Novel reaction kettle

A reaction kettle and a new type of technology, applied in the field of new reaction kettles, can solve problems such as restricting the development of chemical projects and strong corrosiveness of the reaction kettle, and achieve the effects of simple structure, easy popularization and application, and broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

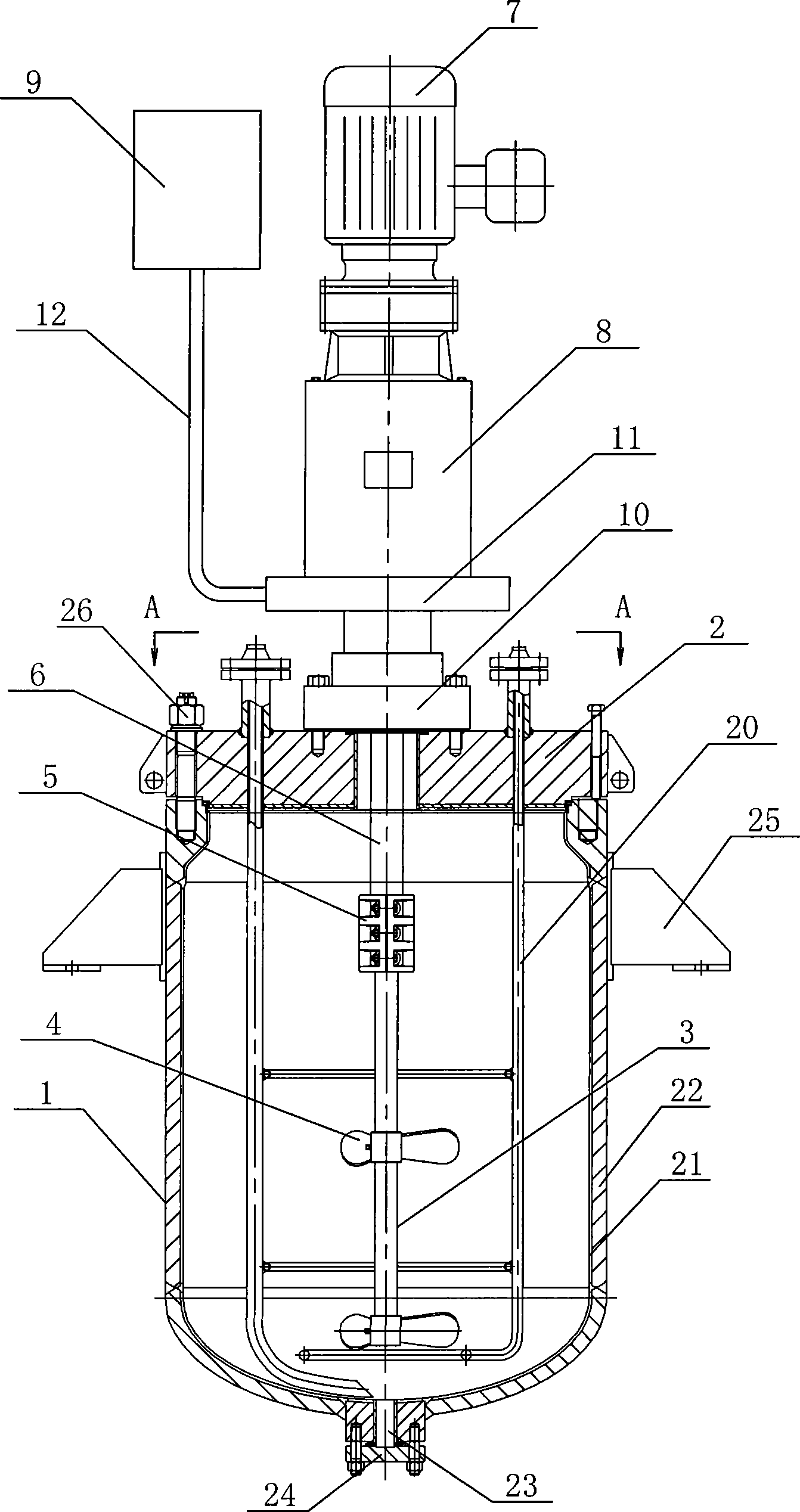

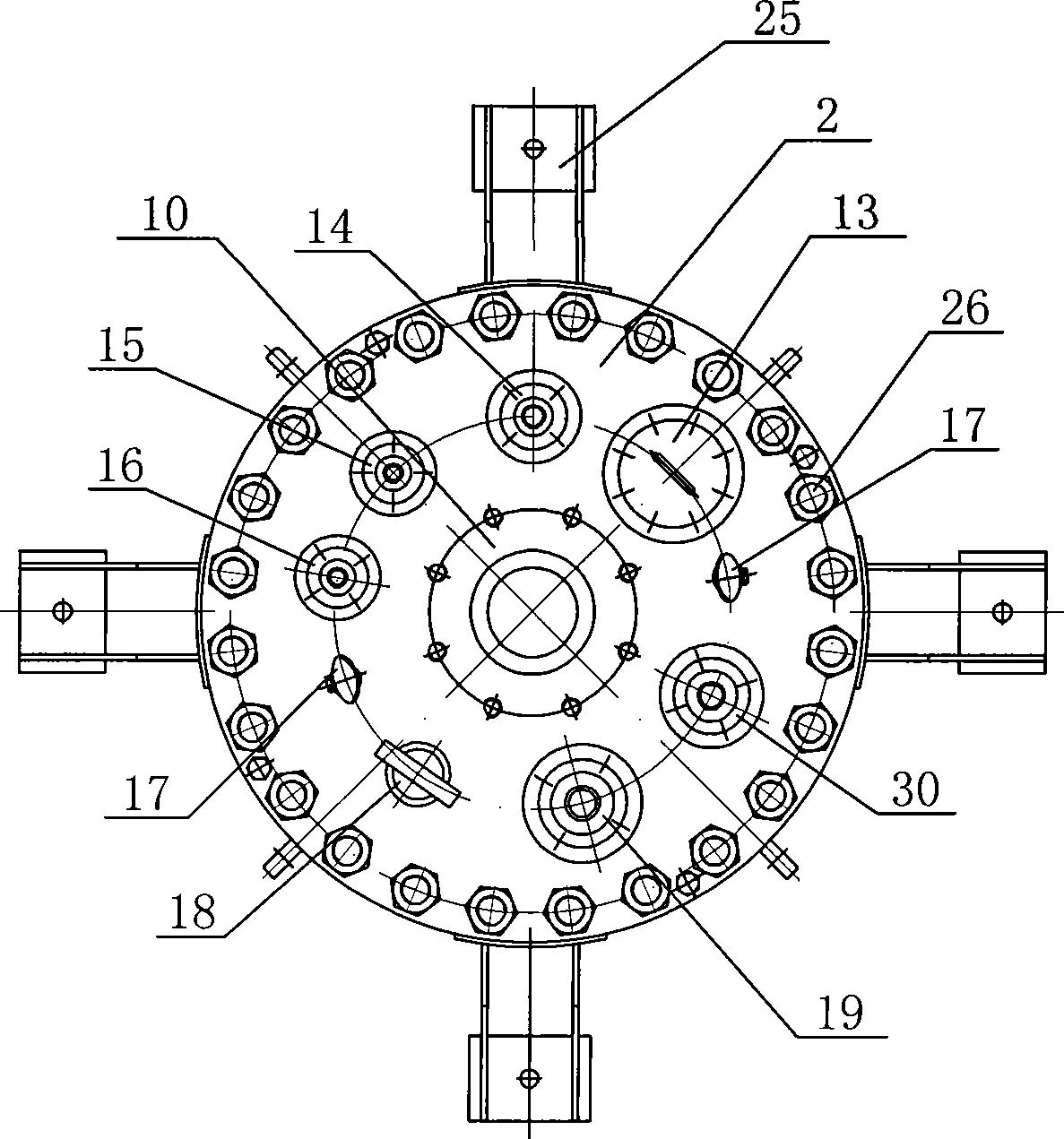

[0014] Such as figure 1 and figure 2 As shown, the novel reaction kettle of the present invention comprises a still body 1 with an open top in a vertical cylindrical shape, and the top of the still body 1 is sealed with a still cover 2, and the still body 1 and the still cover 2 pass through at its peripheral edge. Several bolts 26 are fixedly connected. There is a stirring device inside the kettle body 2, and the stirring device includes a stirring shaft 3 vertically arranged on the central axis of the kettle body 1, and two layers of stirring blades 4 are evenly arranged on the stirring shaft 3, and the top of the stirring shaft 3 passes through a shell coupling 5. The transmission is connected with a transmission shaft 6. The upper end of the transmission shaft 6 penetrates the kettle cover. 2. The external transmission is connected with a power device. The power device is composed of a motor 7 and a reducer 8. The motor 7 is an explosion-proof motor. 6 transmission conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com