Integrated formwork system for construction of super high-rise building

a formwork system and high-rise technology, applied in the direction of form/shuttering/falseworks, building parts shaping, building material handling, etc., can solve the problems of reducing the valuable space of the working plane, reducing the time for the preparation and jacking operation of each formwork jacking, and reducing the deadweight of the structure. , to achieve the effect of increasing the structural stability of the system, reducing the deadweight of the structure, and facilitating r

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

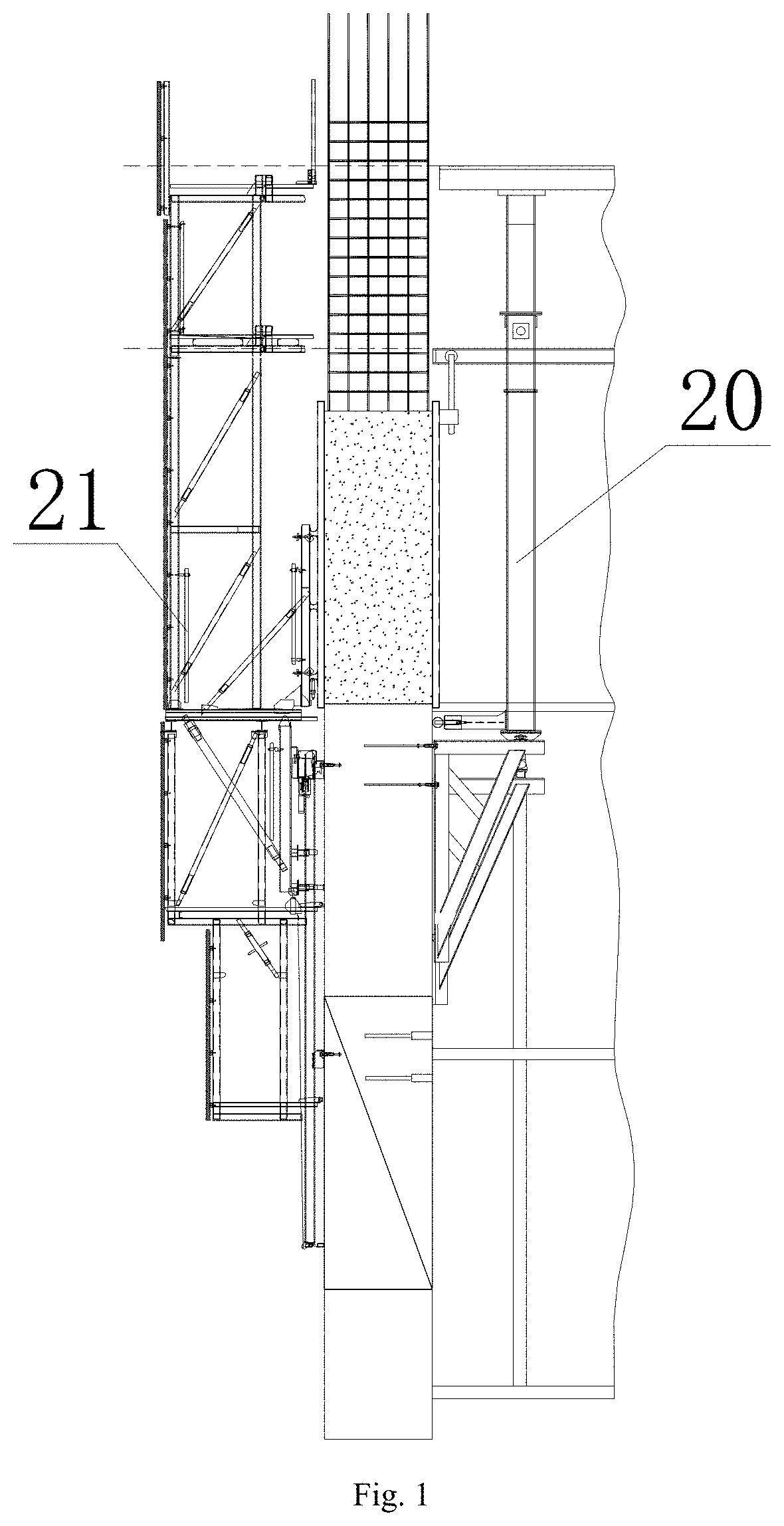

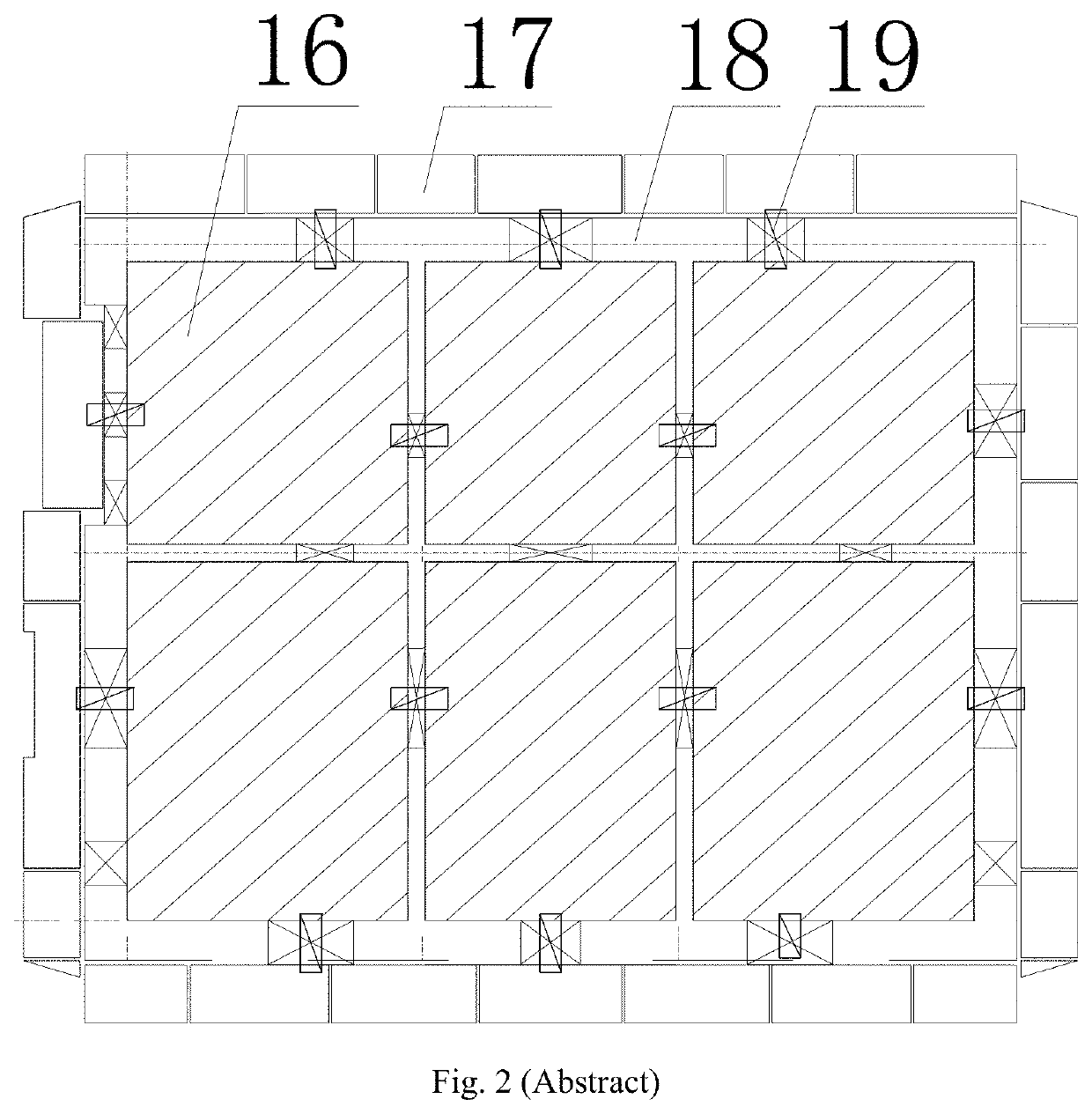

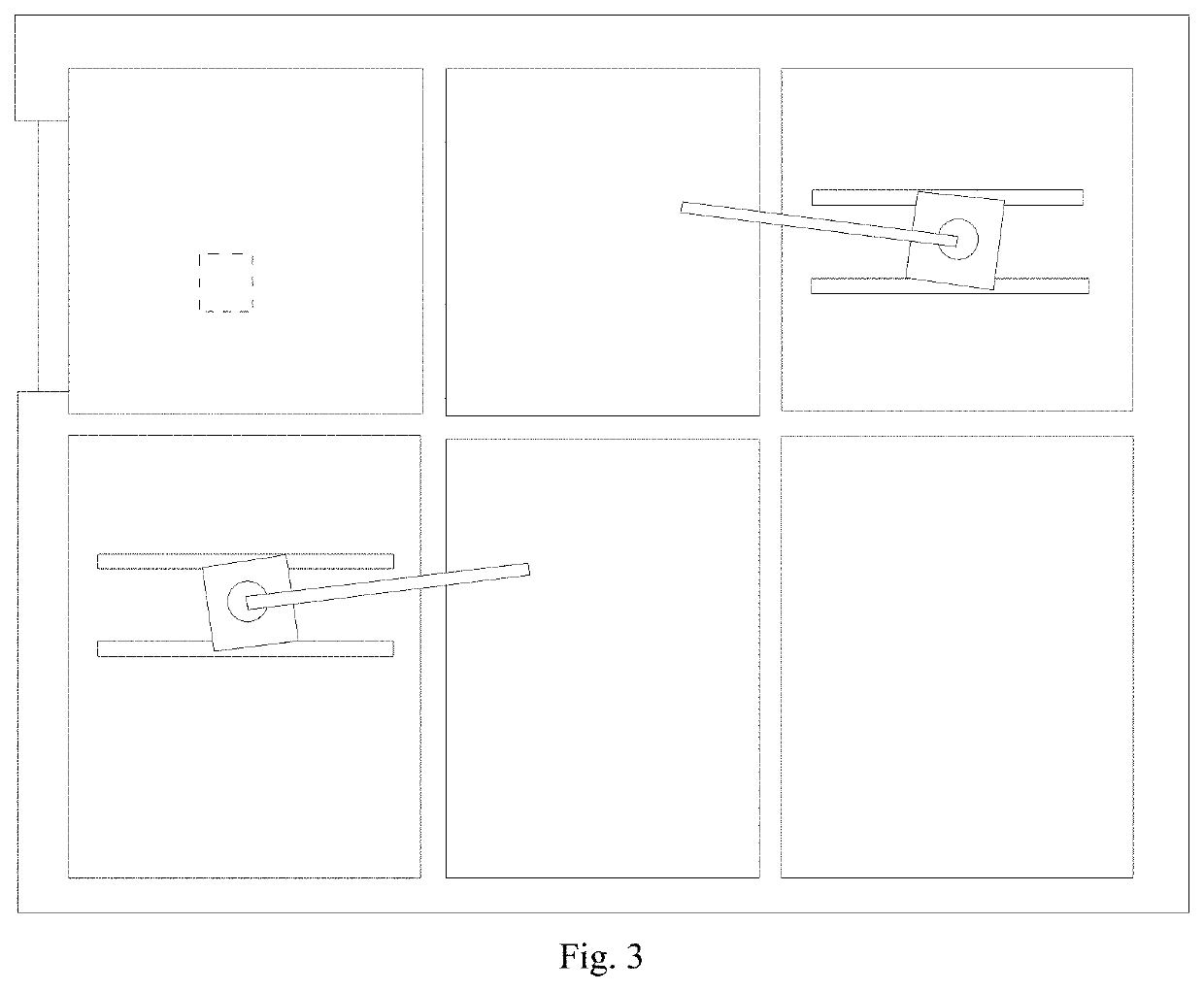

[0070]As shown in FIG. 1 to FIG. 5, an integrated formwork system for construction of a super high-rise building, comprising a climbing system 17 in a stereoscopic structure formed by a successive enclosure of a plurality of climbing formwork units 21, a jacking system 16 formed by a plurality of jacking units 20 arranged side by side being disposed in the stereoscopic structure, and a working space for mounting steel structures and steel bars and pouring concrete walls being formed between the climbing system 17 and the jacking system 16, wherein both the climbing system 17 and the jacking system 16 are capable of moving in a vertical direction, climbing formwork units 21 located at a same side wall of the stereoscopic structure in the plurality of the climbing formwork units 21 all correspond to the jacking units 20 adjacent to the side wall and are capable of moving synchronously or separately, the jacking units are provided thereon with a vertical adjusting device 30 and a horiz...

example 2

[0071]As shown in FIG. 6 and FIG. 7, based on Example 1, the jacking units 20 comprise a lower support frame 11 and an upper support frame 7, wherein the upper support frame 7 is disposed immediately above the lower support frame 11; a hydraulic cylinder 3 is installed on the upper support frame 7, wherein a cylinder pole 8 is disposed in the hydraulic cylinder 3, a bottom of the cylinder pole 8 passes through the upper support frame 7 and is fixed onto the lower support frame 11. During jacking operation the lower support frame 11 or the upper support frame 7 is as a fulcrum, either the lower support frame11 or the upper support frame 7 can move vertically under action of the hydraulic cylinder 3 and the cylinder pole 8, and the lower support frame 11 can be inserted into the upper support frame 7. When the jacking operation is carried out, the upper support frame 7 or the lower support frame 11 can be independently used as the fulcrum to realize the corresponding jacking operation...

example 3

[0079]As shown in FIG. 10. FIG. 11 and FIG. 12, based on the aforementioned examples, since two adjusting conditions are required during jacking operation, this scheme has two adjustment functions, wherein one realizes adjustment in a large range by moving the horizontal adjusting mechanism on the support plate 37, which is generally used when the inside of the jacking space changes; and the other is to adjust the positioning wheel 33 to move horizontally, mainly used for the uneven wall, to maintain the pressed state against the wall surface and bear force, thereby avoiding tilt. Such system has the function of simultaneous adjustments in a large range and in a small range, ensuring the stability of the system during jacking operation.

[0080]When in use, according to the range to be adjusted, the adjustment within a large range is performed first, wherein the installation plate 39 is moved to the position of the support plate 37, after reaching the correct position, four high streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com