Hard bubble polyether polyol and preparation method thereof

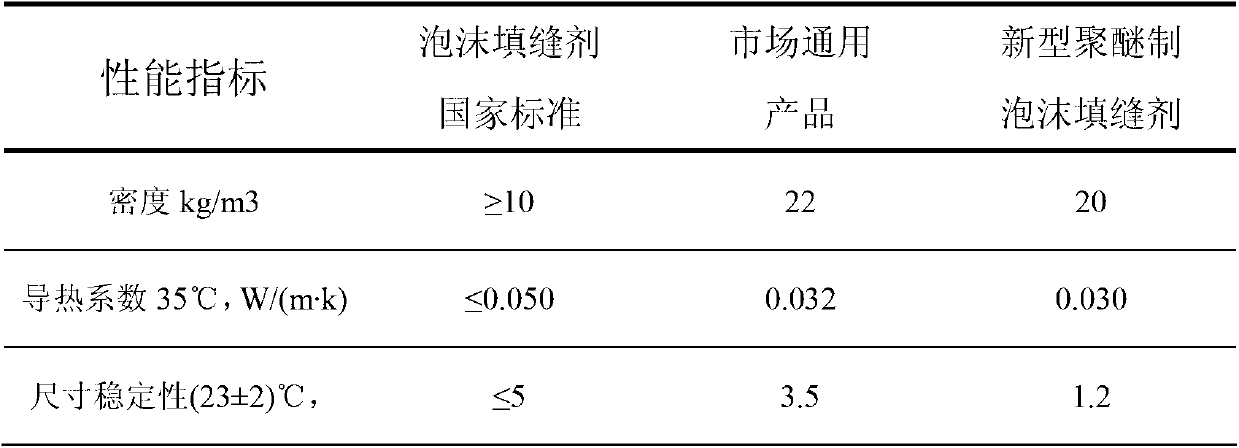

A technology for polyether polyol and rigid foam is applied in the field of rigid foam polyether polyol and its preparation, which can solve the problems of cumbersome processing procedures, complex production process, difficult time control and the like, and achieves short preparation time, cold and heat resistance coefficient The effect of high and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

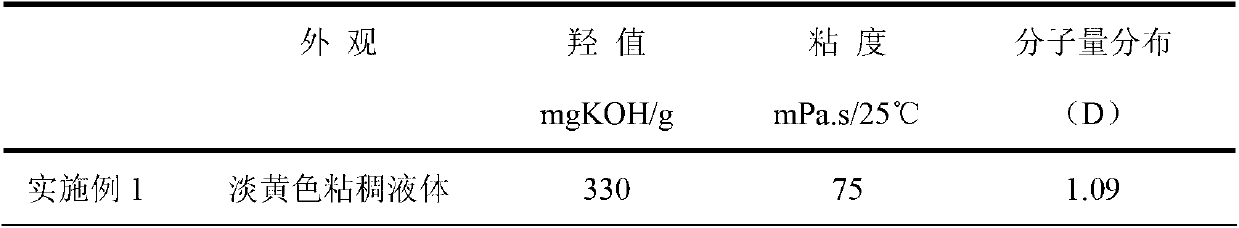

Examples

Embodiment 1

[0035] In a 3L stainless steel reactor, at a temperature of 60-70°C and a pressure of 0.1-0.4MPa, dipropylene glycol and diethylene glycol are fed in a mass ratio of 3:2, totaling 790g, and the reactor is replaced with nitrogen. After the internal oxygen content is less than 100ppm, vacuum pump 25g of triethylenediamine, nitrogen pressurized, 2290g of propylene oxide is fed, the temperature is raised to 60-100°C for reaction, the pressure is not higher than 0.4MPa, and the internal pressure is reacted for 2 hours. The temperature is controlled at 90-120°C, the pressure is 0.05-0.1MPa, and the temperature is lowered to 90°C after the reaction is completed.

Embodiment 2

[0037] In a 3L stainless steel reactor, at a temperature of 60-70°C and a pressure of 0.1-0.4MPa, feed triethylene glycol and dipropylene glycol at a mass ratio of 1:1, totaling 670g; After the internal oxygen content is less than 100ppm, vacuum pump 25g of triethylenediamine; pressurize with nitrogen, feed 1770g of propylene oxide, heat up to 60-100°C for reaction, the pressure is not higher than 0.4MPa, and the internal pressure is reacted for 2 hours, controlled The temperature is 90-120°C, the pressure is 0.05-0.1MPa, after the reaction is completed, the temperature is lowered to 70°C, and samples are taken for testing.

Embodiment 3

[0039] In a 3L stainless steel reactor, at a temperature of 60-70°C and a pressure of 0.1-0.4MPa, a total of 661g of diethylene glycol and triethylene glycol were fed, with a mass ratio of 1:5; After the internal oxygen content is less than 100ppm, vacuum pump 25g of triethylenediamine; pressurize with nitrogen, feed 1760g of propylene oxide, heat up to 60-100°C for reaction, the pressure is not higher than 0.4MPa, and the internal pressure is reacted for 2 hours. The temperature is 90-120°C, the pressure is 0.05-0.1MPa, after the reaction is completed, the temperature is lowered to 60°C, and samples are taken for testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com