Preparation method of polyether polyol used for water-soluble polyurethane grouting materials

A water-soluble polyurethane and polyether polyol technology, applied in the field of polyether polyol synthesis, can solve the problems of low bonding strength and low water inclusion rate, achieve high water inclusion rate and strength, improve activity, and fast water solidification effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

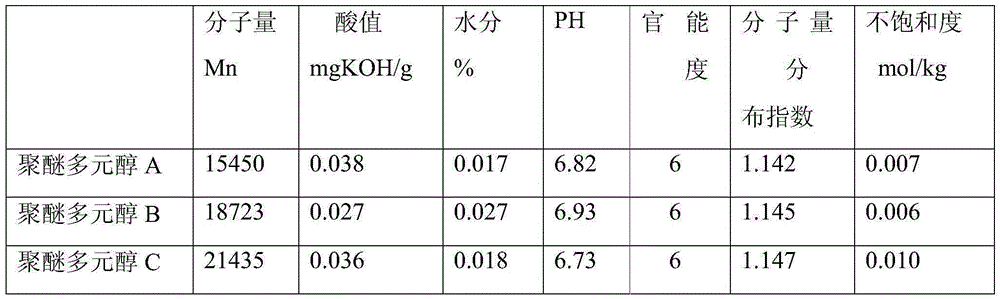

Image

Examples

Embodiment 1

[0027] (1) Add 18.2g of solid sorbitol, 4.5g of potassium hydroxide, 7g of dimethyl sulfoxide, and 7g of tetrahydrofuran into a 1L high-pressure reactor at room temperature, vacuumize to make the vacuum degree ≤ -0.09MPa and replace with nitrogen 4 times, start Stir and raise the temperature to 115°C. Under vacuum ≤ -0.09MPa, dehydrate for 2 hours, remove the solvent at the same time, and then continuously drop 212g of epoxide. In this epoxide, there are 106g of propylene oxide, ethylene oxide Alkanes 106g. The reaction temperature is 113° C. under the control pressure of ≤0.35 MPa in the reaction kettle, and the aging reaction is continued for 1 hour after the feeding is completed. Under the condition of vacuum degree≤-0.09MPa, the unreacted epoxy monomer was removed to obtain 233g of intermediate polyether polyol.

[0028] (2) Take the intermediate polyether polyol and put it into a 2.5L reactor, then raise the reaction temperature to 113°C, pump a vacuum, and continuously ...

Embodiment 2

[0030] (1) Add 18.2g of solid sorbitol, 4.75g of potassium hydroxide, 8g of carbon tetrachloride, and 7g of tetrahydrofuran into a 1L high-pressure reactor at room temperature, vacuumize to make the vacuum degree ≤ -0.09MPa and replace with nitrogen 4 times, start stirring And raise the temperature to 115°C, under the vacuum degree ≤ -0.09MPa, dehydration reaction for 2 hours, remove the solvent at the same time, and then continuously drop 202g of epoxide, 140g of propylene oxide in this epoxide, ethylene oxide 62g. The reaction temperature is 113° C. under the control pressure of ≤0.35 MPa in the reaction kettle, and the aging reaction is continued for 1 hour after the feeding is completed. Under the condition of vacuum degree≤-0.09MPa, the unreacted epoxy monomer was removed to obtain 223.2g of intermediate polyether polyol.

[0031] (2) Take the intermediate polyether polyol and put it into a 2.5L reactor, then raise the reaction temperature to 113°C, pump a vacuum, and co...

Embodiment 3

[0033] (1) Add 18.2g of solid sorbitol, 6.6g of potassium hydroxide, and 22g of tetrahydrofuran into a 1L autoclave at room temperature, evacuate to make the vacuum degree ≤ -0.09MPa and replace with nitrogen 4 times, start stirring and raise the temperature to 115 ℃, under vacuum ≤ -0.09MPa, dehydration reaction for 2 hours, remove the solvent at the same time, then continuously drop 182g of epoxide, the epoxide is all propylene oxide. The reaction temperature is 113° C. under the control pressure of ≤0.35 MPa in the reaction kettle, and the aging reaction is continued for 1 hour after the feeding is completed. Under the condition of vacuum degree≤-0.09MPa, the unreacted epoxy monomer was removed to obtain 204.5g of intermediate polyether polyol.

[0034](2) Take the intermediate polyether polyol and put it into a 2.5L reactor, then raise the reaction temperature to 113°C, pump a vacuum, and continuously drop 2000g of ring polyol into the intermediate polyether polyol at a va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com