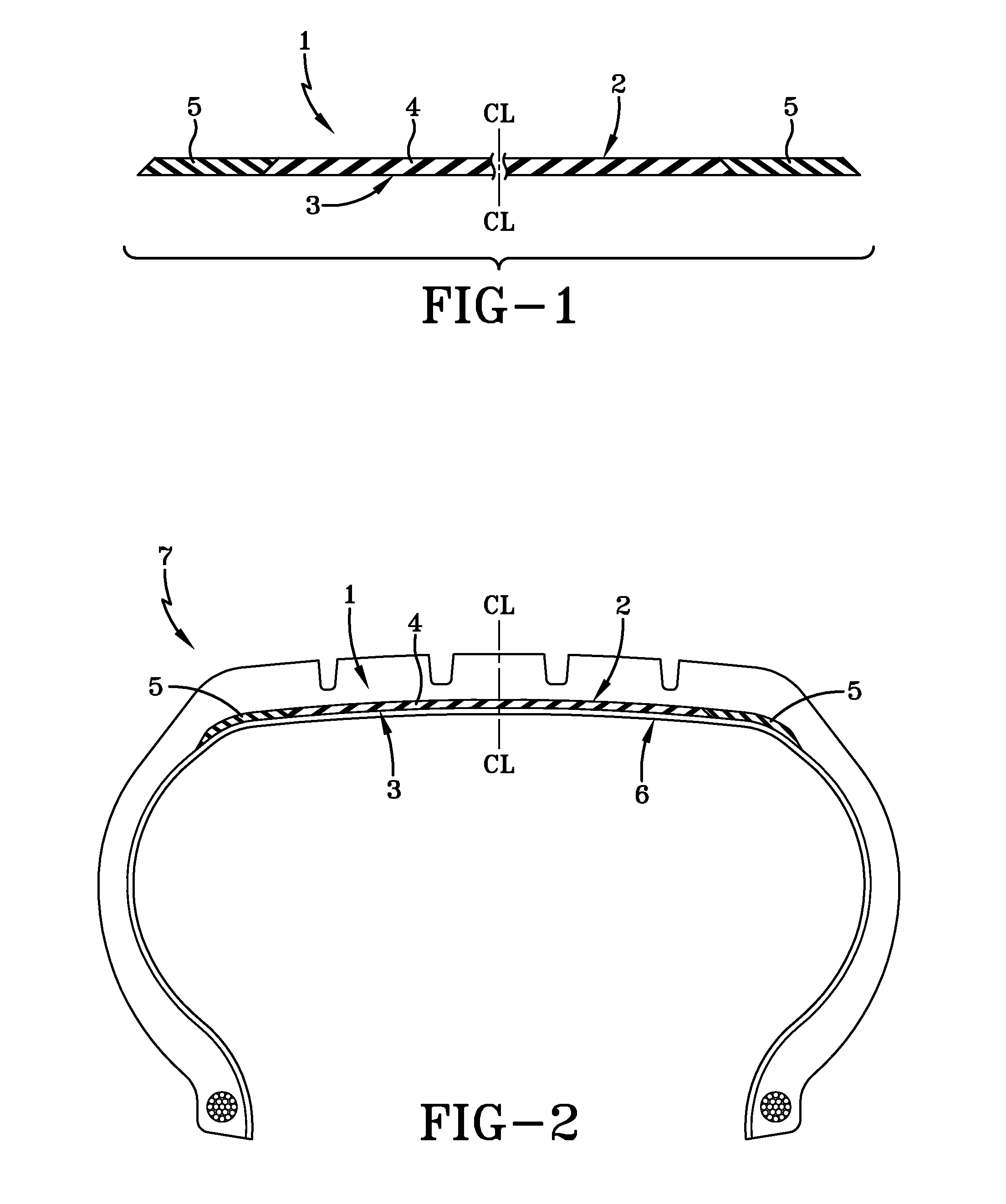

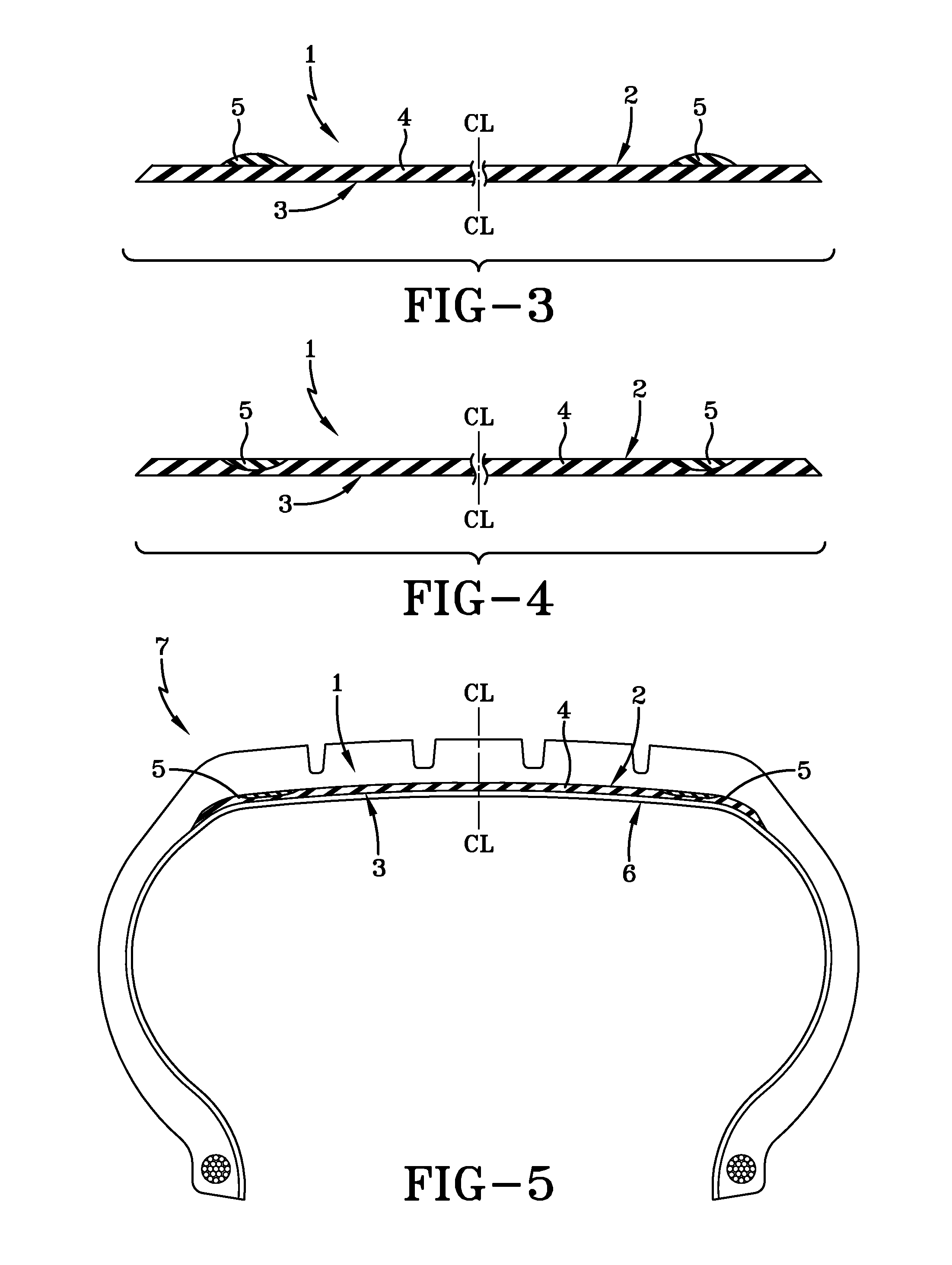

Tire with zoned built-in sealant layer

InactiveUS20090126842A1Promoting aforesaid processingEasy to processWithout separate inflatable insertsTyresEngineeringSealant

The present invention relates to a pneumatic tire which contains a built-in zoned puncture sealant layer. The zoned puncture sealant layer is comprised of organoperoxide depolymerized butyl rubber zones comprised of a central primary zone and lateral zones joined together to form a unitary sealant layer. The sealant of the lateral zones of the sealant layer is of a higher storage modulus (G′) than the sealant of the central zone.

Owner:THE GOODYEAR TIRE & RUBBER CO

Reactive flame-retardant polyether polyol, polyurethane foam and synthesis method

The invention relates to a method for synthesizing a reactive flame-retardant polyether polyol, which comprises the following steps: (1) carrying out ethoxylation reaction on an initiator containing ahydroxyl-containing nitrogen-containing reactive flame retardant and a small molecular polyol compound and a first part of epoxypropane to synthesize a polyether polyol intermediate A; (2) carrying out ethoxylation reaction on the polyether polyol intermediate A and a second part of epoxypropane to synthesize a polyether polyol intermediate B; and (3) carrying out polymerization end-capping reaction on the polyether polyol intermediate B and ethylene oxide to obtain the reactive flame-retardant polyether polyol. The invention also relates to the reactive flame-retardant polyether polyol synthesized by the method. The invention also relates to polyurethane foam prepared from the reactive flame-retardant polyether polyol. The polyether polyol prepared in the invention has the advantages oflow unsaturation degree, high activity, large molecular weight and narrow molecular weight distribution, and the prepared polyether foam material has good resilience, tensile strength and other mechanical properties.

Owner:SHANGHAI DONGDA CHEM

Tire with zoned built-in sealant layer

The present invention relates to a pneumatic tire which contains a built-in zoned puncture sealant layer. The zoned puncture sealant layer is comprised of organoperoxide depolymerized butyl rubber zones comprised of a central primary zone and lateral zones joined together to form a unitary sealant layer. The sealant of the lateral zones of the sealant layer is of a higher storage modulus (G′) than the sealant of the central zone.

Owner:THE GOODYEAR TIRE & RUBBER CO

Foam rubber material for automobile seat cushion

The invention relates to the technical field of rubber compositions, in particular to a foam rubber material for an automobile seat cushion. The foam rubber material for the automobile seat cushion ischaracterized by being prepared from the following raw materials in parts by weight: 80 to 120 parts of ethylene-propylene-diene monomer rubber, 50 to 80 parts of natural rubber, 5 to 15 parts of high abrasion-resistant furnace black, 4 to 12 parts of foaming agent, 1.5 to 3.5 parts of dialkyl dithio amino-phosphate, 2 to 6 parts of accelerant DM, 10 to 20 parts of elastic fiber, 3 to 9 parts ofactive zinc oxide, and 5 to 10 parts of flame-retardant agent. The foam rubber material has the advantages that the mechanical strength is high, the elasticity is good, and the excellent flame-retardant and abrasion-resistant properties are realized; the automobile seat cushion made of the foam rubber material has good elasticity, high comfortability and safety, long service life, and a broad application prospect in automobile industry.

Owner:德清舒华泡沫座椅有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com