Preparation method of MgB2 multi-core superconducting wire/tape

A technology of superconducting wires and strips, applied in the usage of superconducting elements, superconducting/high-conducting conductors, superconducting devices, etc., can solve problems such as critical current attenuation, low wire filling rate, and sheath rupture, etc., to achieve The effect of increasing the critical current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

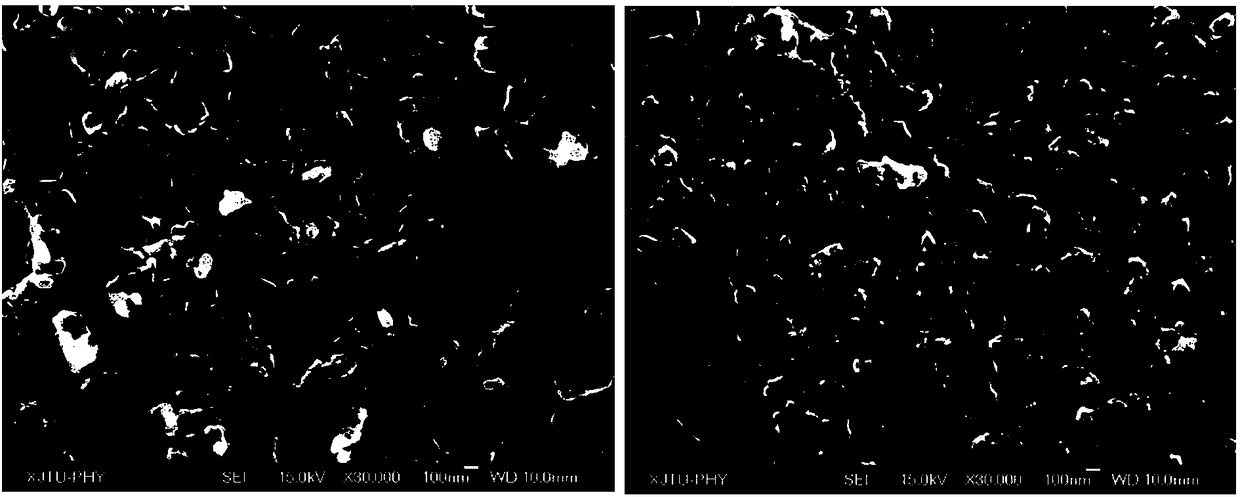

Image

Examples

Embodiment 1

[0022] Step 1: Powder Preparation

[0023] Mg(BH 4 ) 2 , Mg and B powder according to Mg(BH 4 ) 2 The mass ratio of Mg powder and B powder is 19:100, and the atomic ratio of Mg powder and B powder is 1:2. After grinding in the glove box for 1 hour, put it into a stainless steel tube and seal it; then put the stainless steel tube containing the powder into In the heat treatment furnace, flowing N 2 , heating the furnace body to 380° C. and keeping it warm for 2 hours to obtain the precursor powder.

[0024] Step 2: Single Mandrel Processing

[0025] The precursor powder was loaded into a Nb tube in a glove box, and then the powder-filled Nb tube was loaded into a Cu tube, which was machined to Φ2.95 mm by swaging or drawing with a pass processing rate of 20% , to get circular Cu / Nb / MgB 2 Single mandrel.

[0026] Step 3: Preparation of Monel / Cu Center Rod

[0027] Put the Cu rod into the Monel tube, adopt 20% pass processing rate, and draw it to Φ2.95mm to obtain a circ...

Embodiment 2

[0034] Step 1: Powder Preparation

[0035] Mg(BH 4 ) 2 , Mg and B powder according to Mg(BH 4 ) 2 The mass ratio of Mg powder and Mg powder is 19:80, and the atomic ratio of Mg powder and B powder is 1:2. After grinding in the glove box for 1.5h, put it into a stainless steel tube and seal it; then put the stainless steel tube with powder Put it into the heat treatment furnace, turn on the mechanical pump, and evacuate the furnace body. After reaching 6.7Pa, turn on the diffusion pump. After 1 hour, heat the furnace body to 400°C and keep it warm for 40 minutes to obtain the precursor powder.

[0036] Step 2: Single Mandrel Processing

[0037] In the glove box, the precursor powder was loaded into the Nb tube, and then the Nb tube filled with powder was loaded into the Cu tube, and the processing rate of 15% was used to draw to Φ3.8mm to obtain a circular Cu / Nb tube. / MgB 2 Single mandrel.

[0038] Step 3: Preparation of Monel / Cu Center Rod

[0039] Put the Cu rod into...

Embodiment 3

[0045] Step 1: Powder Preparation

[0046] Mg(BH 4 ) 2 , Mg and B powder according to Mg(BH 4 ) 2 The mass ratio of Mg powder and Mg powder is 19:40, and the atomic ratio of Mg powder and B powder is 1:2. After grinding in the glove box for 2 hours, put it into a stainless steel tube and seal it; then put the stainless steel tube with the powder into In the heat treatment furnace, flowing N 2 , heated to 340° C., and kept for 8 hours to obtain the precursor powder.

[0047] Step 2: Single Mandrel Processing

[0048] The precursor powder is loaded into the Nb tube, and then the powder-filled Nb tube is loaded into the Cu tube, and the pass processing rate of 12% is used to draw to H4.2mm to obtain Cu / Nb / MgB 2 Hexagon stick.

[0049] Step 3: Preparation of Monel / Cu Center Rod

[0050] Put the Cu rod into the Monel tube, adopt 12% pass processing rate, and draw it to H4.2mm to prepare the Monel / Cu center rod.

[0051] Step 4: Composite Rod Processing

[0052] Prepare st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical current density | aaaaa | aaaaa |

| Critical current density | aaaaa | aaaaa |

| Critical current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com