Method for modifying carbon fiber surface by assembly of aromatic fused ring molecules and preparation method of carbon fiber interface reinforced resin matrix composite

A technology of carbon fiber and modified carbon, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., and can solve problems such as limiting the high performance of carbon fiber, high chemical inertness, and debonding of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a method for preparing a carbon fiber interface-reinforced resin-based composite material, comprising: after obtaining surface-mounted modified carbon fibers using the method described in the above technical solution, compounding and curing the surface-mounted modified carbon fibers with a resin, Aromatic condensed ring molecular assembly modified carbon fiber interface reinforced resin matrix composites were obtained. The present invention has no special requirements on the type of resin, preferably epoxy resin, more preferably one or more of glycidyl ether type epoxy resin, glycidyl amine type epoxy resin and glycidyl ester type epoxy resin kind.

[0031]The present invention has no special requirements on the embodiment of the composite in the composite curing, and the composite method well known to those skilled in the art can be used. The present invention has no special requirements on the curing conditions, and the curing cond...

Embodiment 1

[0034] (1) Under the catalysis of triethylamine, pyromellitic dianhydride and biphenylenediamine were reacted at 90°C for 24 hours in N,N-dimethylformamide / ether mixed solvent to obtain aromatic thickened Cyclic imide molecular assembly liquid, wherein the molar ratio of pyromellitic dianhydride to biphenyl diamine is 1:1.1, the catalyst is 0.1wt.% of pyromellitic dianhydride, and the aromatic condensed cyclic imide in the assembly liquid The mass fraction of amine molecules in the solvent is 1%;

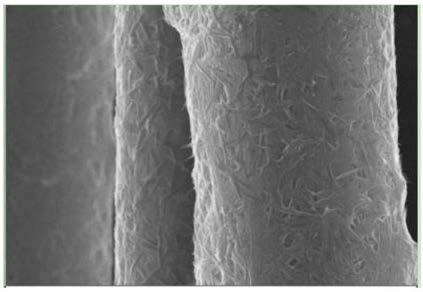

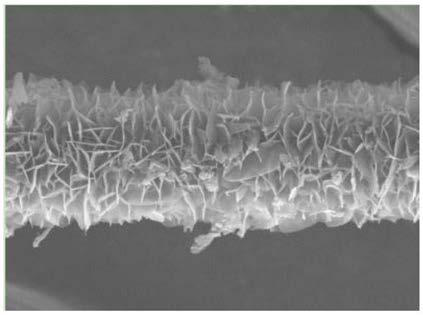

[0035] (2) Immerse unsized M55J carbon fibers in the assembly solution for 10 minutes, and obtain carbon fibers with a nanofibrous assembly layer on the surface after drying, wherein the surface assembly layer is 2.5 wt% of the carbon fiber mass.

[0036] (3) Preparation of interface-reinforced composite material: Glycidyl ester-type epoxy resin was added dropwise onto the M40J carbon fiber containing the surface assembly layer, and cured at 150°C for 5 hours to obtain an interface-...

Embodiment 2

[0038] (1) Under the catalysis of hydroxybenzoic acid, react 3,4,9,10-perylenetetracarboxylic dianhydride and octanediamine at 120°C for 18h in methanol / acetonitrile to obtain aromatic fused ring imide Molecular assembly solution, wherein the molar ratio of 3,4,9,10-perylenetetracarboxylic dianhydride to octyldiamine is 1:1.5, the mass fraction of aromatic fused ring imide molecules in the solvent in the assembly solution is 2%, and the catalyst The mass of is 0.15% of the mass of 3,4,9,10-perylenetetracarboxylic dianhydride;

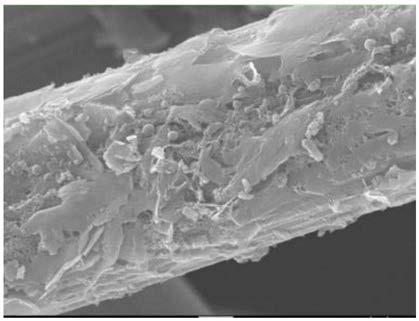

[0039] (2) Immerse the unsized T800 carbon fiber in the assembly solution for 5 minutes, and obtain the carbon fiber with the nanosphere / sheet assembly layer on the surface after vacuum drying, wherein the surface assembly layer is 1.8wt% of the mass of the carbon fiber;

[0040] (3) Preparation of interface-reinforced composite material: Glycidyl ether resin was added dropwise on the surface of T800 carbon fiber with surface assembly layer, and cured a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com