Reacting nano inorganic particle/polymer composite material

A technology of nano-inorganic particles and composite materials, applied in the field of reactive nano-inorganic particles/polymer composite materials, can solve the problems of difficulty in effectively changing the interaction between particles and the matrix, weak entanglement, etc., and achieve improved rigidity, enhanced interface interaction, Improve the effect of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

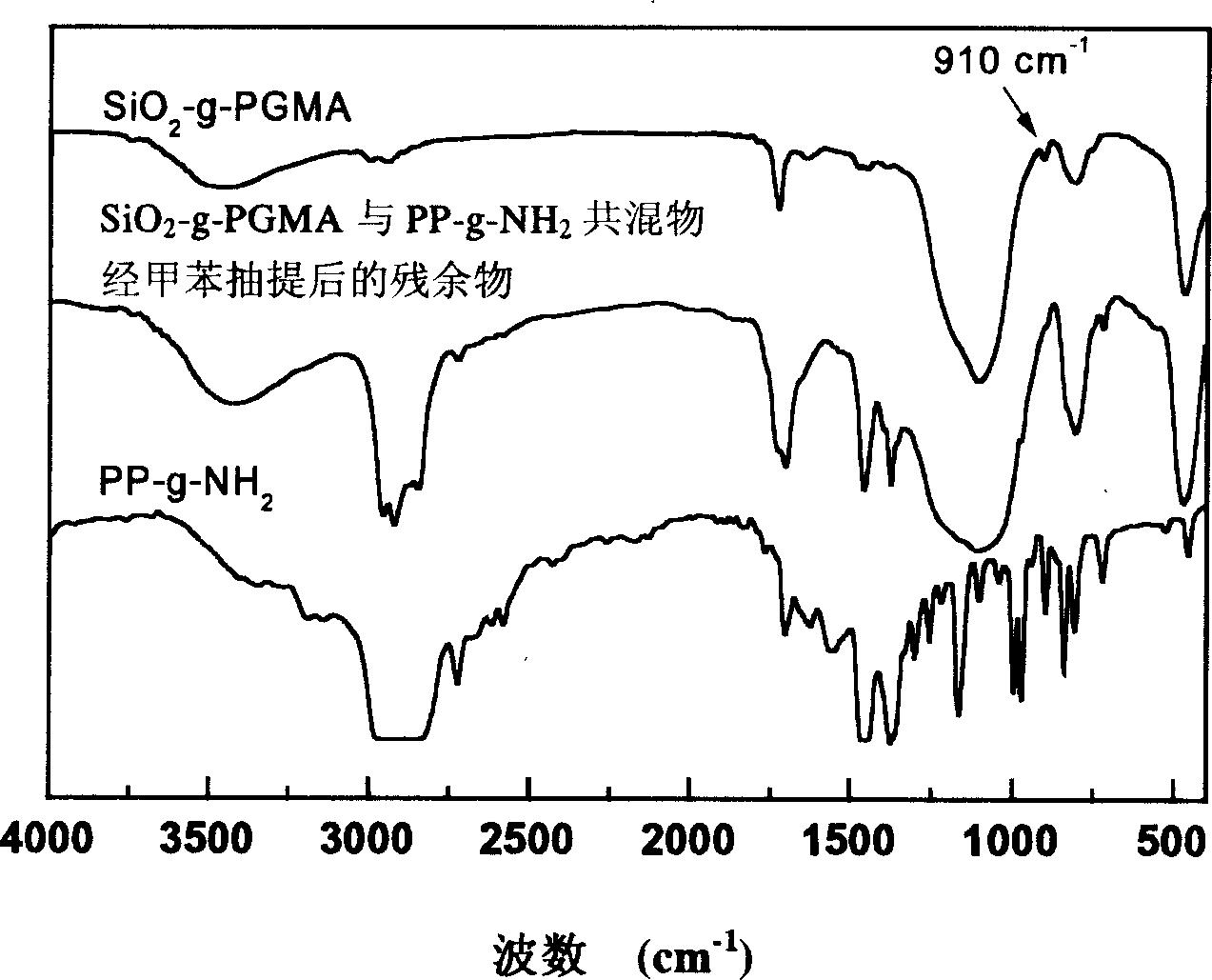

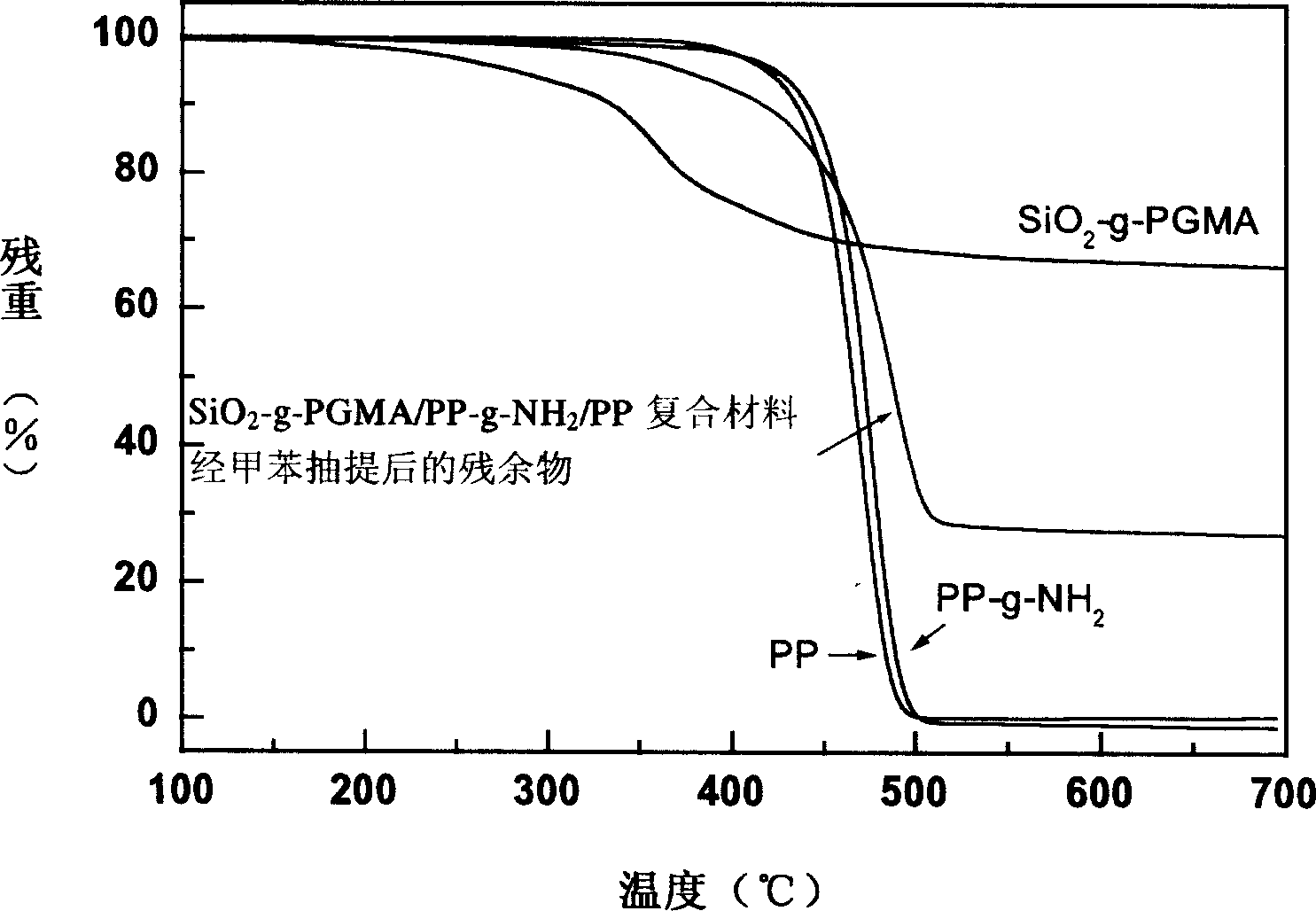

[0021] Using toluene as a solvent, under the protection of nitrogen, the coupling agent is γ-methacryloxypropyltrimethoxysilane and nano-silica particles for reflux reaction for 8 hours to obtain pretreated nano-inorganic particles; Glycidyl acrylate (GMA) was grafted and polymerized in the presence of a free radical initiator azobisisobutyronitrile (AIBN), the reaction temperature was 80°C, and the reaction time was 5 hours; modified nano-silica (SiO 2 -g-PGMA). The GMA consumption is 100% by weight of the pretreatment nano-inorganic particles, and the free radical initiator consumption is 0.4% by weight of the GMA consumption; the consumption of the coupling agent γ-methacryloxypropyltrimethoxysilane is 50% by weight of the particles.

[0022] Using toluene as a solvent, under the protection of nitrogen, the coupling agent is γ-methacryloxypropyltrimethoxysilane and nano-silica particles for reflux reaction for 8 hours to obtain pretreated nano-inorganic particles; Glycidy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com