Patents

Literature

75 results about "Monel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monel is a group of nickel alloys, primarily composed of nickel (from 52 to 67%) and copper, with small amounts of iron, manganese, carbon, and silicon. (Alloys with copper contents 60% or more are called cupronickel.)

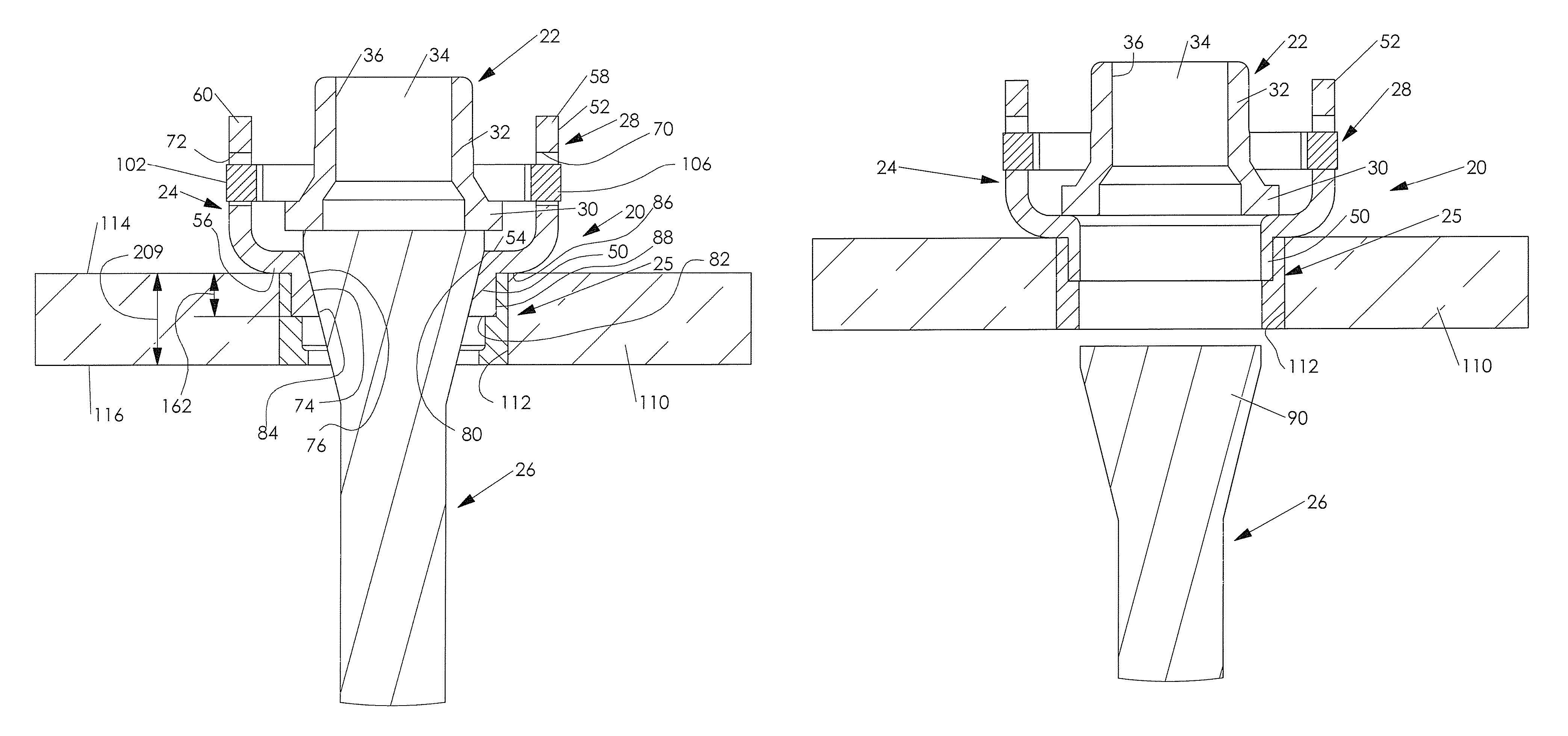

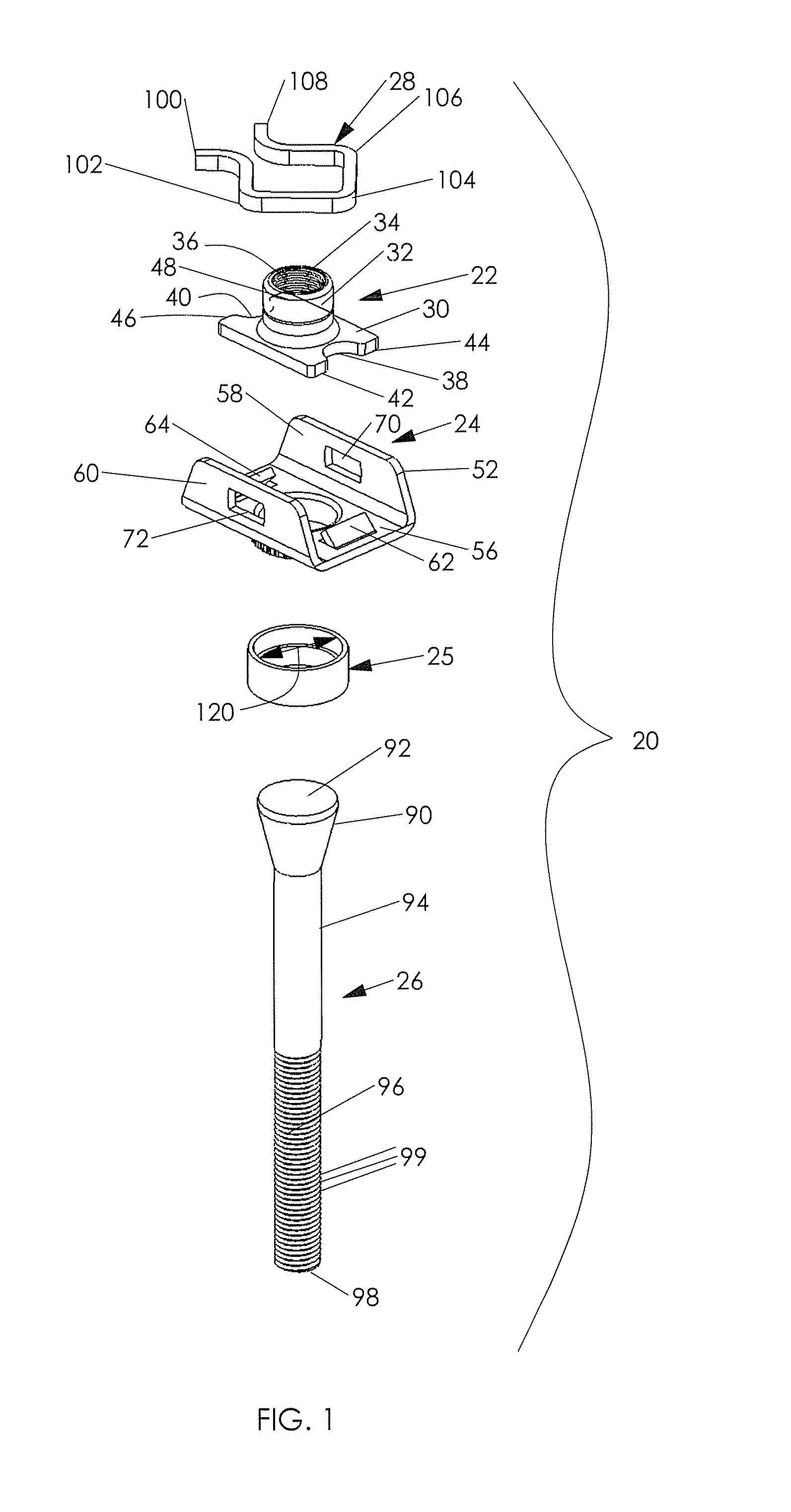

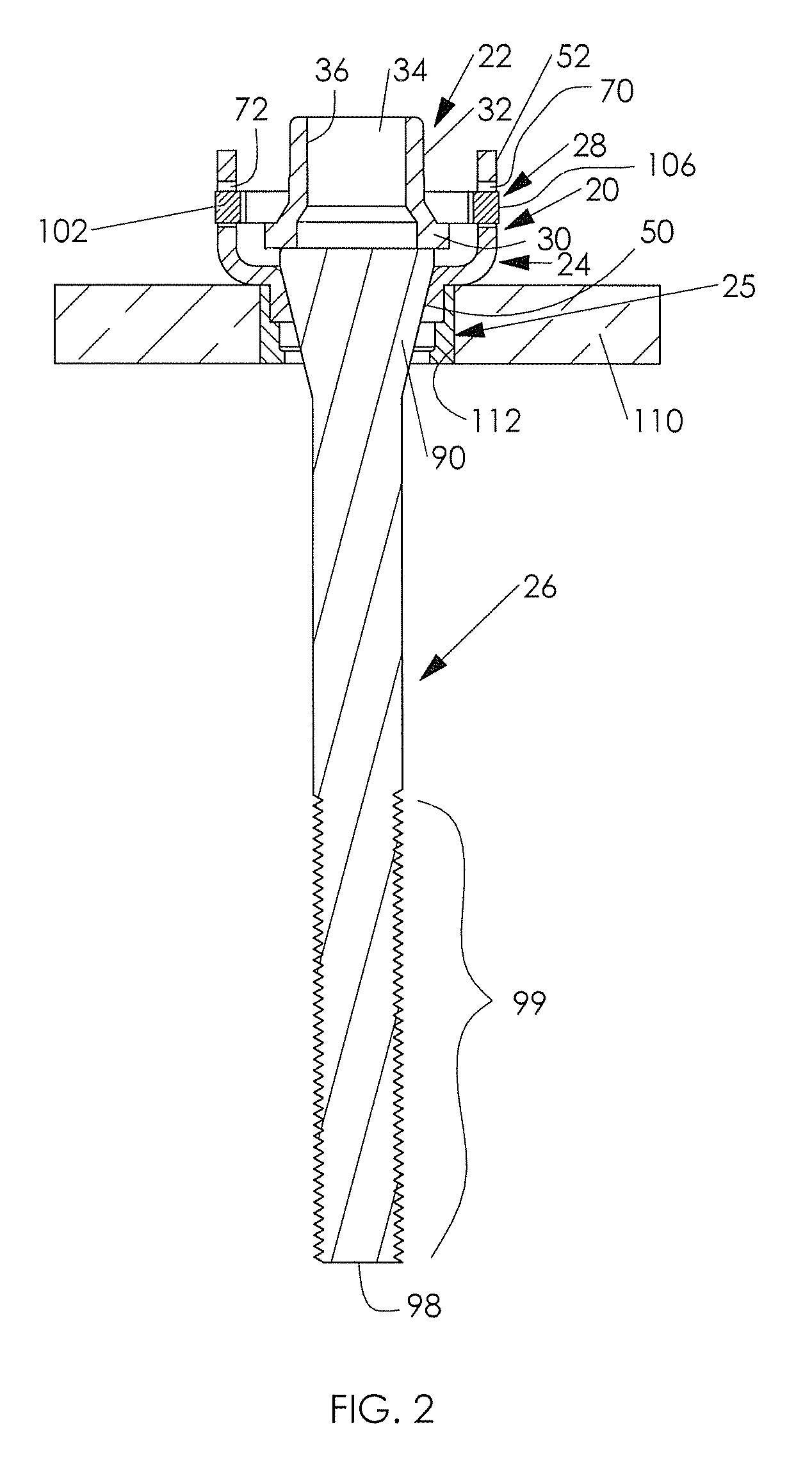

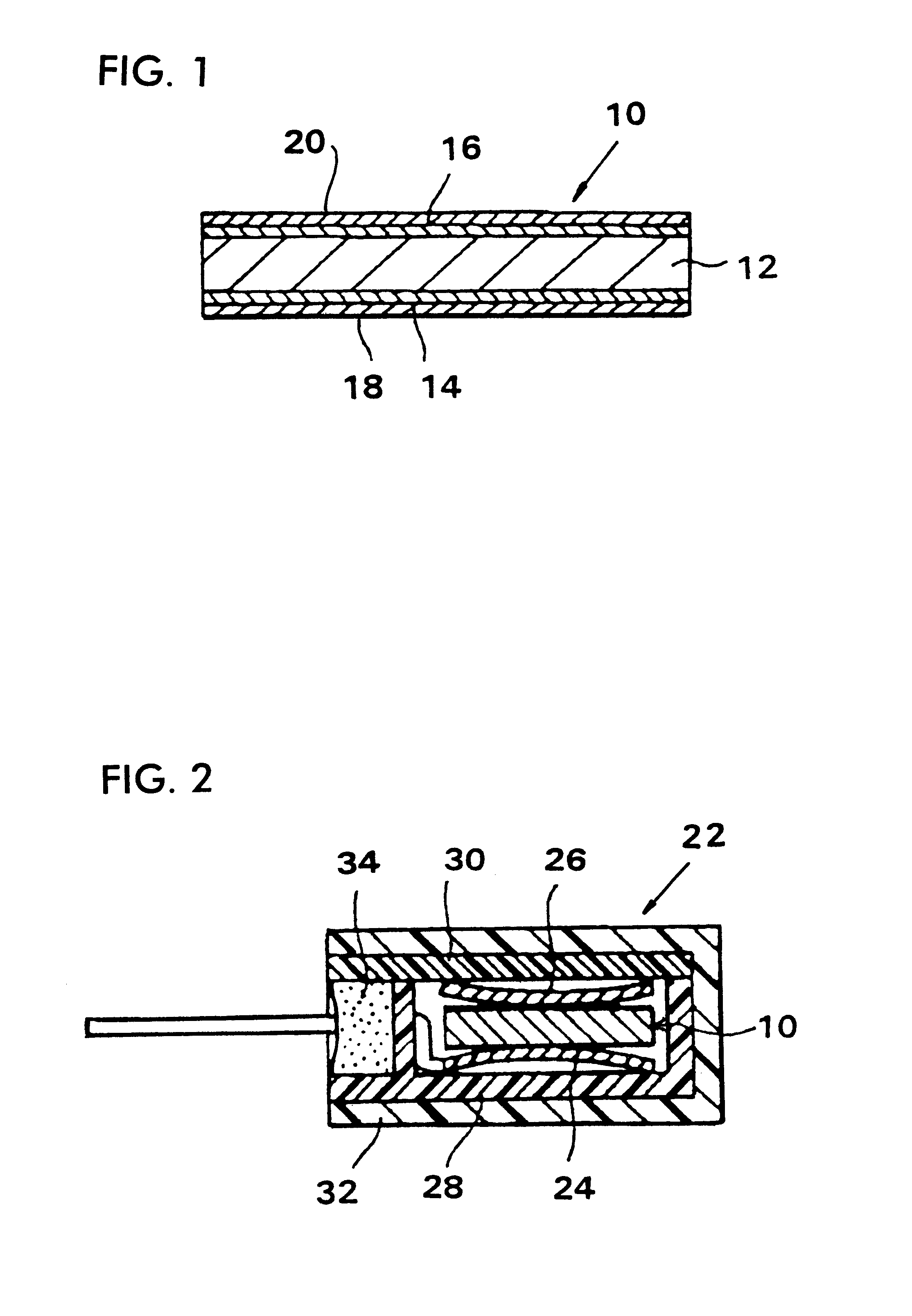

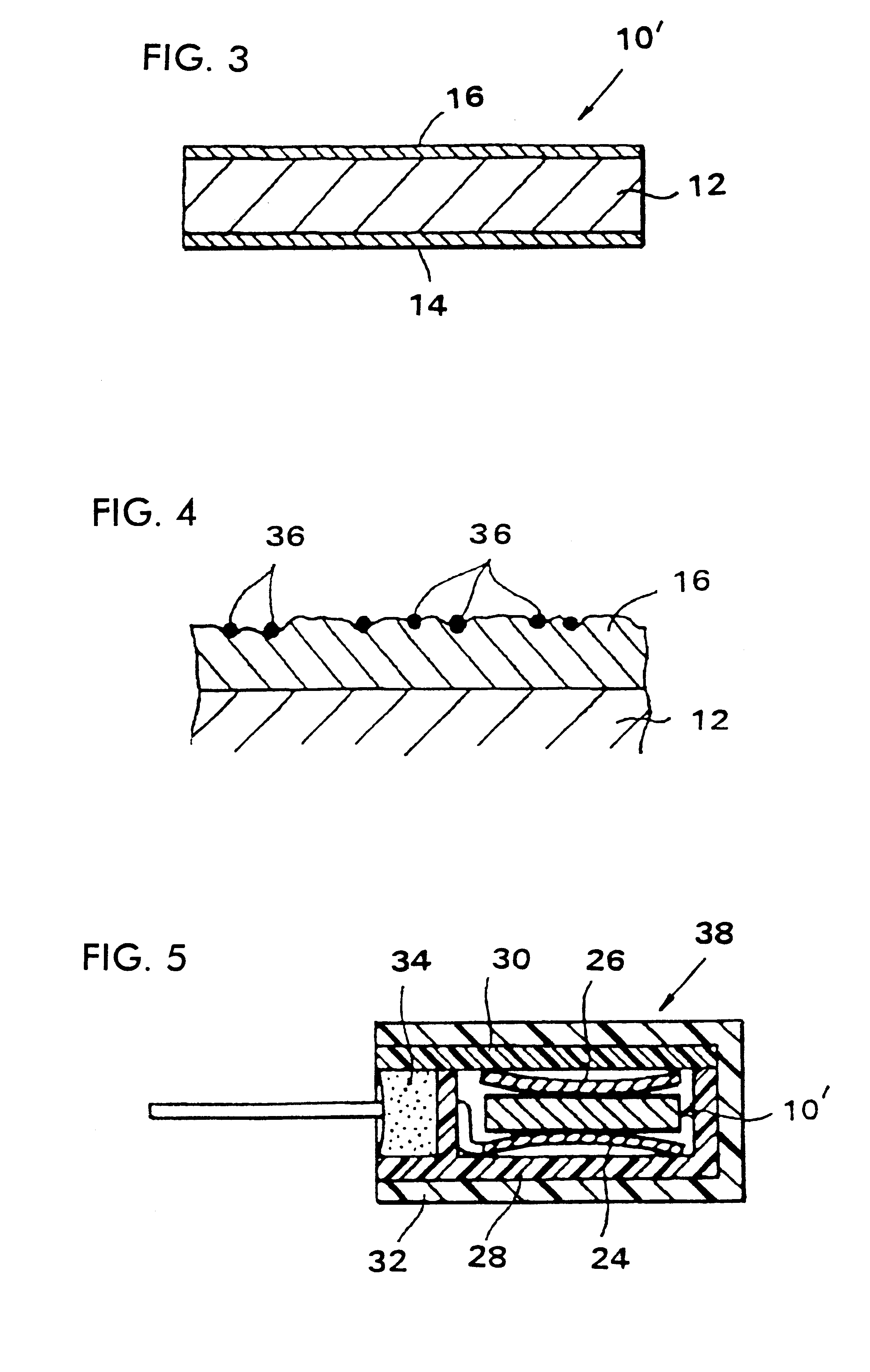

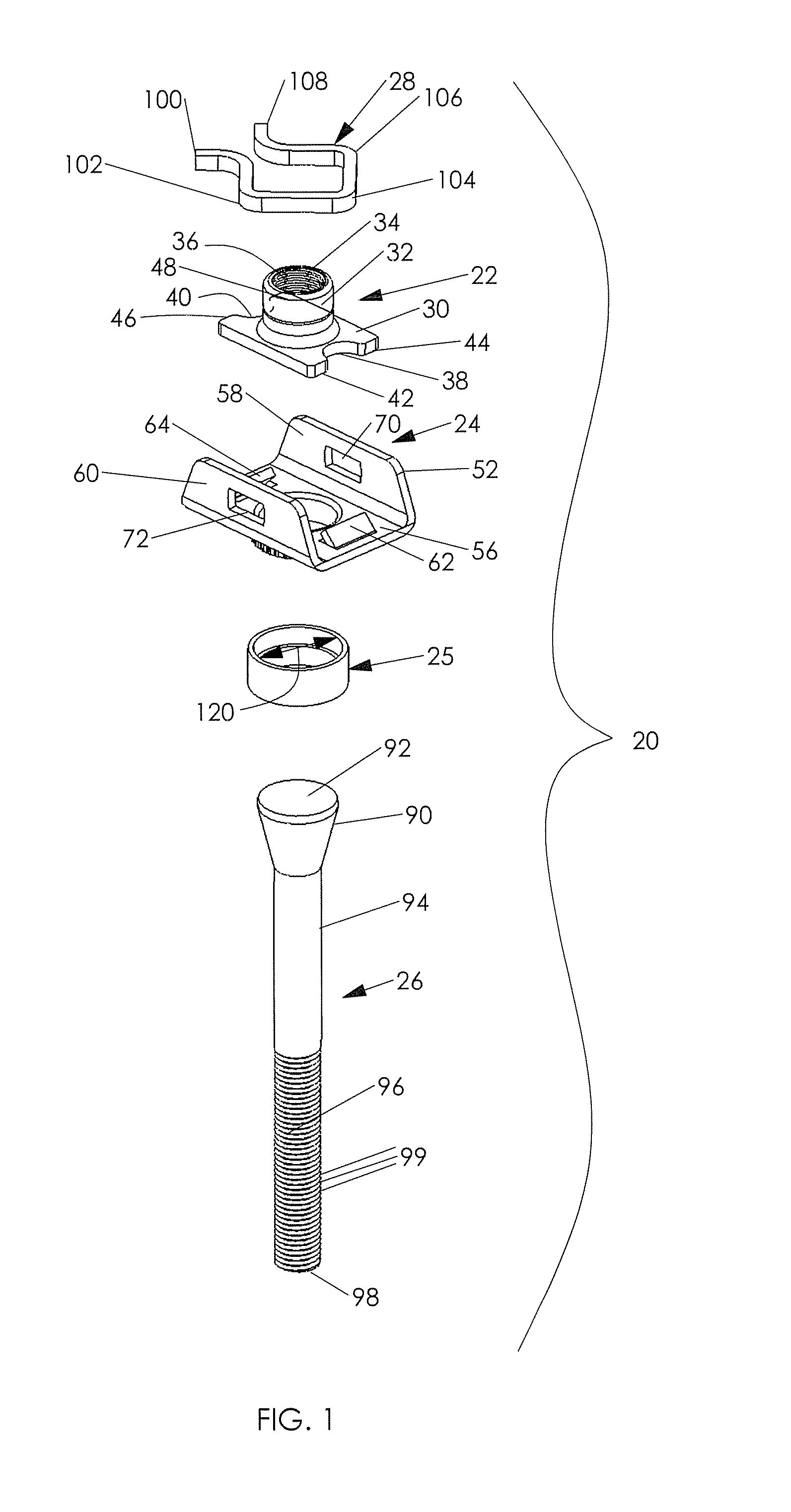

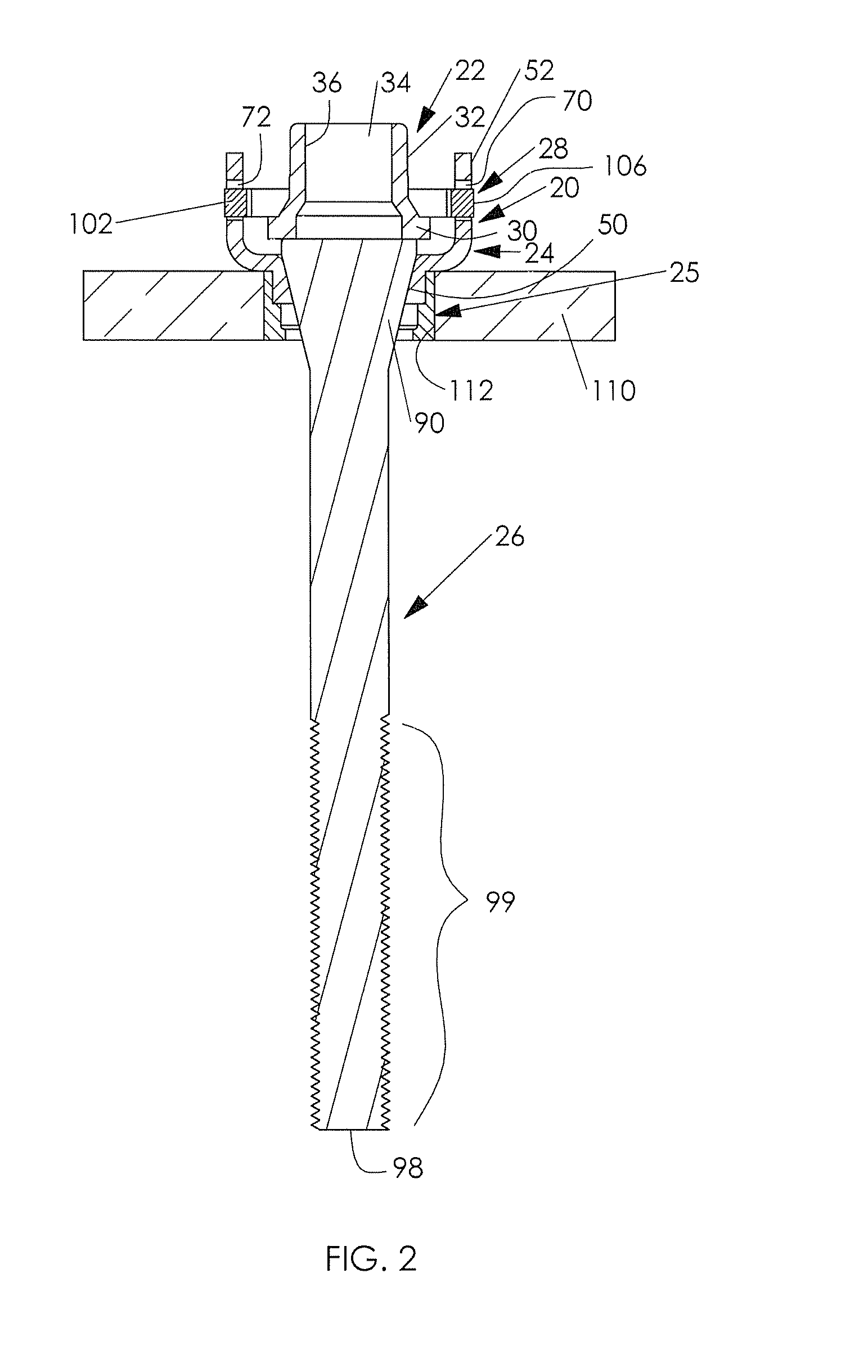

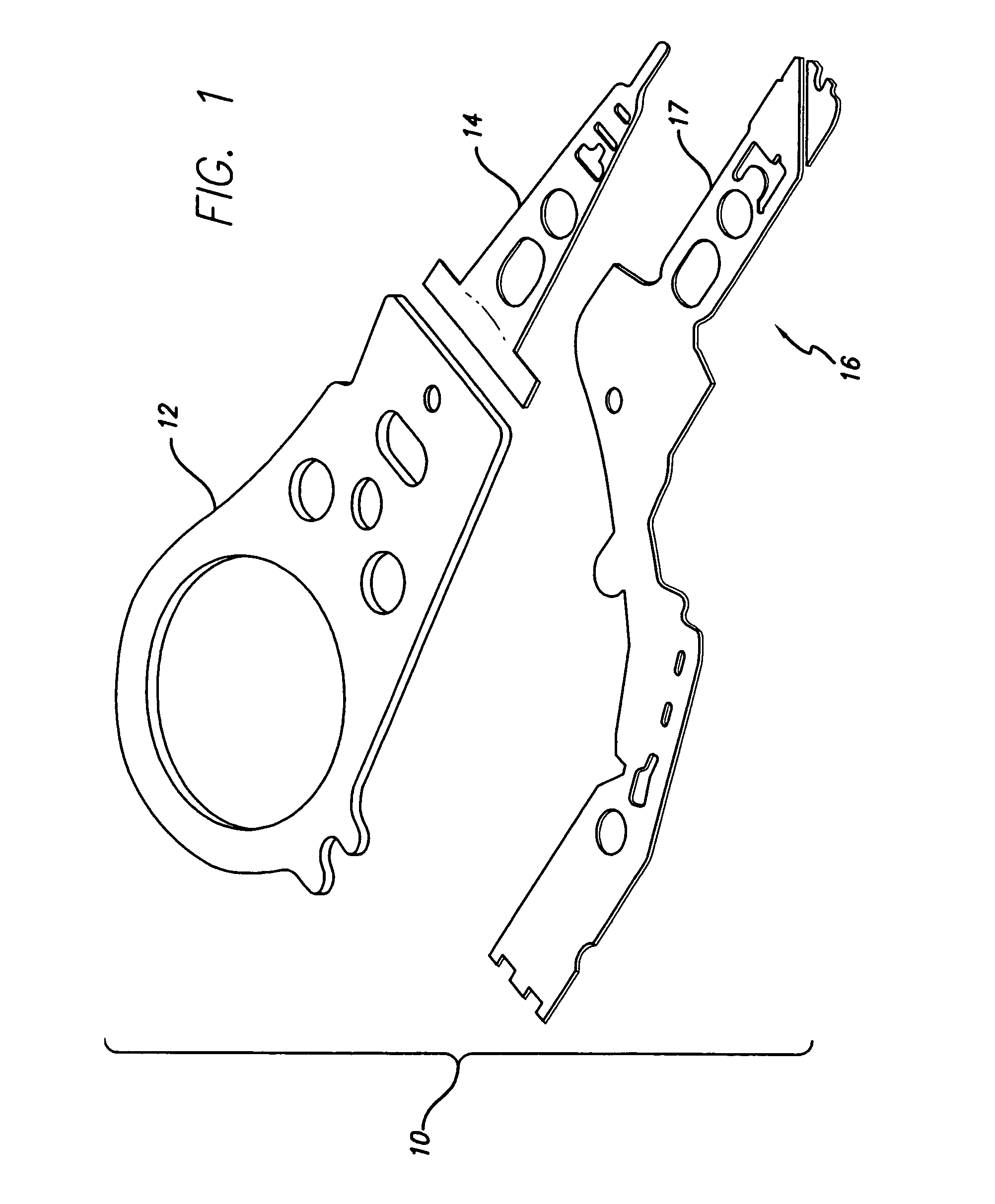

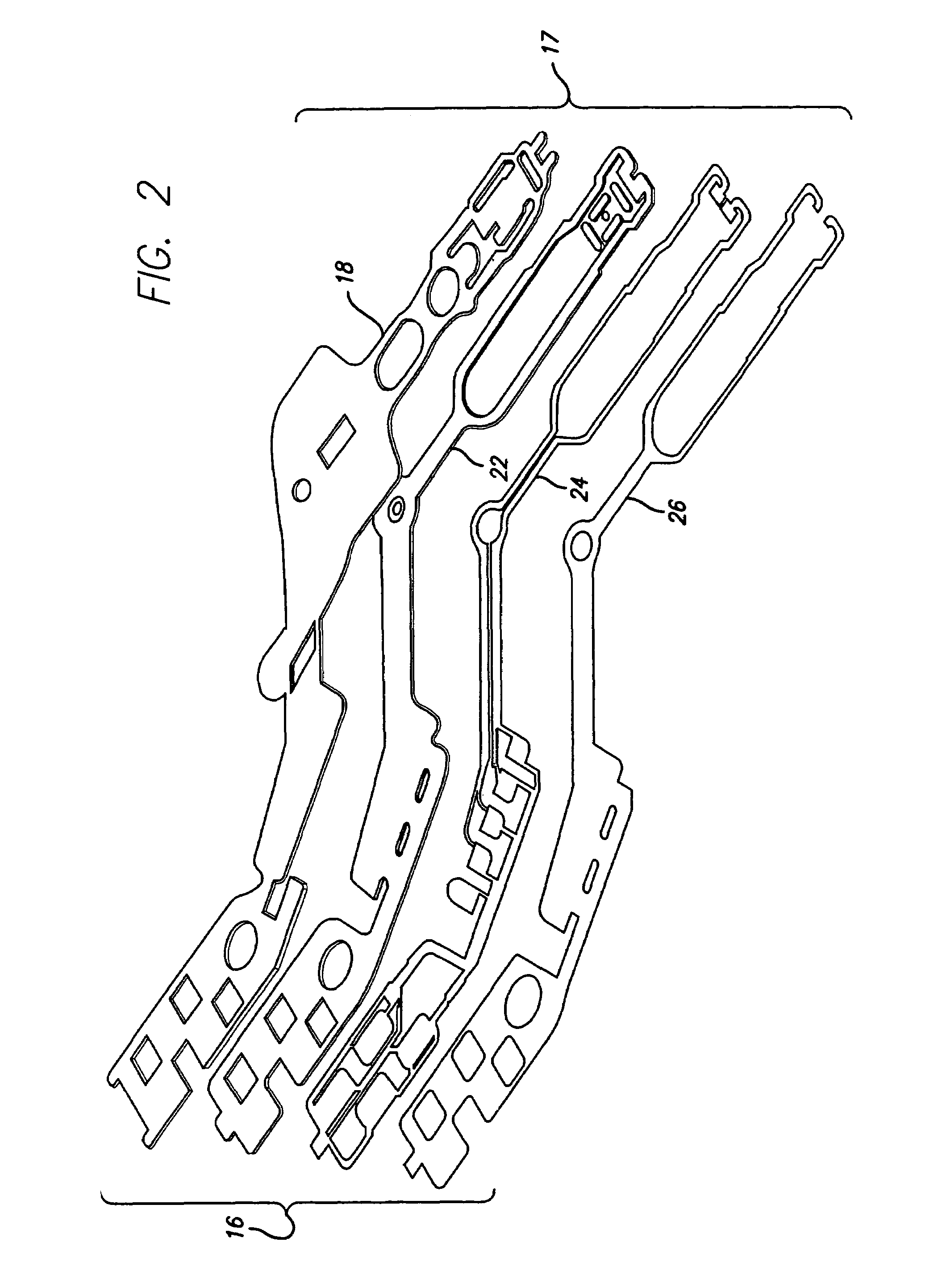

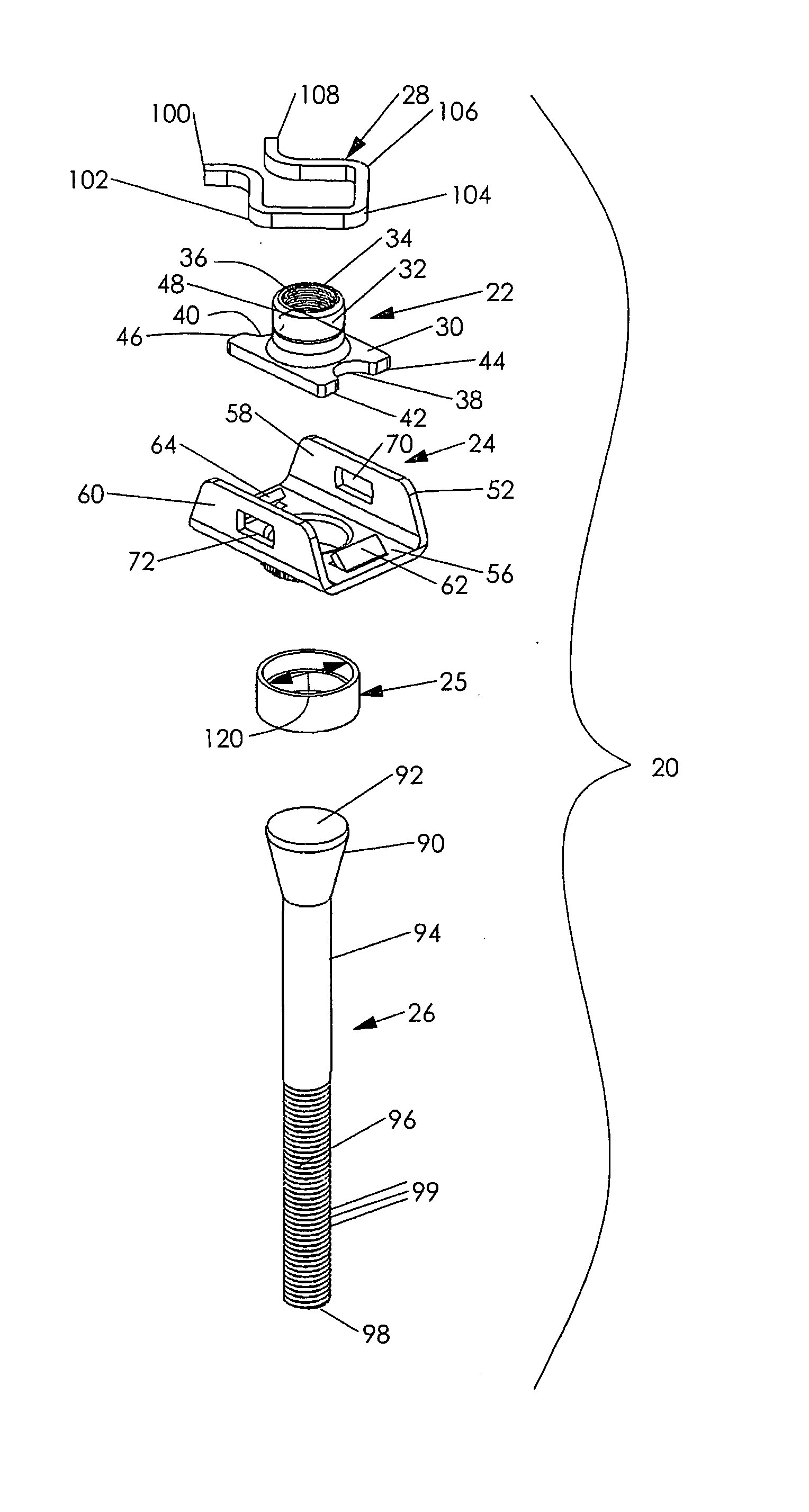

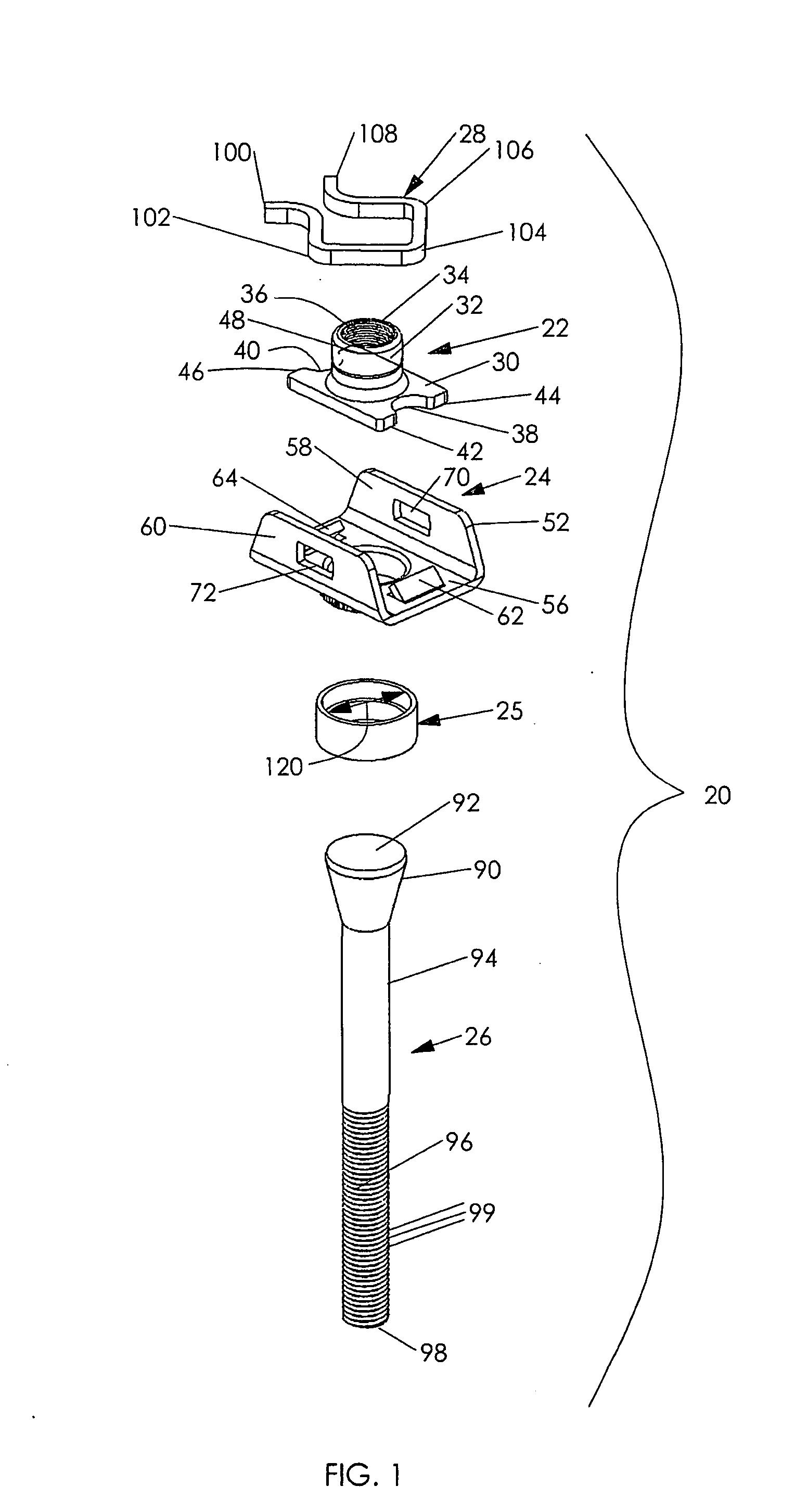

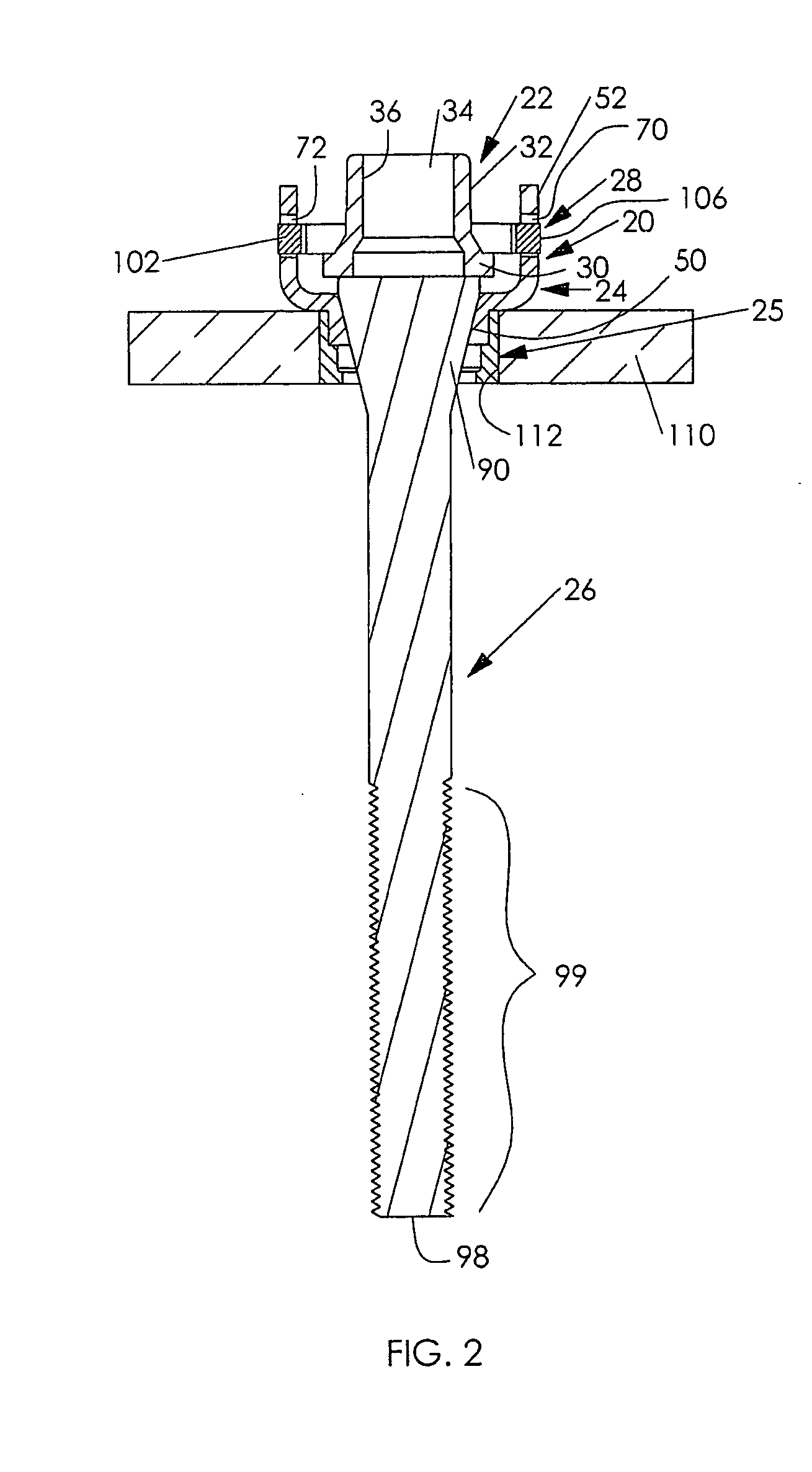

Nut plate fastener assembly for composite materials

InactiveUS7575404B2Without risking delaminationSo as not to damageRivetsNutsMetallic materialsEngineering

A rivetless nut plate assembly, which is fully preassembled, which can be installed into an aperture of a composite material workpiece, such as a carbon fiber structure, without risking delamination of the workpiece. The rivetless nut plate assembly includes a nut, a holding bracket, a retainer, and a sleeve member. Additionally, a stem is used to install the rivetless nut plate assembly. The sleeve member is configured such that the nut plate assembly can be installed in a composite material workpiece without risking delamination. The sleeve member may be formed of 45Cb-55Ti Titanium Columbium, as Titanium Columbium is a high strength and ductile material that resists corrosion in the presence of, for example, a carbon fiber composite structure. Monel, Titanium alloys, and other soft Nickel alloys are also good material selections for the sleeve, for similar reasons. Non-metallic materials with high tensile and shear strengths, such as Torlon or Parmax, would provide the desired corrosion protection and also offer a potential weight savings.

Owner:SPS TECH LLC

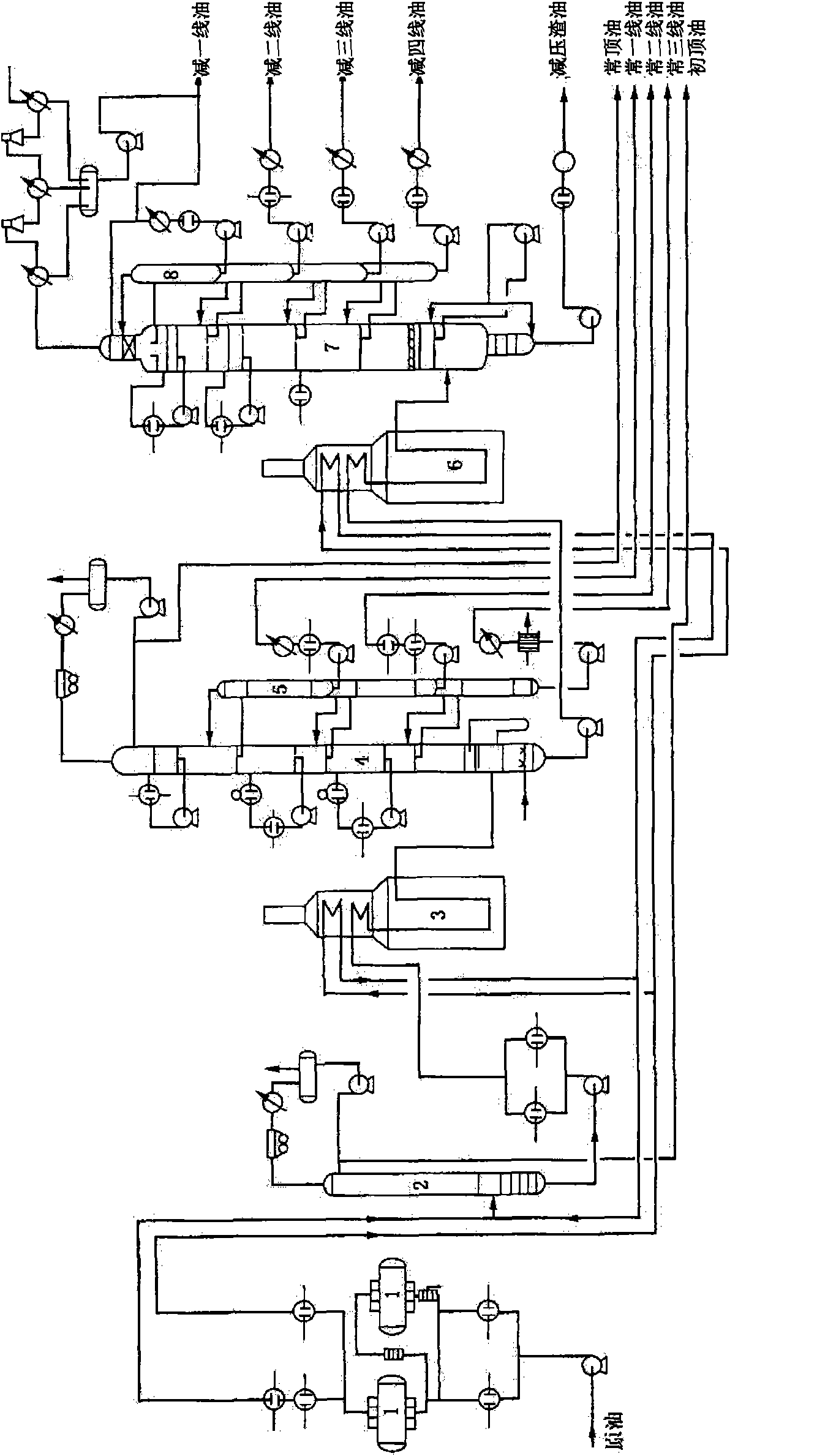

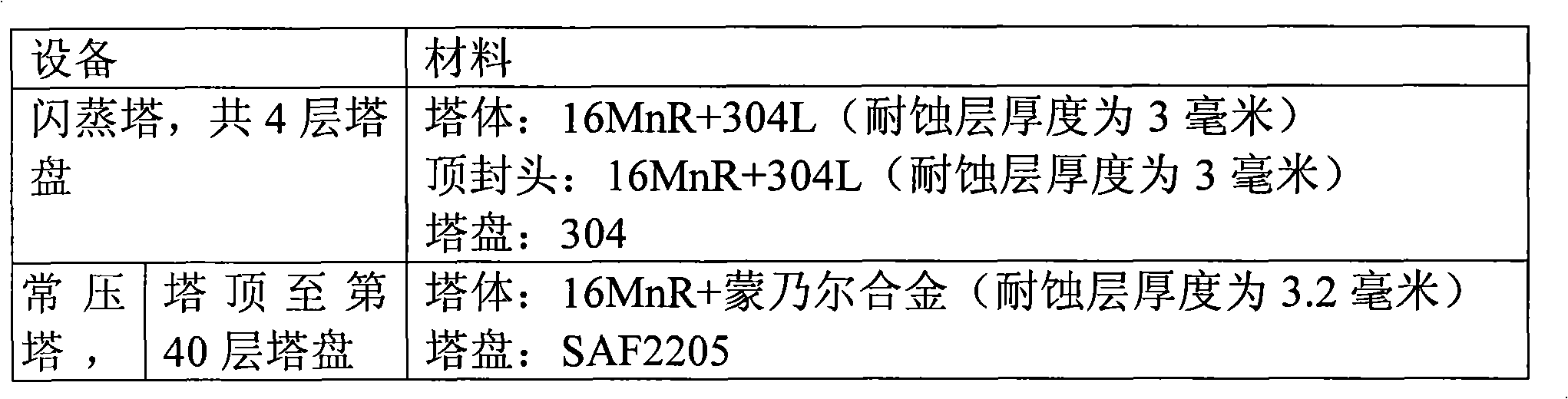

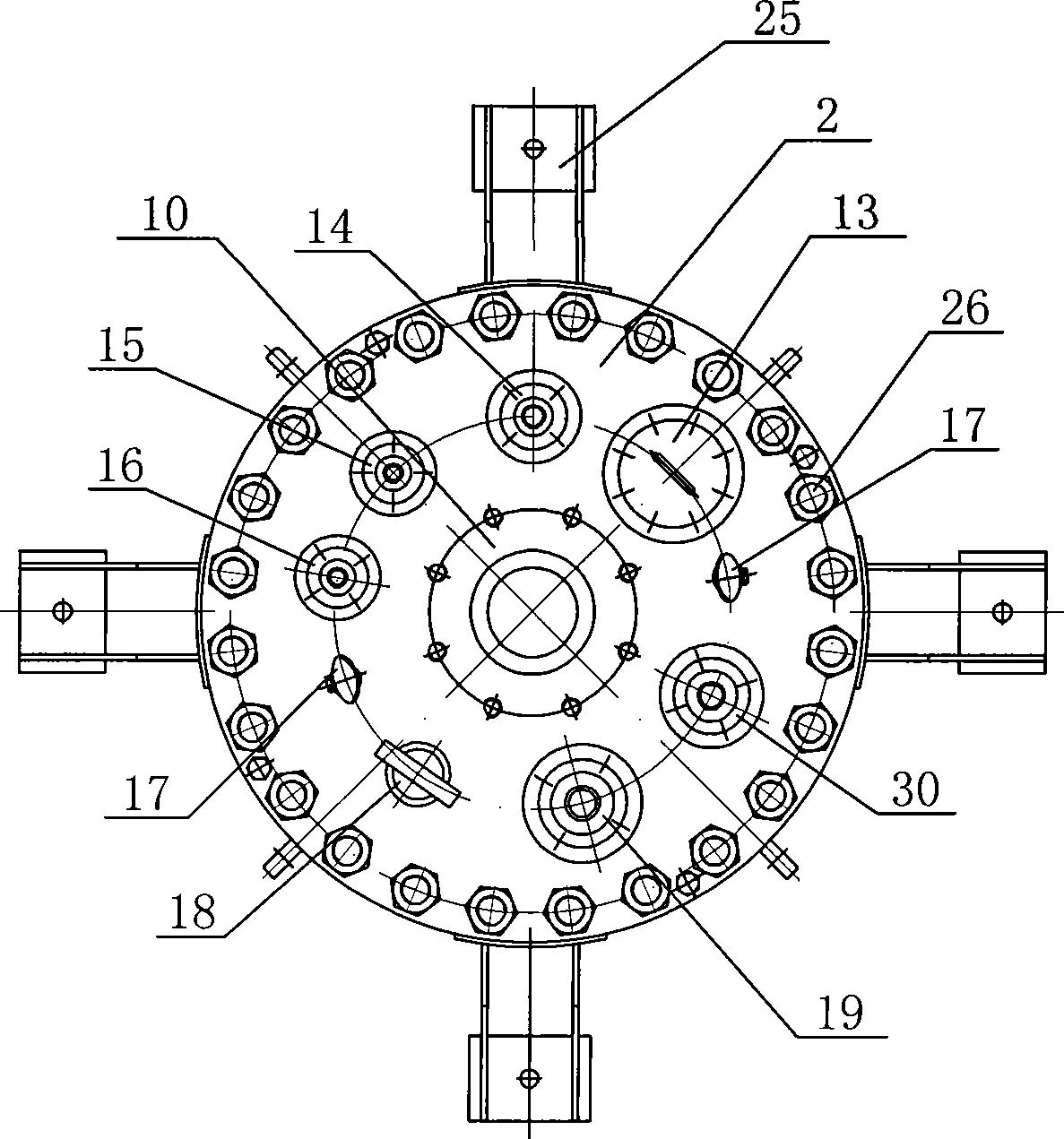

Atmospheric and vacuum distillation device and atmospheric and vacuum distillation method of high acid-content crude oil

ActiveCN101624535ASolving Corrosion ProblemsHigh metal contentHydrocarbon distillationEngineeringTower

The invention provides an atmospheric and vacuum distillation device and an atmospheric and vacuum distillation method of high acid-content crude oil. The device comprises an atmospheric tower, an atmospheric kiln, a vacuum tower and a vacuum kiln, wherein the atmospheric tower comprises a tower body, a tower tray and stuffing. The tower tray of the atmospheric tower has more than 40 layers, wherein the tower body of the atmospheric tower between the 40th layer of the tower tray and the tower top is made of metallic composite of one or a plurality of Monel, 0Cr13, 316L, SAF2205, SAF2507 and SAF 2304 and carbon steel, the tower tray is made of one or a plurality of Monel, 0Cr13, 316L, SAF2205, SAF2507 and SAF 2304, the tower body of the atmospheric tower between the tower bottom and the 40th layer of the tower tray is made of metallic composite of 316 L and carbon steel, the tower trays from the 28th layer to the 39th layer are made of 0Cr13 material and the tower trays from the first layer to the 28th layer are made of 316L. The atmospheric and vacuum distillation device effectively solves the problem of device corrosion in the atmospheric and vacuum distillation of high acid-content crude oil.

Owner:CNOOC OIL & PETROCHEMICALS CO LTD +1

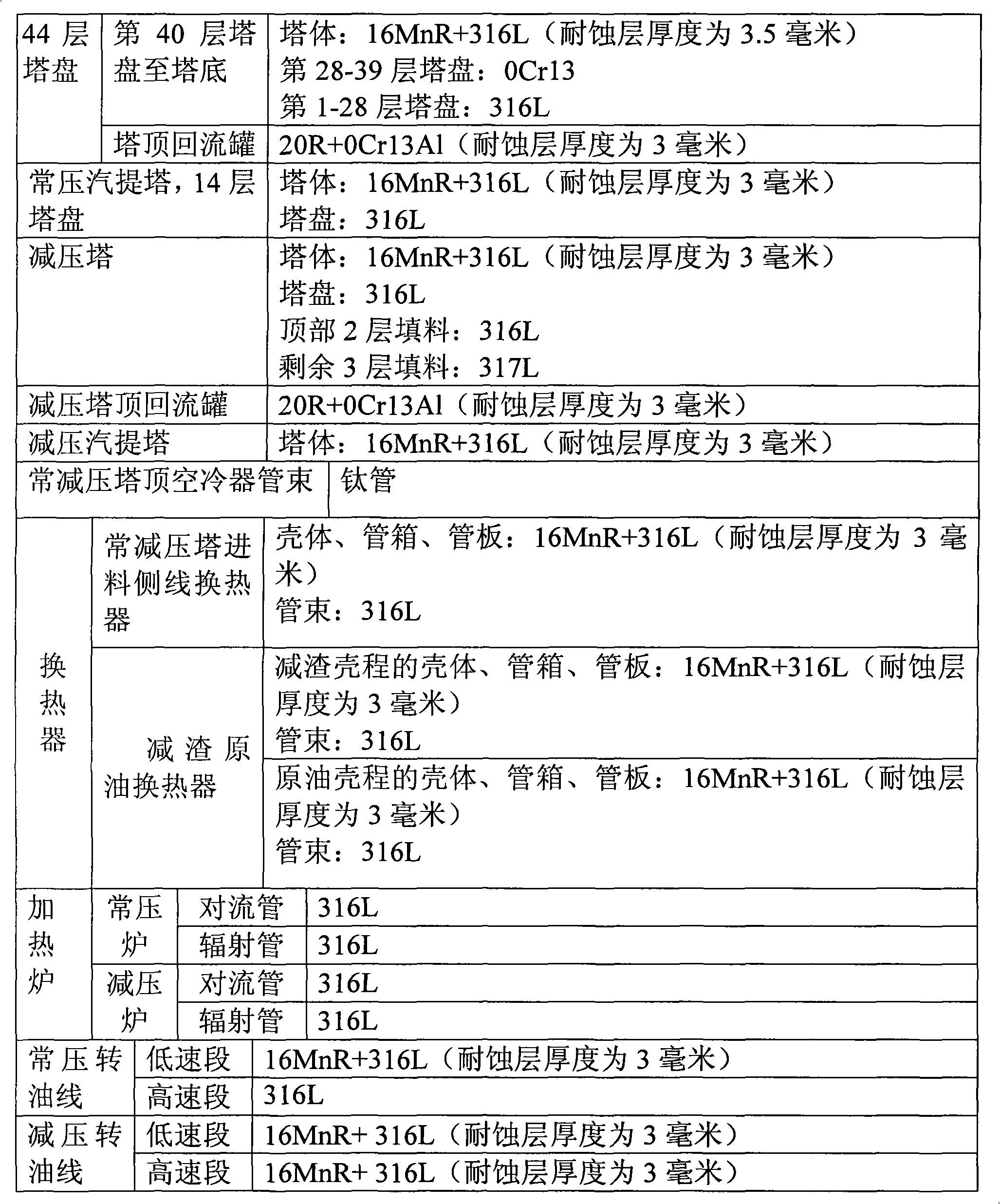

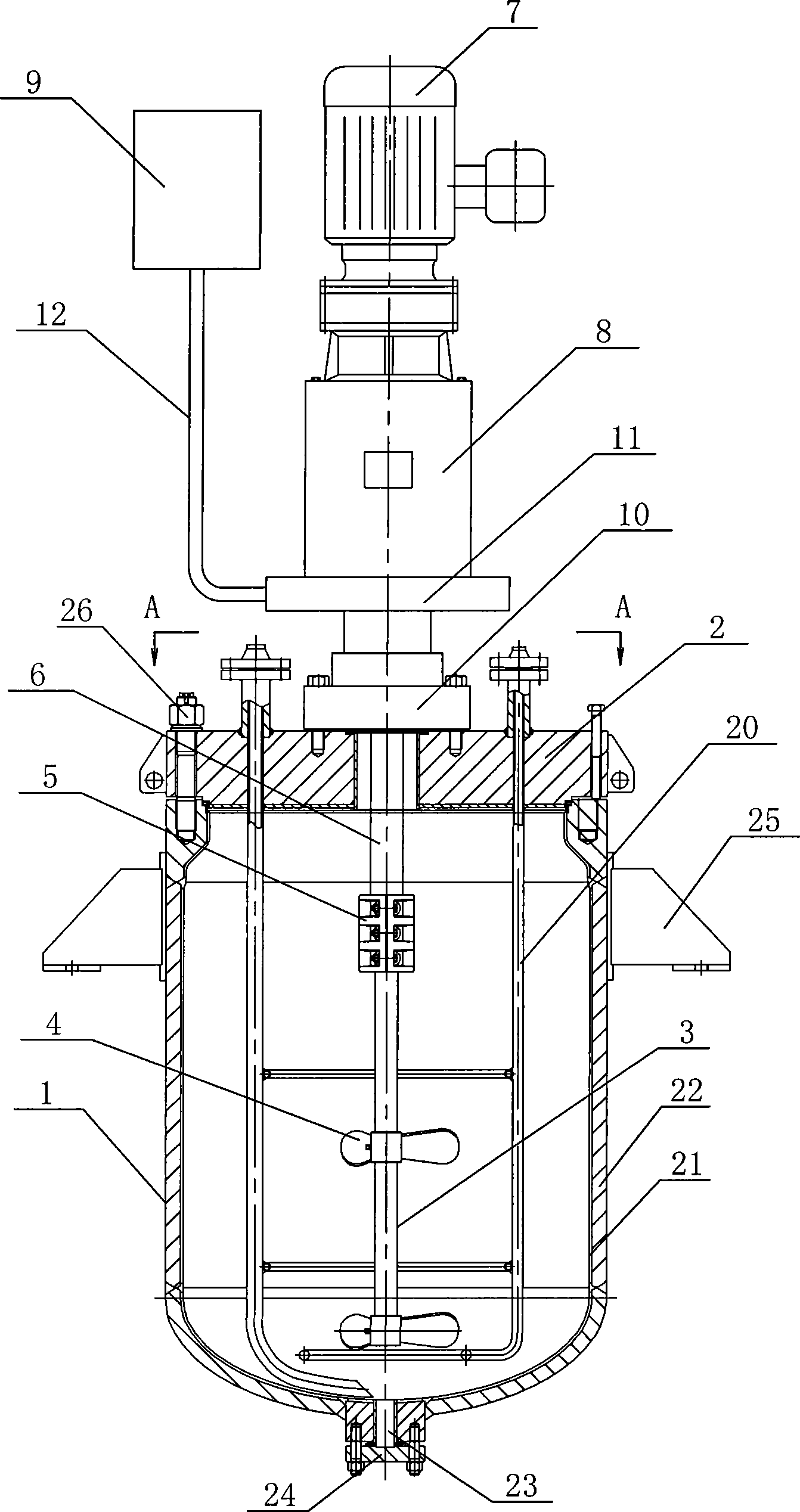

Novel reaction kettle

InactiveCN101518725AHigh strengthReduce the burden onChemical/physical/physico-chemical stationary reactorsChemical industryHydrogen fluoride

The invention discloses a novel reaction kettle which comprises a vertical-type cylindrical kettle body with a top opening, a kettle lid is sealed on the upper opening part of the kettle body, a stirrer is arranged in the kettle body and penetrates out of the kettle lid to be connected with a power device in transmission, the outside of the rotary connecting part of the stirrer and the kettle lid is provided with an air-pressure sealer, the kettle body and the kettle lid are in a double-layer composite structure, the internal layer is made of Monel 400 and the external layer is made of 316 L steel. The invention has novel design, simple structure, low cost and fluorine hydride corrosion resistance under the conditions of high temperature and high pressure, is professionally suitable for the field of chemical industry using fluorine hydride as the medium, has wide market prospect and is easy to popularize and apply.

Owner:河南省东旭碳材塑料有限公司

Method for preparing corrosion and abrasion resisting coating through supersonic electric arc spraying

The invention discloses a method for preparing a corrosion and abrasion resisting coating through supersonic electric arc spraying. The method comprises the following steps that a matrix is subjected to surface roughening, and impurities on the surface of the matrix are removed; a surface roughness tester is used for carrying out quality inspection on a sprayed part of the matrix; an abrasion-proof material such as monel alloy or cobalt-gold alloy or nickel-tungsten alloy or a composite hard material is selected; supersonic electric arc spraying is carried out on the sprayed part of the matrix to prepare the metal coating, wherein the spraying speed ranges from 300 m / s to 400 m / s; and low surface energy matter is sprayed on the coating, drying is carried out at the temperature ranging from 800 DEG C to 1,200 DEG C, and the corrosion and abrasion resisting coating is prepared, wherein the hardness of the coating is HV397, the coating is of a layer texture structure, the void ratio of the coating ranges from 0.9% to 2.3%, and the average particle size of spraying particles is 4.32 micrometers. The obtained coating is better in bonding strength, lower in void ratio, more uniform in compactness, free of deformation of the sprayed matrix and very high in corrosion and abrasion resistance.

Owner:焦作安泰新型耐磨材料有限公司

Piezoelectric resonator and piezoelectric components using the same

InactiveUS6252337B1Piezoelectric/electrostriction/magnetostriction machinesImpedence networksMonelMetal

A piezoelectric resonator which can be used as part of a piezoelectric component prevents self-welding of electrodes including silver provided on the surface of a piezoelectric substrate with silver coated terminals with abut with electrodes by forming high fusion point metals on the electrodes 3. The high fusion point metal is made by using Ni, Cr, W, Ti, Mo, Ni-Cu (monel) or their alloy. The thickness of the high fusion point metal is preferably less than about 1 / 10 of the thickness of the electrode 3 or less than 1 mum.

Owner:MURATA MFG CO LTD

Drawing production process of monel alloy pipe

The invention relates to a drawing production process of a monel alloy pipe, particularly a production process for pipes with an outer diameter smaller than [Phi]12 mm, and belongs to the field of alloy pipe preparation technology. The process comprises the steps of performing vacuum melting, performing peeling extrusion, grinding, cold rolling, rolling, drawing to a finished product, carrying out on-line detection of faults, sizing on a drawing straightening machine, carrying out pressure tests, annealing, detecting and storing. On basis of a conventional process, the drawing production process takes use of a drawing technology, and has high yield and high efficiency.

Owner:江苏隆达超合金股份有限公司

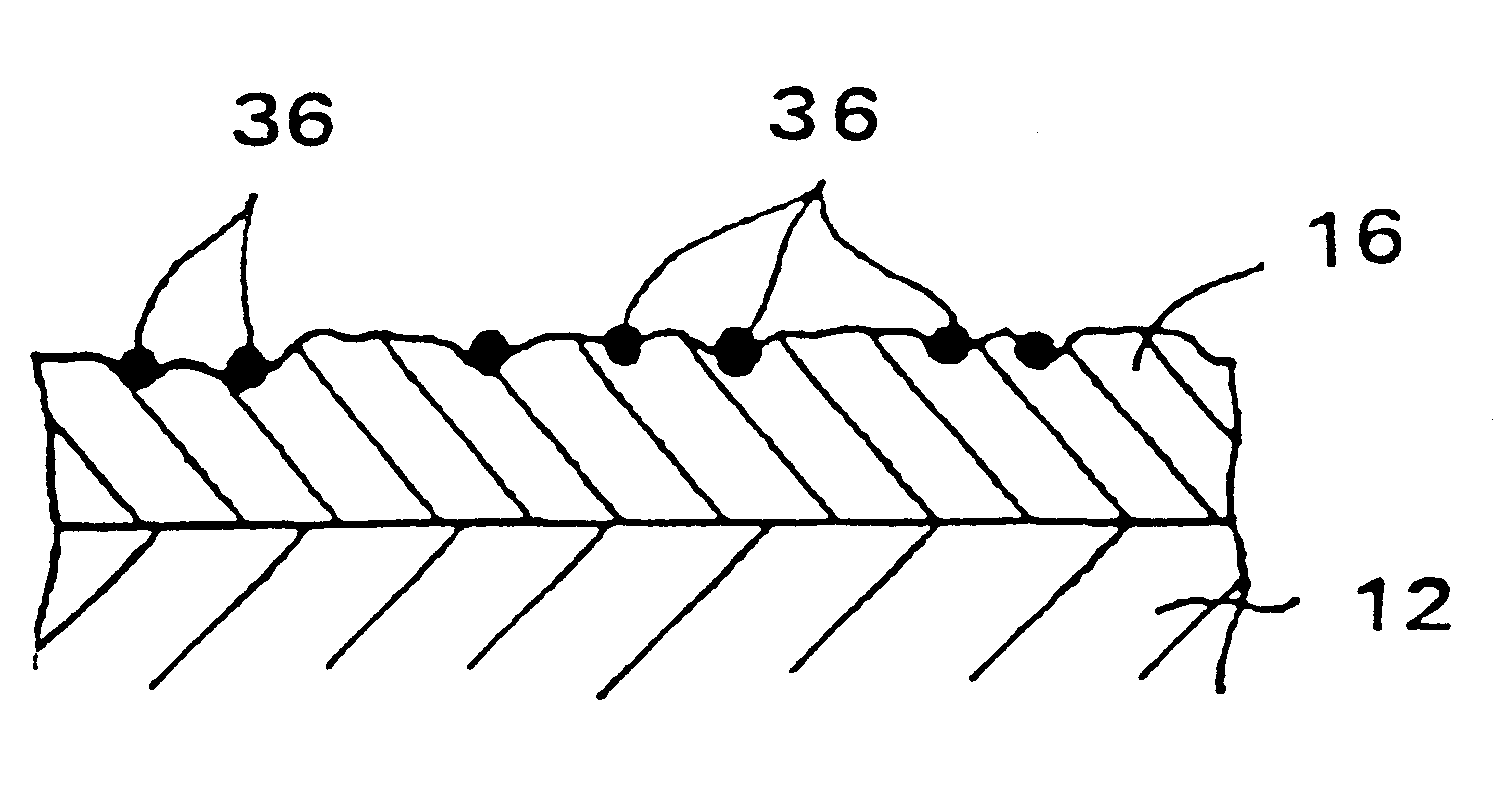

Nut plate fastener assembly for composite materials

InactiveUS20080101887A1Without risking delaminationSo as not to damageRivetsNutsNiobiumMetallic materials

A rivetless nut plate assembly, which is fully preassembled, which can be installed into an aperture of a composite material workpiece, such as a carbon fiber structure, without risking delamination of the workpiece. The rivetless nut plate assembly includes a nut, a holding bracket, a retainer, and a sleeve member. Additionally, a stem is used to install the rivetless nut plate assembly. The sleeve member is configured such that the nut plate assembly can be installed in a composite material workpiece without risking delamination. The sleeve member may be formed of 45Cb-55Ti Titanium Columbium, as Titanium Columbium is a high strength and ductile material that resists corrosion in the presence of, for example, a carbon fiber composite structure. Monel, Titanium alloys, and other soft Nickel alloys are also good material selections for the sleeve, for similar reasons. Non-metallic materials with high tensile and shear strengths, such as Torlon or Parmax, would provide the desired corrosion protection and also offer a potential weight savings.

Owner:SPS TECH LLC

Boron-containing high-silicon Monel alloy and preparation method thereof

InactiveCN101701306AReduce solid solubilityImprove mechanical propertiesBoron containingMechanical property

The invention discloses a boron-containing high-silicon Monel alloy which comprises the following components by weight percent: 28.0%-30.0% of Cu, 0-2.0% of Fe, 0-1.0% of Mn, 3.5%-4.5% of Si, 0.01%-0.10% of B and the balance of Ni, and the sum of the weight weights of all the components is 100%. The method for preparing the alloy comprises the following steps of firstly weighing alloy powder according to the mixing ratio, placing the weighed alloy powder into a mixing machine for mixing for 6-10 hours for leading the alloy powder to be fully evenly mixed, then pressing into a block, placing into an alumina crucible, and placing the alumina crucible containing the block-shaped alloy material into a vacuum furnace for melting, thereby obtaining the boron-containing high-silicon Monel alloy. The boron-containing high-silicon Monel alloy and the preparation method can solve the problems that the existing high-silicon Monel alloy has poor mechanical performance, corrosion-resistant performance and process performance due to dendrite segregation.

Owner:XIAN UNIV OF TECH

Method for purifying gas of nitrogen trifluoride

ActiveCN1727279AEfficient removalFluoride preparationNitrogen and non-metal compoundsPurification methodsElectrolysis

A process for purifying NF3 gas containing N2F2, which is generated by electrolysis method, includes such steps as loading one or more of Fe, stainless steel, Cu, Ni and Monel alloy in cracking tower, heating to 100-400 deg.C, filling the gas mixture of NF3 and N2F2, and removing N2F2 by its high-temp decomposing.

Owner:派瑞科技有限公司

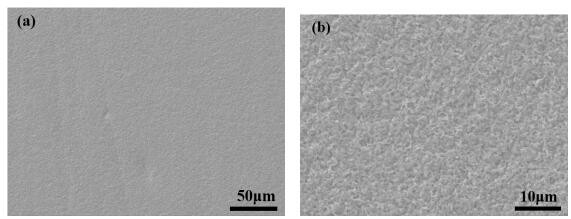

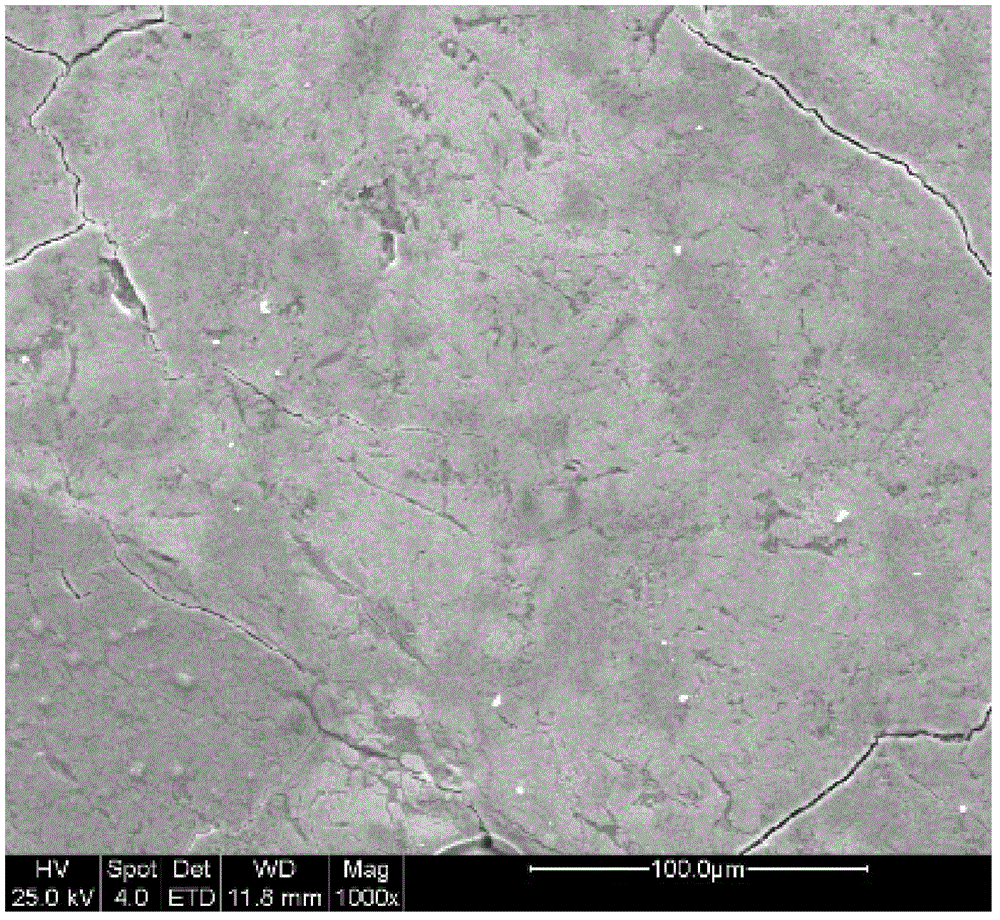

Method for thermally spraying monel metal coating on surface of stainless steel

The invention relates to a method for thermally spraying a monel metal coating on the surface of the stainless steel. The method comprises the following steps: decontaminating the surface of a stainless steel substrate, sand-blasting and roughing the decontaminated stainless steel substrate, thermally spraying a nickel-aluminum bond coating on the roughed surface, thermally spraying a monel metal work coating to cover the bond coating, and carrying out sealing treatment on the monel metal coating. By adopting the method provided by the invention, the test of metallurgical microscopy and microhardness proves that the monel metal coating prepared on the surface of the stainless steel can effectively reduce the pore and cavity of the coating, and can effectively seal the pore and cavity of the surface by using the hole-sealing filler. As the coating hardness is influenced by the characteristics of the thermal spraying, the coating has material oxide inclusion, and the coating hardness is improved by 1.426 times in comparison with that of the primary monel metal.

Owner:上海大豪纳米材料喷涂有限公司

Surface laser-clad Ni-based alloy

InactiveCN108130528AImprove performanceReduce coefficient of frictionMetallic material coating processesAlloy substrateSolid solution

The invention discloses a surface laser-clad Ni-based alloy. A Ni-based alloy modified layer is prepared on the surface of a Monel 400 alloy with a laser cladding technology. The result indicates thatthe structure of the Ni-based alloy modified layer on the surface of the Monel alloy mainly comprises gamma-Ni solid solutions, multi-element eutectics and some primary precipitates. Laser cladding treatment is performed with an optimized laser irradiation process, the Ni-based alloy modified layer with excellent performance can be obtained, and compared with a Monel 400 alloy substrate, the Ni-based alloy laser modified layer has the microhardness 7 times that of the substrate, obviously reduced friction coefficient and relative wear resistance improved by 8.6 times.

Owner:林艳红

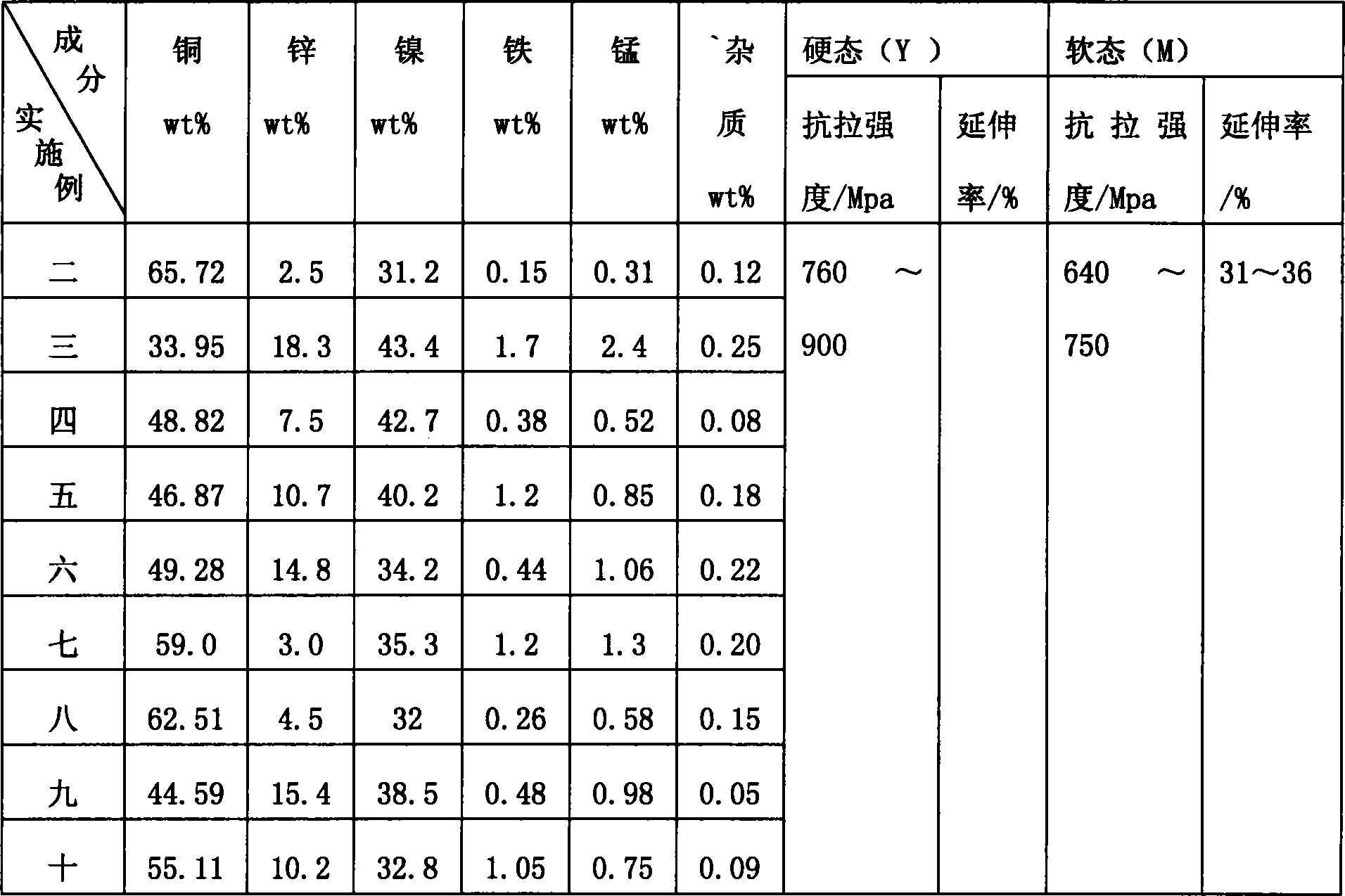

Novel elastic alloy material

A novel elastic alloy material is composed of the following components with a different weight percentage: nickel 30.0-45.0 percent, zinc 2.0-20.0 percent, iron 0.1-2.0 percent, manganese 0.3-3.0 percent and the remainders are copper and unavoidable impurities. Compared with the prior Monel, the dosage of the nickel of the novel elastic alloy material of the present invention is greatly reduced, but has an equivalent color and lustre and mechanical property, an excellent tensile strength and elongation, and is an excellent substitute for the traditional Monel.

Owner:厦门火炬特种金属材料有限公司

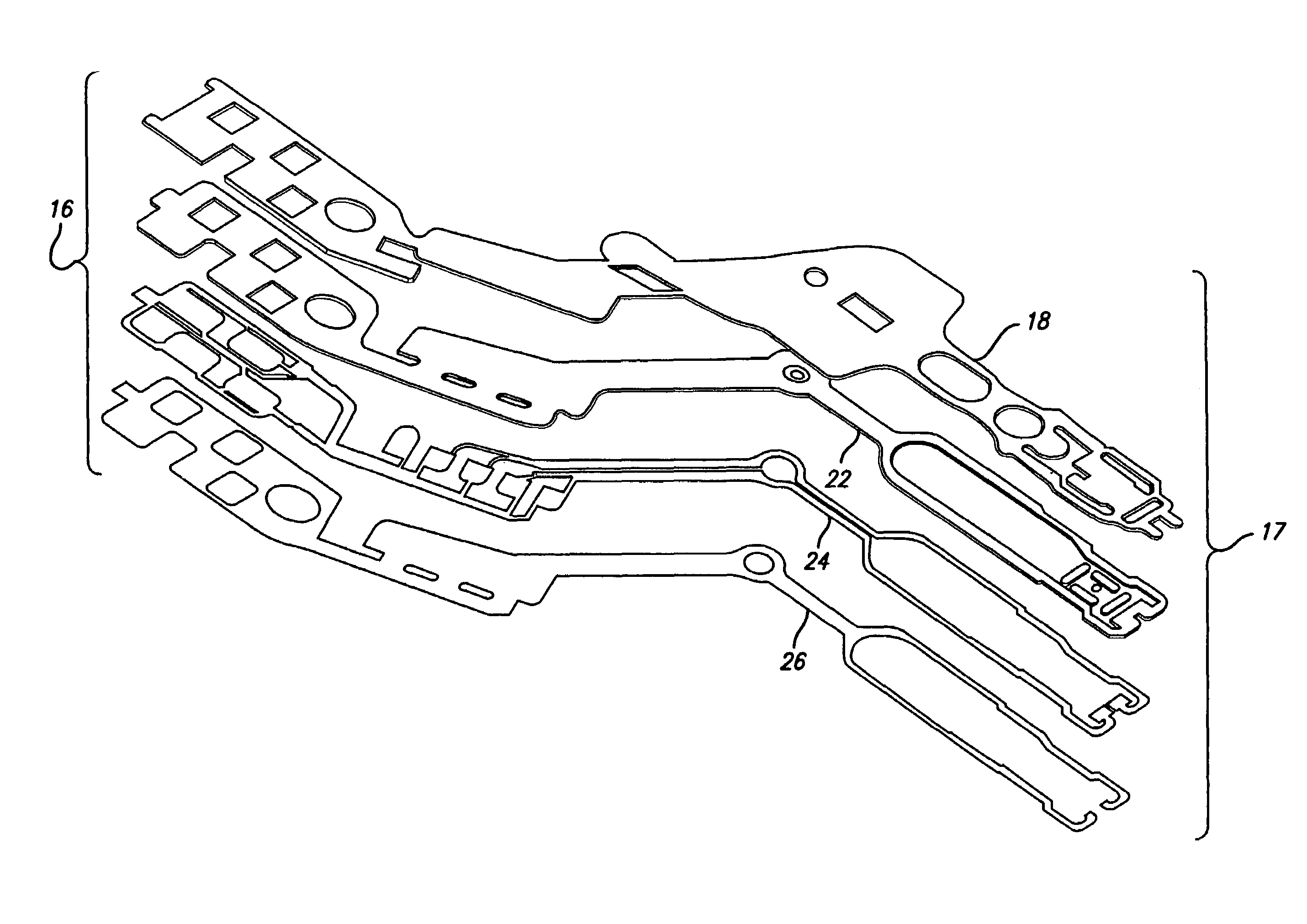

Multilayer gimbal suspension element manufacture with co-etchable layers

ActiveUS7379271B1Few process stepsReduce total usageRecord information storageMounting/attachment of transducer headPlastic filmMonel

Shaping of a gimbal suspension element for a disk drive suspension using fewer process steps includes disposing an element, precursor assembly of a plastic film layer and a copper layer with an interlayer of a copper seed layer and a Monel alloy for etching, and etching the assembly with an etchant such as cupric chloride for both the alloy and the copper seed layer of the interlayer.

Owner:MAGNECOMP

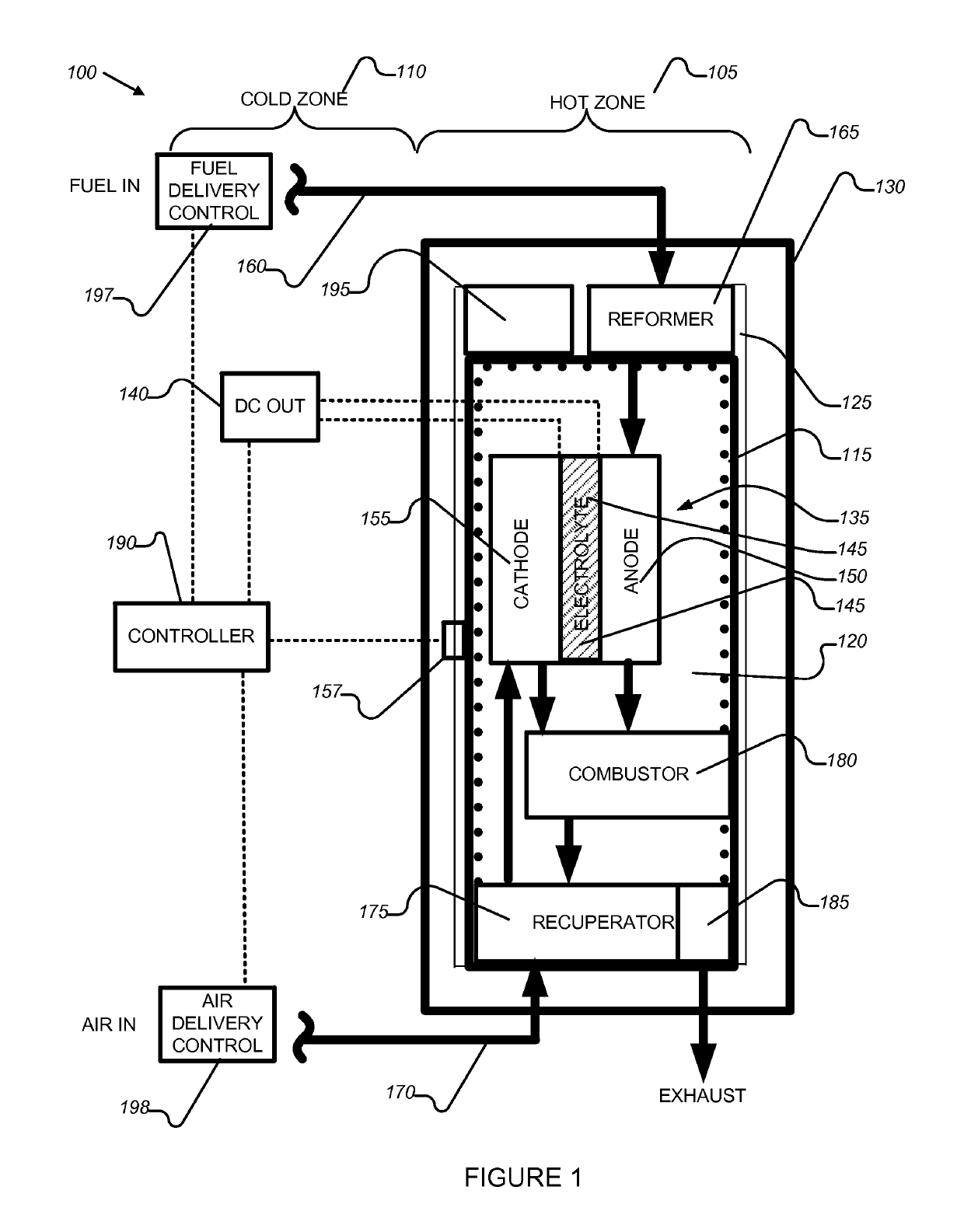

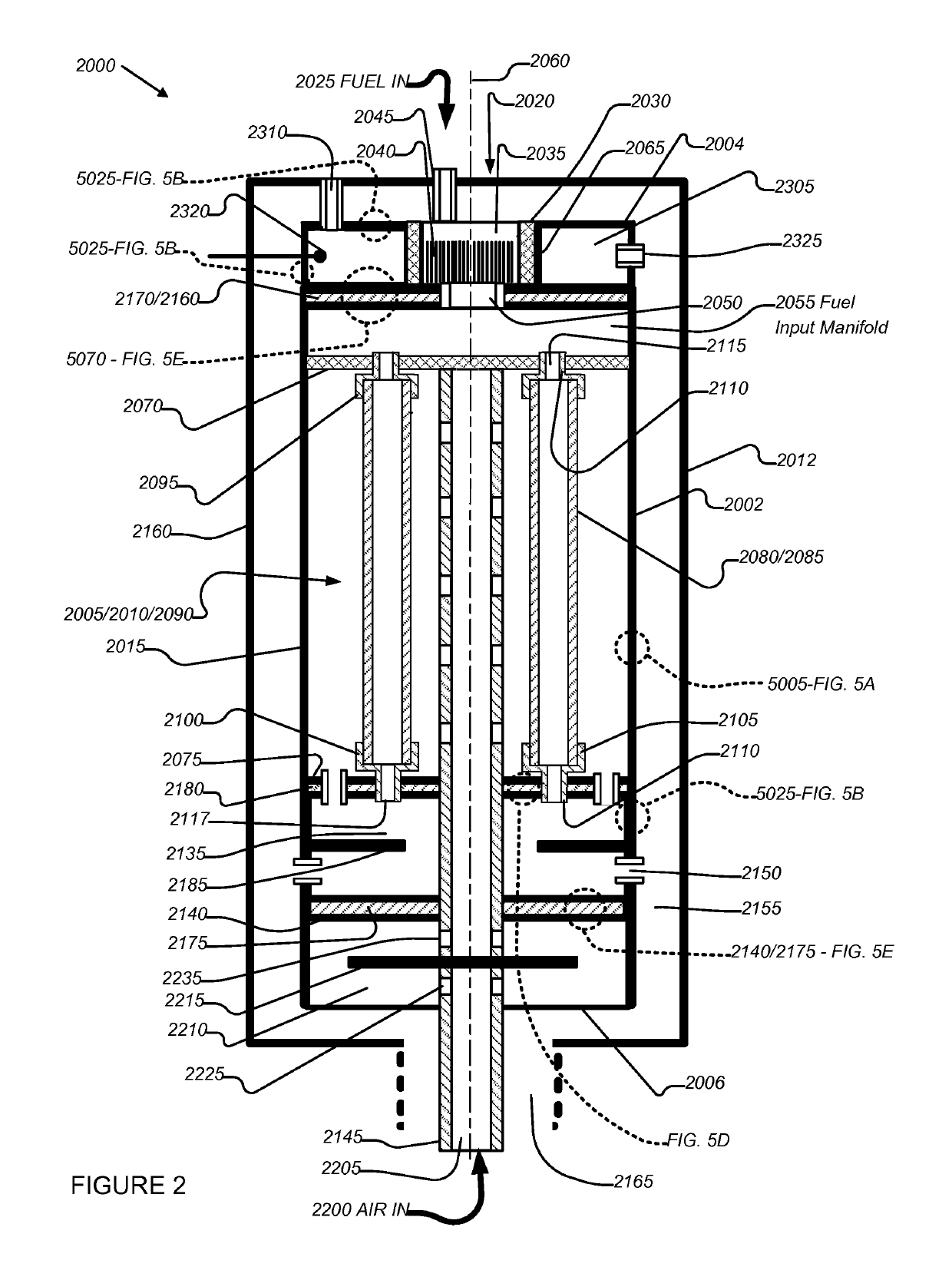

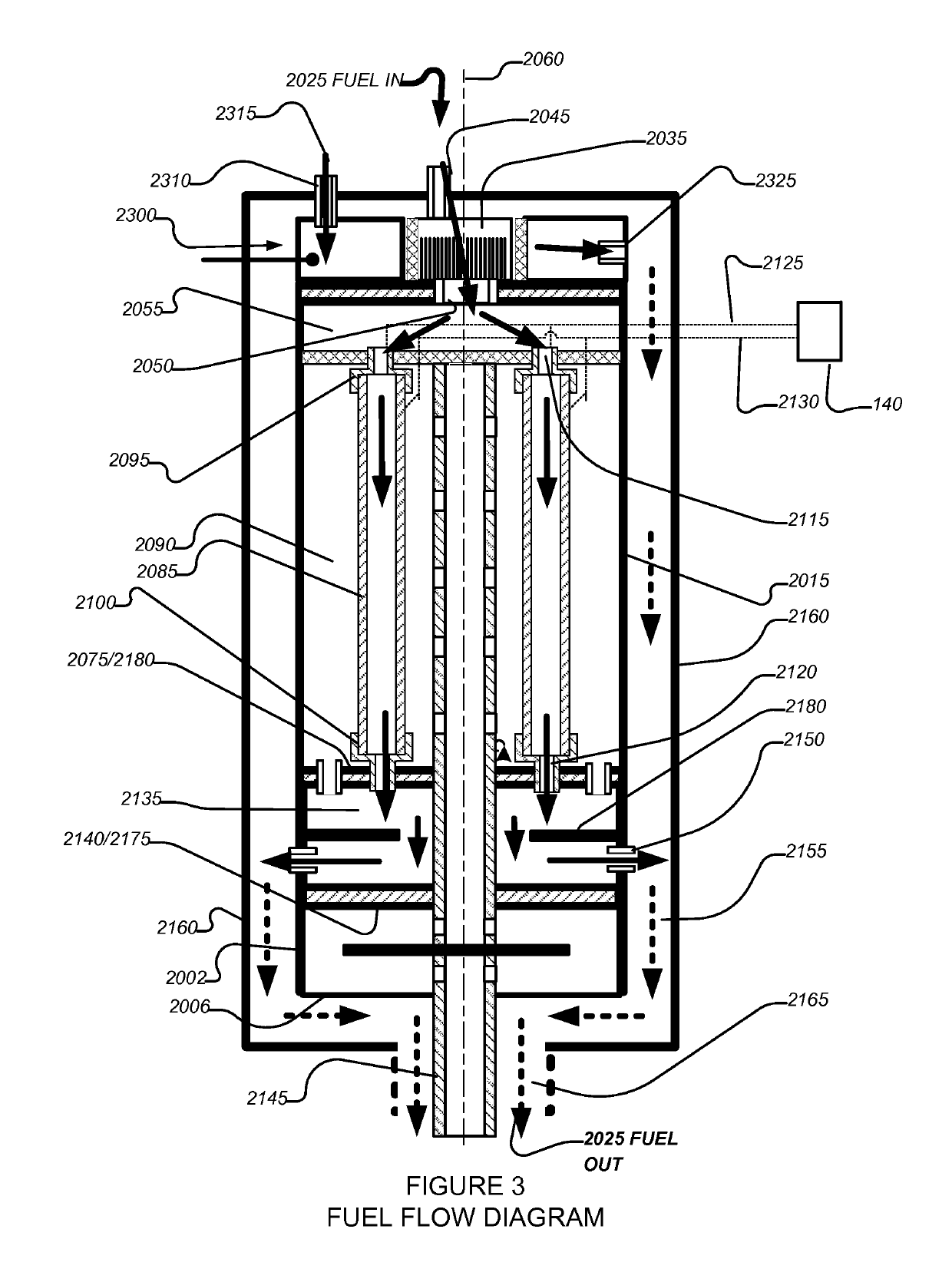

SOFC-conduction

ActiveUS10446858B2Reduce thermal gradientStable temperatureFuel cell heat exchangeSolid electrolyte fuel cellsThermal energyCombustion chamber

A solid oxide fuel cell (SOFC) system included high thermal conductivity materials such as copper to increase thermal energy transfer by thermal conduction. The copper is protected from oxidation by nickel electroplating and protected from thermal damage by providing Hastelloy liners inside combustion chambers. Monel elements are used in the incoming air conduits to prevent cathode poisoning.

Owner:UPSTART POWER INC

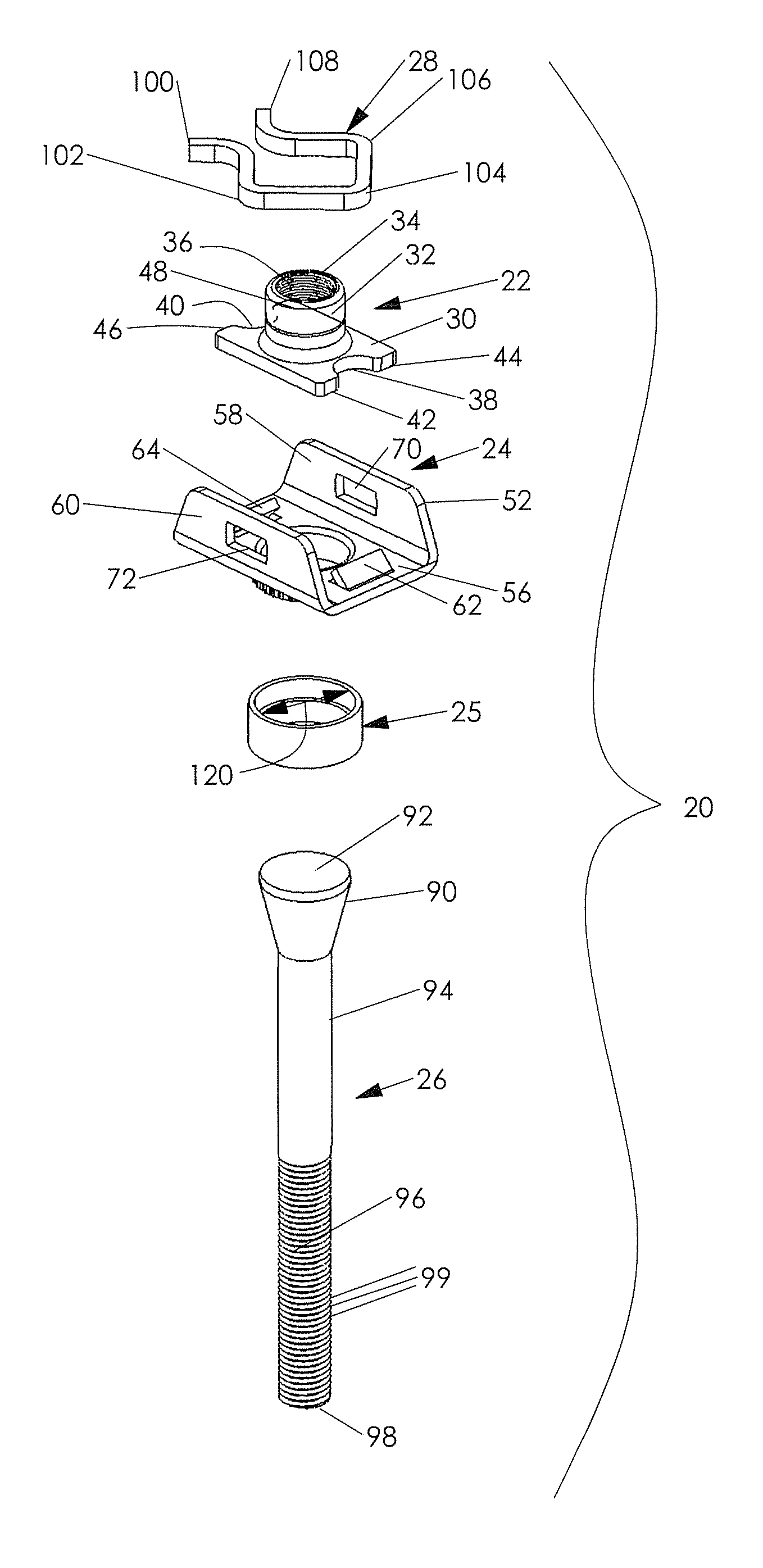

Nut plate fastener assembly for hard metal materials

InactiveUS20080101888A1Without risking delaminationSo as not to damageRivetsNutsEngineeringTitanium alloy

A rivetless nut plate assembly, which is fully preassembled, which can be installed into an aperture of a hard metal material workpiece having a hardness of at least 25 Rc, such as Titanium and Steel Alloys. The rivetless nut plate assembly includes a nut, a holding bracket, a retainer, and a sleeve member. Additionally, a stem is used to install the rivetless nut plate assembly. The sleeve member is configured such that the nut plate assembly can be installed in a hard metal material workpiece. The sleeve member may be formed of a high strength, but ductile material, such as Titanium Columbium, Monel, soft Nickel alloys or soft Titanium alloys.

Owner:SPS TECH LLC

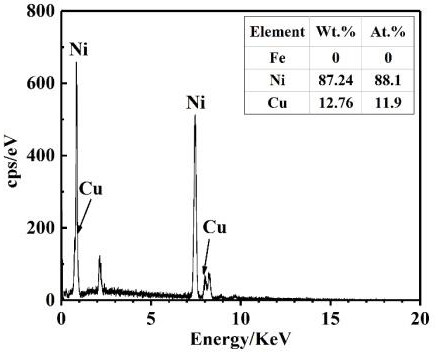

Method for preparing nickel-copper alloy plating layer on surface of carbon steel

The invention discloses a method for preparing a nickel-copper alloy plating layer on the surface of carbon steel. The method specifically comprises the following steps: (1) pretreatment, wherein a carbon steel workpiece is pretreated to obtain a carbon steel base material for later use; (2) preparation of an electroplating solution, wherein nickel sulfate, copper sulfate, trisodium citrate, boric acid, an additive and a brightener are dissolved in deionized water to prepare the electroplating solution for later use, and the concentrations of nickel sulfate, copper sulfate, trisodium citrate, boric acid, the additive and the brightener in the electroplating solution are 170-200 g / L, 5-20 g / L, 60-100 g / L, 10-25 g / L, 0.05-1 g / L and 0.1-1 g / L respectively; and (3) preparation of the nickel-copper alloy plating layer, wherein the carbon steel base material is immersed into the electroplating solution, the carbon steel base material serves as a cathode, one of monel alloy, pure nickel, graphite and pure copper serves as an anode, and electroplating deposition is conducted on the carbon steel base material to form the nickel-copper alloy plating layer. The nickel-copper alloy plating layer prepared through the method not only can effectively solve the problem of corrosion of a fluorine-making electrolytic cell made of carbon steel, but also has good thermal conductivity and strong binding force with the carbon steel base material.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Preparation method of MgB2 multi-core superconducting wire/tape

ActiveCN108511132AIncrease the critical current densitySuperconductors/hyperconductorsSuperconductor detailsPower flowSwaging

The invention discloses a preparation method of an MgB2 multi-core superconducting wire / tape. The preparation method comprises the steps that a certain amount of Mg(BH4)2 is added into Mg powder and Bpowder, the powder is pretreated, then Cu / Nb / MgB2 single-core rods and Monel / Cu center rods are prepared and assembled into an n+m-core composite sheath, wherein n is the number of the Cu / Nb / MgB2 single-core rods, and m is the number of the Monel / Cu center rods; and then a wire / tape is prepared by means of the modes of rotary swaging, drawing, groove rolling and flat seizing, and finally heat treatment is conducted to obtain the MgB2 multi-core superconducting wire / tape. Compared with a tape which is prepared without doping the Mg(BH4)2 precursor powder, the wire / tape prepared through the method has the advantage that the critical current density is increased by 42.31%, has the more excellent superconducting performance and has a wide application prospect.

Owner:西部超导材料科技股份有限公司

Monel alloy plate strip cold rolling lubricant composition

InactiveCN105038929AImprove adhesionImprove wear resistanceLubricant compositionSurface finishShear stress

The invention discloses a monel alloy plate strip cold rolling lubricant composition. The monel alloy plate strip cold rolling lubricant composition adopts No.15 total loss system oil as base oil which is matched with multiple additives such as an extreme pressure agent, an antiwear agent, an oiliness agent, a friction modifier, an anti-foaming agent, an antioxidant, a metal deactivating agent and a reinforcing agent. The monel alloy plate strip cold rolling lubricant composition has the advantages that the good lubricity, cooling property, wettability, liquidity and anti-rust property are achieved, the strength and thickness of an oil film in a deformation zone are improved, the friction coefficients are decreased, and the oil film strength and thickness properties are kept stable; the adhesivity is high, and the antiwear property, the viscosity-temperature property and the washing property are good; the extreme pressure property is high, and adhesion and wear of cold rolling equipment and rollers are reduced; smaller flow shear stress exists, therefore, the cold rolling surface finish and specification precision of a machined monel alloy plate strip are improved, and oil spots and defects on the surface of the cold rolling plate strip are reduced.

Owner:GUANGXI UNIV

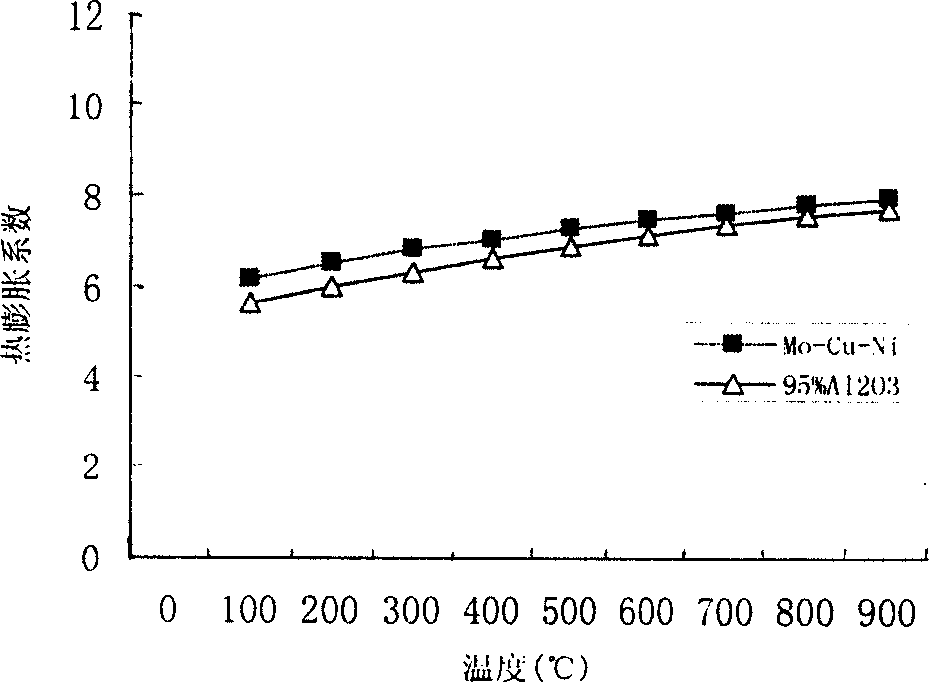

Low-expansion high heat conductivity nonmagnetic ceramic seal alloy and preparation method thereof

The present invention discloses one kind of low expansion coefficient high heat conductivity non-magnetic sealing Mo-Cu-Ni ceramic alloy and its preparation process. The alloy has the recipe comprising Mo 70-80 wt%, Cu 15-20 wt% and Ni 5-10 wt%. It is prepared through a powder metallurgy process including the steps of compounding material, mixing, pressing blank, pre-sintering and sintering to form the alloy. It is applied as structural material for electronic industry, and Compared with kovar alloy and monel alloy, the alloy of the present invention has the advantages of heat expansion coefficient approaching that of 95 %Al2O3 ceramic, high heat conductivity, simple welding process, high machining performance, high heat shock resistance, etc.

Owner:GRIMAT ENG INST CO LTD

Manufacturing method for nickel-copper alloy sintered mesh pipe

The invention discloses a manufacturing method for a nickel-copper alloy sintered mesh pipe. The manufacturing method includes the steps of mesh laying, sintering, cutting, pipe reeling, welding, acid pickling and heat treatment. The nickel-copper alloy sintered mesh is made of monel material 400 and has the advantages of being high in acid-base resistance, resistant to high temperature, wide in application range and the like. The mesh pipe is a filter element high in permeability, the filter precision of the mesh pipe is 3 microns-5 microns, the filter efficiency of the mesh pipe is 99.8%, the permeability coefficient of the mesh pipe is greater than or equal to 20 m<3> / m<2>*kPa*h, and the problems that a powder sintered filter pipe made of the same metal material is poor in permeability, small in pollutant holding quantity, poor in reverse blowing effect and the like are solved effectively.

Owner:江苏云才材料有限公司

Method for producing Monel alloy ingot by using horizontal continuous casting

The invention relates to a method for producing Monel alloy ingots by using horizontal continuous casting, belonging to the technical field of smelting. The method comprises the following steps: selecting and allocating materials, smelting, carrying out rapid ladle analysis, deoxidizing, degassing, measuring the temperature, releasing to a heat preservation continuous casting furnace, refining under the protection of argon, measuring the temperature, carrying out continuous casting and cutting on line so as to obtain the products, namely, the Monel alloy ingots. To overcome the defects that the vacuum sensing furnace smelting is complex in operation and high in cost, and in non-vacuum sensing furnace smelting, cracks generally happen in machining such as later extrusion, casting, rolling and the like, the yield is low, and the like, due to the fact that products absorb the gas in the smelting process, the invention provides the method for producing the Monel alloy ingots by using horizontal continuous casting, by utilizing such method, the production cost is saved, the effect is identical to vacuum smelting, and industrial popularization and application are facilitated.

Owner:江苏隆达超合金股份有限公司

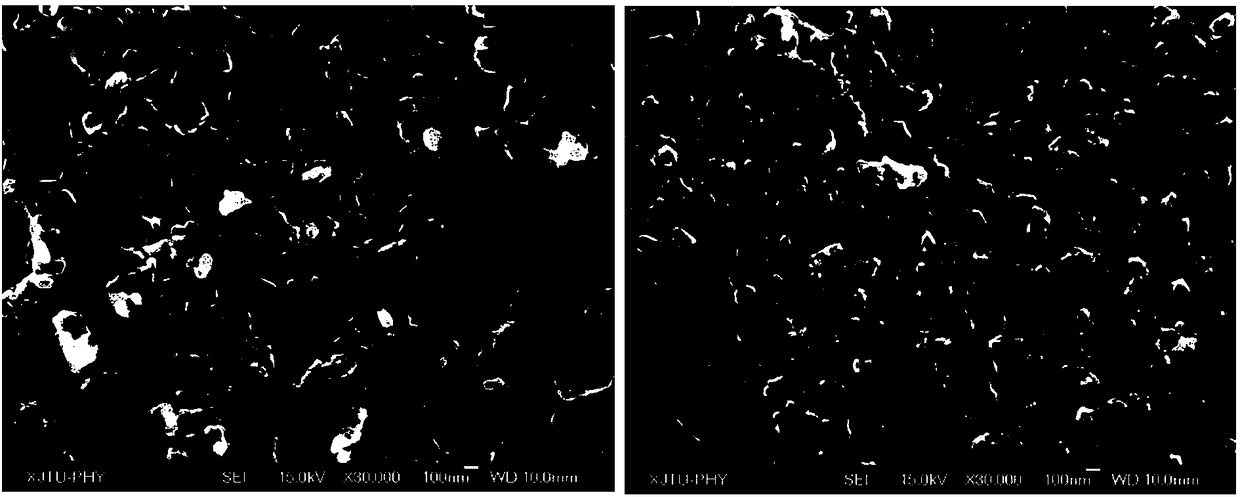

Preparation method for graphene-reinforced monel alloy

The invention provides a preparation method for a graphene-reinforced monel alloy. According to the preparation method, graphene is used as a reinforcing phase to be added into a monel alloy substrate. The preparation method comprises the steps that mixed powder of the graphene and the monel alloy or mixed powder of graphene oxide and the monel alloy is prepared; and the mixed powder is subjected to cold rolling, sintering forming and hot forging forming to obtain a monel alloy plate reinforced by the graphene. The invention provides the novel method for reinforcing the monel alloy through dispersion strengthening, and the corrosion resistance of the alloy is improved while the mechanical strength of the substrate is improved. The preparation method is simple in operation process and needed equipment, high in production efficiency, low in manufacturing cost and easy to industrialize in a large scale.

Owner:北京石墨烯技术研究院有限公司

Preparation method of PbMo6S8 superconducting wire

ActiveCN111554505AIncrease the critical current densityGuaranteed uniformityInorganic material magnetismInductances/transformers/magnets manufactureWire rodCopper wire

The invention discloses a preparation method of a PbMo6S8 superconducting wire. The method comprises the steps that: precursor powder is prepared through adoption of a high-energy ball milling method;then, the PbMo6S8 precursor powder is put into a Mo pipe; the Mo pipe is processed into a PMS single-core wire / bar; and then a plurality of PMS single-core wires / rods and a central copper wire / rod are loaded into a stainless steel pipe or a Monel 400 jacketed pipe for secondary assembly, a multi-core PMS precursor wire rod is manufactured through stretching, and the wire rod is subjected to high-temperature melting quenching treatment and phase-forming heat treatment to obtain the PMS superconducting wire rod. MRHQ and phase-forming heat treatment are adopted to replace traditional diffusionphase-forming heat treatment, intergranular impurities in the superconductor are remarkably reduced, grain connectivity is improved, and therefore the critical current density of the wire is remarkably improved. The method is simple, is suitable for preparing the superconducting long wire, is beneficial to large-scale popularization and application, and has huge commercial value.

Owner:合肥夸夫超导科技有限公司

Preparation method of Monel metal for pressed plates

InactiveCN110257650AImprove tissue uniformityGuaranteed to be accurateCrucible furnacesSurface layerCrucible

The invention discloses a preparation method of Monel metal for pressed plates. The preparation method is implemented according to the following process: (1) Monel metal raw materials are prepared; (2) refractory material crucibles for smelting alloys are prepared; (3) a vacuum induction smelting furnace is used for vacuum induction smelting to obtain Monel metal ingots; (4) the ingots are machined; the head loose and empty parts are cut off; and the surfaces are polished without scales; (5) the vacuum arc remelting is performed; and (6) the surface layers of the Monel metal ingots are removed through lathe machining. The method guarantees precise metal components, and prevents the metal element oxidation problem; and through the subsequent vacuum arc remelting process, the component segregation is further reduced, and the metal structure uniformity is improved.

Owner:陕西宝锐金属有限公司

Nickel copper niobium alloy material and application thereof in high strength slender shafts

The invention discloses a nickel copper niobium alloy material and an application thereof in high strength slender shafts. The nickel copper niobium alloy material comprises the components by the mass percentage: 65%-70% of Ni, 25%-33% of Cu, 1.0%-2.0% of Nb, 0.5%-1.5% of Fe, 0.5%-1.5% of Mn, 0%-1.5% of Si, 0.3%-1.0% of Ti, and 0%-0.25% of C. In accordance with a Monel alloy ingot casting process, ingots are poured by opening a furnace; then various high strength slender shafts are prepared from the casted ingots according to a high strength slender shaft stretching process, wherein the shafts comprise electrical submersible pump shafts, separator shafts and protector shafts. Compared with high strength slender shafts prepared by a high strength Monel alloy material K500, the various high strength slender shafts prepared by applying the nickel copper niobium alloy material have better corresponding mechanical strengths and have the tensile finished product rate basically equal to K500.

Owner:ZHEJIANG ZHENXING PETROCHEM MACHINERY

Monel alloy bar, tube and wire material cold drawing lubricant composition

InactiveCN105038931AImprove adhesionGood viscosity temperature performanceLubricant compositionSurface finishShear stress

The invention discloses a monel alloy bar, tube and wire material cold drawing lubricant composition. The monel alloy bar, tube and wire material cold drawing lubricant composition adopts HVIW 650 base oil as base oil which is matched with multiple additives such as an antiwear agent, an extreme pressure agent, an oiliness agent, a friction modifier, an antioxidant, an antioxidation preservative, an anti-foaming agent and an auxiliary agent. The monel alloy bar, tube and wire material cold drawing lubricant composition can be directly used in the lubricating process of monel alloy bar, tube and wire material cold drawing and has the advantages that the good lubricity, cooling property, wettability, liquidity and anti-rust property are achieved, the strength and thickness of an oil film in a deformation zone are improved, the friction coefficients are decreased, and the oil film strength and thickness properties are kept stable; the adhesivity is high, and the antiwear property, the viscosity-temperature property and the washing property are good; the extreme pressure property is high, and therefore adhesion and wear of drawing equipment and moulds are reduced; smaller flow shear stress exists, therefore, the surface finish and specification precision of machined monel alloy bar, tube and wire materials are improved, and oil spots and defects on the surface of a drawing profile are reduced.

Owner:GUANGXI UNIV

Nickel-copper alloy sintered silk screen filter plate and manufacturing method thereof

InactiveCN104474783AImprove permeabilitySolve the small amount of pollutionFiltration separationMicrometerPermeability coefficient

The invention discloses a nickel-copper alloy sintered silk screen filter plate and a manufacturing method thereof. The manufacturing process comprises the steps of screen laying, sintering, machining and acid pickling. A nickel-copper alloy sintered silk screen is made of Monel 400, and has the advantages of being highly acid-base resistant, high temperature resistant, wide in application range and the like. The nickel-copper alloy sintered silk screen filter plate is a filter element with high permeation performance, filtering precision is 3-100 micrometers, filtering efficiency reaches 99.8%, the permeability coefficient is not smaller than 15 m<3> / m<2>.kPa.h, and the problems that a powder sintered filter plate made of the same metal material is poor in permeation performance, low in pollutant holding quantity, poor in back flushing effect and the like are effectively solved.

Owner:江苏云才材料有限公司

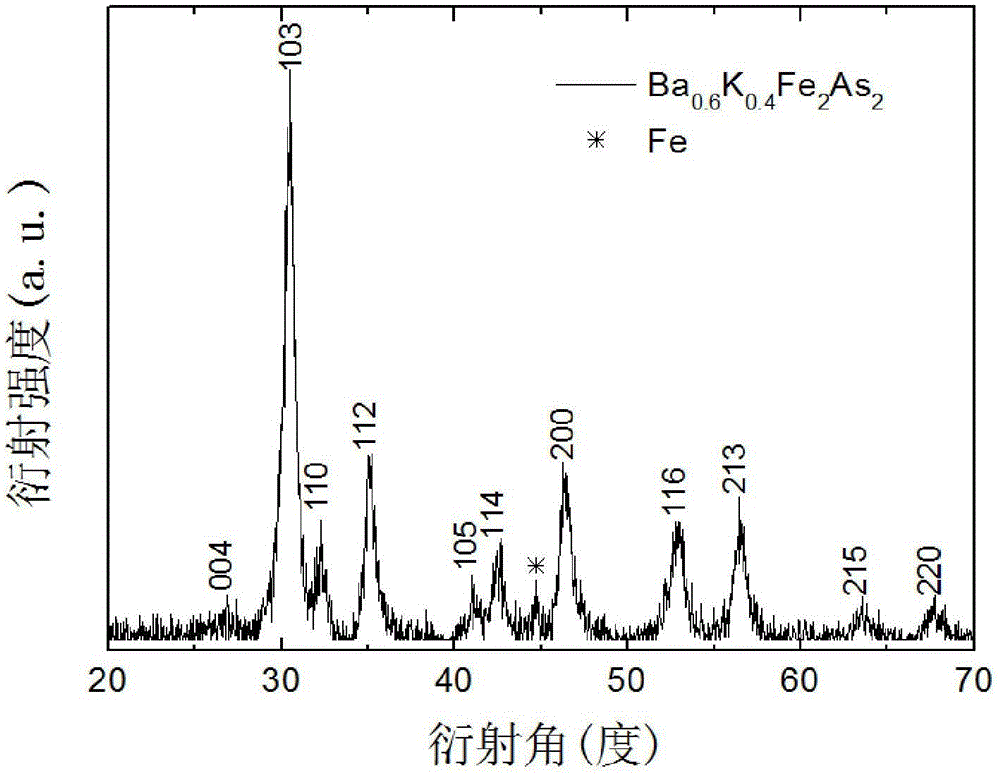

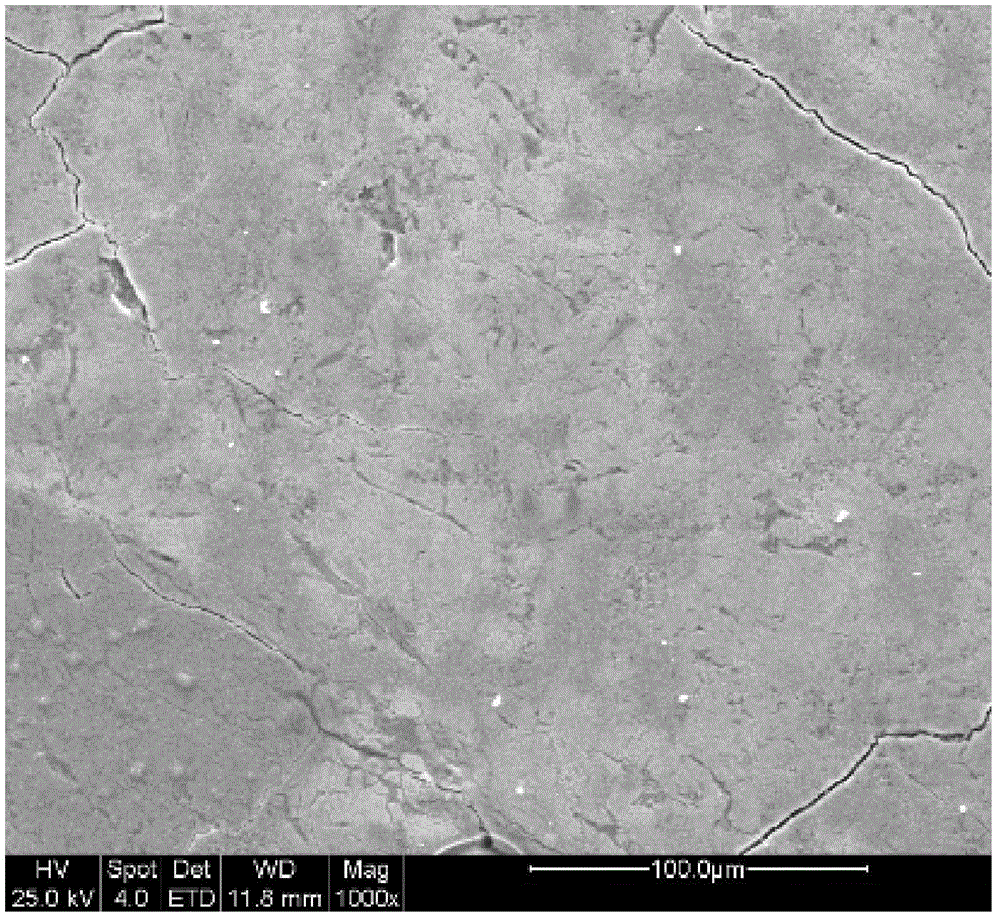

Method for preparing Ba0.6K0.4Fe2As2 superconductive wire through mechanical alloying without sintering

The invention discloses a method for preparing a Ba0.6K0.4Fe2As2 superconductive wire through mechanical alloying without sintering. The method includes the following steps of: a, proportioning Ba tablets with degree of purity of 99.5%-99.9%, K tablets and Fe powder both with degree of purity of 95%-99%, and As powder with degree of purity of 99.%-99.99% at atomic ratio of 0.6:0.4:2:2 in a glove box, and putting the mixture into a ball grinder, wherein the K tablets are overdosed by 5%-10%, the ball grinding medium is stainless steel balls, and the weight ratio of the stainless steel balls to the raw materials is (10:1)-(20:1); b, grinding the raw materials proportioned in step a in the ball grinder for 1-2hours with the rotating speed of 1,425-1,725RPM (Revolutions Per Minute) to obtain powder; c, intensively mixing the powder obtained in step c and In or Sn powder at mass ration of 5%-10% in a mortar, then loading the powder mixture into a Monel alloy tube and compressing and sealing the two ends of the alloy tube; and d, directly rolling and drawing the Monel alloy tube which contains the powder mixture into a Ba0.6K0.4Fe2As2 superconductive wire.

Owner:SOUTHEAST UNIV

Smelting method of monel alloy

InactiveCN110284014AReduce segregationUniform coagulation tissueIncreasing energy efficiencyGrain boundaryMonel

The invention discloses a smelting method of monel alloy. The smelting method comprises a vacuum induction smelting process and an electroslag remelting process, wherein the vacuum induction smelting process comprises the following steps of smelting a target steel grade by adopting a vacuum induction furnace, carrying out low-temperature tapping at 40-60 DEG C, and pouring into a water-cooled ingot mold to prepare a consumable electrode; the melting rate in the electroslag remelting process is 3.5kg / min-4kg / min. According to the smelting method, smelting and smelting by virtue of the vacuum induction furnace, carrying out low-superheat pouring and cooling the water-cooled ingot mold are carried out, so that the consumable electrode with low segregation, uniform structure and high quality is obtained, and then protection atmosphere electroslag remelting is carried out; and the solidification structure of the cast ingot is effectively guaranteed to be uniform, component segregation and crystal grain boundary cracking are avoided, so that the obtained cast ingot is fine in crystal grain and better in quality.

Owner:HEBEI IRON AND STEEL

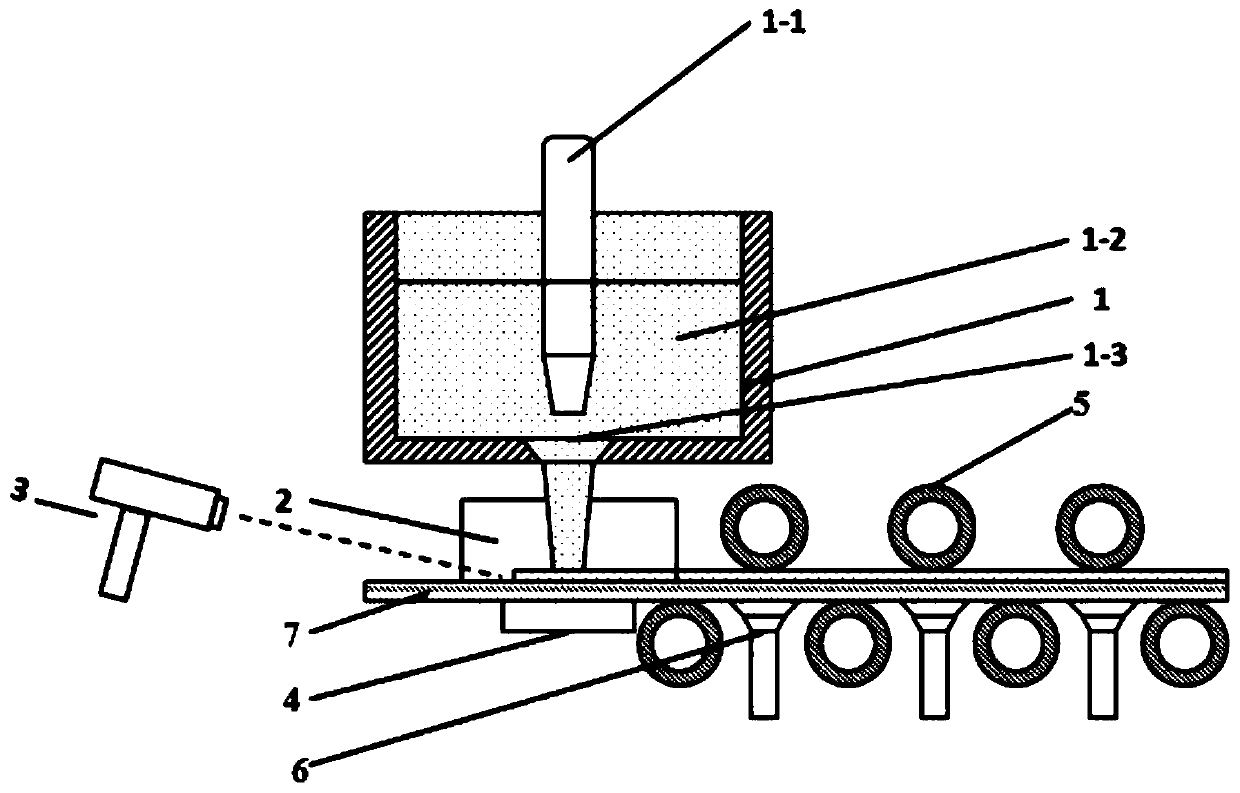

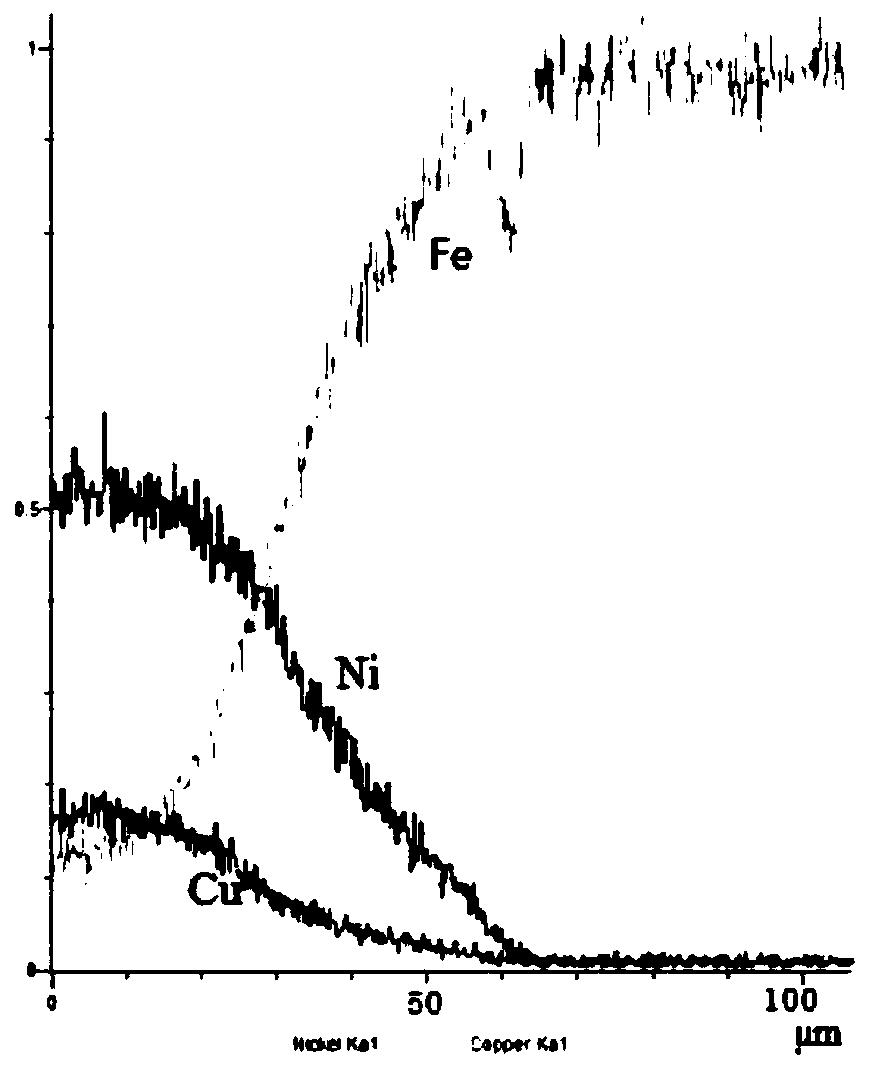

Bottom injection type casting device and preparation method of carbon steel-monel alloy layered composite material

InactiveCN110340321AImprove interfacial bond strengthIncrease productivityMelt-holding vesselsMedium frequencyUltimate tensile strength

The invention provides a bottom injection type casting device and a preparation method of a carbon steel-monel alloy layered composite material, and relates to the technical field of alloy materials.The invention provides the bottom injection type casting device which comprises a medium-frequency induction smelting furnace 1, a protective gas application device 2, an infrared thermometer monitoring device 3, a high-frequency induction heating device 4, a double-roller transmission device 5 and a cooling device 6; and the medium-frequency induction smelting furnace 1 comprises a stopper rod 1-1, a furnace body 1-2 and a sprue 1-3. By adopting the bottom injection type casting device, the carbon steel-monel alloy layered composite material is prepared, high in reliability and safety and high in production efficiency, the prepared carbon steel-monel alloy layered composite material is high in cleanliness and high in interface bonding strength, and a wide range of Ni-Fe-Cu diffusion layers can be obtained.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com