Atmospheric and vacuum distillation device and atmospheric and vacuum distillation method of high acid-content crude oil

An atmospheric and vacuum distillation and equipment technology, which is applied in hydrocarbon distillation, petroleum industry and other directions, can solve the problems of low service life of equipment, influence, product quality corrosion, etc., and achieve good economic benefits and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] This embodiment is used to illustrate the atmospheric and vacuum distillation equipment and atmospheric distillation method for high sour crude oil provided by the present invention.

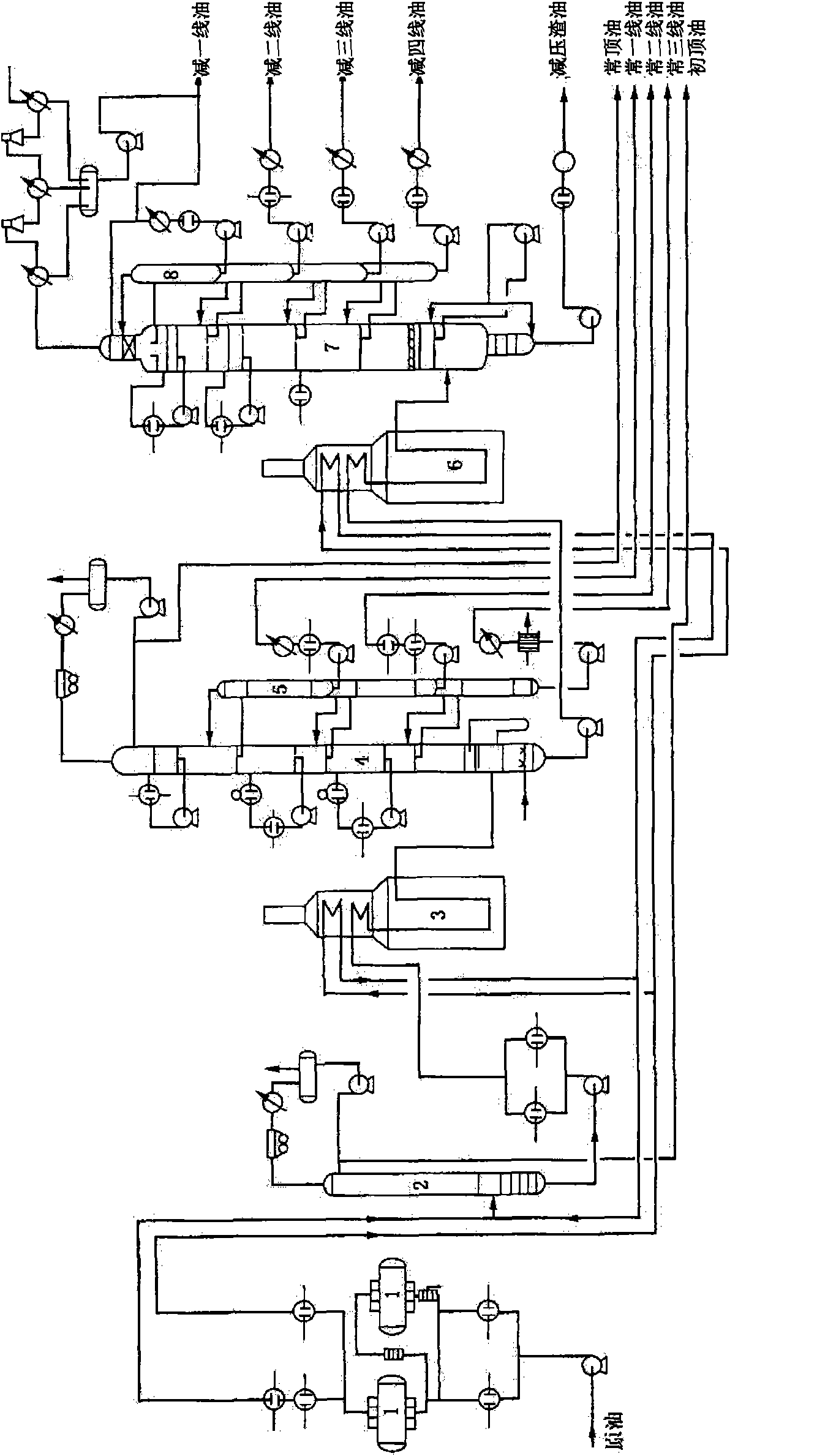

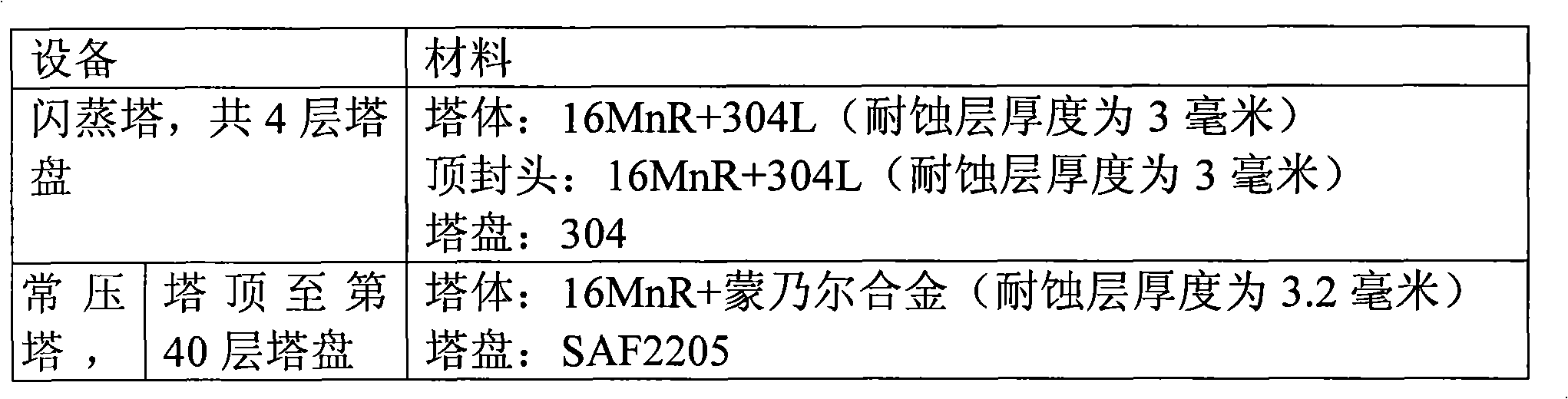

[0054] use figure 1 The shown atmospheric and vacuum distillation equipment and process flow are used for atmospheric and vacuum distillation processing of Penglai PL19-3 crude oil after electric desalination. Among them, the properties of No. PL19-3 crude oil are as shown in the above table 1. After electric desalting, the salt content is less than 3 mg / liter (test method GB6532-86), and the water content is less than 0.1% by weight (test method GB260-77). Less than 1 mg / L (atomic absorption spectrometry). The processing capacity is 12 million tons / year. The atmospheric tower in the atmospheric and vacuum distillation equipment has a total of 44 trays, and the tower body between the top of the tower and the 40th tray is made of 16MnR steel with a thickness of 22 mm and Monel alloy with...

Embodiment 2

[0062] This embodiment is used to illustrate the atmospheric and vacuum distillation equipment and atmospheric distillation method for high sour crude oil provided by the present invention.

[0063] According to the method of Example 1, the PL19-3 crude oil with an acid value content of 3.3 mg KOH / gram is subjected to atmospheric and vacuum distillation. The difference is that only the atmospheric tower, vacuum tower, and atmospheric furnace in the atmospheric and vacuum distillation equipment The material of the vacuum furnace is the same as that of Example 1, and the material of other parts or parts shown in Table 2 is the material 16MnR used in conventional atmospheric and vacuum distillation equipment.

[0064]It was found that after one year of continuous operation of the equipment, the corrosion amount of the tower body between the top of the atmospheric tower and the 40th tray was 0.01 mm, the corrosion amount of the tray was 0.01 mm, and the corrosion amount from the 40...

Embodiment 3

[0066] This embodiment is used to illustrate the atmospheric and vacuum distillation equipment and atmospheric distillation method for high sour crude oil provided by the present invention.

[0067] According to the method of Example 1, the PL19-3 crude oil with an acid value content of 3.5 mg KOH / g was subjected to atmospheric and vacuum distillation. The difference is that the materials of the atmospheric and vacuum distillation equipment are shown in Table 3.

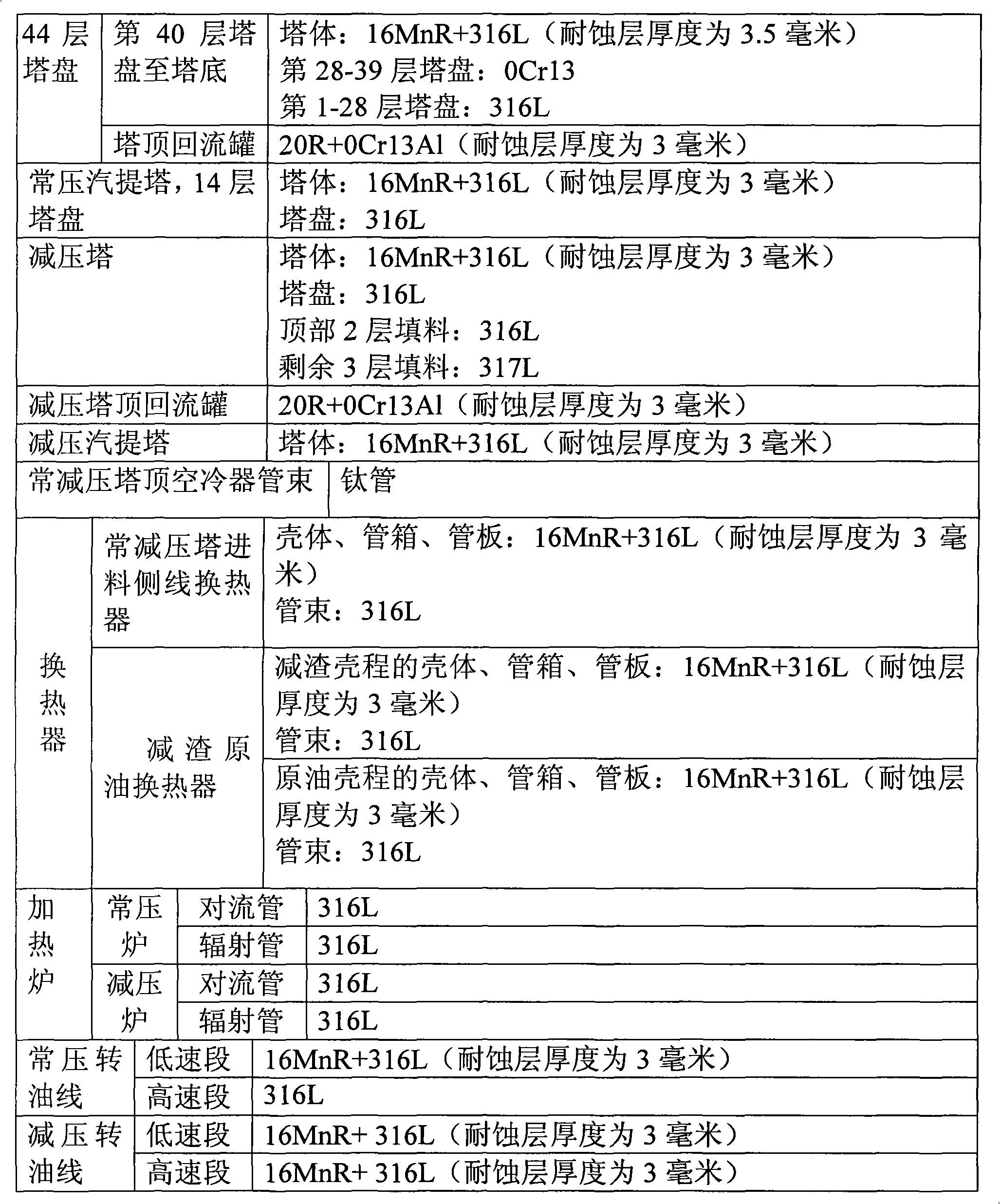

[0068] table 3

[0069]

[0070]

[0071] It was found that after one year of continuous operation of the equipment, the corrosion amount of the tower body between the top of the atmospheric tower and the 40th tray was 0.02 mm, and the corrosion amount of the tray was 0.01 mm. The corrosion amount of the tower body between the bottom is 0.02 mm, the corrosion amount of the tray is 0.02 mm, the corrosion amount of the convection tube of the atmospheric furnace is 0.01 mm, and the corrosion amount of the radiant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com