Low-expansion high heat conductivity nonmagnetic ceramic seal alloy and preparation method thereof

A ceramic sealing alloy and high thermal conductivity technology, applied in the field of low expansion, high thermal conductivity, non-magnetic Mo-Cu-Ni ceramic sealing alloy and its preparation, can solve the problems of poor machining performance, complicated welding process, easy cracking, etc. The effect of good processing performance, simple welding process and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Preparation of Mo-Cu-Ni ceramic sealing alloy used as conductor structure material of wave tube in radar system. The process is as follows:

[0020] (1) Prepare materials according to the following alloy composition: Mo 77wt%, Cu 17wt%, Ni 6wt%.

[0021] (2) Mixing: Mix the prepared alloy materials uniformly in the mixer for 24 hours.

[0022] (3) compact, mixed alloy powder at 2T / cm 2 Cold isostatic internal pressing or alloy billets (pieces) of various specifications

[0023] (4) Pre-bonding: The alloy billet (piece) is pre-bonded within the temperature range of 850°C, and the time is set according to the charging amount.

[0024] (5) Sintering: The pre-sintered billets (pieces) are sintered at a temperature range of 1200°C, and the time is set according to the amount of charge. After sintering, it can be made into non-magnetic Mo-Cu-Ni ceramic sealing alloy.

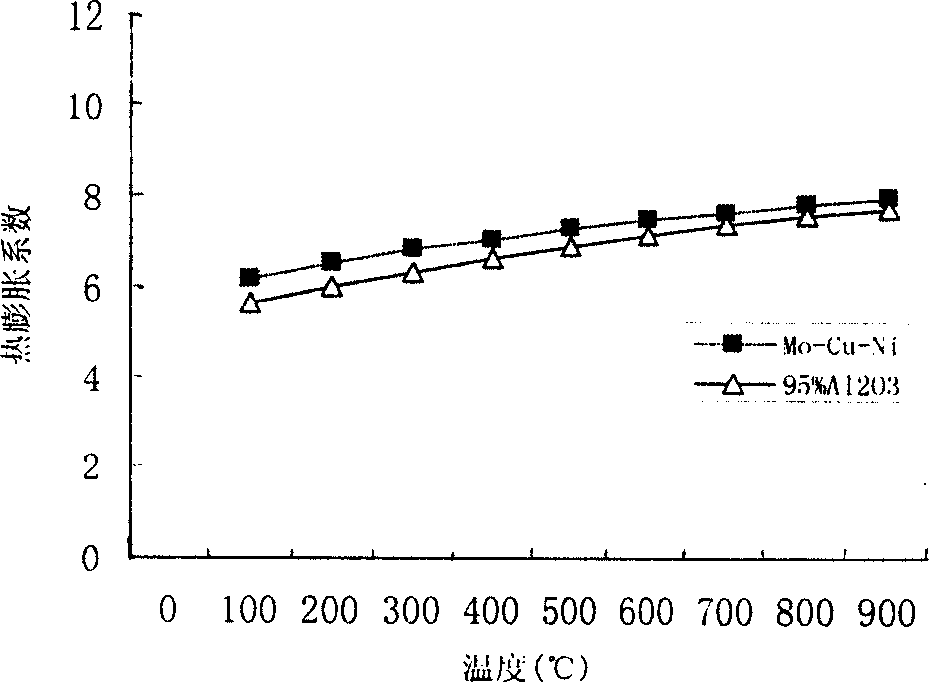

[0025] Example 1 The non-magnetic Mo-Cu-Ni ceramic seal alloy is made to be used as the conductor struc...

Embodiment 2

[0027] Except that the alloy composition is different from Example 1, the others are the same as Example 1. The alloy composition of Example 2 is: Mo 80wt%, Cu 15wt%, Ni 5wt%.

Embodiment 3

[0029] Except that the alloy composition is different from Example 1, the others are the same as Example 1. The alloy composition of Example 3 is: Mo 70wt%, Cu 20wt%, Ni 10wt%.

[0030] The non-magnetic Mo-Cu-Ni ceramic sealing alloys produced in Example 2 and Example 3 are used as ceramic sealing materials and conductive heat dissipation elements on various electric vacuum tubes. Ceramic materials such as alloys and alumina can be directly sealed, and the weld seam is dense and reliable. up to 1×10 -10 Pa·m 3 / s high level.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com