Compressed-steel sandwich combination wallboard

A profiled steel plate and profiled steel technology, applied in building materials, building components, buildings, etc., can solve the problems of insufficient rigidity and ductility, inapplicability, etc., and achieve the effect of wide application range, improved ductility, and convenient transportation and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

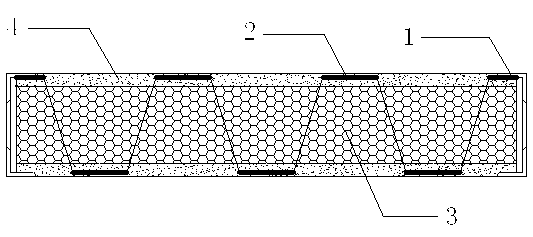

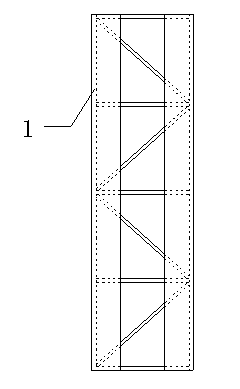

[0029] Such as figure 1 and 2 Shown: a profiled steel sandwich composite wallboard, comprising steel truss frame 1, U-shaped steel plate 2, concrete or cement mortar surface layer 4 and core material 3, said concrete or cement mortar surface layer 4 is divided into upper layer and The lower layer is respectively connected to the frame 1 of the steel truss, and a core material 3 is provided between the upper layer and the lower layer. The flange of the steel plate 2 is wrapped in the surface layer 4 of concrete or cement mortar. The core material 3 is composed of biomass with thermal insulation function (such as straw, reed, etc.) and inorganic reinforcing materials (cement, raw soil, etc.), or rock wool, expanded perlite, flame-retardant paper honeycomb, and industrial and agricultural materials. scrap.

Embodiment 2

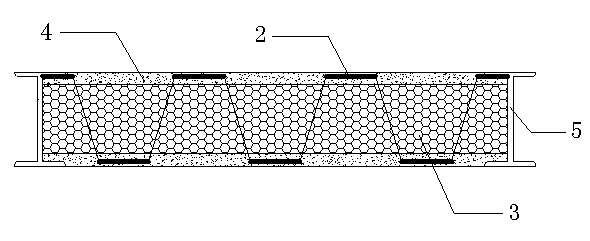

[0031] Such as image 3 As shown, a profiled steel sandwich composite wallboard includes an I-shaped steel frame 5, a U-shaped steel plate 2, a concrete or cement mortar surface layer 4 and a core material 3, and the concrete or cement mortar surface layer 4 is divided into an upper layer and the lower layer are respectively connected with the I-shaped steel frame 5, a core material 3 is provided between the upper layer and the lower layer, the U-shaped steel plate 2 is arranged in the composite wall panel, and the U-shaped steel plate 2 is welded to the I-shaped steel frame 5 , The flange of the U-shaped steel plate 2 is wrapped in the surface layer 4 of concrete or cement mortar. The core material 3 is composited with biomass with thermal insulation function (such as straw, reed, etc.) and inorganic reinforcing materials (cement, raw soil, etc.), or rock wool, expanded perlite, flame-retardant paper honeycomb, and industrial and agricultural materials. scrap.

Embodiment 3

[0033] Such as Figure 4 As shown, a profiled steel sandwich composite wallboard includes an I-shaped steel frame 5, a serrated profiled steel plate 6, a concrete or cement mortar surface layer 4 and a core material 3, and the concrete or cement mortar surface layer 4 is divided into The upper layer and the lower layer are respectively connected with the I-shaped steel frame 5, and the core material 3 is arranged between the upper layer and the lower layer. In the mortar surface layer 4. The core material 3 is composited with biomass with thermal insulation function (such as straw, reed, etc.) and inorganic reinforcing materials (cement, raw soil, etc.), or rock wool, expanded perlite, flame-retardant paper honeycomb, and industrial and agricultural materials. scrap. Such as Figure 5 As shown, a thin-walled steel web 7 is welded between the serrated profiled steel plates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com