Cross-linking waterborne polyurethane and preparation method thereof

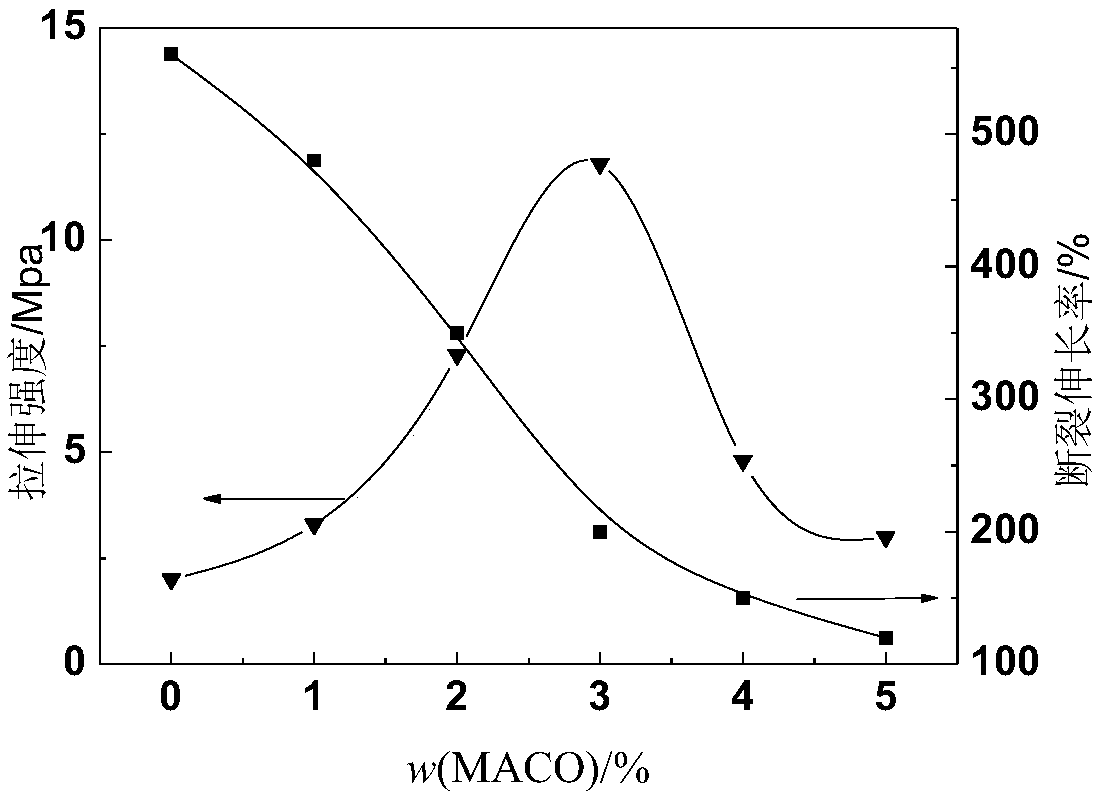

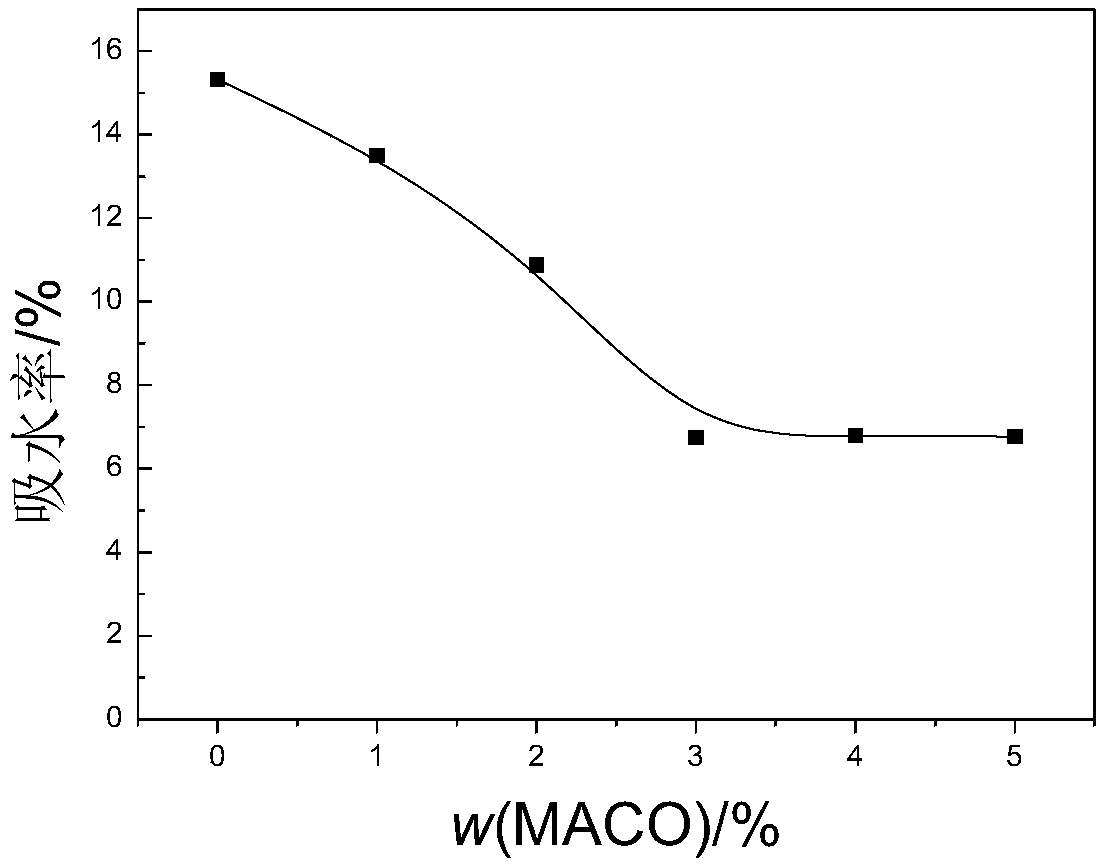

A water-based polyurethane and cross-linked technology, which is applied in the field of cross-linked water-based polyurethane and its preparation, can solve the problems of difficulty in controlling the ratio of the soft and hard segments of the prepolymer, and the mechanical properties of the film are reduced, and achieves improved water resistance and mechanical mechanics. The effect of enhanced performance and increased spatial density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

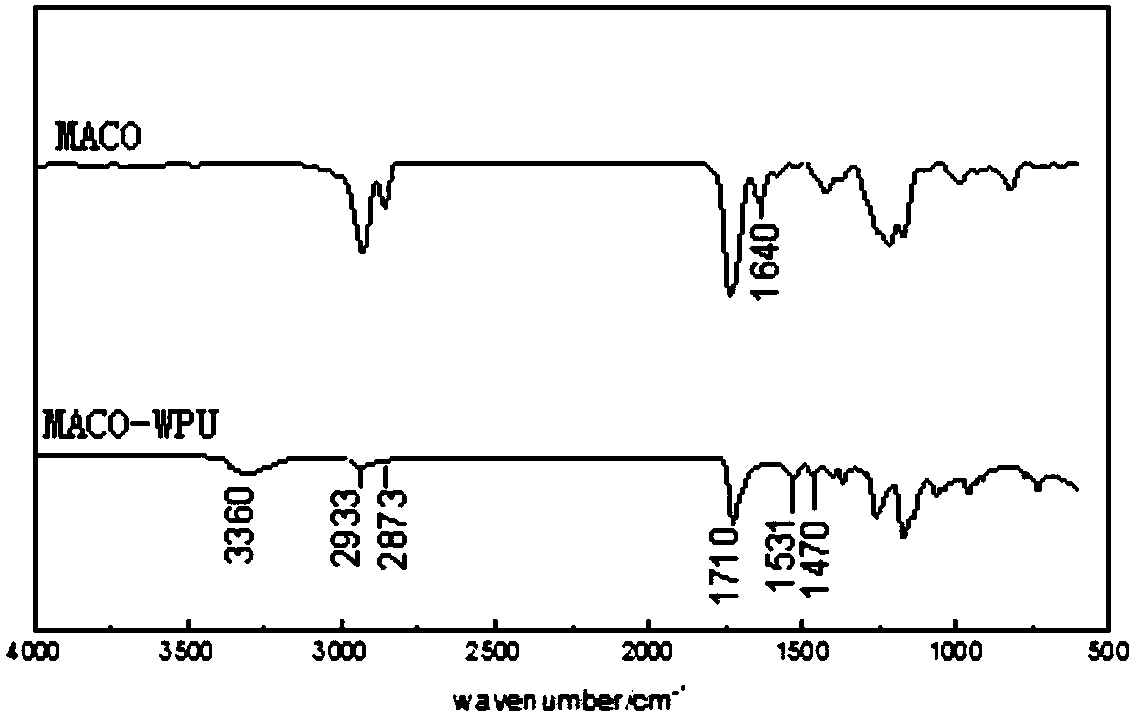

Image

Examples

preparation example Construction

[0029] A preparation method for cross-linked water-based polyurethane, comprising the following steps:

[0030] Step 1: Dissolve maleic anhydride in an organic solvent, stir to make it fully dissolved, and then slowly drop it into refined castor oil for esterification reaction. The reaction is carried out in a microwave reactor with a microwave power of 400W~600w, in which the maleic anhydride is adjusted. The molar ratio of acid anhydride and castor oil is (2.7-3): 1. After the reaction, adjust the pH=7-8 with ammonia water, add a certain amount of distilled water to dilute to a concentration of 50% to prepare a multi-double bond castor oil (MACO) aqueous solution ; The reaction formula is as follows:

[0031]

[0032] Step 2: Remove water from polyester polyol under reduced pressure at 120°C for 2 hours for later use; add polyester polyol and diisocyanate with a molar ratio of 1: (2.6 to 3.2) into the reaction vessel, and add diisocyanate dropwise 1. Catalyst dibutyltin ...

Embodiment 1

[0041] Step 1: Dissolve maleic anhydride in an organic solvent, stir to make it fully dissolved, and slowly add it dropwise to refined castor oil for esterification reaction. The reaction is carried out in a microwave reactor with a microwave power of 400W and 100°C for 60 minutes. Adjust the molar ratio of maleic anhydride and castor oil to 2.7:1. After the reaction, adjust the pH to 7 with ammonia water, add a certain amount of distilled water to dilute to a concentration of 50% to prepare an aqueous solution of castor oil with multiple double bonds.

[0042] Step 2: Remove water from polyester polyol PE-3020 at 120°C for 2 hours for later use; add polyester polyol PE-3020 and hexamethylene diisocyanate (HDI) with a molar ratio of 1:2.6 into a three-necked flask 0.05% catalyst dibutyltin dilaurate (DBTDL) based on the total mass of HDI and PE-3020 was added dropwise, and nitrogen gas was introduced to raise the temperature to 60°C for 3h;

[0043] Step 3: Add 4% of 2,2-dimet...

Embodiment 2

[0046] Step 1: Dissolve maleic anhydride in an organic solvent, stir to make it fully dissolved, and slowly add it dropwise to refined castor oil for esterification reaction. The reaction is carried out in a microwave reactor with a microwave power of 500W and 90°C for 50 minutes. Adjust the molar ratio of maleic anhydride and castor oil to 2.8:1. After the reaction, adjust the pH to 7 with ammonia water, and add a certain amount of distilled water to dilute to a concentration of 50% to prepare an aqueous solution of castor oil with multiple double bonds.

[0047] Step 2: Remove water from polycaprolactone polyol under reduced pressure at 120°C for 2 hours for later use; add polycaprolactone polyol and isophorone diisocyanate (IPDI) with a molar ratio of 1:2.7 into a three-necked flask, Add dropwise 0.06% of the catalyst dibutyltin dilaurate DBTDL based on the total mass of polycaprolactone polyol and isophorone diisocyanate (IPDI), and heat up to 70° C. for 2.5 hours with nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com