Reactive flame-retardant polyether polyol, polyurethane foam and synthesis method

A polyether polyol, reactive flame retardant technology, applied in the field of reactive flame retardant polyether polyol and its synthesis, and polyurethane foam, can solve problems such as product loss of advantages, poor flame retardant effect, and impact on polyurethane foam performance. , to achieve the effects of good mechanical properties, reduced product color value, and narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

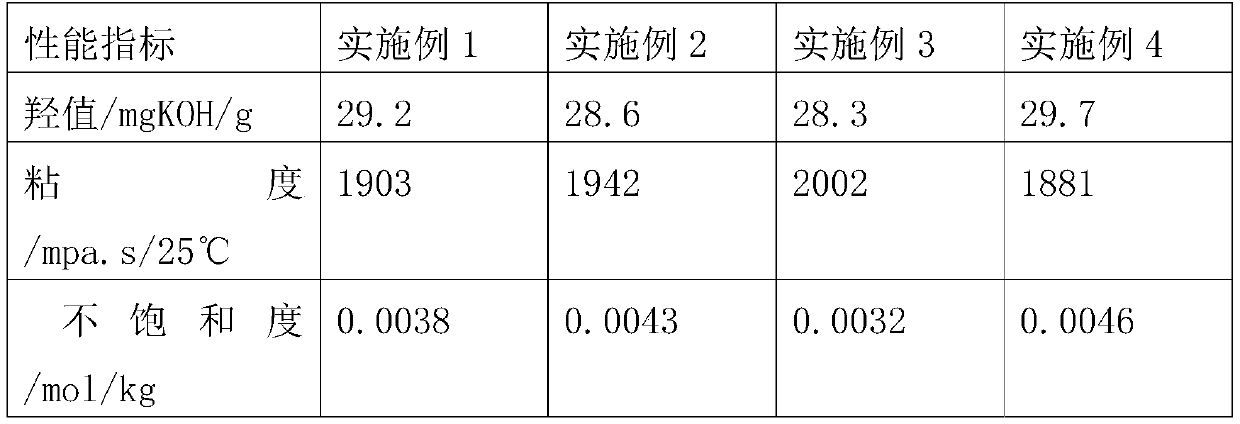

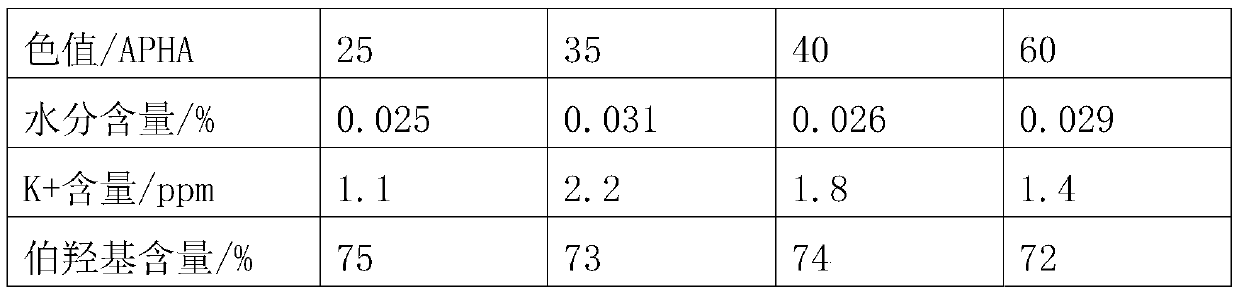

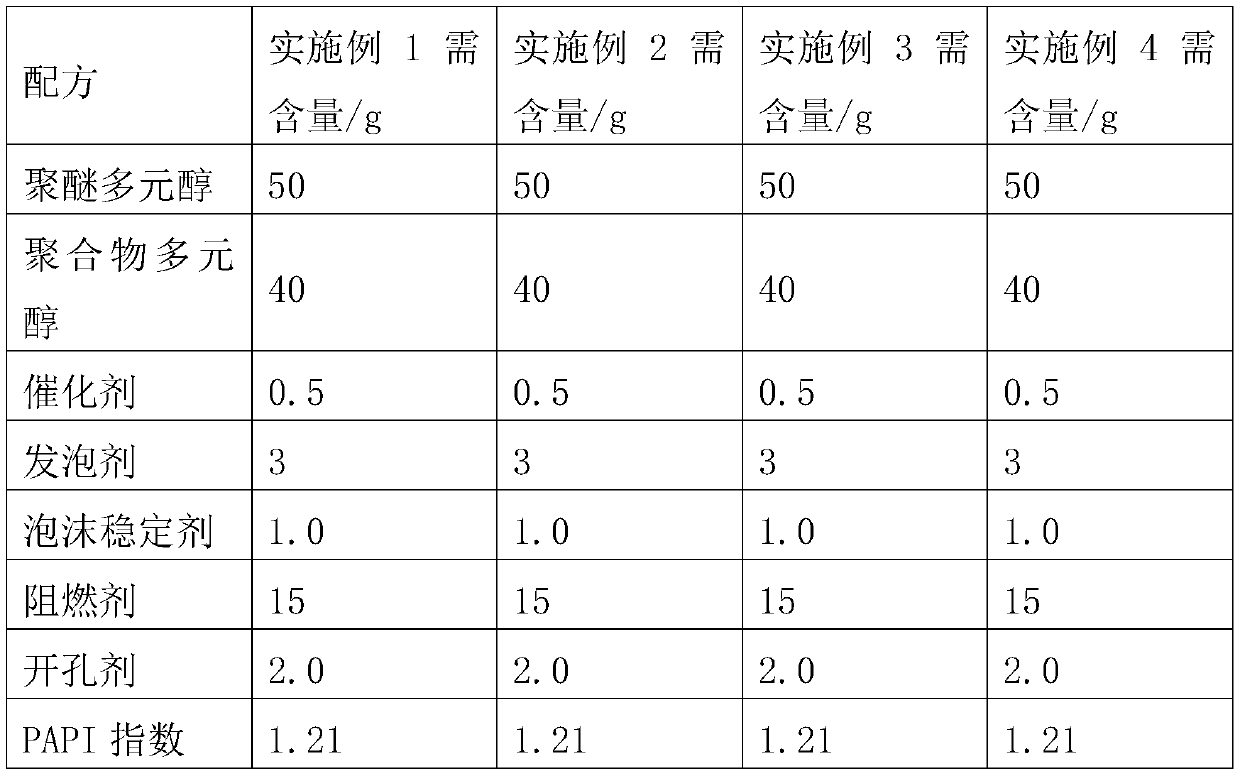

Examples

preparation example Construction

[0036] In a specific embodiment, the application provides a low unsaturation, high activity, high resilience flame retardant polyether polyol synthesis method, which is characterized in that it comprises the following steps:

[0037] (1) The mixture composed of hexamethylolmelamine and small molecule polyol compound is used as the initiator, potassium hydroxide is used as the catalyst, and the ethoxylation reaction is carried out with propylene oxide at a reaction temperature of 105-115°C, The pressure is 0.2-0.3Mpa, polyether polyol intermediate A is synthesized, the adsorbent is refined, and the material is discharged at 70°C;

[0038](2) Use polyether polyol intermediate A as the initiator, and use bimetallic (DMC) as the catalyst to undergo ethoxylation reaction with propylene oxide, and control the pressure inside the kettle to maintain a slight positive pressure (0-0.05Mpa) , the reaction temperature is 130±5°C, the pressure in the kettle is controlled to maintain 0.2-0....

Embodiment 1

[0058] (1) Add 234.21g of sorbitol and 2.7g of potassium hydroxide to a 2.5L stainless steel reaction kettle, replace with positive and negative nitrogen pressure for 3 times, raise the temperature to 110°C and start dehydration with nitrogen blowing for 2 hours, the pressure is -0.085Mpa, and then slowly add 1566g Propylene oxide, reaction temperature 105-115°C, reaction pressure 0.2-0.3Mpa, curing for 4 hours after feeding, curing temperature 105-115°C, curing pressure 0.2-0.3Mpa, nitrogen supplementary pressure during curing, pumping after curing Vacuum degassing for 0.5h, degassing temperature 100-110°C, pressure -0.101Mpa, lower the temperature to 70°C to obtain low molecular weight crude polyether polyol A1. During the post-refining treatment process, add phosphoric acid (modulate pH=4.5~5.5), 3.6g of magnesium silicate adsorbent, 54g of distilled water, vacuum dehydration and drying for 6h, drying temperature 100°C, moisture ≤0.03%, filter to remove slag, and obtain low ...

Embodiment 2

[0061] (1) Add 175.67g of sorbitol, 98.44g of hexamethylolmelamine, 2.7g of potassium hydroxide to a 2.5L stainless steel reaction kettle, replace it with positive and negative nitrogen pressure for 3 times, raise the temperature to 110°C and start dehydrating with nitrogen for 2 hours, and the pressure is -0.085 Mpa, then slowly add 1526g of propylene oxide, the reaction temperature is 105-115°C, the reaction pressure is 0.2-0.3Mpa, after feeding, it is matured for 4h, the curing temperature is 105-115°C, the curing pressure is 0.2-0.3Mpa, and nitrogen supplement is added during the curing After aging, vacuumize and degas for 0.5h. The degassing temperature is 100-110°C, the pressure is -0.101Mpa, and the temperature is lowered to 70°C to obtain low molecular weight crude polyether polyol A1. During the post-refining treatment process, add phosphoric acid (modulate pH=4.5~5.5), 3.6g of magnesium silicate adsorbent, 54g of distilled water, vacuum dehydration and drying for 6h, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com