Micro-nano composite dual-layer skin framework and manufacturing method thereof

A composite double-layer, micro-nano technology, applied in medical science, prosthesis, additive processing, etc., can solve the problems of mechanical strength to be improved, adhesion carrier is not ideal, etc., to achieve low preparation cost, facilitate migration and proliferation, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

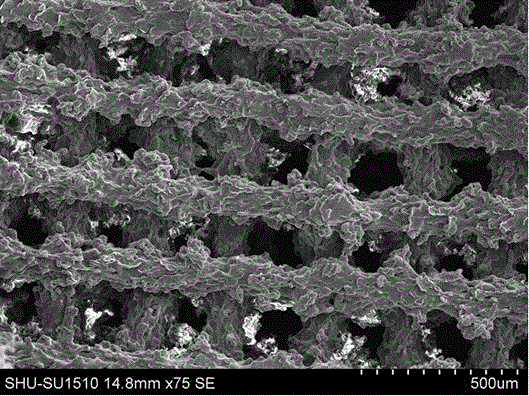

[0033] In this example, see Figure 1~6, a micro-nano composite double-layer skin scaffold, which is composed of a nanofiber layer and a three-dimensional structure scaffold layer. The nanofiber membrane is a flat nanofiber membrane prepared by electrospinning, which is conducive to cell adhesion and growth, the three-dimensional structure support layer is combined on the nanofiber layer, providing a microenvironment for cell growth, which is conducive to cell penetration and proliferation, and the three-dimensional structure support layer is directly written by electrohydrodynamic jet printing method A three-dimensional structural scaffold composed of microfibers, the three-dimensional structural scaffold layer has a higher porosity than the nanofiber layer, and the nanofibrous membrane is used as an epidermal scaffold for the adhesion and growth of skin cells, and the The three-dimensional structure support layer is used as a dermis support for the penetration and proliferat...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, especially in that:

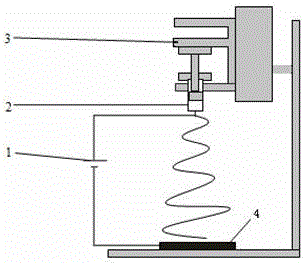

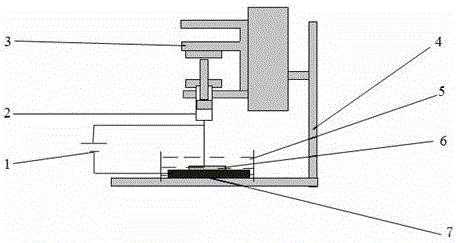

[0045] In this example, see figure 2 and image 3 , a method for preparing a micro-nano composite double-layer skin scaffold, comprising the steps of:

[0046] a. This step is identical with embodiment one;

[0047] b. This step is identical with embodiment one;

[0048] c. This step is identical with embodiment one;

[0049] d. Using an electrohydrodynamic jet printing device, see image 3 , the nanofiber membrane 6 obtained in the step b is fixed on the metal collecting plate 4 of the electrohydrodynamic jet printing device, the metal collecting plate 4 is placed in the ethanol container 5 containing the ethanol solution, and the ethanol liquid is The surface is higher than the metal collecting plate 4 to be 2 mm, and then the container is fixed on the working platform of the electrohydrodynamic jet printer, and as a receiving device, the organic phase B in the step c is loaded into the...

Embodiment 3

[0052] This embodiment is basically the same as the previous embodiment, and the special features are:

[0053] In this example, see figure 2 and image 3 , a method for preparing a micro-nano composite double-layer skin scaffold, comprising the steps of:

[0054] a. This step is identical with embodiment one;

[0055] b. This step is identical with embodiment one;

[0056] c. This step is identical with embodiment one;

[0057] d. Using an electrohydrodynamic jet printing device, see image 3 , the nanofiber membrane 6 obtained in the step b is fixed on the metal collecting plate 4 of the electrohydrodynamic jet printing device, the metal collecting plate 4 is placed in the ethanol container 5 containing the ethanol solution, and the ethanol liquid is The surface is higher than the metal collecting plate 4 to be 2 mm, and then the container is fixed on the working platform of the electrohydrodynamic jet printer, and as a receiving device, the organic phase B in the step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com