Bottom injection type casting device and preparation method of carbon steel-monel alloy layered composite material

A carbon steel, bottom injection technology, applied in casting equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of lack of safety and stability, difficult precise control, high equipment and technical requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

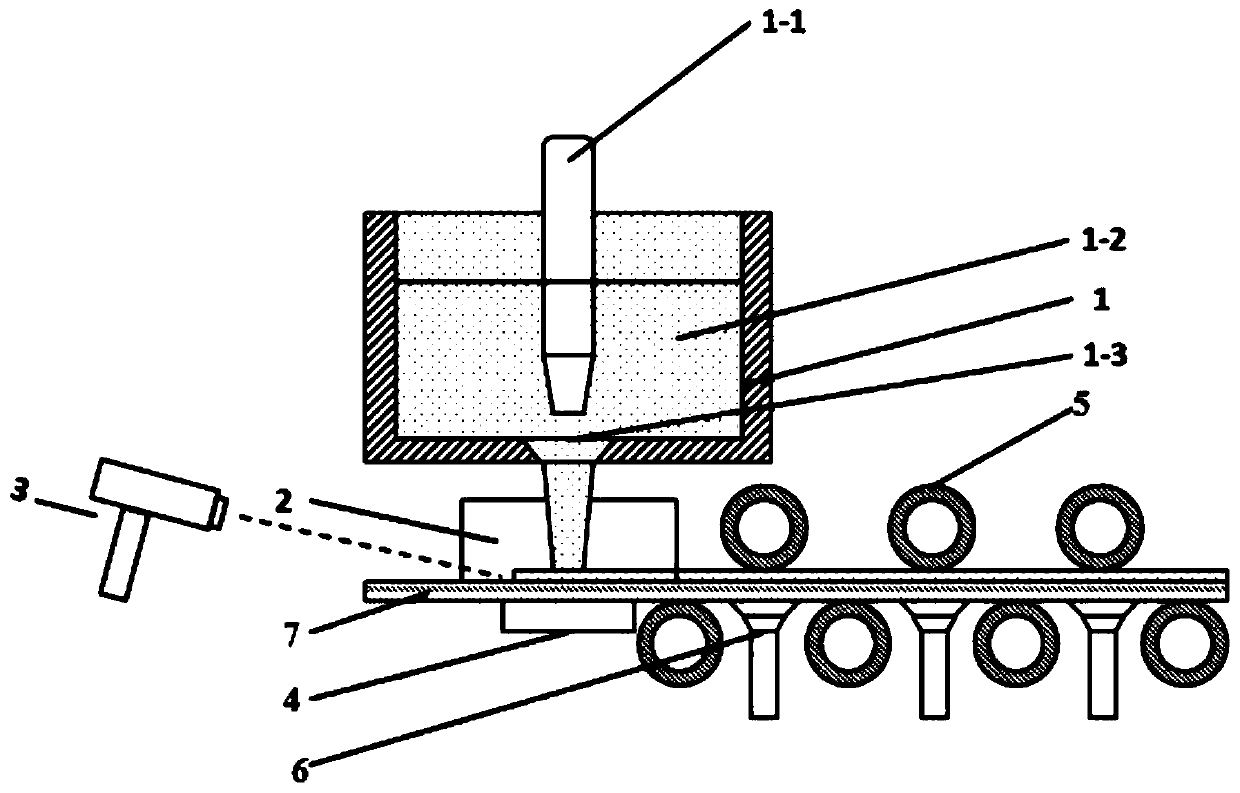

[0033] The invention provides a kind of preparation method of carbon steel-monel alloy laminated composite material, comprises the following steps:

[0034] Melting Ni and Cu in the medium frequency induction melting furnace 1 to obtain a Monel alloy melt;

[0035] Place the carbon steel substrate on the double-roller transmission device 5, and after being preheated by the high-frequency induction heating device 4, the Monel alloy melt flows out from the gate 1-3 of the medium-frequency induction melting furnace 1, and is protected by a protective gas. Casting down to the surface of the carbon steel substrate that is moving at a constant speed; the preheating temperature of the carbon steel substrate is monitored by the infrared thermometer monitoring device 3;

[0036] The carbon steel substrate casted with Monel alloy is conveyed by the double-roller transmission device 5 to the top of the cooling device 6 for cooling, and a carbon steel-Monel alloy layered composite materia...

Embodiment 1

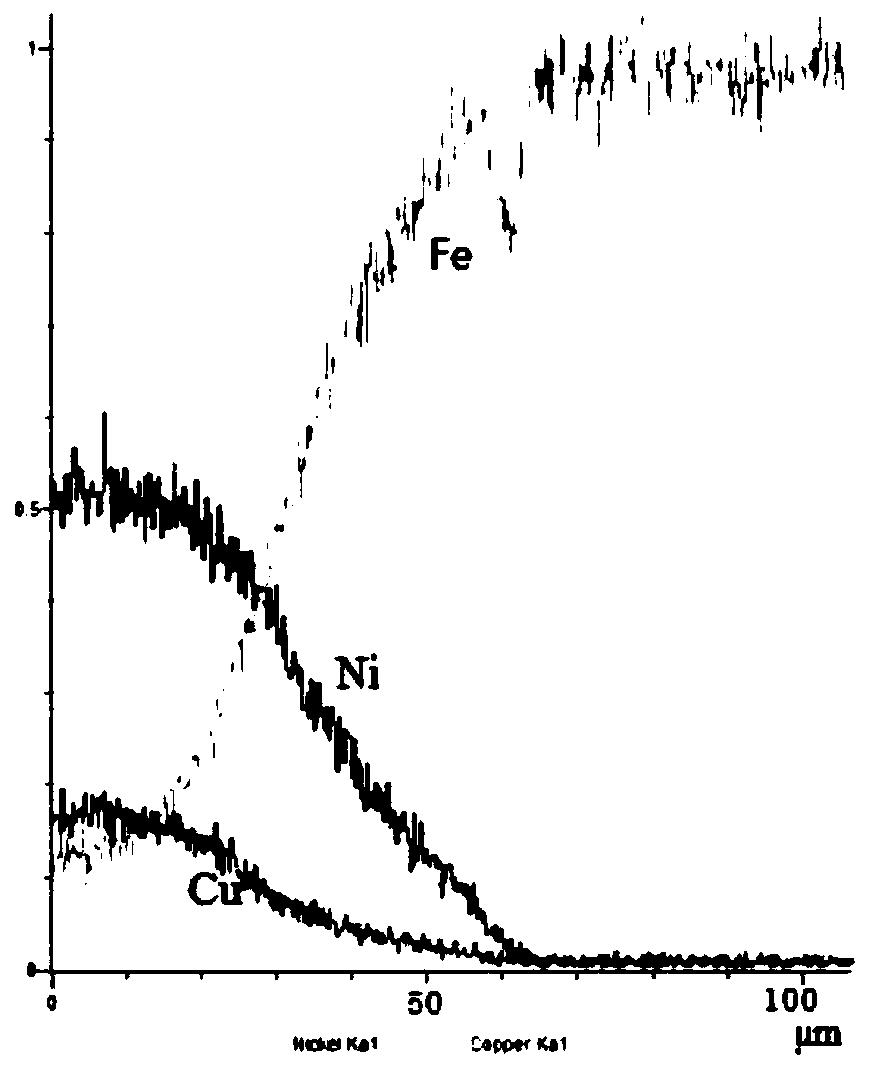

[0043] Ni and Cu raw materials were weighed according to a mass ratio of 7:3, and pure metal raw materials with a purity of 99.9 wt% and above were selected. When smelting alloys, Ni and Cu are placed in a magnesia crucible and heated through an intermediate frequency induction heating furnace 1, and the entire smelting process needs to be carried out under the protection of a covering agent. Heat the melt to 1480°C for 2 minutes, reduce the heating power, and when the melt temperature drops to 1430°C, under the action of protective gas, evenly cast the alloy melt onto the surface of the carbon steel substrate 7 traveling at a uniform speed. It is preheated to 1000°C by the high-frequency induction heating device 4 and is pulled by the double-roller transmission device 5 (with a rolling straightening device) to advance at a constant speed, and the forward speed is 88mm / min. After the casting is completed, when the temperature of the composite plate is naturally cooled to 1000°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com