Method for synthesis of low-unsaturation degree, high-molecular weight and high-activity polyether polyol

A high-activity polyether and high molecular weight technology, applied in the chemical field, can solve problems such as narrow molecular weight distribution, high average functionality, and increased side reactions, and achieve the effects of regular molecular weight distribution, short demoulding time, and improved resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

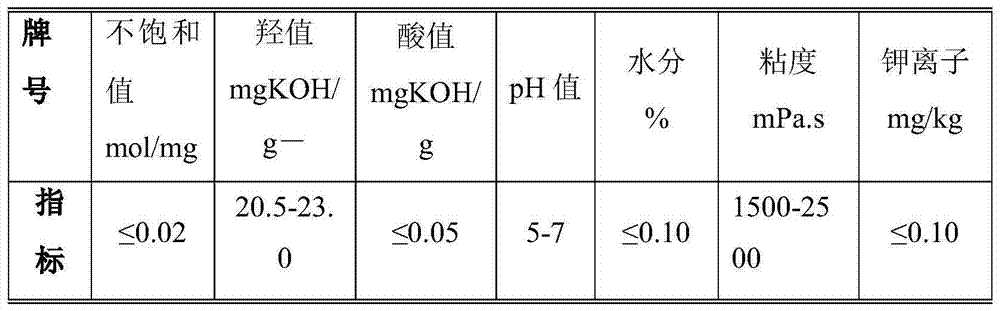

Method used

Image

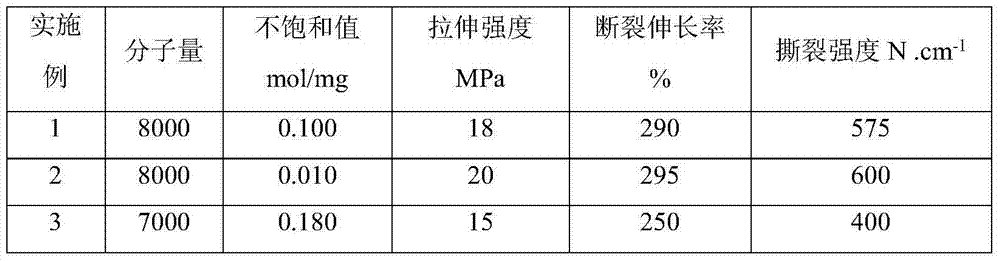

Examples

Embodiment 1

[0026] Preparation of low unsaturation, high molecular weight, high activity polyether polyol, the steps are as follows:

[0027] Step 1: In a 5L stainless steel reaction kettle, at a temperature of 65±5°C, add 400g of glycerin and 1,1,1-trimethylolpropane each, then add 8g of KOH, carry out nitrogen replacement, and measure the oxygen content in the kettle When it is less than 100ppm, pressurize nitrogen, feed propylene oxide 2200g, heat up the reaction, and react under internal pressure for 2 hours, control the temperature at 115±2°C, and the pressure at 0.05-0.1MPa. After the reaction is completed, cool down to 80°C for finishing treatment. Product A is obtained and is ready for use.

[0028] Step 2: In a 5L stainless steel reaction kettle, at a temperature of 80°C, add 250g of product A, then add 8gKOH, and carry out nitrogen replacement. After the oxygen content in the kettle is less than 100ppm, pressurize with nitrogen, and feed 2200g of propylene oxide , the temperatu...

Embodiment 2

[0031] Preparation of low unsaturation, high molecular weight, high activity polyether polyol, the steps are as follows:

[0032] Step 1: In a 5L stainless steel reaction kettle, at a temperature of 65±5°C, add 400g of glycerin and 1,1,1-trimethylolpropane each, then add 8g of KOH, carry out nitrogen replacement, and measure the oxygen content in the kettle When it is less than 100ppm, pressurize nitrogen, feed propylene oxide 2200g, heat up the reaction, and react under internal pressure for 2 hours, control the temperature at 115±2°C, and the pressure at 0.05-0.1MPa. After the reaction is completed, cool down to 70°C for finishing treatment. Product A is obtained and is ready for use.

[0033] The second step: In a 5L stainless steel reaction kettle, at a temperature of 80°C, add 250g of product A, then add 0.2g of double metal cyanide complex, add acid to adjust to acidity, dehydrate for 30 minutes, and then add 250g of product A at a pressure of -0.07- 0.1MPa, feed propyl...

Embodiment 3

[0036] Preparation of low unsaturation, high molecular weight, high activity polyether polyol, the steps are as follows:

[0037] Step 1: In a 5L stainless steel reaction kettle, at a temperature of 65±5°C, add 400g of glycerin and 1,1,1-trimethylolpropane each, then add 8g of KOH, carry out nitrogen replacement, and measure the oxygen content in the kettle When it is less than 100ppm, pressurize nitrogen, feed propylene oxide 2200g, heat up the reaction, and react under internal pressure for 2 hours, control the temperature at 115±2°C, and the pressure at 0.05-0.1MPa. After the reaction is completed, cool down to 80°C for finishing treatment. Product A is obtained and is ready for use.

[0038] Step 2: In a 5L stainless steel reaction kettle, at a temperature of 80°C, add A250g product, then add 8gKOH, and carry out nitrogen replacement. After the oxygen content in the kettle is less than 100ppm, pressurize nitrogen, and feed 2200g propylene oxide. Raise the temperature to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com