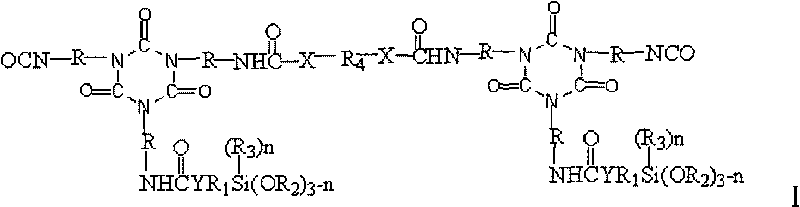

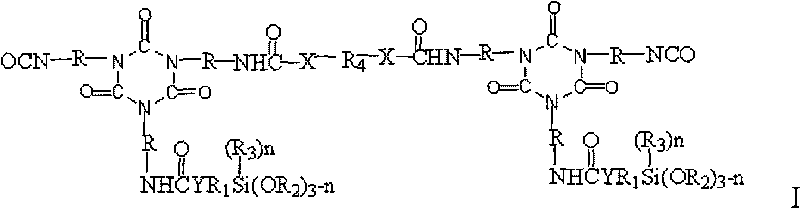

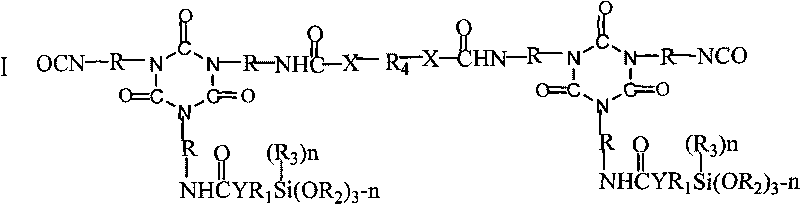

Polyisocyanates containing diphenyl-methane-group diisocyanate, and preparation method

A technology of diphenylmethane diisocyanate and polyisocyanate, applied in the field of polyisocyanate and its preparation, can solve problems such as high cost, harm to construction personnel and environment, high toxicity, etc., and achieves improved adhesion, multiple cross-linking points, high The effect of functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In a 500mL four-neck flask equipped with a thermometer, reflux condenser, stirring, and dropping funnel, at 0°C (ice-water mixed bath) and Ar gas protection, add 75g of MDI trimer, and dissolve it with 200g of ethyl acetate. Dissolve, slowly add 23.5g of N-butylaminopropyltrimethoxysilane and 0.085g of dibutyltin dilaurate dropwise, and react for 3h under stirring; then raise the temperature to 60°C and add 3g of 1,4-butanediol to continue the reaction 4 hours is enough. Part of the solvent was removed from the above product under reduced pressure to obtain a final product with a solid content of 90% and a viscosity of 1285 mPa.s.

Embodiment 2

[0042] In a 500mL four-necked flask equipped with a thermometer, a reflux condenser, stirring, and a dropping funnel, at room temperature 0°C (ice-water mixed bath) and under the protection of Ar gas, add 75g of MDI trimer, and dissolve it with 200g of ethyl acetate. It dissolves, slowly add 22.1g of aminopropyltriethoxysilane and 0.07g of dibutyltin dilaurate dropwise, and react for 3h under stirring; then raise the temperature to 60°C and add 2.3g of ethylene glycol, and continue the reaction for 4h. Part of the solvent was removed from the above product under reduced pressure to obtain a final product with a solid content of 90% and a viscosity of 1055 mPa.s.

Embodiment 3

[0044] In a 500mL four-neck flask equipped with a thermometer, reflux condenser, stirring, and dropping funnel, at room temperature and under the protection of Ar gas, add 75g of MDI trimer, dissolve it with 200g of ethyl acetate, and slowly add 19.6g of it dropwise. Mercaptotriethoxysilane and 0.07g of stannous octoate were reacted for 3h under stirring; then the temperature was raised to 60°C and 20g of polytetrahydrofuran ether polyol with a molecular weight of 500 was added, and the reaction was continued for 4h. Part of the solvent was removed from the above product under reduced pressure to obtain a final product with a solid content of 75% and a viscosity of 1418 mPa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com