Reaction system and method for preparing polyether polyol

A technology of polyether polyol and reaction system, which is applied in the field of reaction system and preparation of polyether polyol synthesized by alkali-catalyzed process, can solve the problems of many residual small molecular substances, low conversion rate of raw materials, wide molecular weight distribution, etc., and achieve reduction The side reaction occurs, the effect of increasing the reaction rate and reducing the degree of unsaturation of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

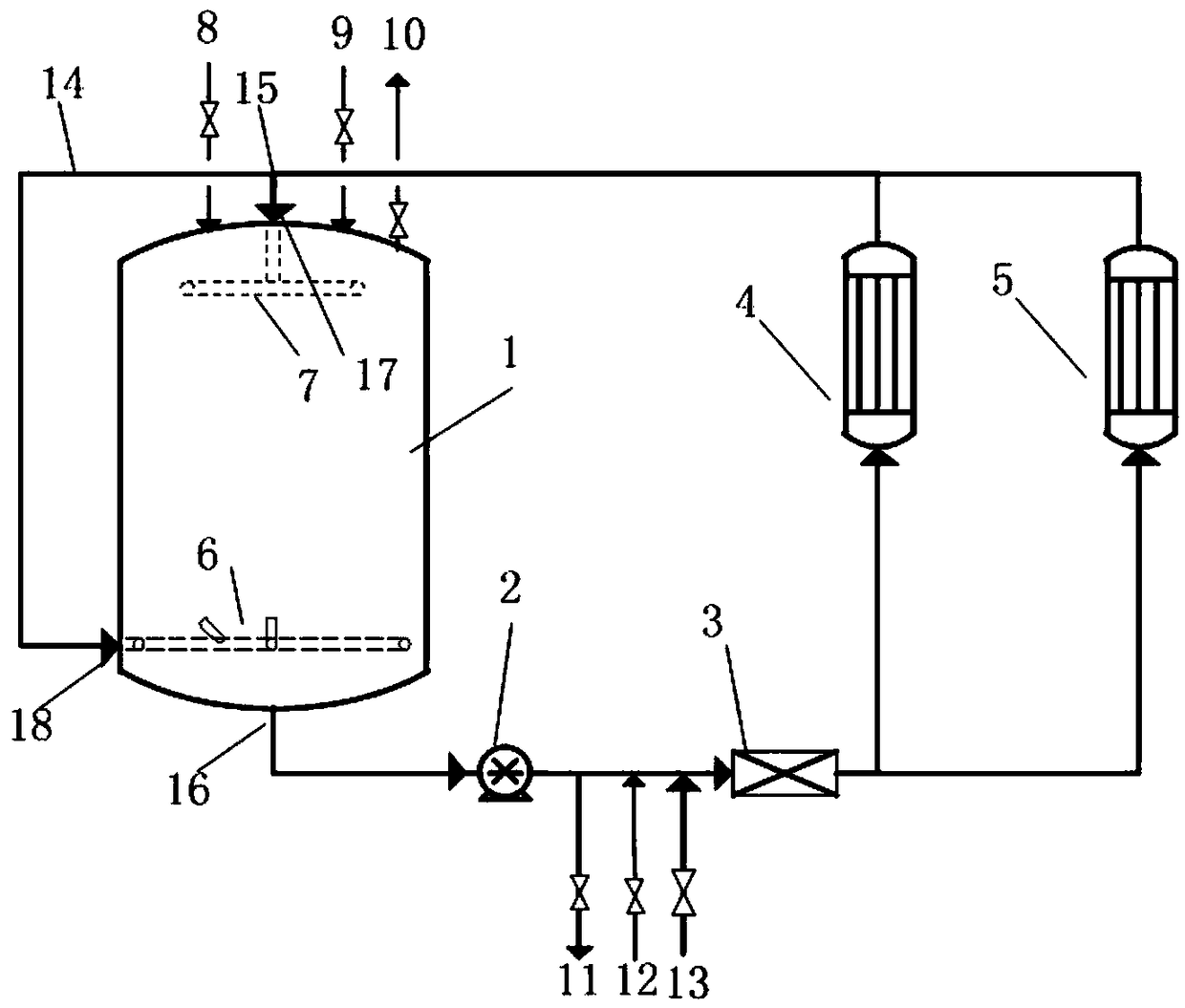

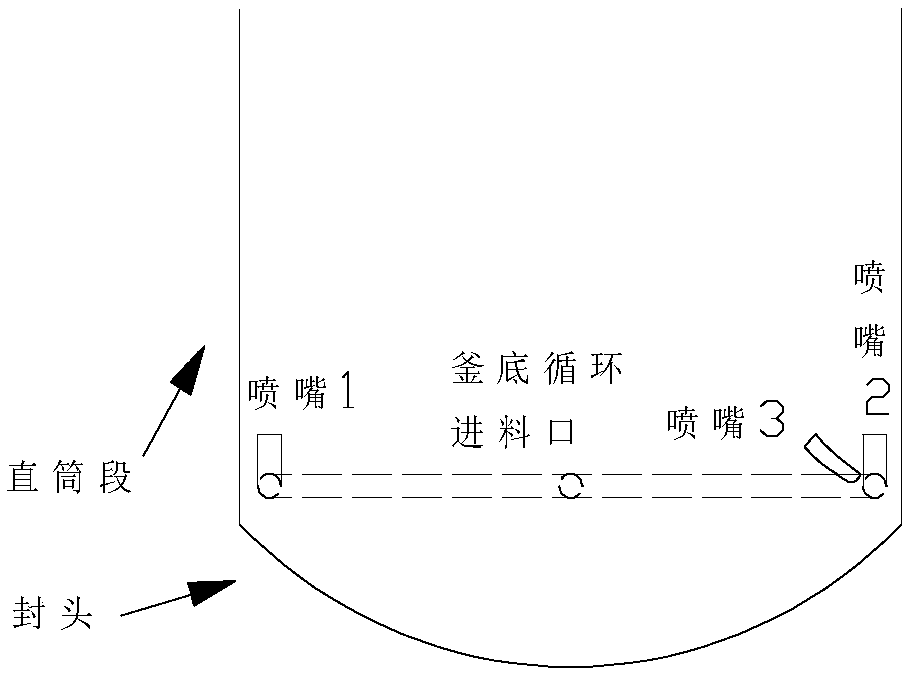

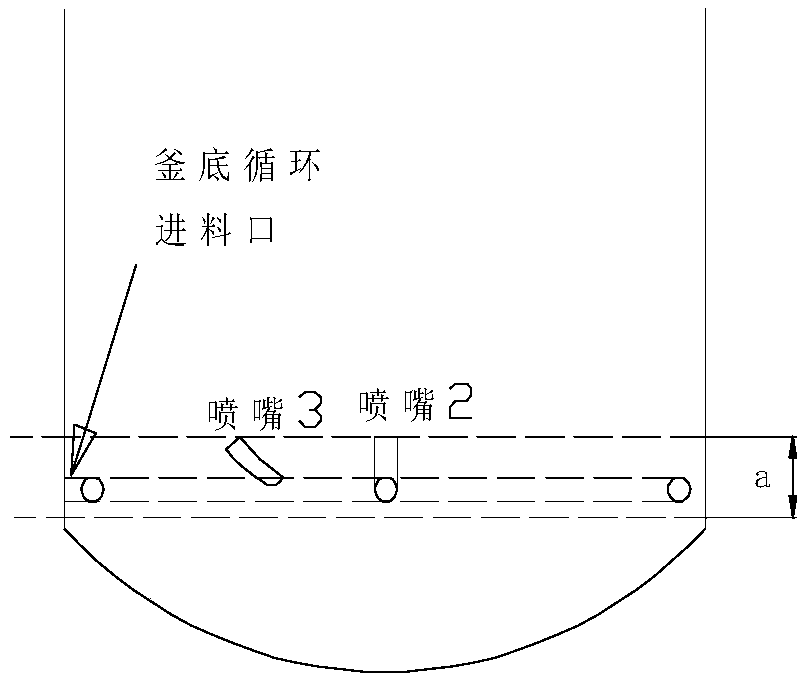

[0090] The volume of the reaction kettle is 8L, the Monel 600 mixed with 400ppm cerium oxide is sprayed inside the selected static mixer, the height a=9 of the nozzle of the liquid phase jet mixer at the bottom of the tank, degrees, θ=15 degrees.

[0091] (1) inject respectively the aqueous potassium hydroxide solution of 197g glycerol and 30g49wt% of reactor from starter feed port 8 and catalyst feed port 9;

[0092] (2) Close the feed valve, feed nitrogen to 0.2MPa from the nitrogen feed port 12, then evacuate to -0.08MPa from the vacuum outlet 10, and replace 3 times;

[0093] (3) After the replacement is completed, open the external circulation pump 2 and begin to circulate through the external circulation pipeline 15 on the top of the kettle. The flow rate of the external circulation pump 2 is 75L / h, and it is heated through the heating heat exchanger 4. Nitrogen feed port 12 is fed with nitrogen gas at 50mL / min, vacuum is drawn from vacuum outlet 10 to -0.08MPa, the te...

Embodiment 2

[0101] The volume of the reaction kettle is 8L, the Monel 600 mixed with 400ppm cerium oxide is sprayed inside the selected static mixer, the height a=6 of the nozzle of the liquid phase jet mixer at the bottom of the tank, degrees, θ=20 degrees.

[0102] (1) inject respectively the aqueous potassium hydroxide solution of 197g glycerol and 30g49wt% of reactor from starter feed port 8 and catalyst feed port 9;

[0103] (2) Close the feed valve, feed nitrogen to 0.2MPa from the nitrogen feed port 12, then evacuate to -0.08MPa from the vacuum outlet 10, and replace 3 times;

[0104] (3) After the replacement is completed, open the external circulation pump 2 and begin to circulate through the external circulation pipeline 15 on the top of the kettle. The flow rate of the external circulation pump 2 is 80L / h, and it is heated through the heating heat exchanger 4. Nitrogen feed port 12 feeds nitrogen gas at 70mL / min, vacuumizes to -0.09MPa from vacuum outlet 10, and maintains the...

Embodiment 3

[0112] The volume of the reaction kettle is 8L, the Monel 600 mixed with 800ppm cerium oxide is sprayed inside the selected static mixer, the height a=7 of the nozzle of the liquid phase jet mixer at the bottom of the tank, degrees, θ=10 degrees.

[0113] (1) inject respectively the aqueous potassium hydroxide solution of 197g glycerol and 30g49wt% of reactor from starter feed port 8 and catalyst feed port 9;

[0114] (2) Close the feed valve, feed nitrogen to 0.2MPa from the nitrogen feed port 12, then evacuate to -0.08MPa from the vacuum outlet 10, and replace 3 times;

[0115] (3) After the replacement is completed, open the external circulation pump 2 and begin to circulate through the external circulation pipeline 15 on the top of the kettle. The flow rate of the external circulation pump 2 is 68L / h, and it is heated through the heating heat exchanger 4. Nitrogen feed port 12 feeds nitrogen gas at 30mL / min, vacuumizes to -0.08MPa from vacuum outlet 10, and maintains the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com