Patents

Literature

80results about How to "Maintain catalytic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

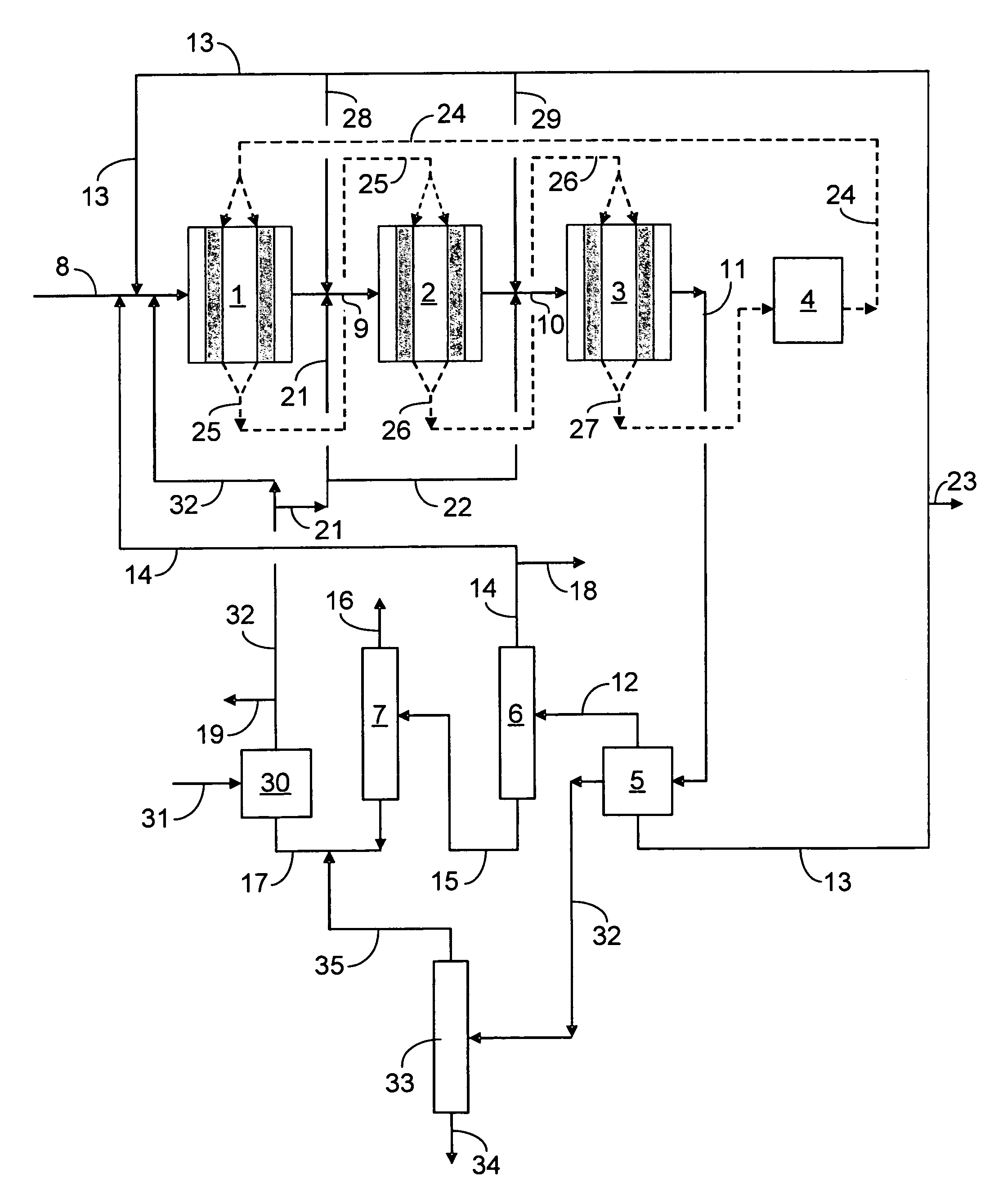

Conversion of oxygenate to propylene with selective hydrogen treatment of heavy olefin recycle stream

ActiveUS20060063956A1Improve economyMinimize severityMolecular sieve catalystHydrocarbons from unsaturated hydrocarbon additionPtru catalystOxygenate

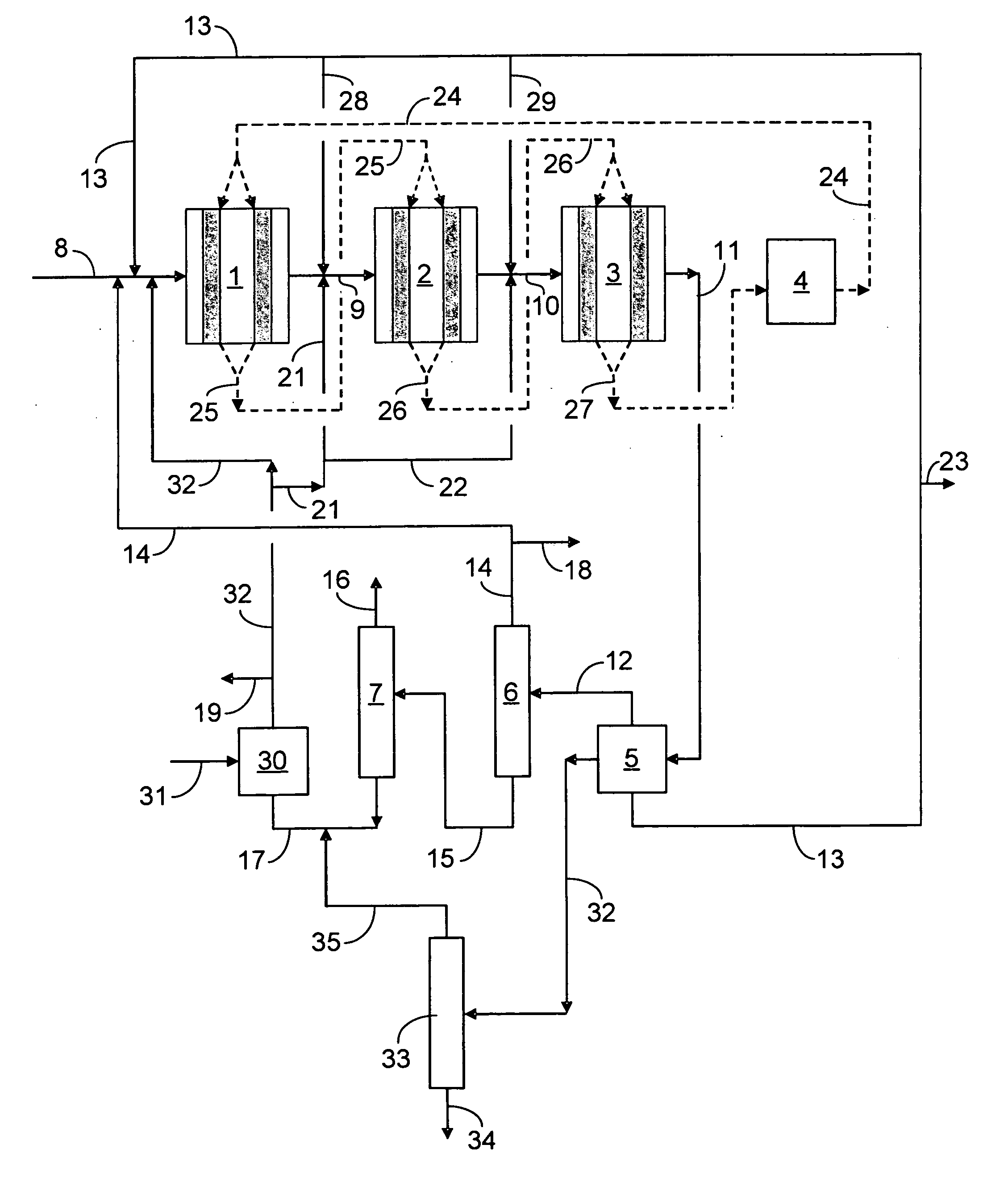

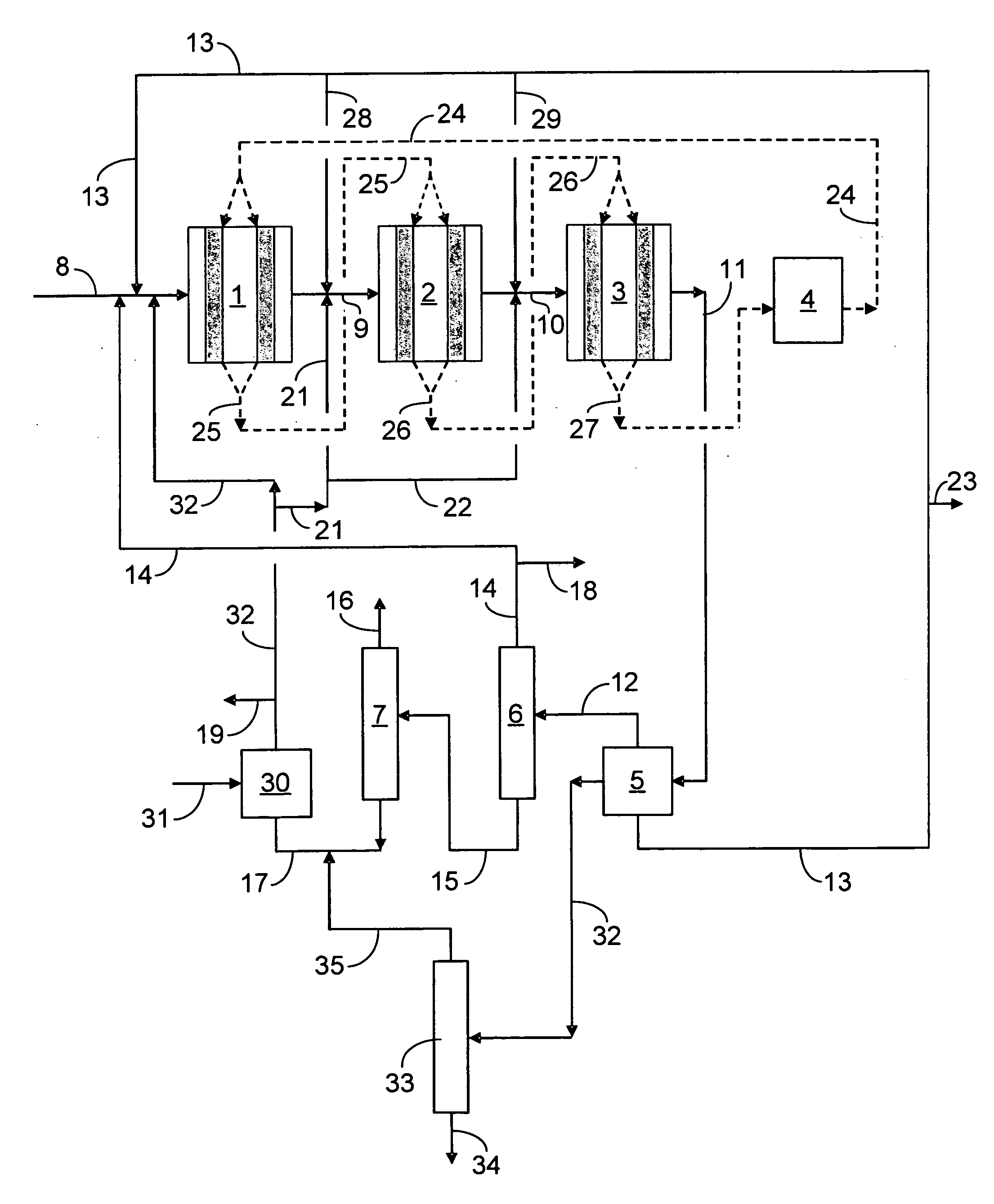

The average cycle propylene selectivity of an oxygenate to propylene (OTP) process using one or more fixed or moving beds of a dual-function oxygenate conversion catalyst with recycle of one or more C4+ olefin-rich fractions is substantially enhanced by the use of selective hydrotreating technology on these C4+ olefin-rich recycle streams to substantially eliminate detrimental coke precursors such as dienes and acetylenic hydrocarbons. This hydrotreating step helps hold the build-up of detrimental coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling a substantial improvement in propylene average cycle yield. The propylene average cycle yield improvement enabled by the present invention over that achieved by the prior art using the same or a similar catalyst system but without the use of the hydrotreating step on the C4+ olefin-rich recycle stream is of the order of about 1.5 to 5.5 wt-% or more.

Owner:UOP LLC

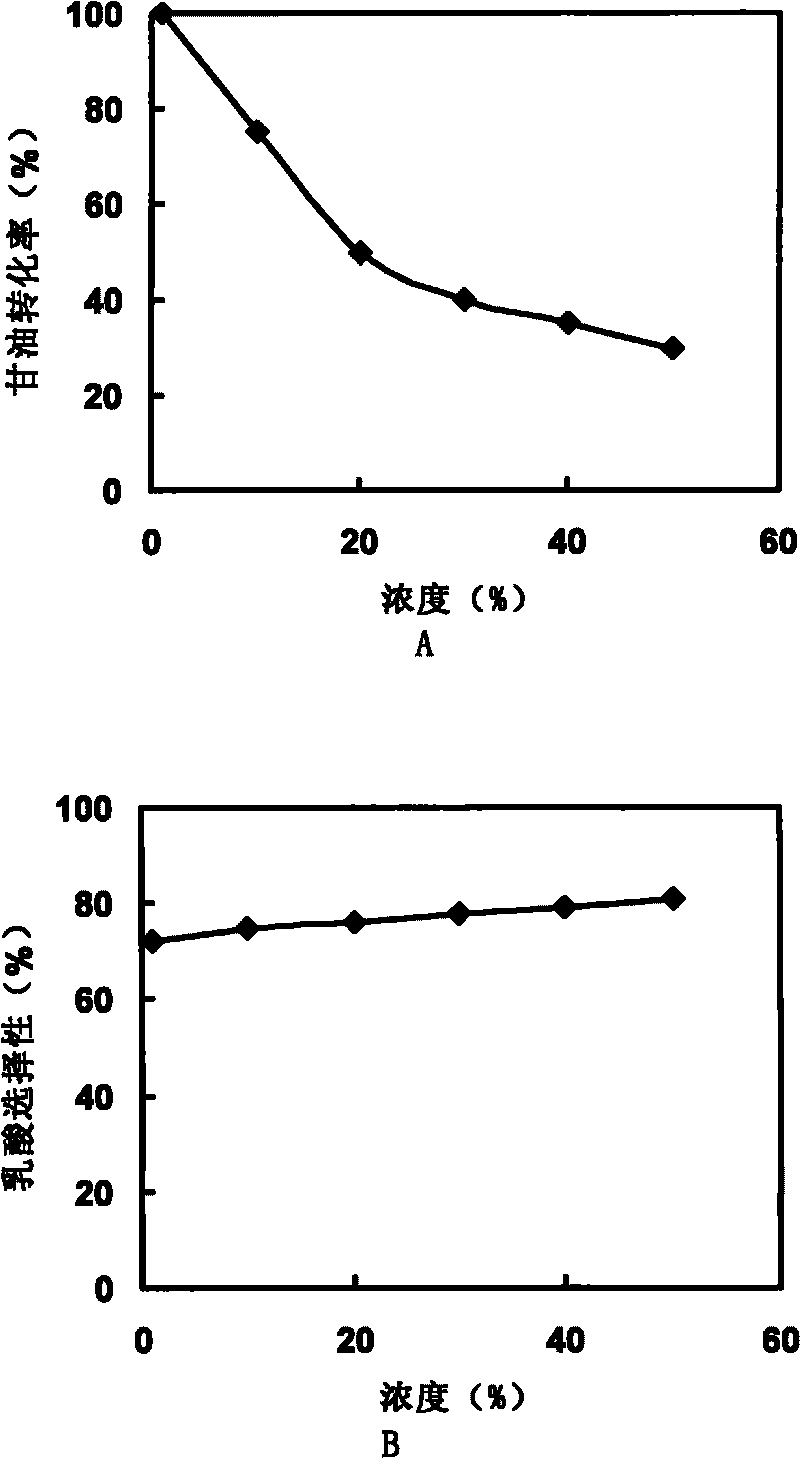

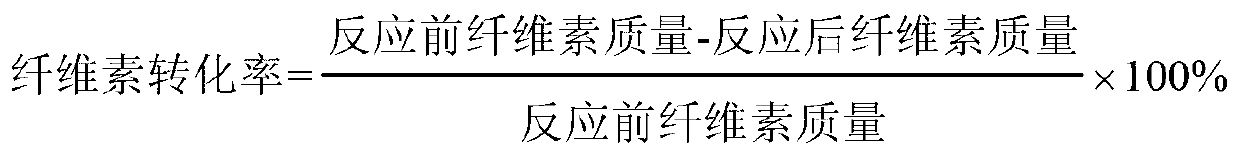

Method for producing lactic acid by using glycerin and special catalyst for production of lactic acid by using glycerin

ActiveCN101695657AImprove performanceImprove reaction efficiencyOrganic compound preparationCatalyst activation/preparationGlycerolBULK ACTIVE INGREDIENT

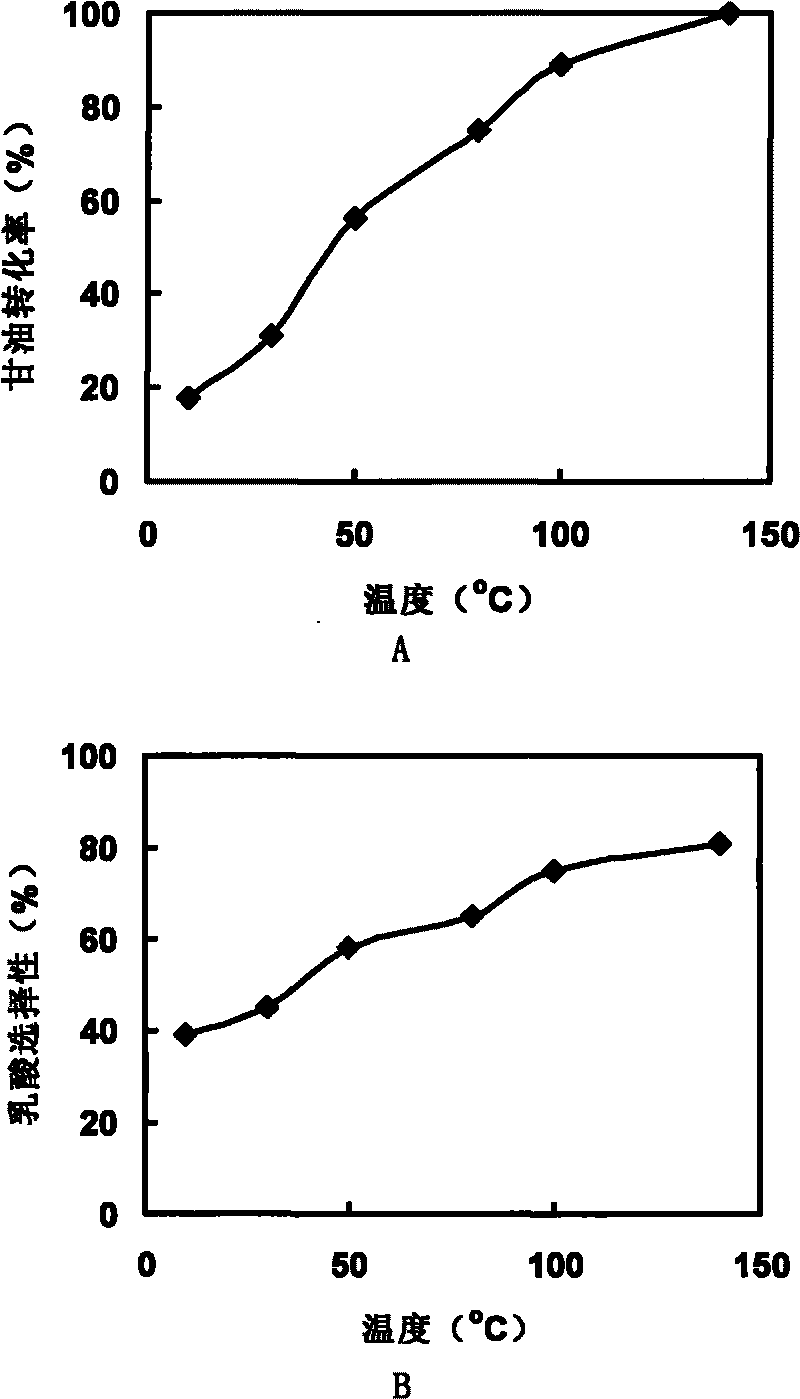

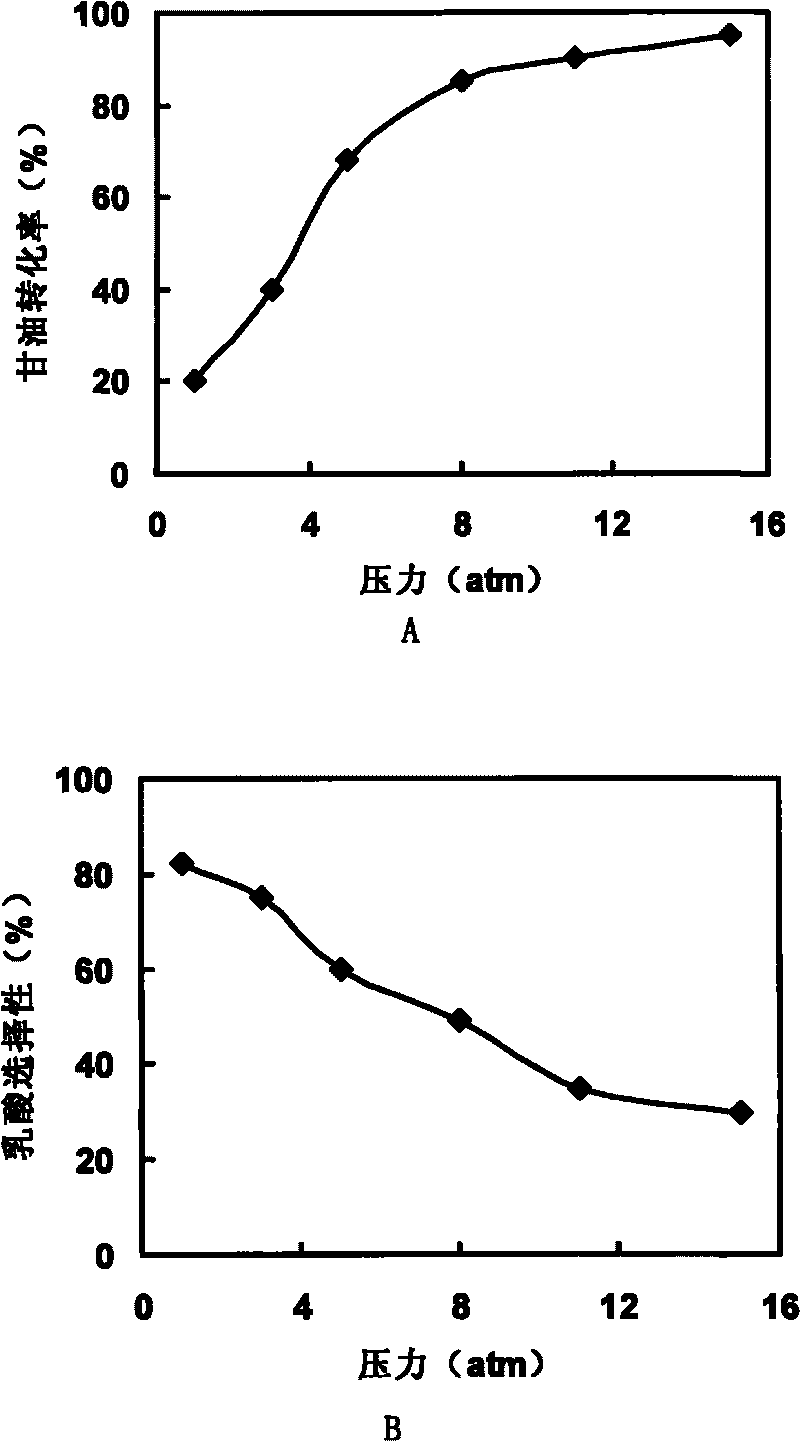

The invention provides a method for producing lactic acid by using glycerin and a special catalyst for the production of the lactic acid by using the glycerin. The catalyst provided by the invention is obtained by loading 0.1 to 30 mass parts of an active ingredient onto 100 mass part of carrier, wherein active ingredient is (1) Pt or (2) a composite of Pt and other noble metals. The catalyst can be used in the production of the lactic acid by using the glycerin. In the presence of the catalyst of the invention, the glycerin can be converted into the lactic acid effectively under a mild reaction condition. The catalyst of the invention has the advantages of high activity and selectively, easy preparation, low price, easy industrialization, long service life, loss prevention and good application prospective.

Owner:PEKING UNIV

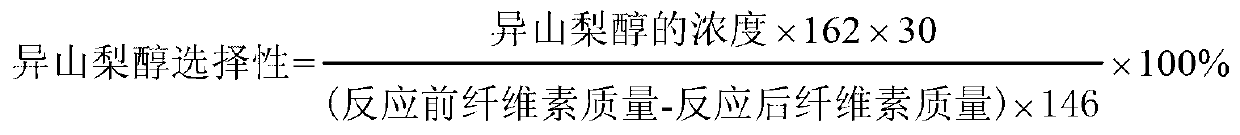

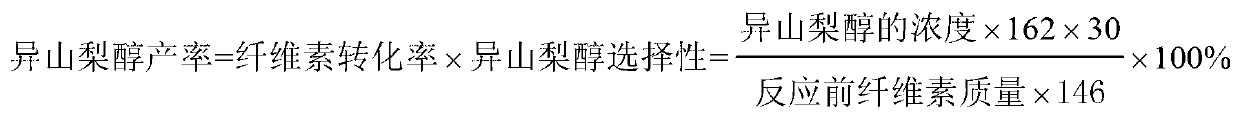

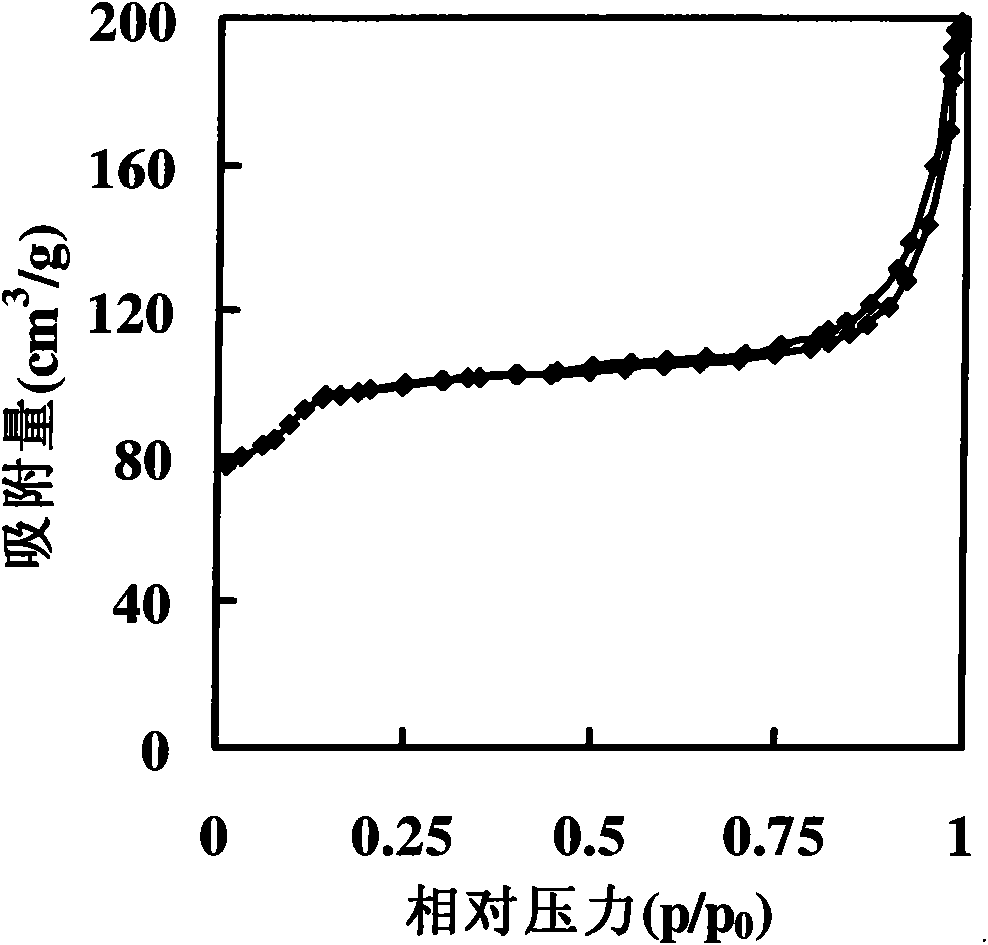

Catalyst for preparing isosorbide by utilizing celluloses and preparation method of catalyst

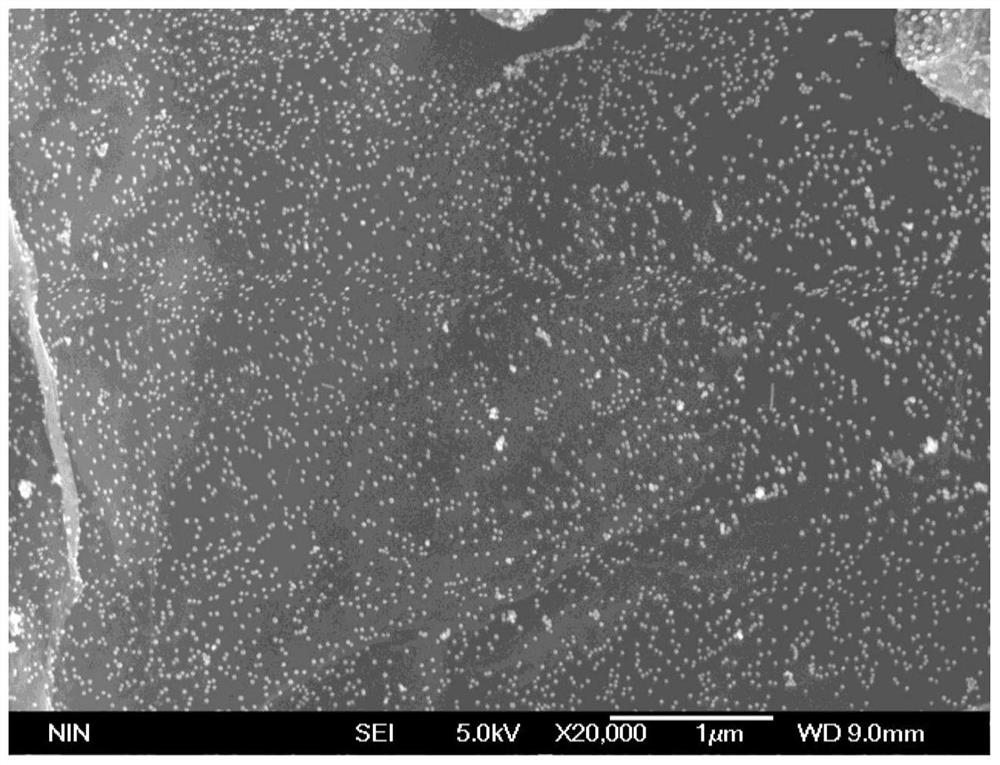

InactiveCN103272595AImprove stabilityMaintain catalytic performanceOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsCelluloseIsosorbide

The invention relates to the technical field of fine chemical engineering and discloses a catalyst for preparing isosorbide by utilizing celluloses and a preparation method of the catalyst. The catalyst is a bifunctional catalyst comprising a solid acid loading metal. The bifunctional catalyst disclosed by the invention can be used for realizing the process of catalyzing the celluloses to obtain the isosorbide under the reaction condition that no inorganic liquid acid is added, and avoiding the corrosion problem of equipment caused by using the inorganic liquid acid, and is easy to recycle; the maximum conversion rate of the celluloses can reach 100%, and the maximum selectivity of the isosorbide can reach 55%; the catalyst has very high stability under the existing reaction condition, still maintains the catalytic performance without loss after being cycled for ten times and has low requirements on equipments; and the catalyst is suitable for the existing common industrial production conditions and has very good application prospect.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI +1

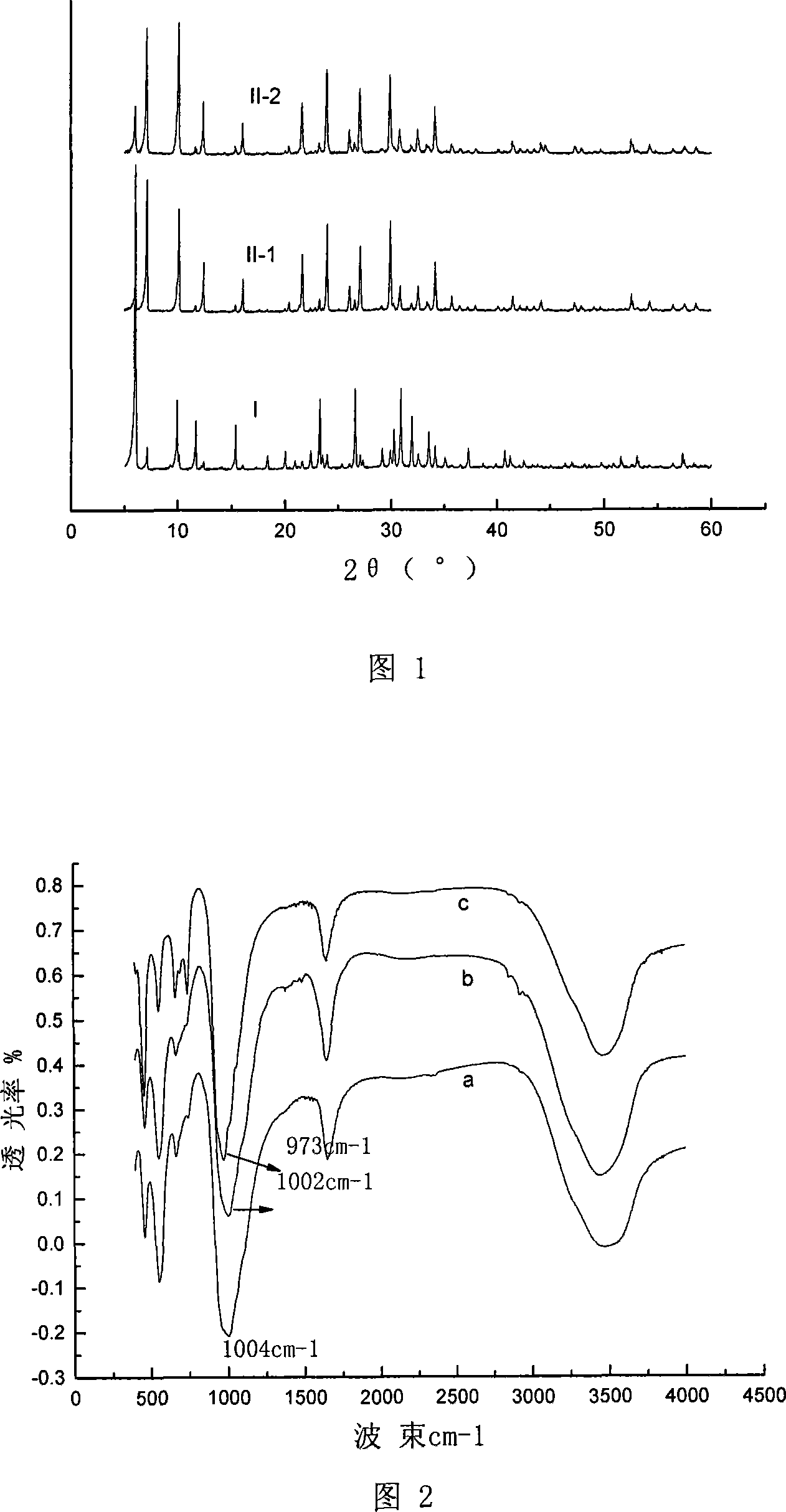

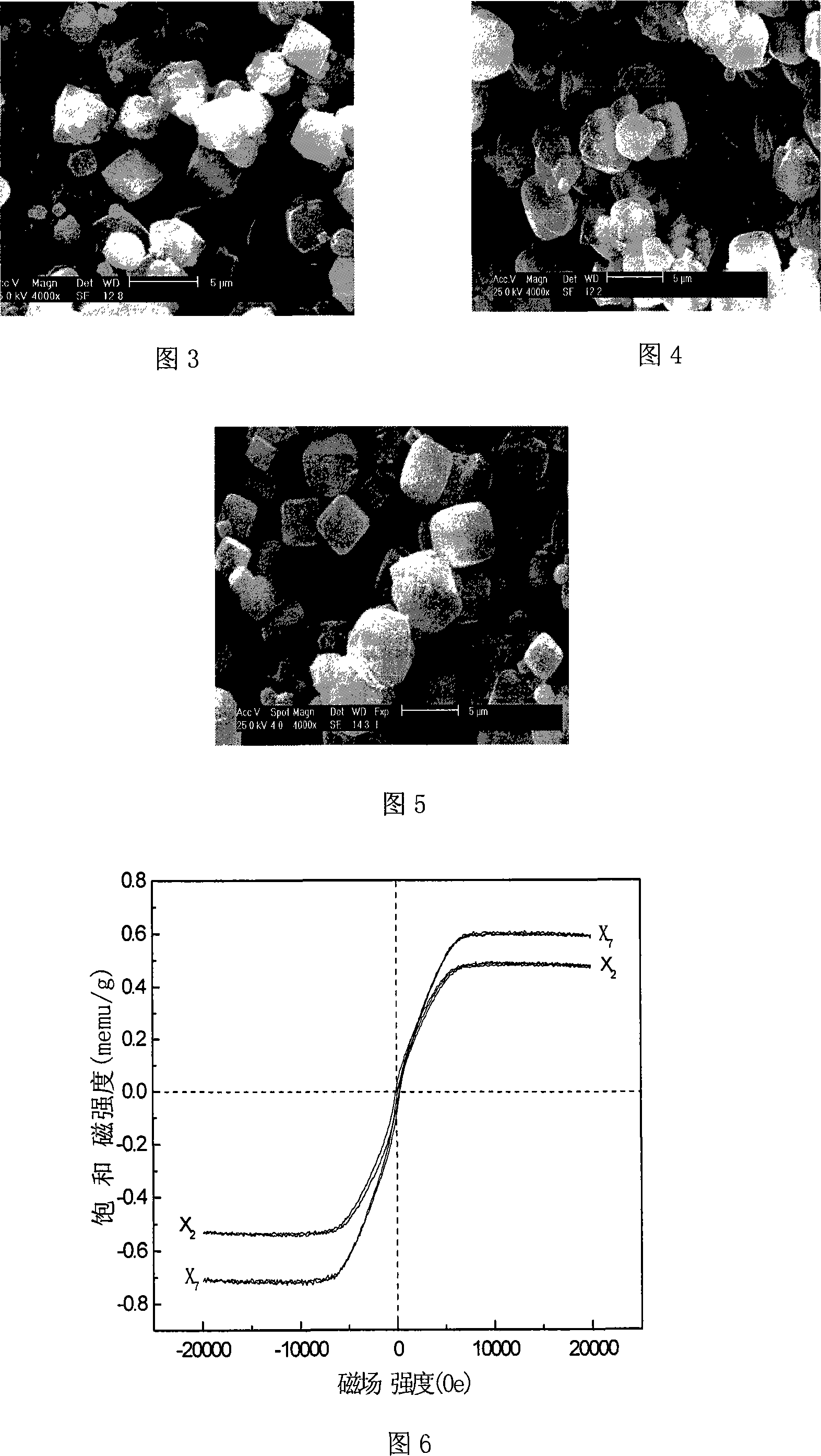

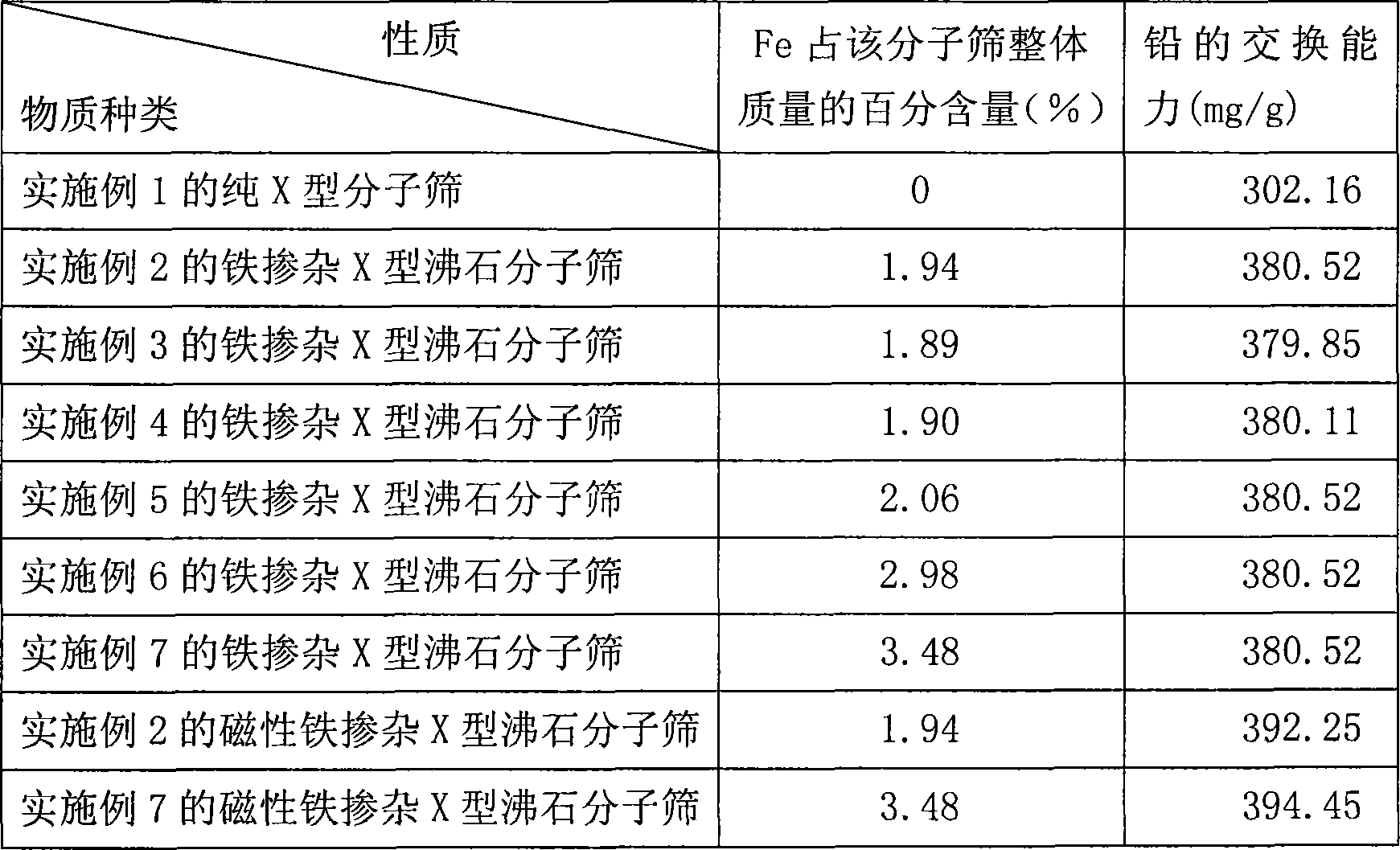

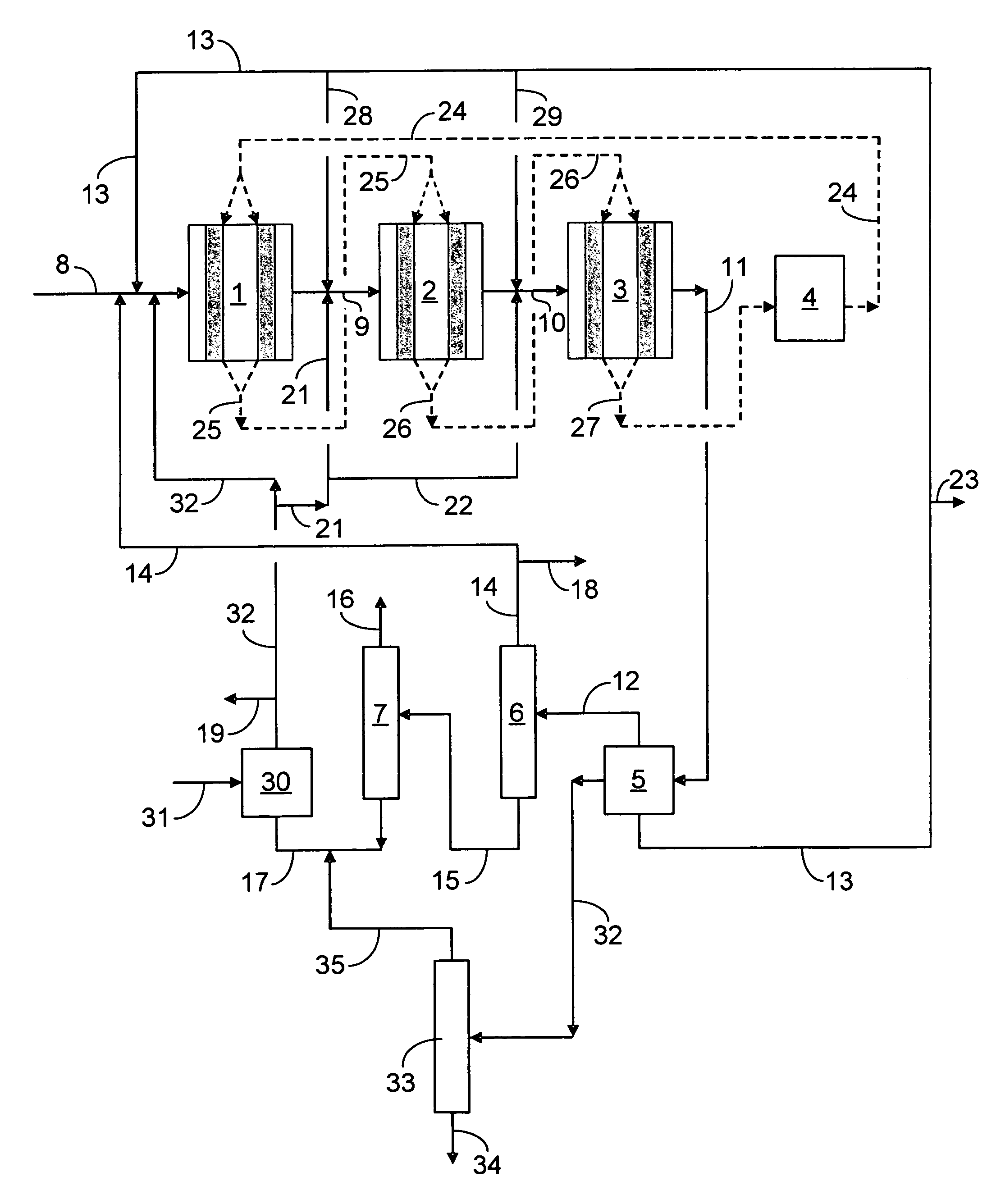

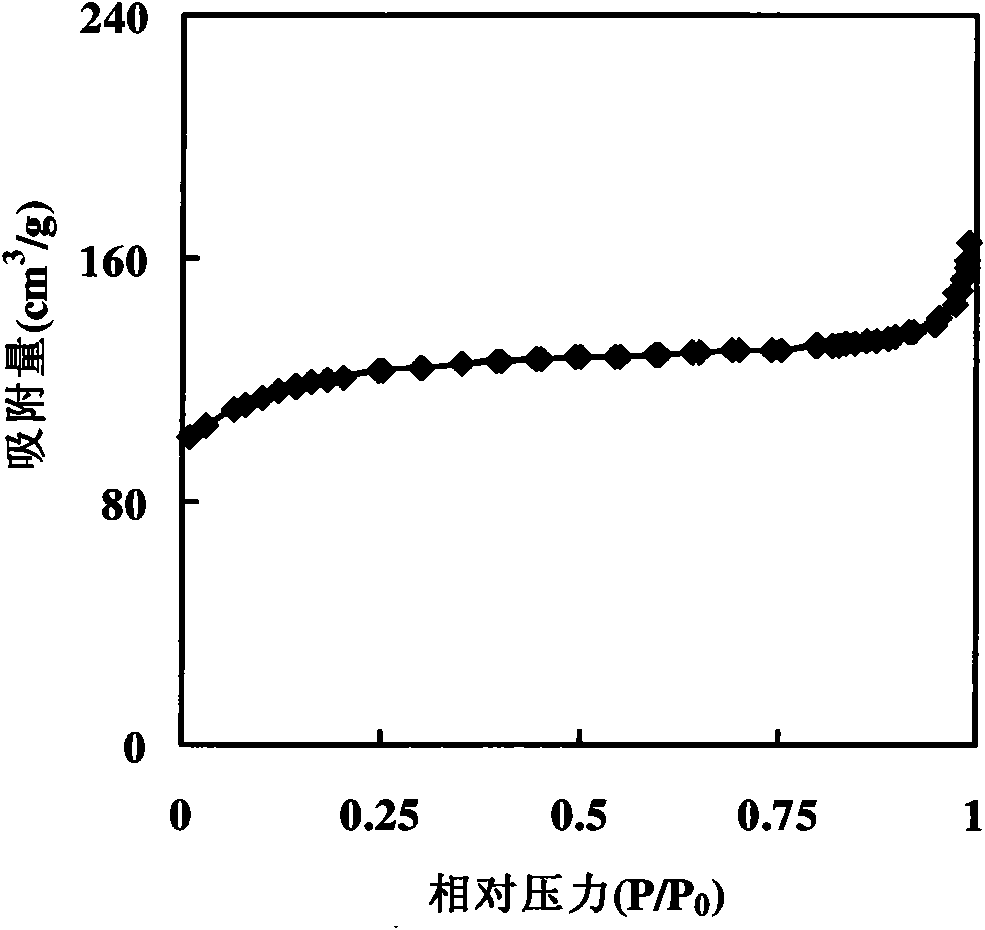

X type zeolite molecular sieve and method for producing the same

InactiveCN101219795AImprove performanceImprove adsorption capacityFaujasite aluminosilicate zeoliteMolecular sieveMagnetic stability

The invention relates to an X-shaped zeolite molecular sieve and a method for preparing thereof, relating to a field of zeolite molecular sieve material; The X-shaped zeolite molecular sieve is a magnetic iron-doped X-shaped zeolite molecular sieve; magnetic ferroferric oxide is formed in the zeolite lattice, wherein, quality percentage of Fe occupying the molecular sieve is 1.89 percent to 3.48 percent. The preparing method comprises the steps that, iron-doped X-shaped zeolite molecular sieve is firstly compounded and then the magnetized magnetic iron-doped X-shaped zeolite molecular sieve is prepared through hydrogen reduction; the method results in a structure of Fe3O4 formed in frame of the iron-doped X-shaped zeolite molecular sieve. The magnetic iron-doped X-shaped zeolite molecular sieve has strong magnetism and magnetic stability, which not only solves the problem that the existing powdery zeolite molecular sieve is difficult to be recycled in reaction solution, and further improves absorption property of the sieve, but also enlarge application range of the zeolite molecular sieve, thereby allowing the zeolite molecular sieve to be applied to catalytic reaction in which iron acts as the catalyst.

Owner:HEBEI UNIV OF TECH

Conversion of oxygenate to propylene with selective hydrogen treatment of heavy olefin recycle stream

ActiveUS7405337B2Improve economyMinimize severityMolecular sieve catalystHydrocarbons from unsaturated hydrocarbon additionOxygenateHydrogen treatment

The average cycle propylene selectivity of an oxygenate to propylene (OTP) process using one or more fixed or moving beds of a dual-function oxygenate conversion catalyst with recycle of one or more C4+ olefin-rich fractions is substantially enhanced by the use of selective hydrotreating technology on these C4+ olefin-rich recycle streams to substantially eliminate detrimental coke precursors such as dienes and acetylenic hydrocarbons. This hydrotreating step helps hold the build-up of detrimental coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling a substantial improvement in propylene average cycle yield. The propylene average cycle yield improvement enabled by the present invention over that achieved by the prior art using the same or a similar catalyst system but without the use of the hydrotreating step on the C4+ olefin-rich recycle stream is of the order of about 1.5 to 5.5 wt-% or more.

Owner:UOP LLC

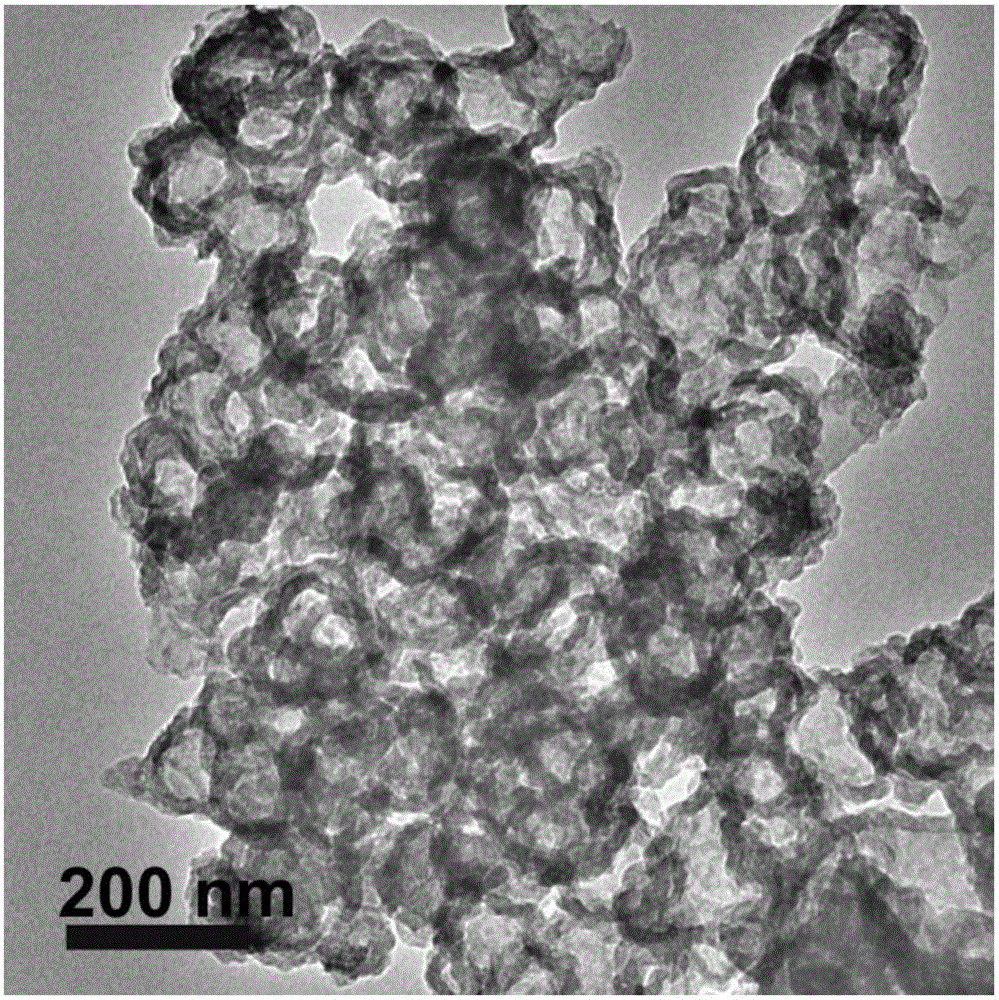

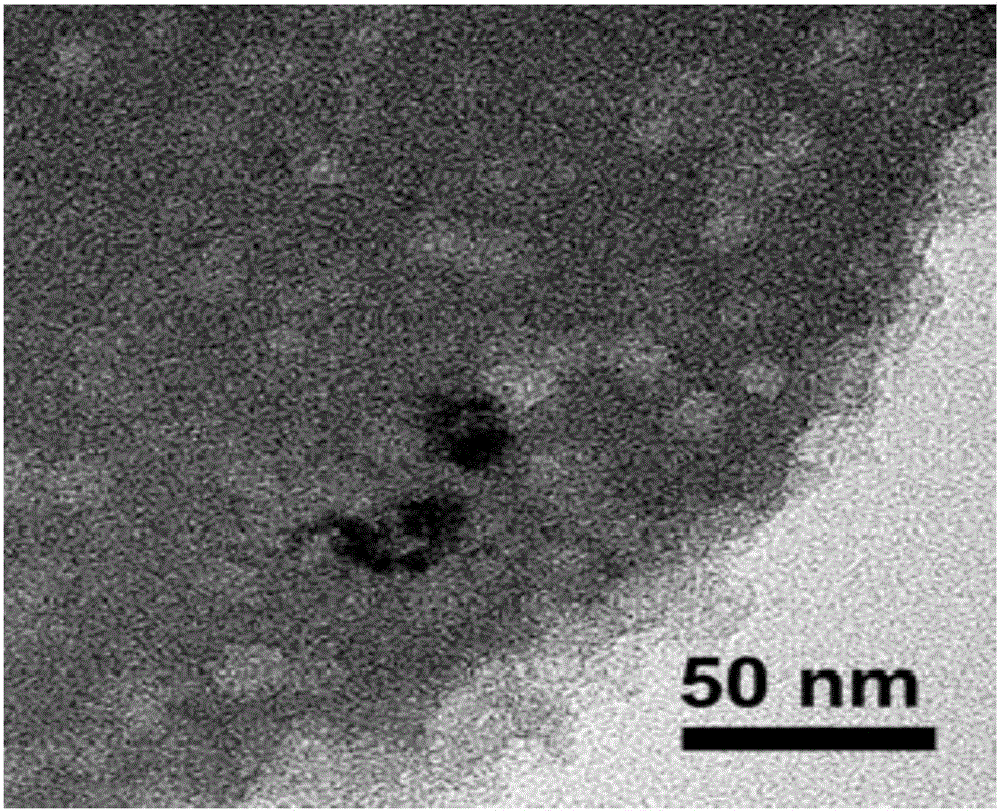

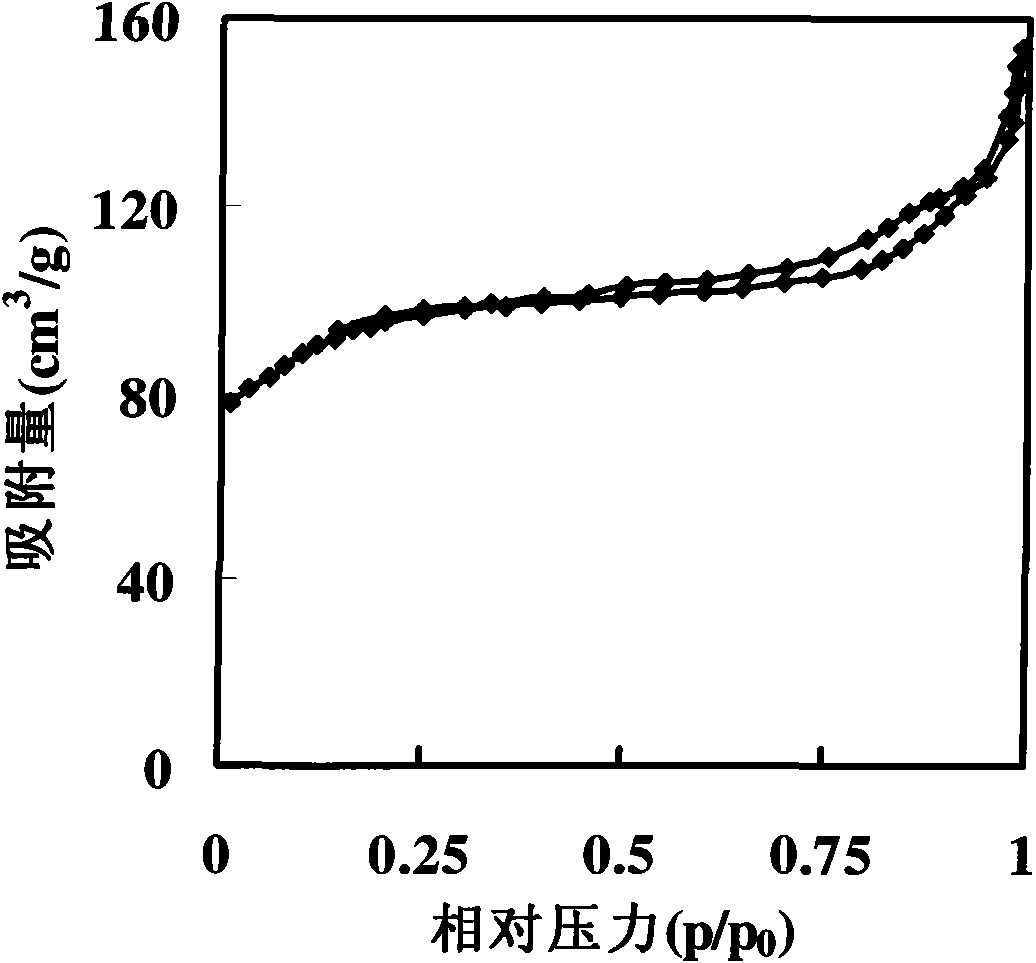

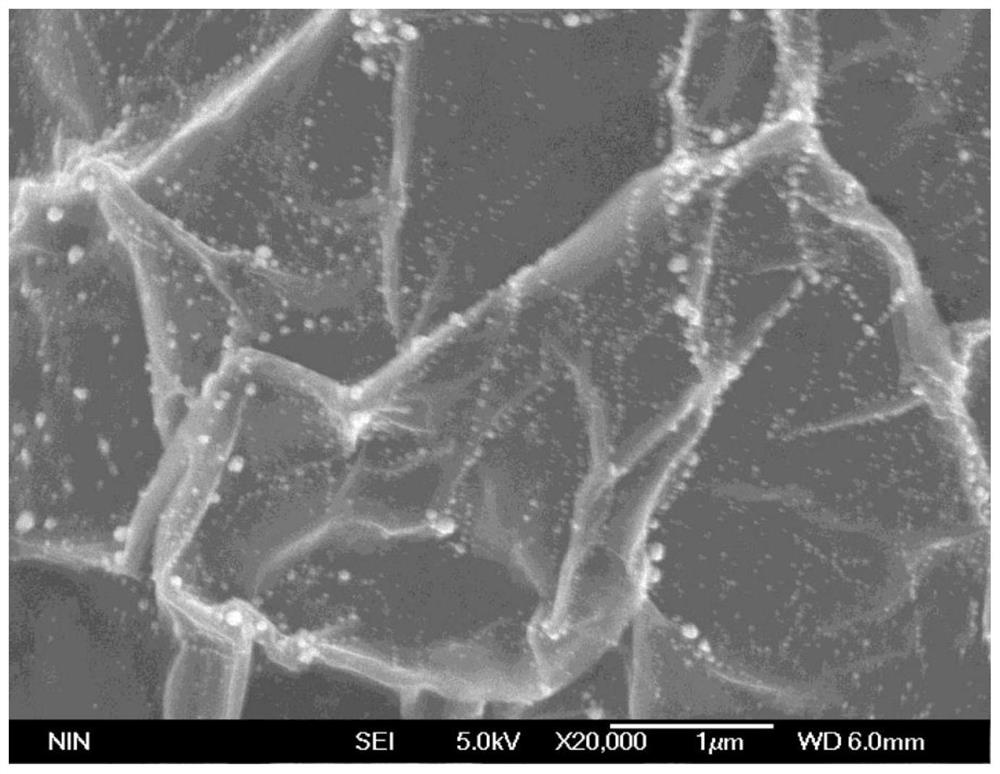

Nitrogen-doped carbon aerogel catalyst used for metal-air battery, and preparation method

InactiveCN106129421AMaintain catalytic performanceEasy to prepareCell electrodesPolypyrrolePorous carbon

The invention belongs to the technical field of a catalyst, and discloses a nitrogen-doped carbon aerogel catalyst used for a metal-air battery, and a preparation method. The preparation method comprises the following steps of (1) adding pyrrole, polyvinylpyrrolidone and sodium chloride into ethyl alcohol, heating and stirring until the ethyl alcohol is fully volatilized to obtain an intermediate product A; (2) adding a ferric salt solution to the intermediate product A obtained in the step (1), and heating and stirring to obtain a polypyrrole nanosheet; and (3) heating the polypyrrole nanosheet obtained in the step (2) to obtain the nitrogen-doped carbon aerogel catalyst. The preparation method is simple without involving the conventional complicated and time-consuming template pore-forming step; instead, a precursor is carbonized directly to obtain the required porous carbon material; the catalytic performance of the material is maintained to the maximum degree; the obtained nitrogen-doped carbon aerogel catalyst is large in specific surface area, high in catalytic property and high in stability; and in addition, the nitrogen-doped carbon aerogel catalyst, used as the negative electrode material of a zinc air battery, has excellent oxygen reduction catalytic activity, so that the nitrogen-doped carbon aerogel catalyst can be applied to the fields of fuel cells.

Owner:SOUTH CHINA UNIV OF TECH

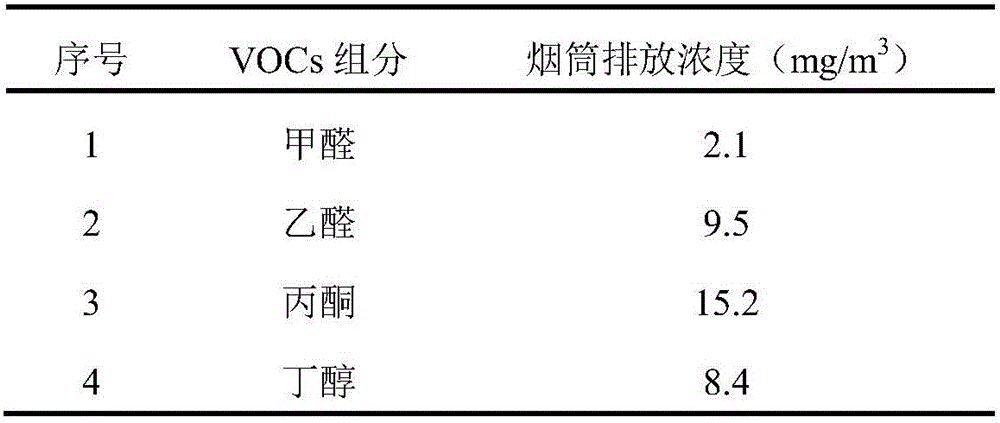

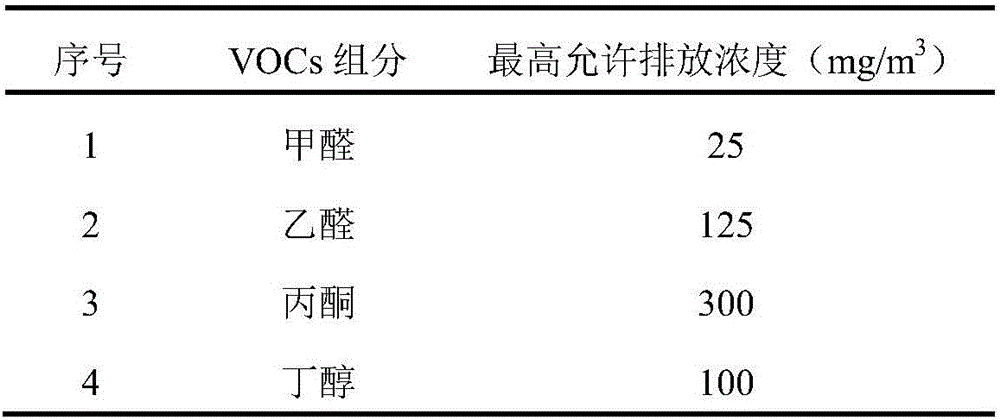

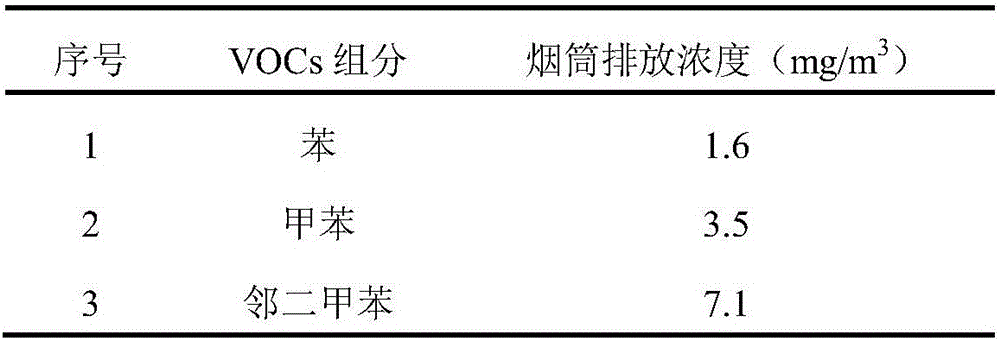

Preparation method of catalyst for catalyzing ozonization and decomposition volatile organic compounds (VOCs) at normal temperature

InactiveCN106238041AIncrease the areaPore structure highGas treatmentHeterogenous catalyst chemical elementsDecompositionRare earth

The invention discloses a preparation method of a catalyst for catalyzing ozonization and decomposition volatile organic compounds (VOCs) at normal temperature. The preparation method comprises the following steps: (1) loading nano rare earth oxide coating serving as an auxiliary agent on a catalyst carrier, coating an active component, namely nano perovskite, on the carrier, on which the rare earth oxide is loaded, calcining the catalyst carrier, on which the auxiliary agent and the active component are loaded, and forming a large amount of micropores in the surface of and inside the catalyst carrier to obtain a target catalyst with pores; and (2) fixing the prepared target catalyst on a catalytic bed layer of a catalytic oxidation tower, starting an ozone generator, introducing VOC waste gas subjected to pretreatment in the catalytic oxidation tower, and performing deep oxidation on the VOCs at normal temperature of -10 to 40 DEG C to generate non-toxic and odorless substances. By the method, the VOCs can be completely oxidized at room temperature to generate carbon dioxide and water, so the method is safe in operation and low in energy consumption.

Owner:TIANJIN UNIV

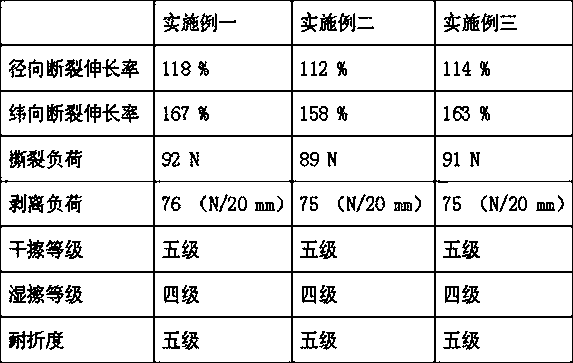

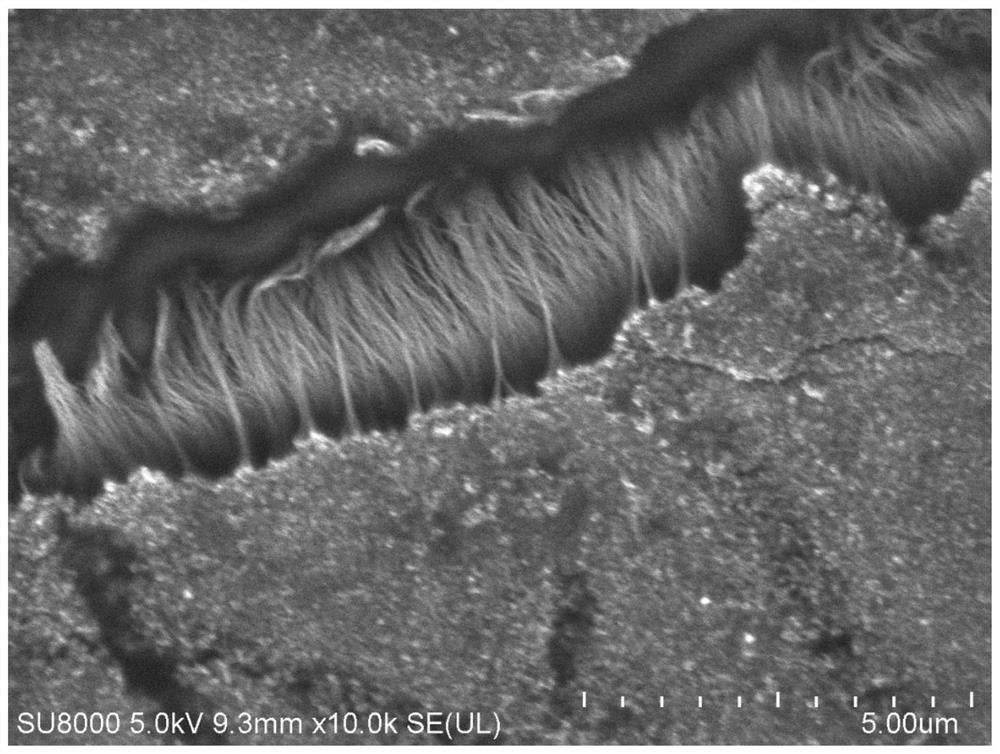

Graphene superfine fiber polyurethane synthetic leather and preparation method thereof

The invention discloses a graphene superfine fiber polyurethane synthetic leather and a preparation method thereof. The graphene superfine fiber polyurethane synthetic leather comprises a surface layer, a middle layer and an adhering layer which are respectively prepared from the following components of high-performance waterborne non-yellowing polyurethane resin, nylon, graphene, superfine fiberpolyurethane synthetic substrate, an abrasion-resistant agent, a light-resistant agent, a flame-retardant master batch and pure water. The preparation method comprises the following steps of S1, weighing the raw materials according to a ratio; S2, treating the graphene; S3, mixing and stirring the raw materials; S4, filtering the solution by a filtering net, and preparing an automobile superfine fiber leather by a dry type synthetic leather production line. The prepared graphene superfine fiber polyurethane synthetic leather has the advantages that the comprehensive property is excellent, thetesting result in each aspect is good, the physical indexes are basically the same with the physical indexes of common superfine fiber automobile interior trim, the moisture and air ventilating property is realized, the abrasion-resistant property is excellent, and the touch feel of the natural leather is realized.

Owner:TIANSHOU FUJIAN SUPERFIBER TECH

Nickel-copper (111) alloy single crystal film and preparation method thereof

PendingCN108754608AMaintain catalytic performanceNo breakagePolycrystalline material growthAfter-treatment detailsCopper atomCrystal orientation

The invention relates to a method for preparing a nickel-copper (111) alloy single crystal film. The method comprises: S1, providing a sapphire base, S2, depositing a metal film with thickness of 50 to 5000 nm on the crystal plane Al2O3 (0001) of the sapphire base to obtain a sapphire substrate on which a nickel-copper alloy is deposited, wherein the metal film is an alloy thin film composed of 1-40% of nickel atoms, and copper atoms, and S3, putting the sapphire substrate in a chemical vapor deposition furnace and carrying out annealing treatment in a gas atmosphere of argon gas and hydrogengas to obtain a single crystal thin film with (111) crystal orientation. The invention also relates to a nickel-copper (111) alloy single crystal film obtained by the method. The nickel-copper (111) alloy single crystal film greatly improves the performances of graphene and lays a foundation for the application of graphene in the field of microelectronics.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Carbon nitride-carbon-TiO2-selenium nano composite material as well as preparation method and application thereof

InactiveCN108855196APromote formationMaintain catalytic performancePhysical/chemical process catalystsWater/sewage treatment by irradiationCarbon nanotubeCarbon nitride

The invention provides a carbon nitride-carbon-TiO2-selenium nano composite material applied to photocatalytic degradation of pollutants. According to the invention, an azide-modified nano-carbon nitride-nano-titanium dioxide composite material is covalently chelated to the surface of an alkynylation-modified multi-walled carbon nanotube-nano selenium composite material to obtain a carbon nitride-carbon-TiO2-selenium nano composite material. The material can be applied to photocatalytic degradation of pollutants and has excellent photocatalytic degradation properties for the pollutants.

Owner:李忠

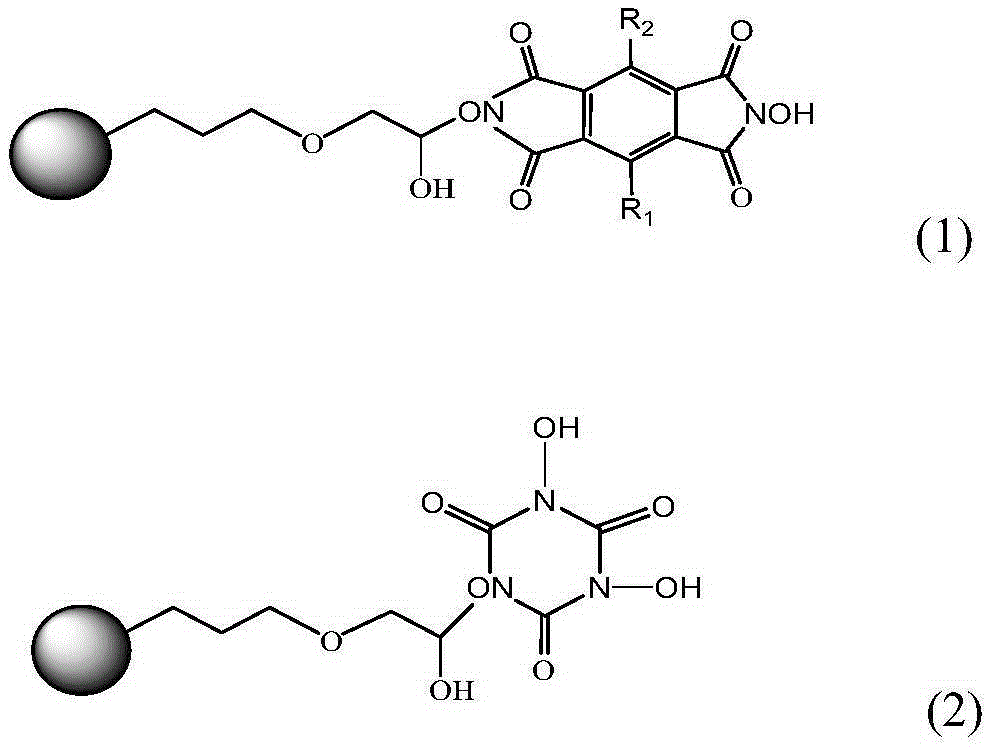

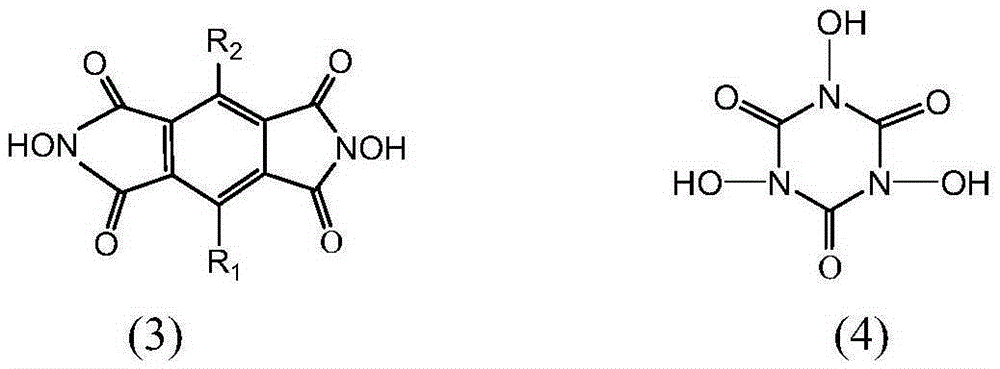

Preparation method and application of a solid-supported catalyst for hydrocarbon oxidation

ActiveCN104148110BEasy to prepareAvoid condensationPreparation by oxidation reactionsOrganic compound preparationMesoporous materialOxygen

Owner:XIANGTAN UNIV

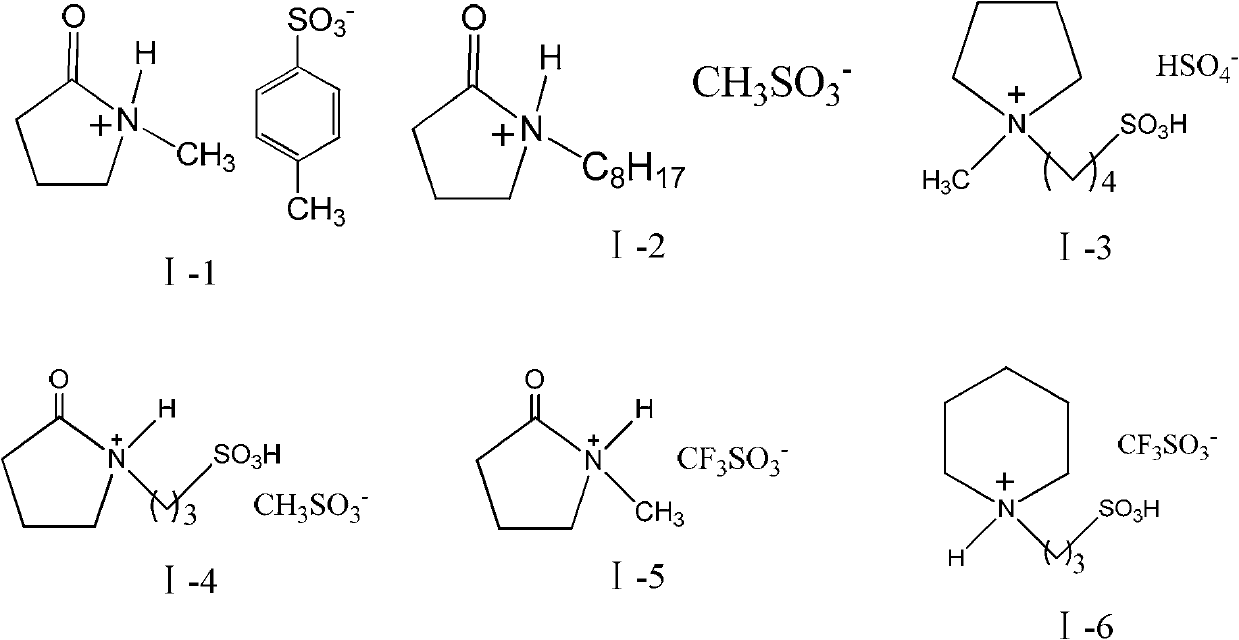

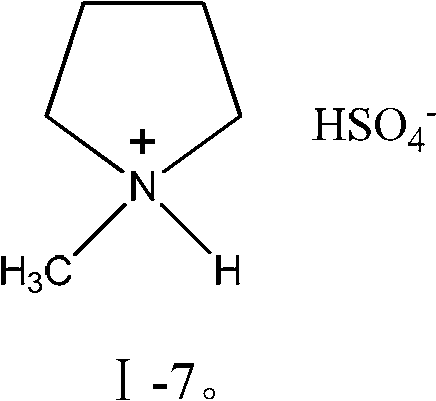

Method for synthesizing trioxymethylene

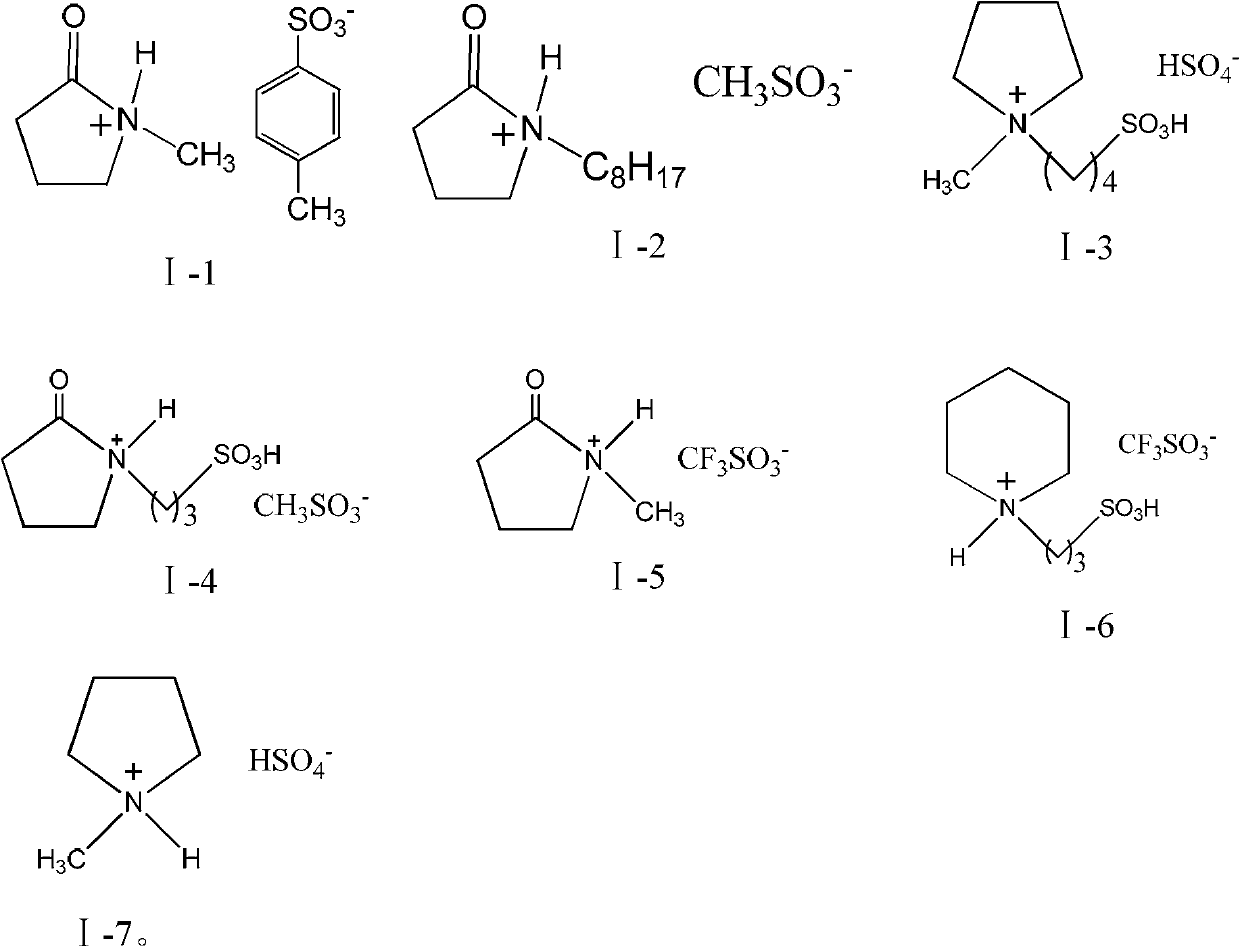

ActiveCN103373980AEasy to manufactureImprove promotion effectOrganic chemistryChemical recyclingAqueous solutionIonic liquid

The invention discloses a method for synthesizing trioxymethylene. The method comprises the following step of carrying out a reaction on the aqueous solution of formaldehyde under the presence of an ionic liquid and an accelerant, wherein the accelerant is a salt compound, and the mass percent of the aqueous solution of formaldehyde is 30-70%. The method disclosed by the invention has the advantages that (1) the accelerant is convenient to prepare and has a good acceleration effect; (2) the activity of the ionic liquid which serves as a catalyst can be improved significantly without affecting the selectivity of the product of reaction, and the use amount and the cost of the ionic liquid can be reduced under the condition that the catalytic performance is guaranteed; (3) the concentration of the formaldehyde which serves as a raw material is wide and ranges between 30wt.% and 70wt.%, and the reaction condition is mild; (4) the continuous distillation reaction is adopted, and the accelerant can be recycled; (5) the concentration of the product of reaction is wide, and the accelerant has low corrosivity and a significant accelerating effect and can be recycled.

Owner:CHINA NAT OFFSHORE OIL CORP +2

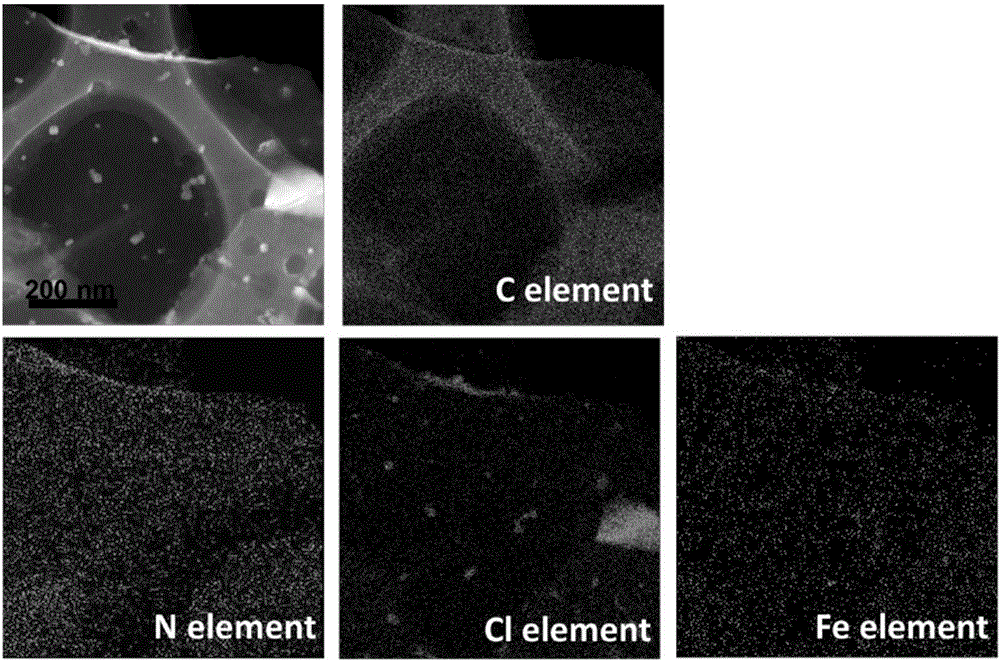

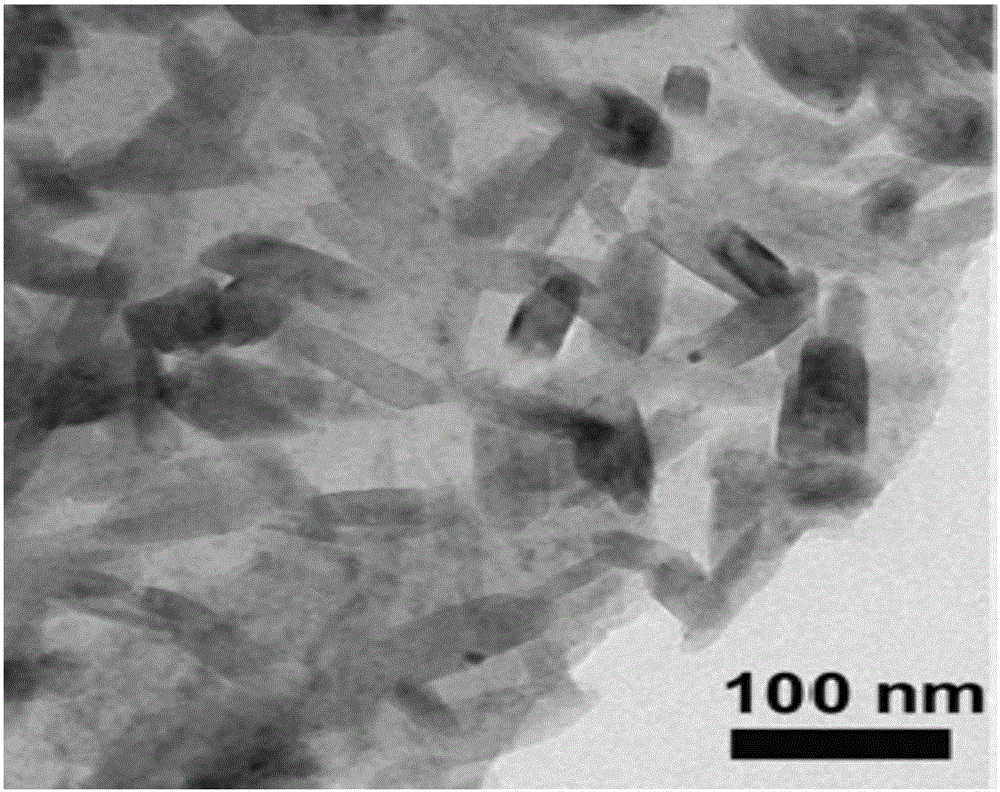

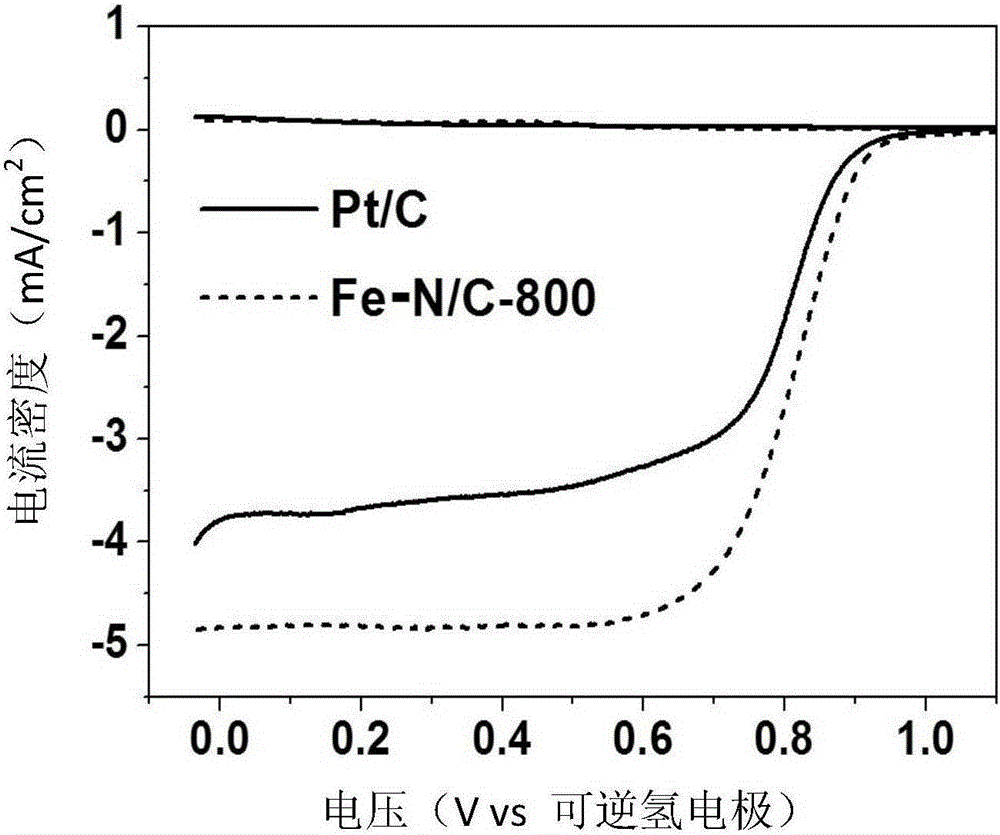

Iron-nitrogen-codoped porous carbon catalyst for proton exchange membrane fuel cell and method of iron-nitrogen-codoped porous carbon catalyst

InactiveCN105226298AEasy to prepareMaintain catalytic performanceMaterial nanotechnologyCell electrodesIonTube furnace

The invention belongs to the technical field of catalysts, and discloses an iron-nitrogen-codoped porous carbon catalyst for a proton exchange membrane fuel cell and a preparation method of the iron-nitrogen-codoped porous carbon catalyst. The method comprises the following steps: (1) adding 2-fluoroaniline and a ferric iron salt to deionized water, and stirring the deionized water evenly to obtain a mixed liquid; (2) transferring the mixed liquid obtained in the step (1) to a hydrothermal reaction kettle for a hydrothermal reaction, and cooling, filtering, cleaning and drying the mixed liquid to obtain a 2-fluoroaniline flake; (3) putting the 2-fluoroaniline flake obtained in the step (2) into a quartz tube furnace, introducing nitrogen, warming to 750-850 DEG C, carrying out a thermal reaction for 2-3 hours, and cooling the 2-fluoroaniline flake to obtain the iron-nitrogen-codoped porous carbon catalyst. The prepared catalyst is large in specific surface area, good in catalytic property, high in anti-methanol poisoning capability, good in durability, high in stability and simple in preparation method, and can be applied to the field of the fuel cell.

Owner:SOUTH CHINA UNIV OF TECH

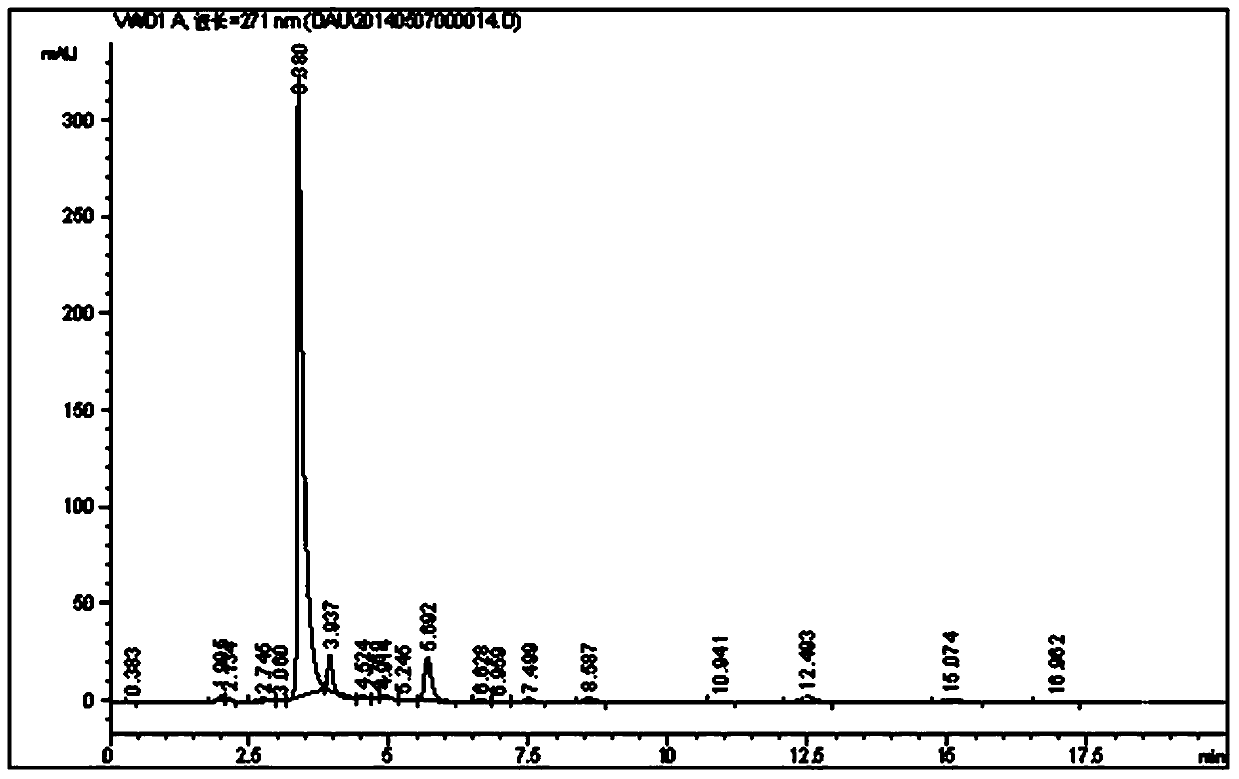

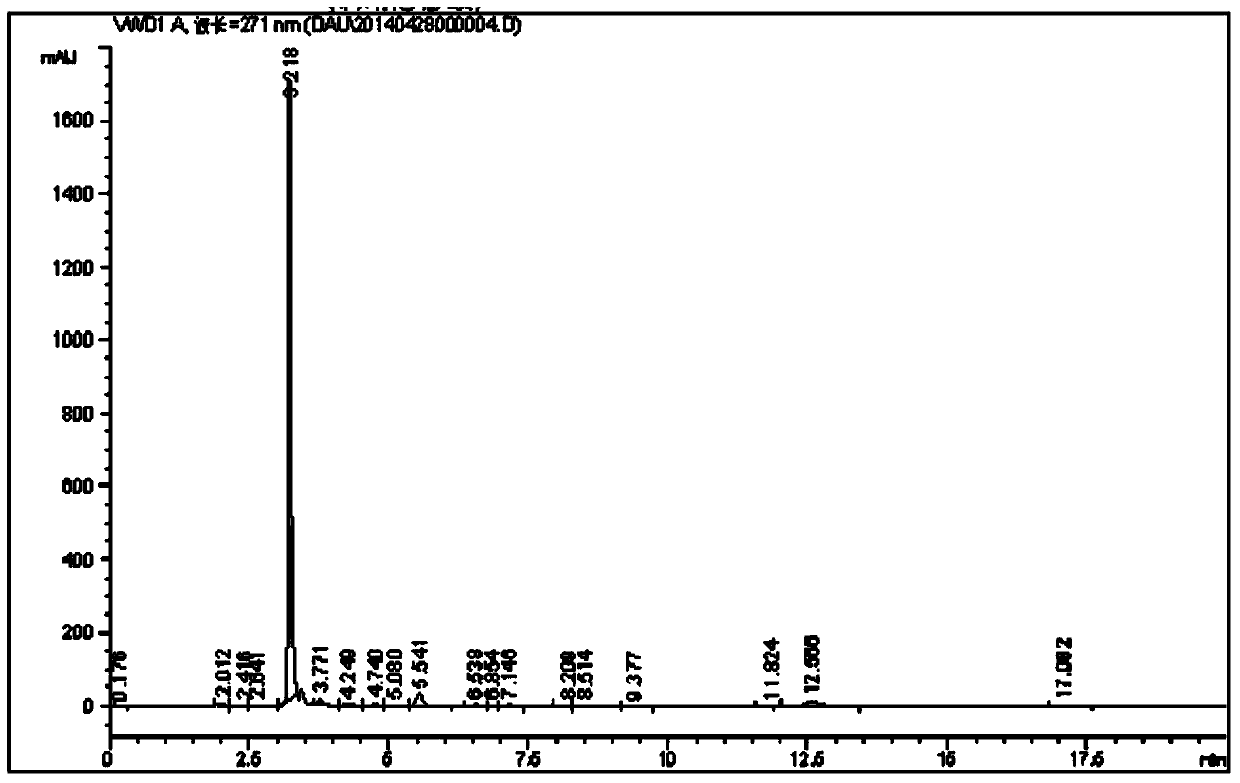

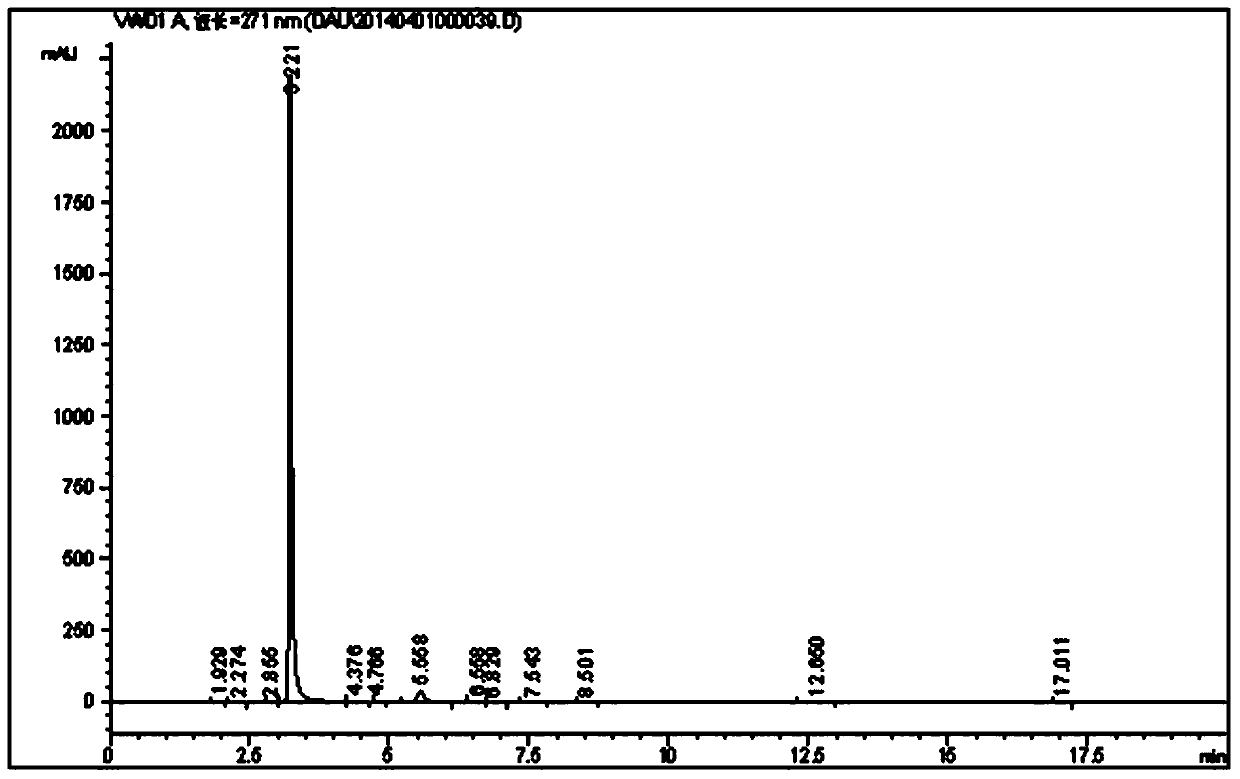

Preparation method of caffeine intermediate N,N-1,3-dimethyl-4,5-diamido urazine

The invention relates to a preparation method of the caffeine intermediate N,N-1,3-dimethyl-4,5-diamido urazine and belongs to the technical field of synthesis and preparation of organic compounds. According to the preparation method, a hydrogen addition reaction is carried out under heated and pressurized conditions with N,N-1,3-dimethyl-4-imido-5-isonitroso urazine as the starting material and raney nickel as the catalyst, an aqueous solution containing metal halide and alkaline substances is used as the reaction medium, the preparation method has the advantages of being smooth and controllable in reaction, high in catalytic activity and stable in quality of dimethyl-DAU, and the yield and the quality of the dimethyl-DAU are improved.

Owner:CSPC INNOVATION PHARMA

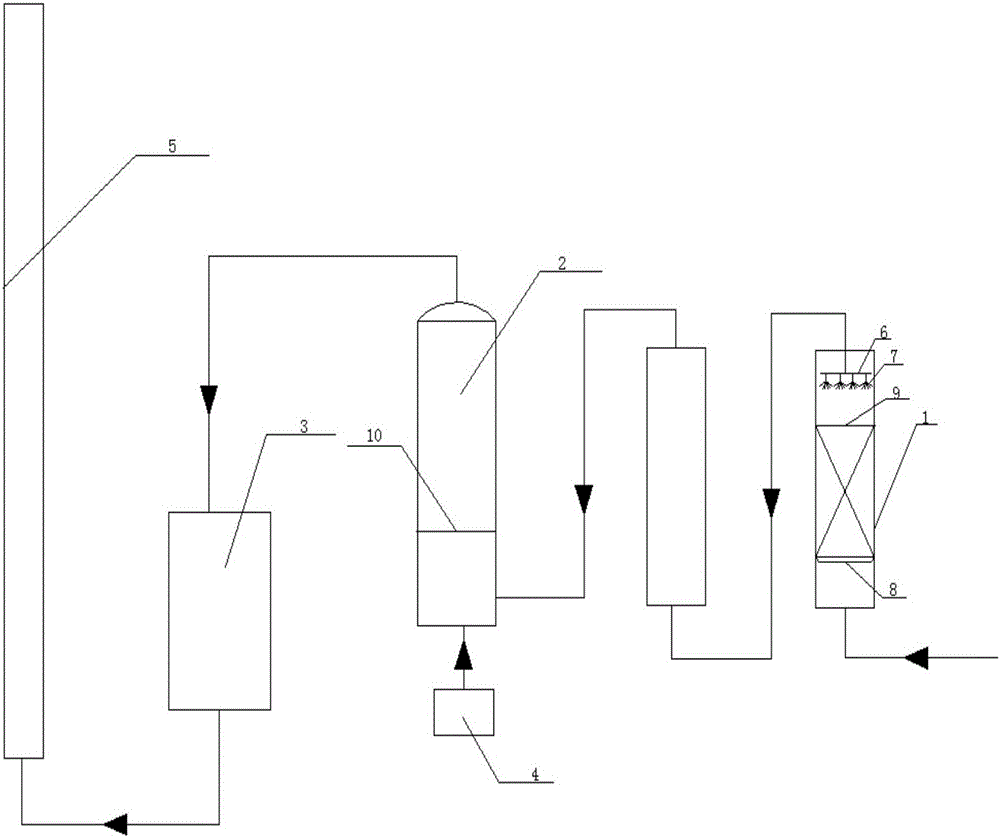

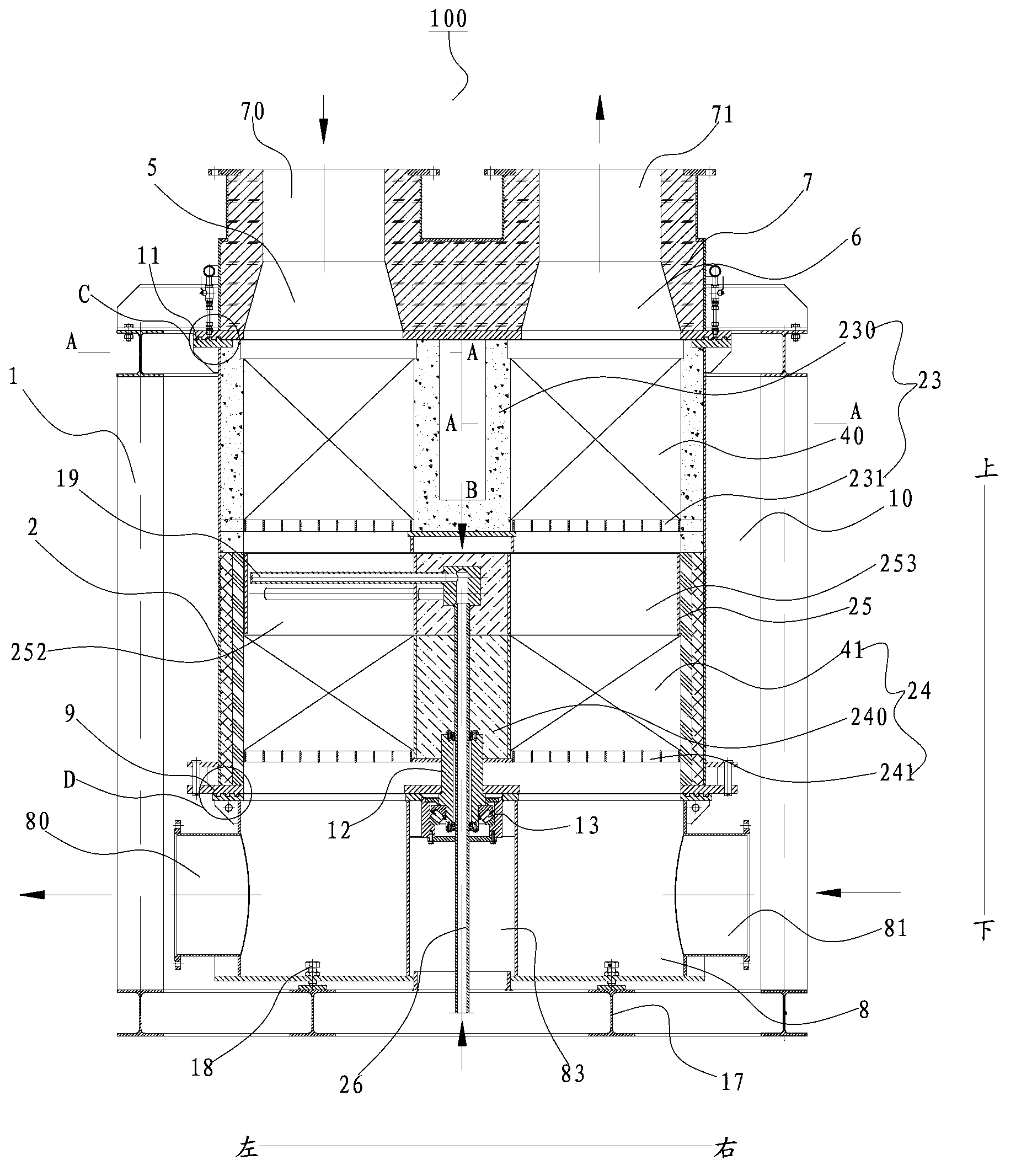

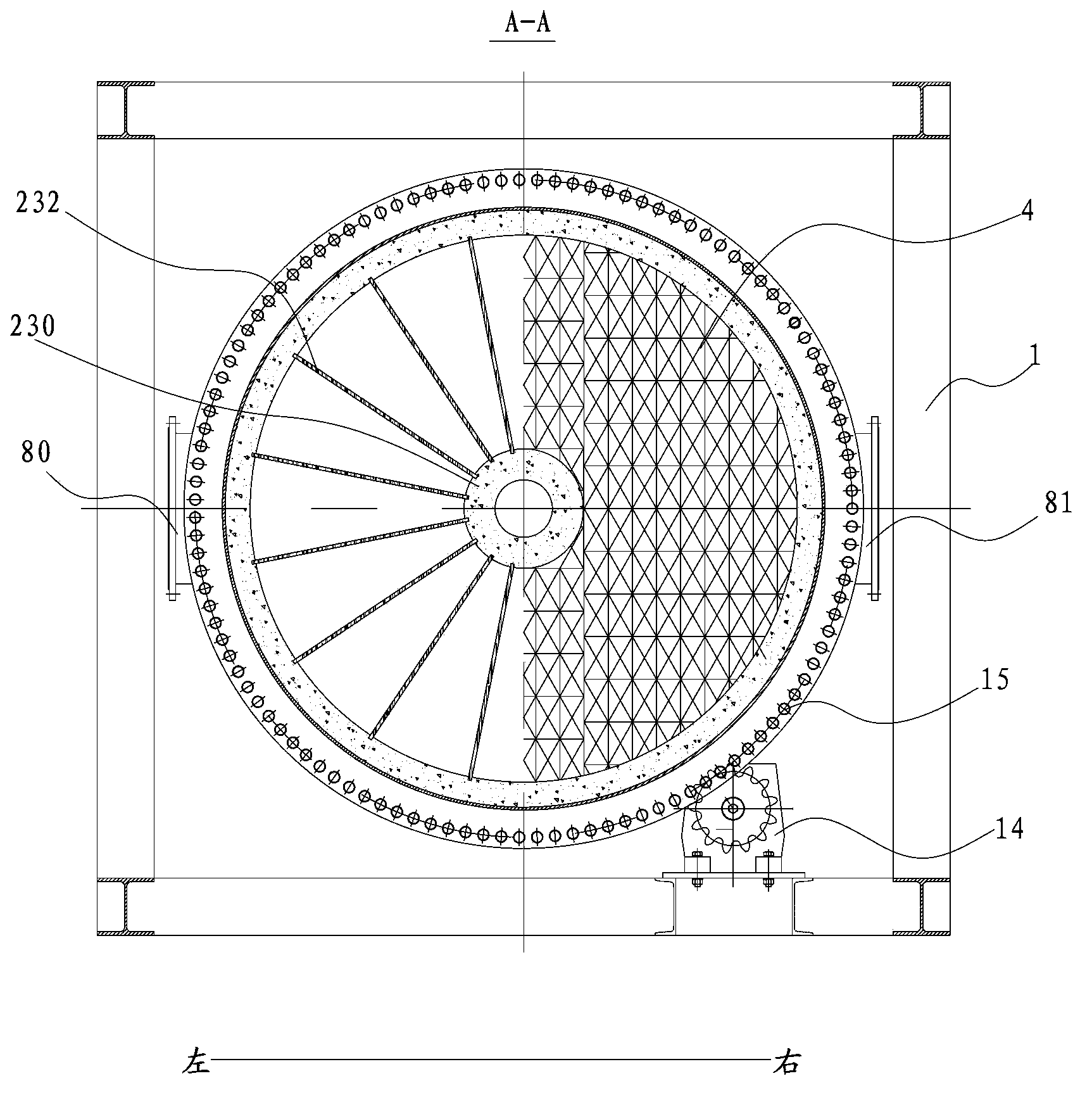

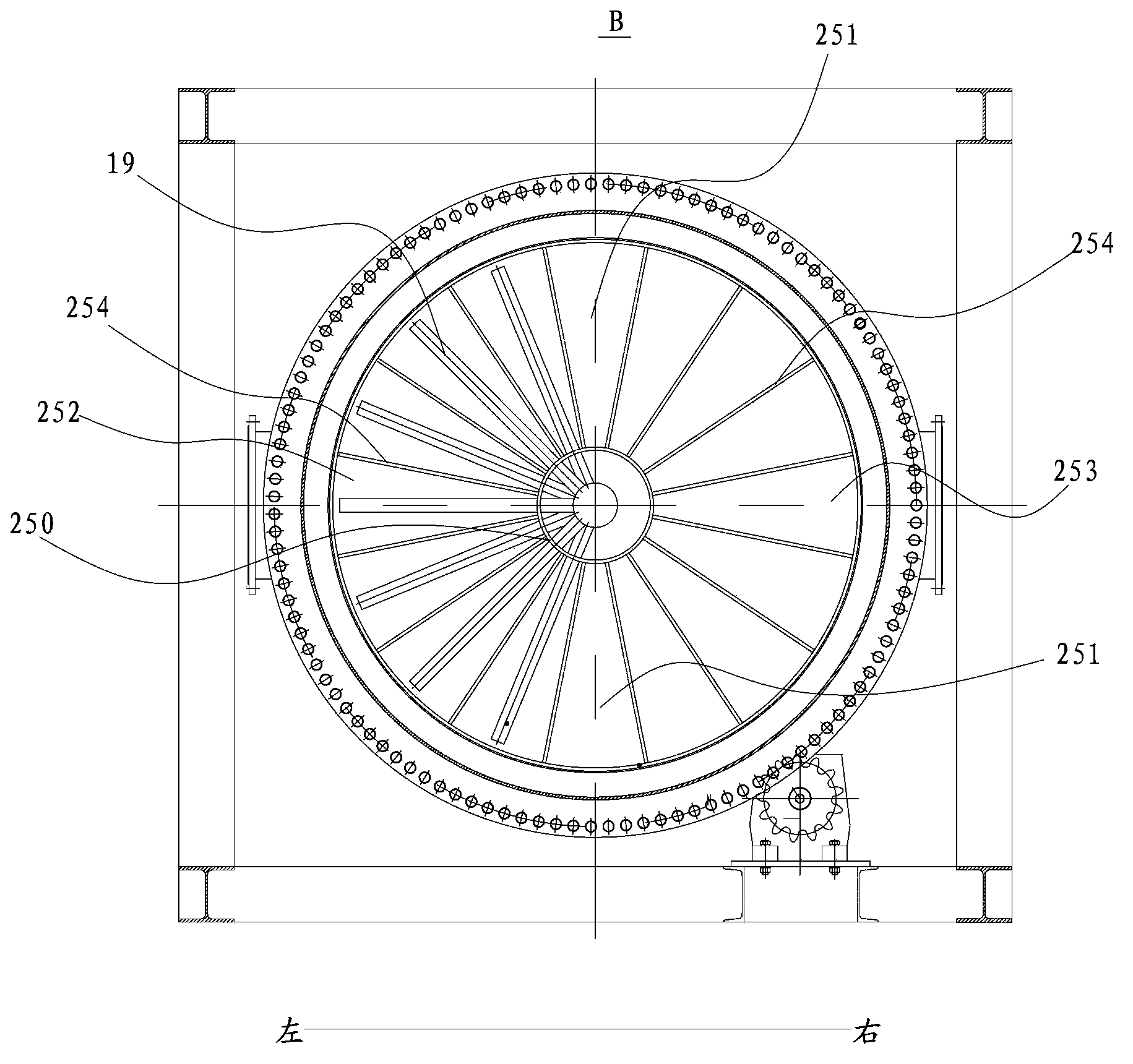

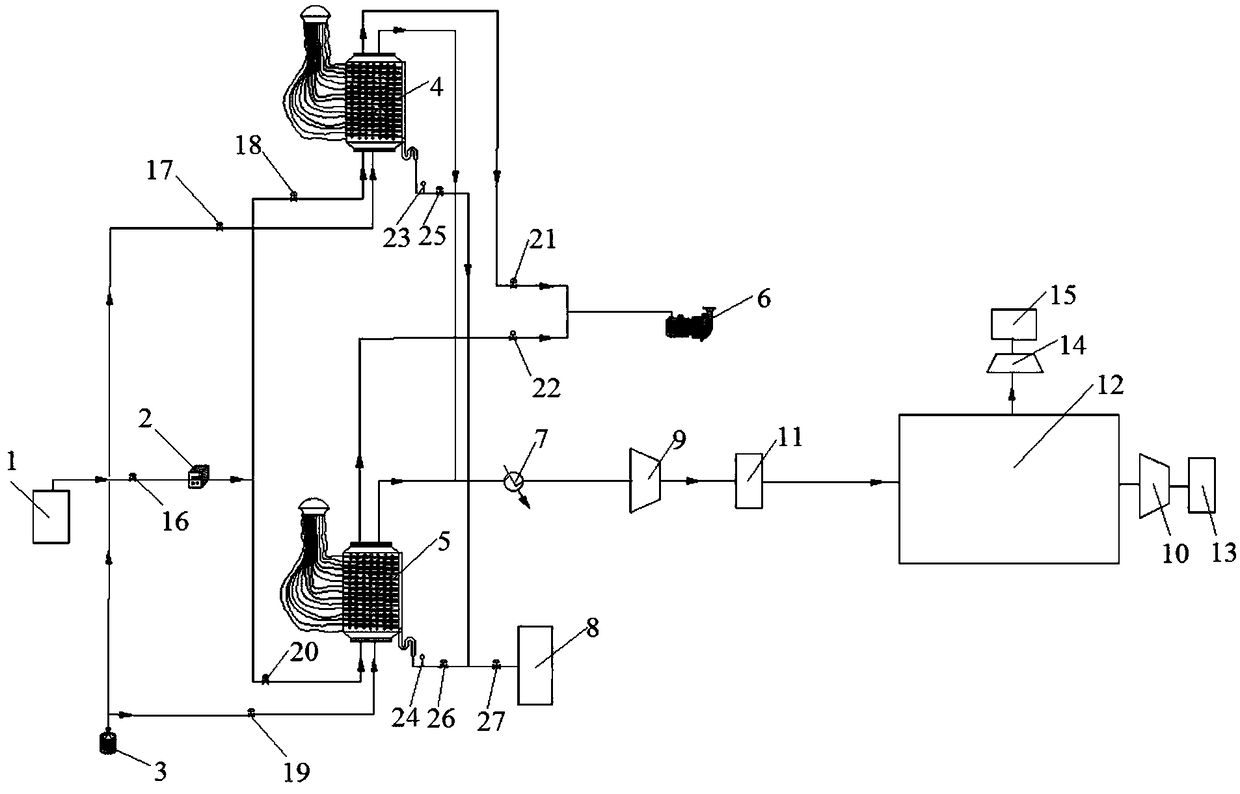

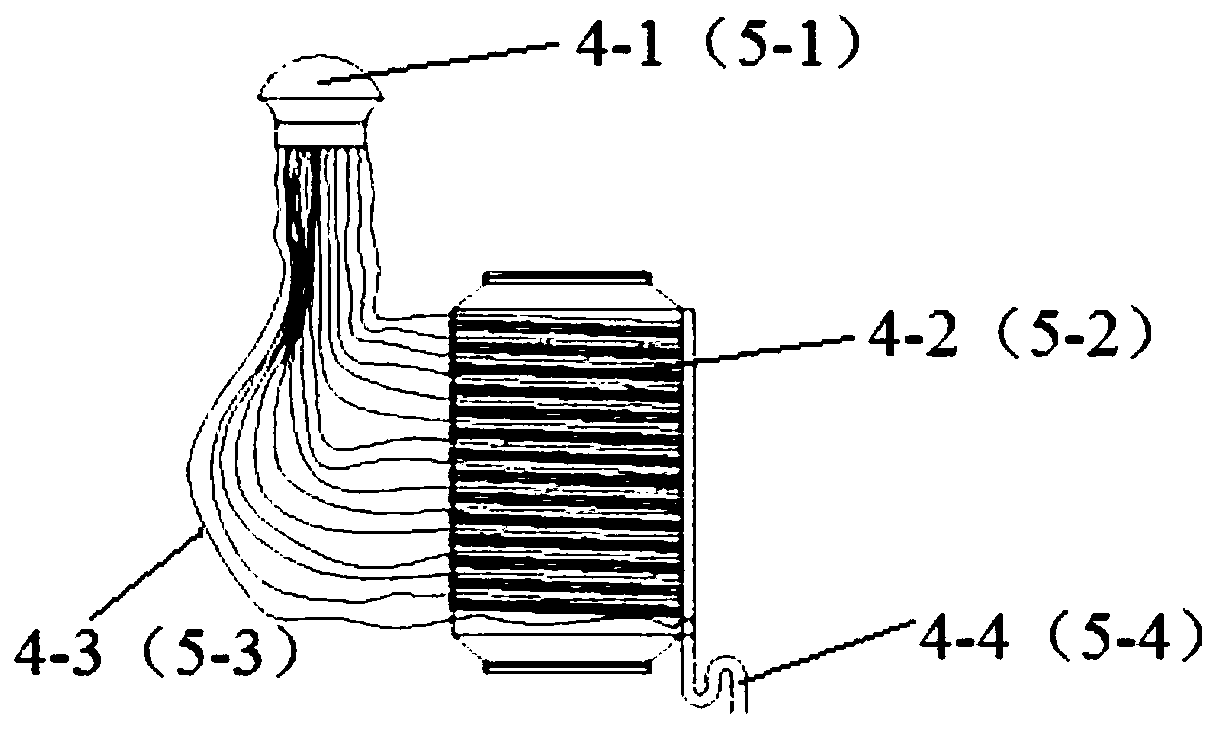

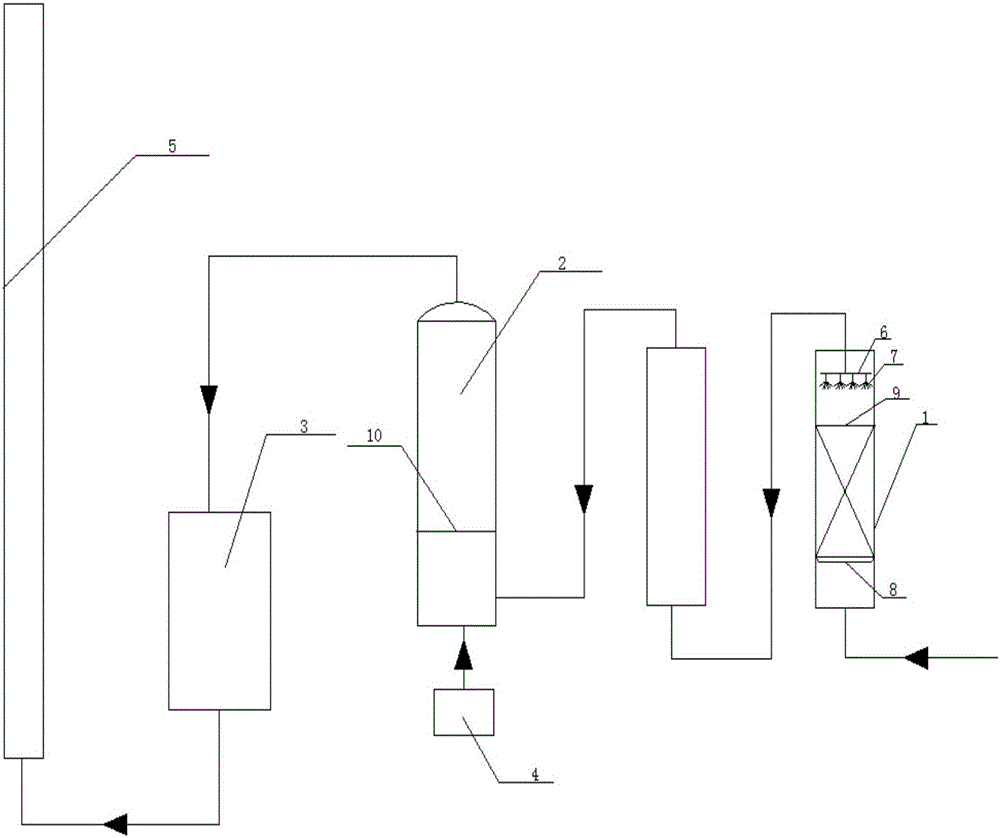

Catalytic purification and heat exchange system

ActiveCN103657402AAvoid contactAchieve reuseDispersed particle separationRegenerative heat exchangersHeat carrierFlue gas

The invention discloses a catalytic purification and heat exchange system. The catalytic purification and heat exchange system comprises a shell, a heat exchanger main body, a separation element, a heat carrier, a flue gas channel and an air channel, wherein a cavity is defined by the shell; the heat exchanger main body is arranged in the cavity and can rotate around the central axis of the heat exchanger main body; the separation element is arranged in the heat exchanger main body along the central axis, and the heat exchanger main body is separated into a first containing part and a second containing part, which are opposite to each other; the heat carrier contains catalysts which are contained in the first containing part and the second containing part, respectively; the flue gas channel is communicated with one of the first containing part and the second containing part, and the air channel is communicated with the other one of the first containing part and the second containing part so as to enable air and the heat carrier contained in the containing parts to exchange heat. According to the catalytic purification and heat exchange system provided by the invention, harmful gases can be removed through continuous catalysis, or waste heat can be recycled in the denitrification process.

Owner:SHENWU TECH GRP CO LTD

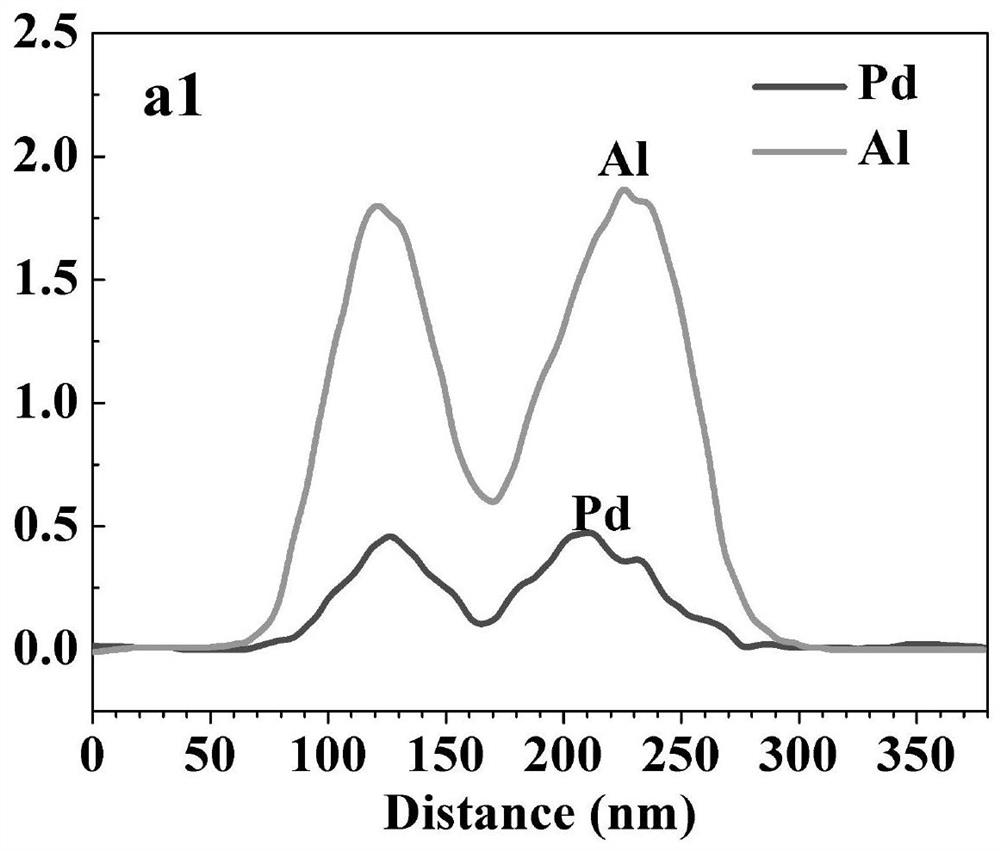

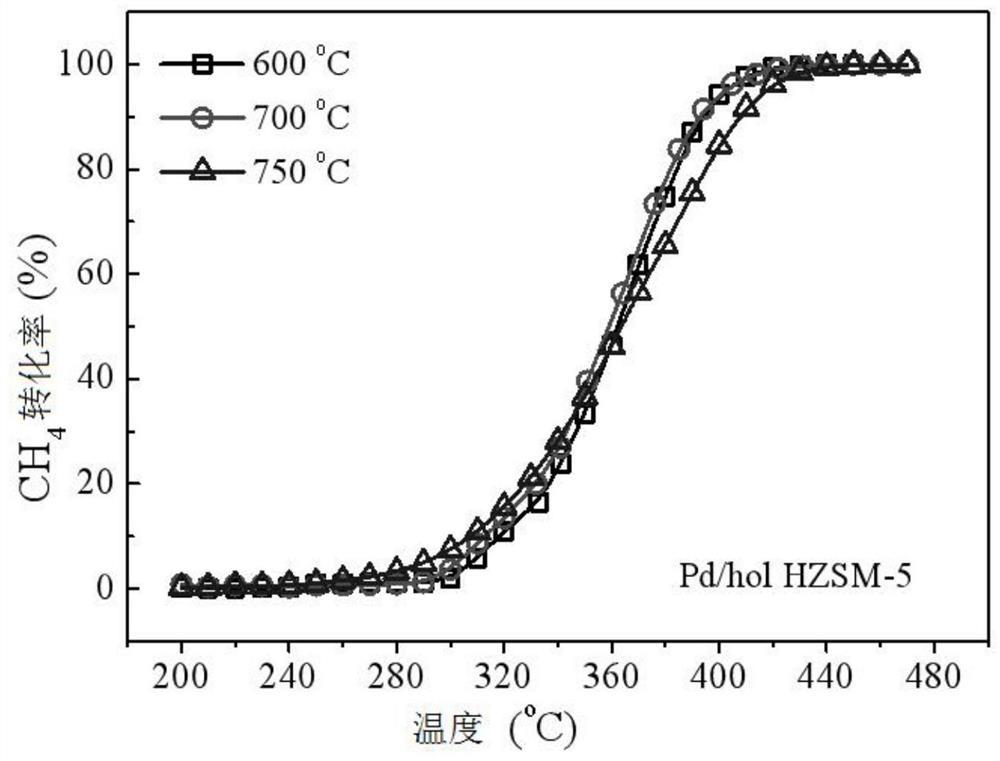

Molecular sieve packaged noble metal catalyst as well as preparation method and application thereof

PendingCN113559916AAvoid reunionEasy accessMolecular sieve catalystsMolecular sieve catalystMolecular sievePtru catalyst

The invention provides a molecular sieve packaged noble metal catalyst as well as a preparation method and application thereof, and belongs to the technical field of catalysts. In the presence of polyvinyl alcohol, precious metal is reduced into precious metal sol under the reduction action of NaBH4, so that agglomeration of precious metal particles can be avoided; a molecular sieve and the precious metal sol dispersion liquid are mixed, the polyvinyl alcohol is removed after first roasting, and the precious metal is loaded on the surface of the molecular sieve. In the invention, the organic amine in a template agent and the noble metal on the surface of the molecular sieve form an organic ligand, the molecular sieve is subjected to secondary crystallization in the heating crystallization process, and the noble metal is brought into the pore channel of the molecular sieve; meanwhile, the molecular sieve is promoted to form a larger cavity in the heating crystallization process, so that entering and diffusion of reactants and products are facilitated. The preparation method provided by the invention is simple to operate and low in difficulty, and does not generate crystal transformation reaction, so that the catalytic performance of the catalyst is ensured, and the obtained molecular sieve packaged noble metal catalyst has good catalytic performance.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

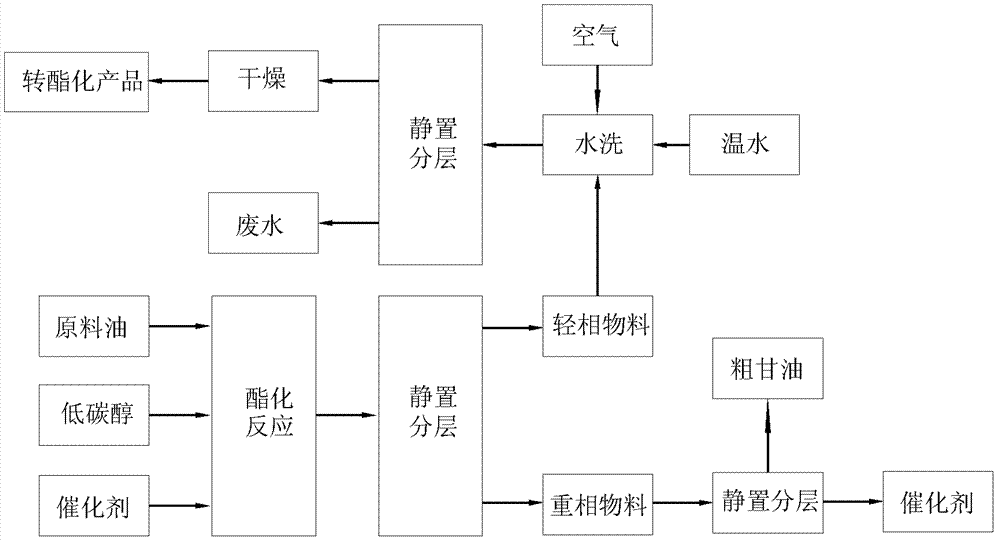

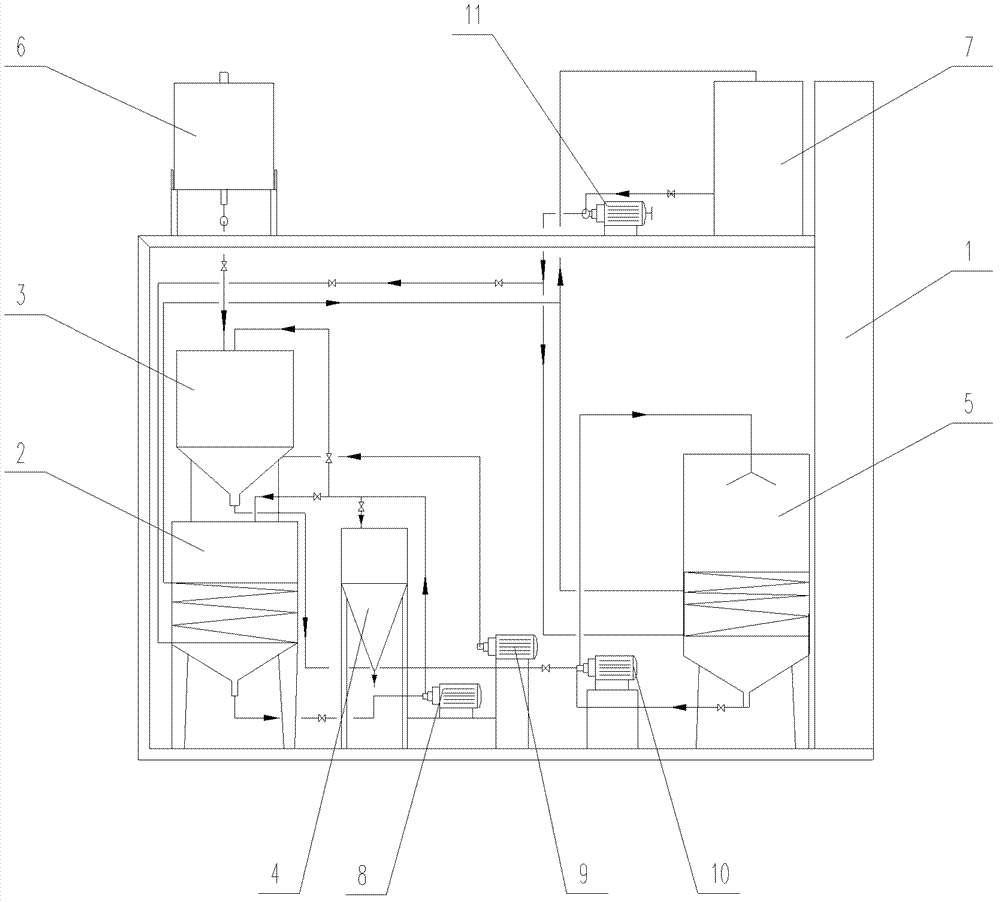

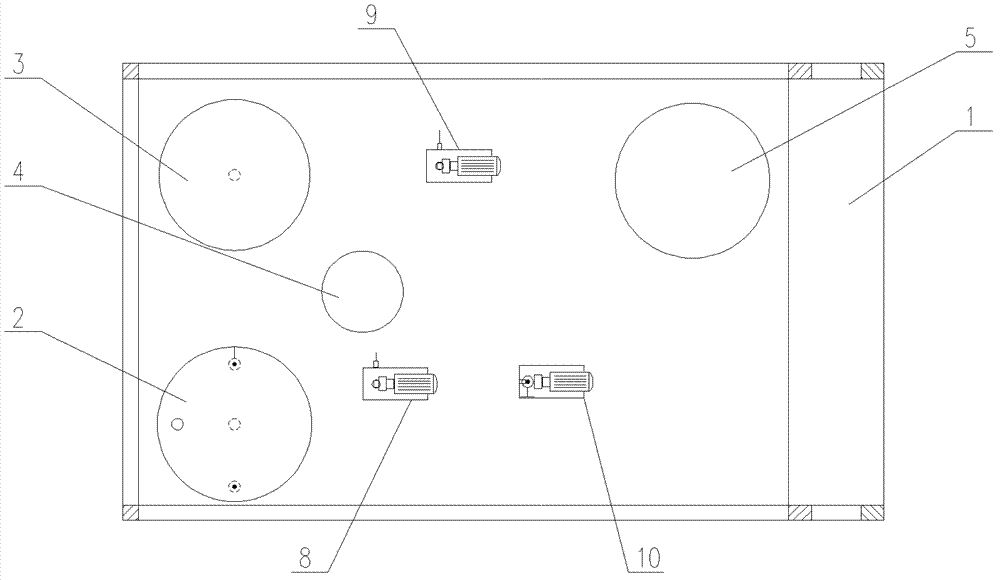

Production device and production method for distribution type plant oil transesterification

InactiveCN102492560BEasy to recycleShort process routeFatty acid esterificationFatty-oils/fats refiningHeat conductingWarm water

The invention discloses a production device and a production method for distribution type plant oil transesterification. The production device comprises an equipment frame, a reaction kettle, a washing tank, a catalyst recovering tank, a drier, a warm water storage tank, a heat conducting oil heating tank, a reaction circulating pump, an air pump, a material pump and a heat conducting oil pump. The production method comprises the following steps of: heating and stirring a mixture of plant fat raw material oil, low-carbon alcohol and a pyridyl trifluoromethanesulfonate ion liquid catalyst to react for 3-5 hours; standing so that reaction materials are divided into a light phase and a heavy phase, and separating the light phase from the heavy phase; standing the heavy-phase material and naturally cooling, so that the catalyst is precipitated to the bottom, and the rest is crude glycerol containing alcohol; adding warm water to the light-phase material for washing, and then standing so that the light phase and the heavy phase are formed again; and pumping the light-phase material into the drier for drying, so as to obtain the plant oil. The production method disclosed by the invention can achieve homogeneous catalysis and different-phase separation through process integration, and the yield of the plant oil is improved; and the production device disclosed by the invention is handy and simple, and is convenient for real-time processing of a dispersed raw material.

Owner:SOUTH CHINA UNIV OF TECH

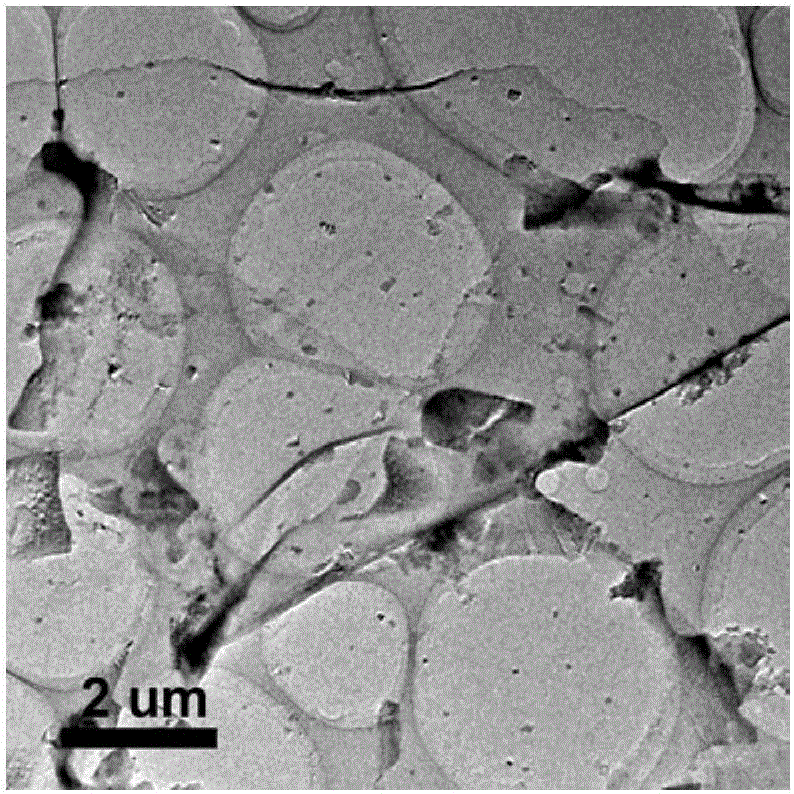

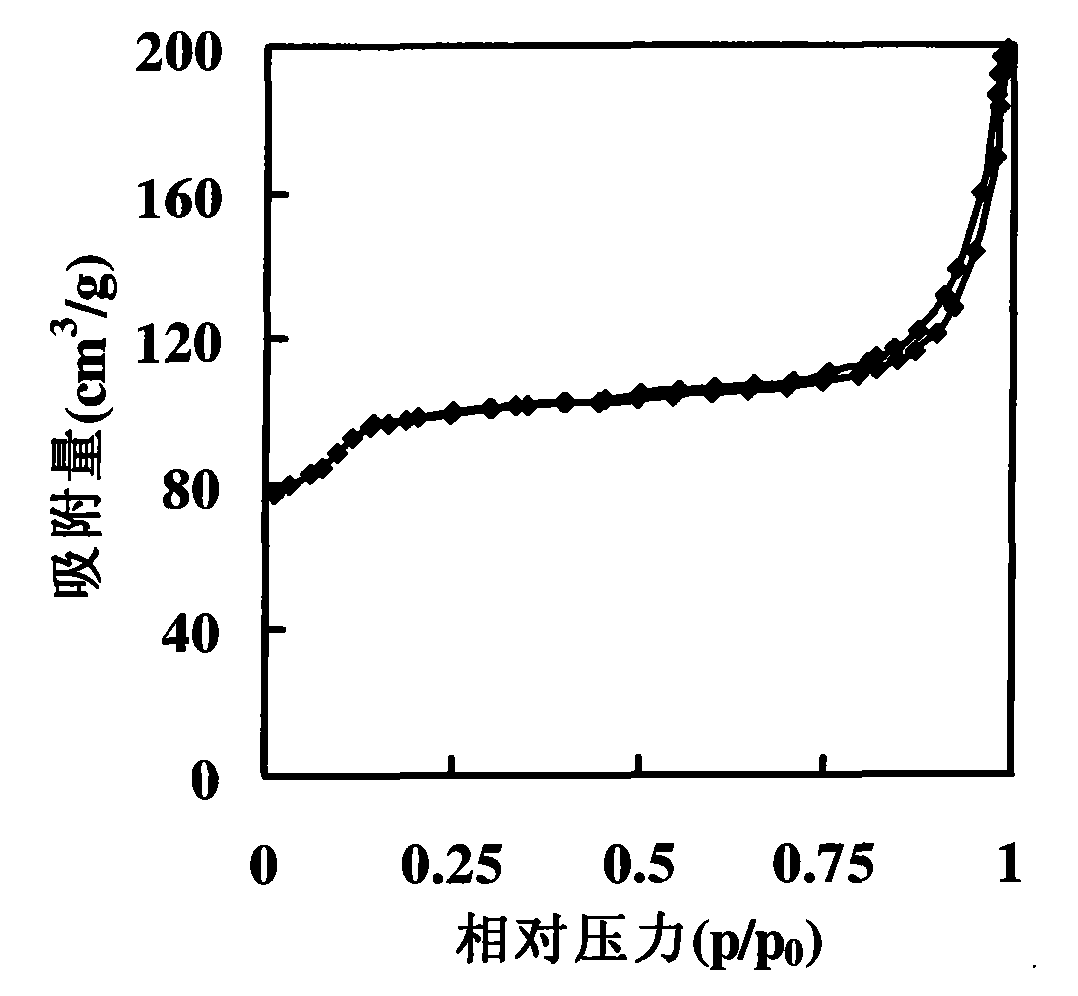

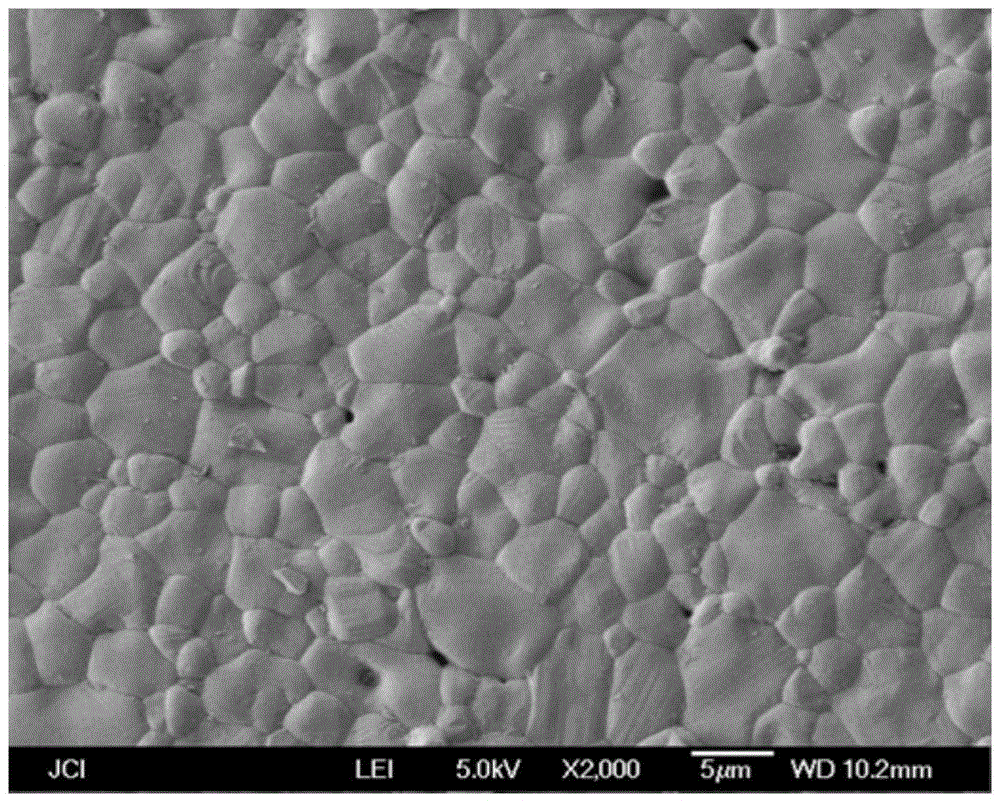

Granular titanium-silicon molecular sieve catalyst and preparation method thereof

InactiveCN101596463ALarge particle sizeHigh strengthOrganic chemistryMolecular sieve catalystsMolecular sievePropylene glycol

The invention discloses a granular titanium-silicon molecular sieve catalyst and a preparation method thereof. The granular titanium-silicon molecular sieve catalyst is prepared by using the following method: hydrochloric acid is added into water, the mixture is stirred and added with a glycol-propylene glycol-glycol copolymer, ethyl orthosilicate is dropped after the glycol-propylene glycol-glycol copolymer is dissolved, titanium-silicon molecular sieve fine powder is added into the mixture after the ethyl orthosilicate is completely hydrolyzed to be evenly mixed into a slurry state substance; and the slurry state substance is calcined for 5 to 30 hours in the air at 500 to 950 DEG C to obtain the granular titanium-silicon molecular sieve catalyst which has a middle hole, is covered with a silica gel layer and has a particle diameter of 5mu m to 75mu m. The granular titanium-silicon molecular sieve catalyst prepared by the invention has large particle diameter and high strength, is not easy to pulverize, is easy to separate after catalyzed reaction is completed, keeps the catalysis property of the titanium-silicon molecular sieve fine powder and is used for preparing propylene oxide by catalyzing propylene ring oxidation, and the oxydol conversion rate and the propylene oxide selectivity of the granular titanium-silicon molecular sieve catalyst approach to those of titanium-silicon molecular sieve fine powder.

Owner:TIANJIN UNIV

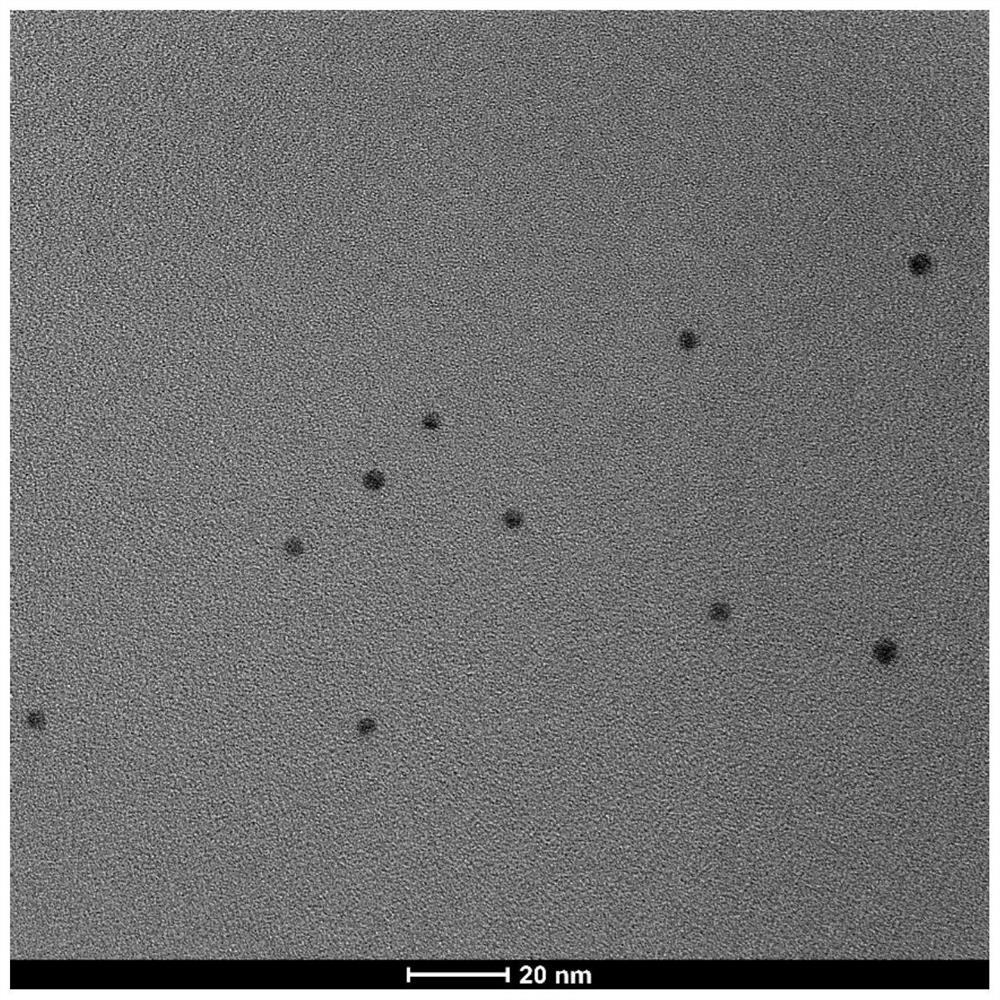

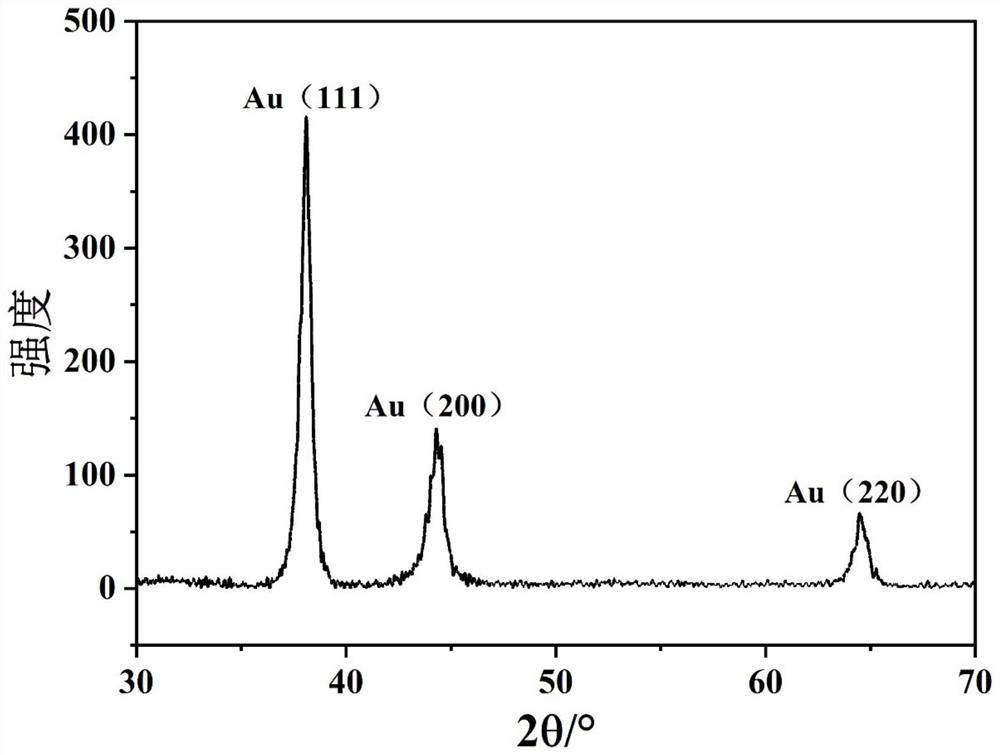

Flexible enzyme-free glucose sensor electrode and preparation method thereof

PendingCN113340961AImprove Sensing PerformanceImprove catalytic performanceMaterial electrochemical variablesGlucose sensorsNanowire

The invention belongs to the field of electrochemical sensors, and discloses a flexible enzyme-free glucose sensor electrode and a preparation method thereof. The flexible enzyme-free glucose sensor electrode comprises an Ecoflex flexible substrate, a plurality of Au nanowires are arranged on the Ecoflex flexible substrate, and Au nanoparticles are arranged at the end, away from the Ecoflex flexible substrate, of each Au nanowire. The method comprises the following steps: pasting a PET film on a glass plate to obtain a supporting layer, and coating Ecoflex glue on the surface of the supporting layer to form an Ecoflex flexible substrate; carrying out hydroxyl modification and amination treatment on the Ecoflex flexible substrate, soaking the Ecoflex flexible substrate in an Au nano seed solution for Au nano particle deposition to obtain an Ecoflex flexible substrate deposited with Au nano particles, and stripping the Ecoflex flexible substrate from the supporting layer; and placing the Ecoflex flexible substrate on which the Au nano-particles are deposited in an Au nano-wire growth solution, and carrying out Au nano-wire growth. The Au nanowires avoid warping and layering fracture of the electrode through excellent conductivity and ductility, the Au nanoparticles improve the sensing performance of the electrode through excellent catalytic performance, the preparation process is simple and safe, and batch preparation can be achieved.

Owner:XI AN JIAOTONG UNIV

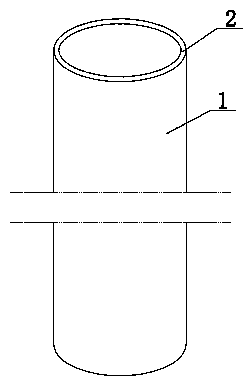

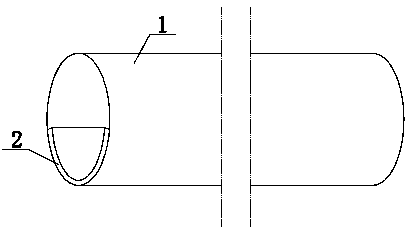

Capillary micro-fluidic reactor with controllable catalytic material fixing area and preparation method thereof

ActiveCN111346575AHigh load rateEasy to fixChemical/physical/physico-chemical microreactorsCapillary TubingEngineering

The invention discloses a capillary micro-fluidic reactor with a controllable catalytic material fixing area and a preparation method thereof, wherein the preparation method comprises the following steps: (1) coating a layer of PDMS liquid in a designated tube wall area in a capillary tube, wherein the capillary tube is made of an airtight and transparent material; (2) introducing a powdery catalytic material to be fixed into the capillary tube, adhering part of the catalytic material to a PDMS liquid coating layer, and enabling the surplus catalytic material to flow out of the capillary tube;and (3) curing the PDMS liquid and fixing the catalytic material adhered to the PDMS layer. According to the capillary micro-fluidic reactor with the controllable catalytic material fixing area, thecoating area of PDMS on the inner wall of the capillary tube can be controlled by adjusting the coating condition, and the capillary wall has no air permeability, so that the concentration change of reaction liquid caused by air permeability of a PDMS layer is avoided, and the reaction is stable.

Owner:QILU UNIV OF TECH

Preparation method of graphene-based iridium copper nano composite material

InactiveCN111969218AEvenly dispersedReduce reunionMaterial nanotechnologyCell electrodesSpray driedNanocomposite

The invention discloses a preparation method of a graphene-based iridium-copper nano composite material. The method comprises the following steps: 1, dissolving iridium salt and copper salt in deionized water to obtain a mixed solution; 2, adding graphene oxide powder into the mixed solution, and carrying out ultrasonic dispersion to obtain a turbid liquid; 3, atomizing and drying the turbid liquid to obtain graphene oxide-loaded mixed metal salt powder; and 4, carrying out synchronous thermal reduction treatment on the graphene oxide-loaded mixed metal salt powder to obtain the graphene-basediridium-copper nano composite material. According to the invention, a method of combining spray drying with synchronous thermal reduction is adopted, nano particles of iridium and copper mixed salt are uniformly loaded on the surface of the graphene oxide, the graphene-based iridium-copper nano composite material prepared by adopting the method has the advantages that agglomeration of nano particles of iridium and copper mixed salt is reduced, the number of active sites on the surface of the graphene-based iridium-copper nano composite material is increased, the catalytic performance of the graphene-based iridium-copper nano composite material is improved, the service life of the graphene-based iridium-copper nano composite material is prolonged, and the utilization efficiency of the graphene-based iridium-copper nano composite material is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Carbon dioxide capture-photocatalysis coupling reaction apparatus and application method thereof

ActiveCN108744966AIncrease speedReduce wasteGas treatmentDispersed particle separationWater vaporEngineering

The invention discloses a carbon dioxide capture-photocatalysis coupling reaction apparatus. The carbon dioxide capture-photocatalysis coupling reaction apparatus comprises two reactors having a samestructure, a gas storage tank for providing exhaust gas for two reactors, and a gas separator connected with two reactors, several photocatalyst plates are uniformly distributed in two reactors, optical fibers are distributed between adjacent photocatalyst plates, the optical fibers are stretched from the reactors and connected with a light source introduction device, the photocatalyst plates arethe active carbon plates with the surfaces coated with a photocatalyst, gas flow meters are arranged between the reactors and the gas storage tank, the reactor is connected with a water vapor generator, a vacuum pump and a cooler, a first compressor and a first storage tank are arranged between the cooler and the gas separator, and a second compressor and a second storage tank are arranged at an outlet of the gas separator. The invention also discloses an application method of the apparatus. The photocatalyst plate in the apparatus absorbs the CO2 and performs in-situ photocatalysis, the photocatalysis rate is increased, and the application method of the apparatus is simple and easy to control.

Owner:XIAN UNIV OF SCI & TECH

Granular titanium-silicon molecular sieve catalyst and preparation method thereof

InactiveCN101596463BHigh strengthNot easy to crushOrganic chemistryMolecular sieve catalystsSlurrySilica gel

The invention discloses a granular titanium-silicon molecular sieve catalyst and a preparation method thereof. The granular titanium-silicon molecular sieve catalyst is prepared by using the following method: hydrochloric acid is added into water, the mixture is stirred and added with a glycol-propylene glycol-glycol copolymer, ethyl orthosilicate is dropped after the glycol-propylene glycol-glycol copolymer is dissolved, titanium-silicon molecular sieve fine powder is added into the mixture after the ethyl orthosilicate is completely hydrolyzed to be evenly mixed into a slurry state substance; and the slurry state substance is calcined for 5 to 30 hours in the air at 500 to 950 DEG C to obtain the granular titanium-silicon molecular sieve catalyst which has a middle hole, is covered witha silica gel layer and has a particle diameter of 5mu m to 75mu m. The granular titanium-silicon molecular sieve catalyst prepared by the invention has large particle diameter and high strength, is not easy to pulverize, is easy to separate after catalyzed reaction is completed, keeps the catalysis property of the titanium-silicon molecular sieve fine powder and is used for preparing propylene oxide by catalyzing propylene ring oxidation, and the oxydol conversion rate and the propylene oxide selectivity of the granular titanium-silicon molecular sieve catalyst approach to those of titanium-silicon molecular sieve fine powder.

Owner:TIANJIN UNIV

Catalyst for synthesizing methyl glycolate by formaldehyde and methyl formate and preparation method and application thereof

ActiveCN102962065AMaintain catalytic performanceImprove catalytic performanceOrganic compound preparationCarboxylic acid esters preparationPtru catalystSolid acid

A catalyst for synthesizing methyl glycolate by formaldehyde and methyl formate uses an aluminum oxide and silicon oxide composite solid acid as an active component, and a VIII group non-noble metal oxide as an active coagent, wherein aluminum oxide accounts for 40-70wt%, silicon oxide accounts for 20-30wt% and the VIII group non-noble metal oxide accounts for 10-30wt%. The catalyst provided by the invention is suitable for a fixed bed reactor and has the advantages of high activity and high selectivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

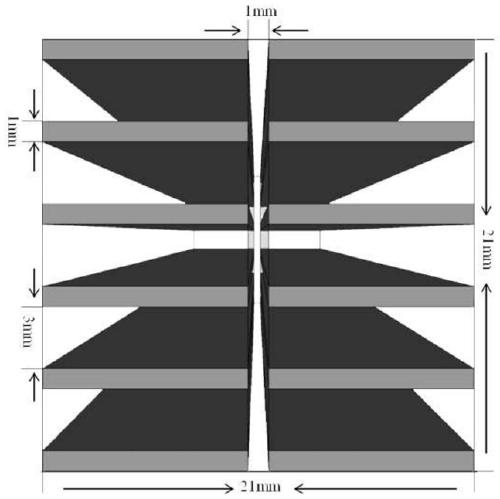

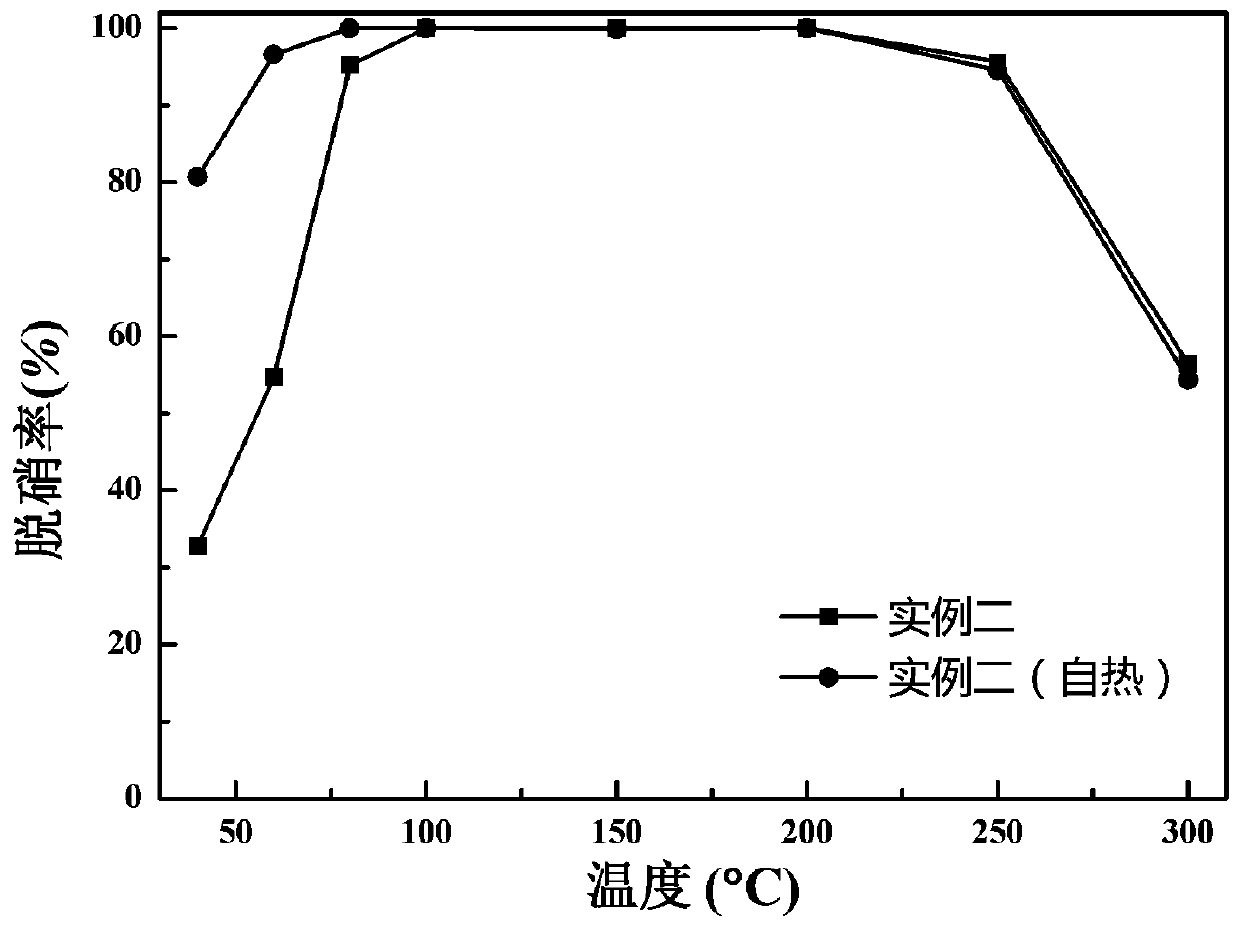

Self-heating coating type low-temperature denitration catalyst and preparation method thereof

PendingCN111135821ALow temperature SCR performance is goodExcellent ultra-low temperature catalytic performanceGas treatmentHeterogenous catalyst chemical elementsAir atmospherePtru catalyst

The invention discloses a self-heating coating type low-temperature denitration catalyst, and relates to the field of denitration catalysts. The self-heating coating type low-temperature denitration catalyst comprises a matrix and a catalyst coating, wherein the catalyst coating is arranged above the matrix, and the catalyst disclosed by the invention can be initially used as a normal low-temperature denitration catalyst, and can be subjected to electrifying self-heating online regeneration after ammonium bisulfate is inactivated. The invention further discloses a preparation method. Accordingto the preparation method disclosed by the invention, Al2O3 is deposited on the surface of an electrothermal metal alloy by utilizing an electro-deposition technology to form a transition layer film,the upper surface of the Al2O3 transition layer is coated with a catalyst slurry coating, and then roasting is carried out in an air atmosphere, so that the catalyst coating slurry is sintered on thesurface of the Al2O3 transition layer.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

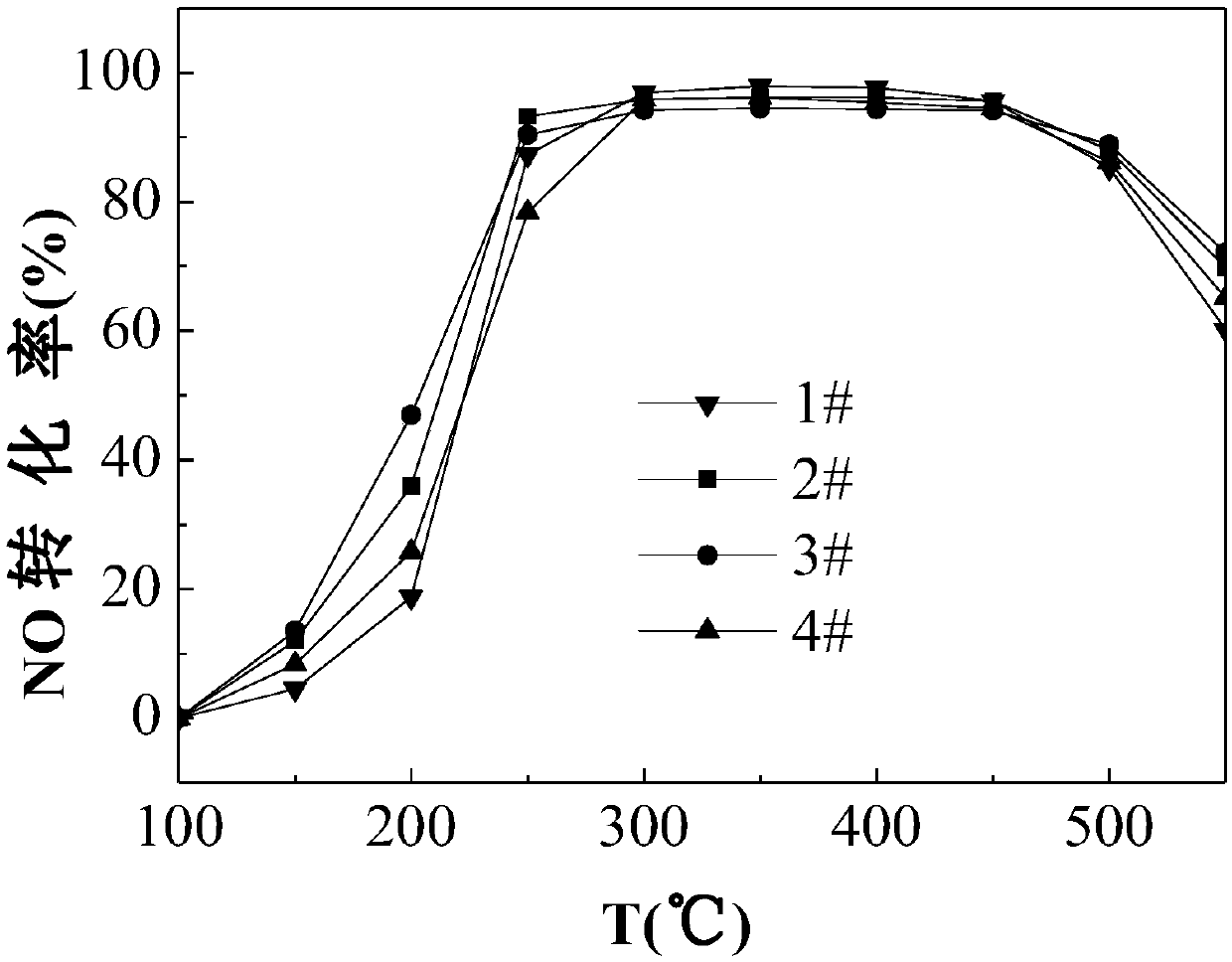

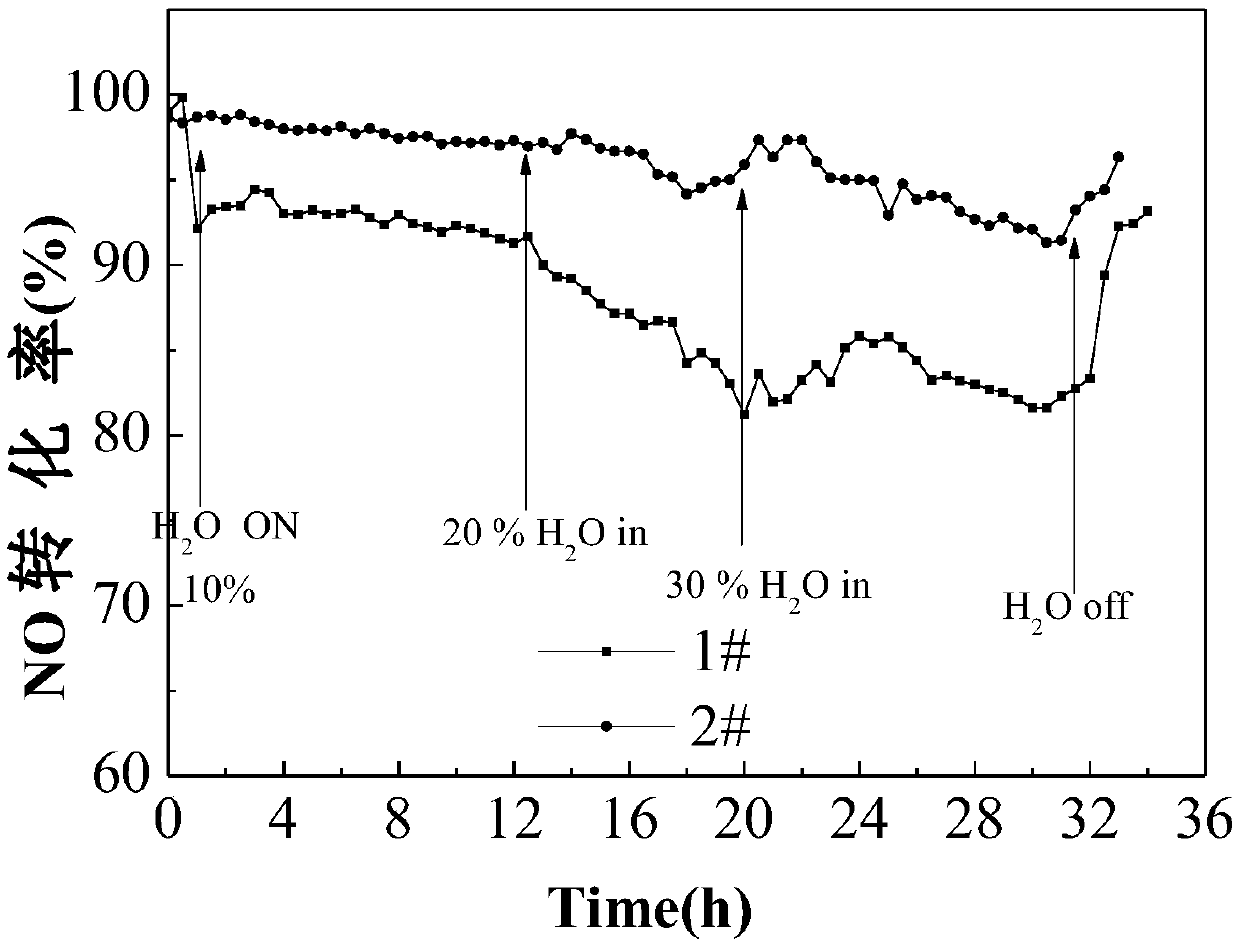

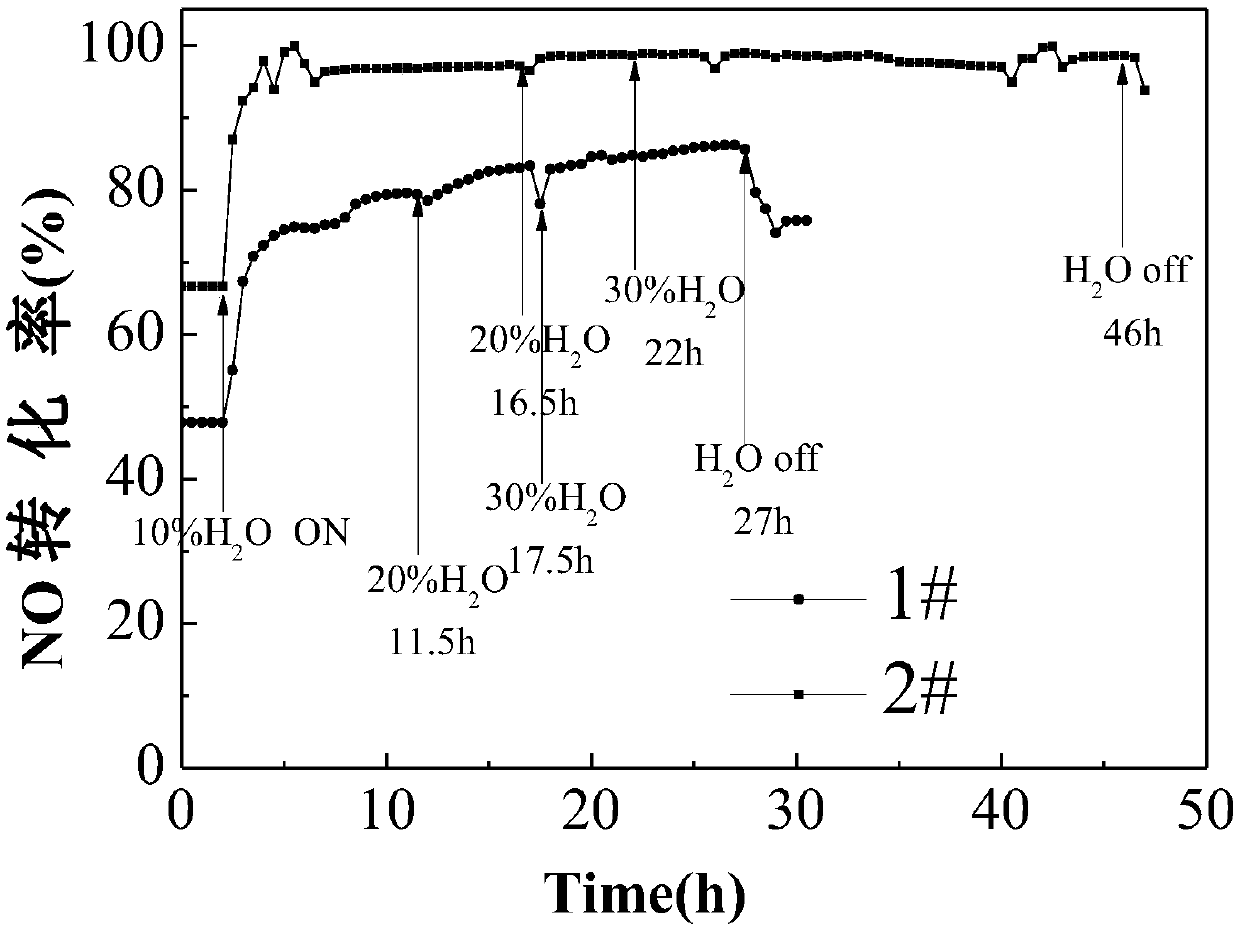

SCR catalyst applicable to medium-and-high-temperature and high-humidity flue gas conditions and preparation method thereof

InactiveCN109529812ARaw materials are cheap and easy to getEasy to makeGas treatmentHeterogenous catalyst chemical elementsHigh humidityFlue gas

The invention relates to an SCR catalyst applicable to medium-and-high-temperature and high-humidity flue gas conditions and a preparation method thereof, belonging to the technical field of catalystpreparation. The preparation method comprises the following concrete steps: placing a cerium precursor, a molybdenum precursor and a carrier namely TiO2 with calculated amounts into a ball mill tank,carrying out ball milling for 1 to 6 h, and calcining a uniformly-mixed powder in a muffle furnace by two steps so as to obtain a MoO3-CeO2 / TiO2 composite oxide catalyst, wherein the content of CeO2 accounts for 5 to 40 wt% of the total amount of a cerium-titanium composite oxide, and the content of MoO3 accounts for 0 to 10 wt% of the total amount of a molybdenum-cerium-titanium composite oxide.The SCR catalyst provided by the invention maintains an NO conversion rate to be 85% or above in a medium and high temperature range (250 to 500 DEG C) under a high-humidity flue gas condition. The preparation method provided by the invention has the advantages of simple preparation process, easily-controllable conditions, low raw material price, and potential application value in the field of denitration.

Owner:BEIJING UNIV OF TECH

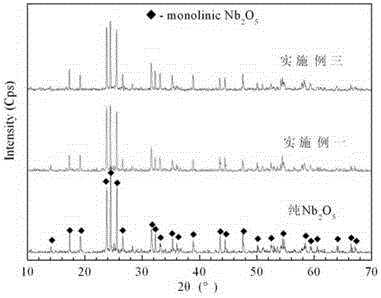

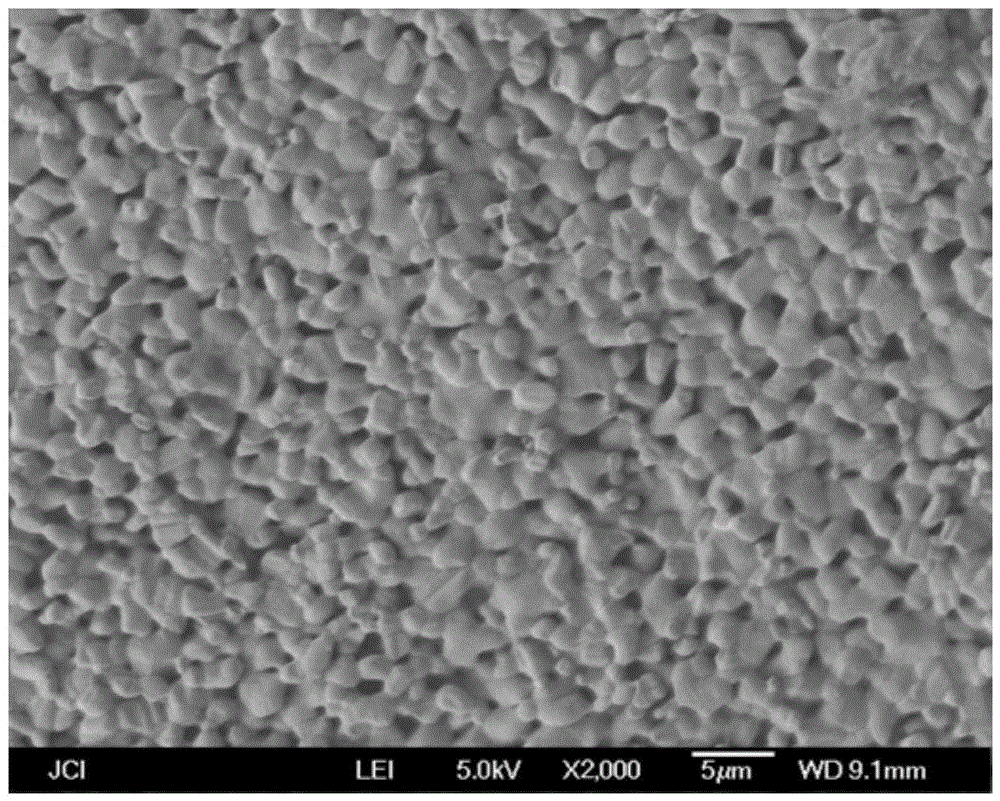

A kind of high porosity and high permeability nb2o5 ceramic membrane and preparation method thereof

InactiveCN104529448BHigh porosityImprove permeabilitySemi-permeable membranesPorositySeparation technology

The invention discloses a high-porosity high-permeability Nb2O5 ceramic membrane which is represented by the following general formula: Nb(2-2x-2y)Ta2xTiyO(5-delta), wherein x and y represents mole fractions, 0.1<=x<=0.3, and 0.02<=y<=0.07. Besides, the invention also discloses a preparation method of the high-porosity high-permeability Nb2O5 ceramic membrane. The Nb2O5 ceramic membrane disclosed by the invention simultaneously has high porosity, narrow pore size distribution range, high permeability, high mechanical strength and other performance, and effectively solves the problems that existing ceramic membranes made of aluminum oxide, cordierite, mullite and the like have performance defects, catalyst incompatibility and low catalytic conversion efficiency exist in waste water and waste gas purification treatment and so on, thus bringing major technical breakthrough to the ceramic membrane field, and being beneficial to promote application and development of fine filtration and separation technology in the fields of water treatment, food, medicine, chemical engineering and the like.

Owner:JINGDEZHEN CERAMIC UNIV

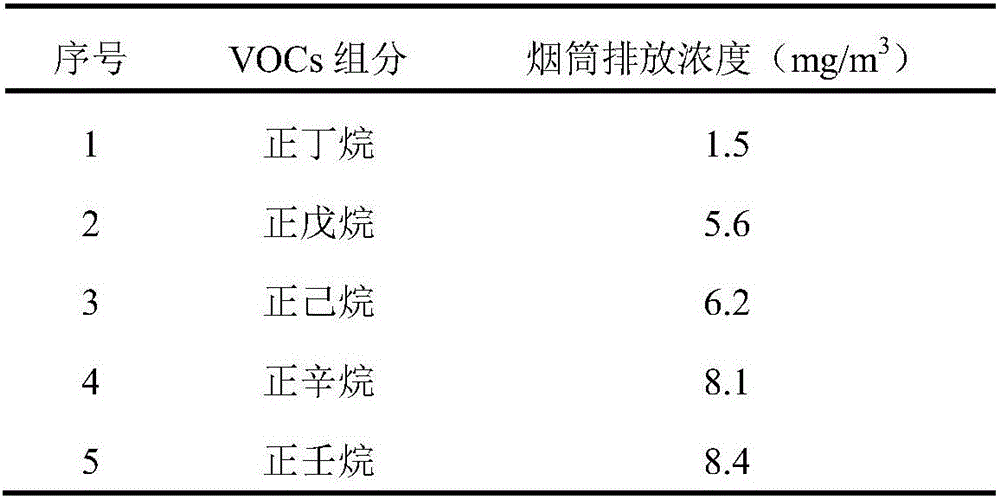

Nanometer rare earth catalyzed ozonation method for normal temperature digestion of volatile organic matters

InactiveCN106166442AIncrease the areaPore structure highGas treatmentUsing liquid separation agentRare-earth elementCatalytic oxidation

The invention discloses a nanometer rare earth catalyzed ozonation method for normal temperature digestion of volatile organic matters. The nanometer rare earth catalyzed ozonation method comprises: (1) loading a nanometer rare earth element coating adopted as an auxiliary agent on a catalyst carrier, coating nanometer spinel adopted as the active component of the catalyst on the obtained carrier, and finally calcining the catalyst carrier loading the auxiliary agent and the active component to form a large number of micro-pores on the surface and in the internal of the catalyst carrier so as to obtain a target catalyst with pores; and (2) fixing the prepared target catalyst on the catalytic bed layer of a catalytic oxidation tower, starting an ozone generator, introducing volatile organic matters into the catalytic oxidation tower, and carrying out deep oxidation on the volatile organic matters into non-toxic and odorless substances at a room temperature of -10-40 DEG C, wherein the volatile organic matters are pre-treated and acid gas, alkali gas and other dust and particles are removed from the volatile organic matters before the volatile organic matters are introduced into the catalytic oxidation tower. According to the present invention, with the method, the VOCs can be completely oxidized at the room temperature to produce carbon dioxide and water, such that the operation is safe, and the energy consumption is low.

Owner:TIANJIN UNIV

Fatty alcohol tertiary amine load type catalyst and preparation method and application thereof

InactiveCN109126801ALow technical requirementsGuaranteed catalytic performanceOrganic compound preparationHeterogenous catalyst chemical elementsIonChemistry

The invention provides a preparation method of a fatty alcohol tertiary amine load type catalyst. The preparation method of the fatty alcohol tertiary amine load type catalyst comprises the followingspecific steps: premixing the following metal oxides and a carrier in parts by mass: 20-40 parts of copper oxide, 5-10 parts of nickel oxide, 0-10 parts of zinc oxide, 0-5 parts of magnesium oxide and35-75 parts of the carrier in a ball-miller, successively adding deionized water and a dispersing agent and dispersing and grinding for 1-4 hours, after filtering and drying, roasting for 2-4 hours at the temperature of 300-400 DEG C, and after grinding and hydrogen reduction, catalyzing fatty alcohol under the condition of normal pressure to react with dimethylamine so as to prepare tertiary aliphatic amine. A preparation process of the catalyst is simple, and is easy to operate, the preparation method is energy-saving and environmentally friendly, and the performance of the catalyst is good.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

Supported carbon-coated bimetallic catalyst and application thereof

PendingCN114308027AGood contact fusionEvenly wrappedOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsCarbon layerAir atmosphere

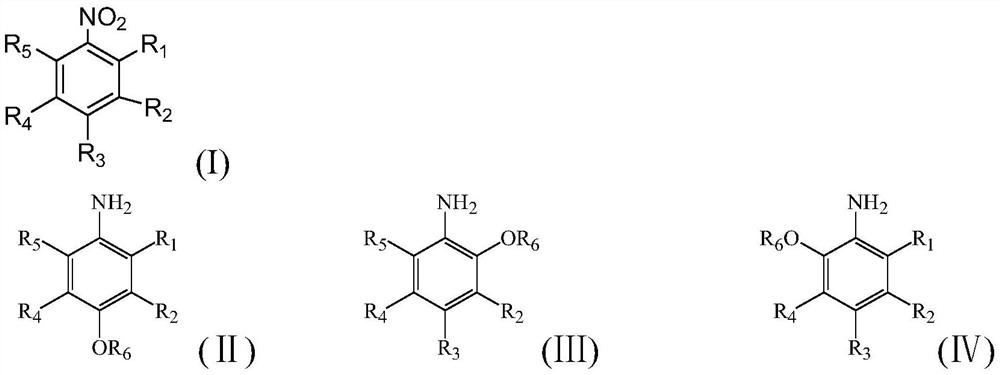

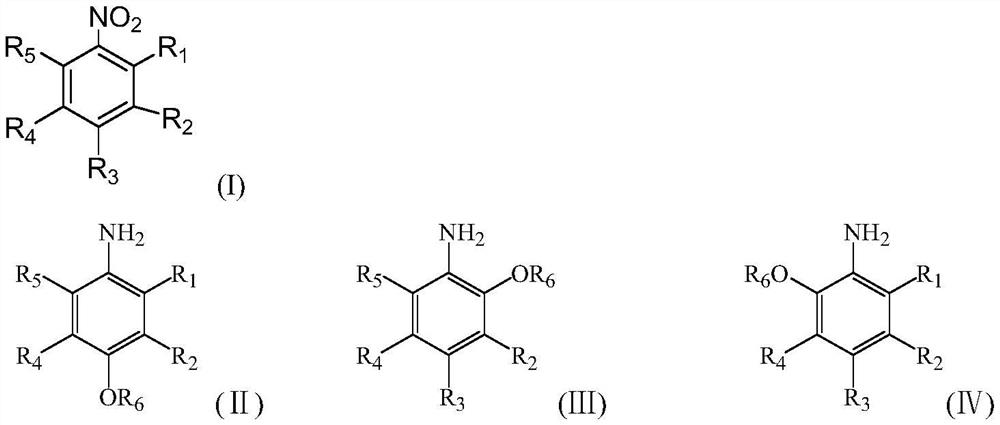

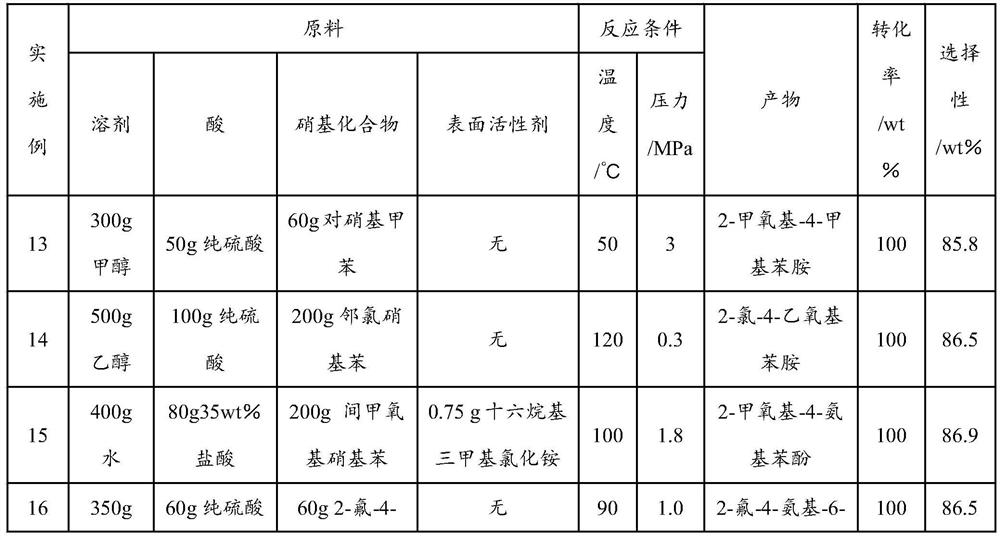

The invention discloses a preparation method of a supported carbon-coated bimetallic catalyst, which comprises the following steps: (1) weighing a supported bimetallic catalyst, uniformly mixing the supported bimetallic catalyst with water, adding an aqueous solution of a soluble saccharide carbon source compound and an aqueous solution of hydroxyethyl cellulose, dipping at room temperature for 0.5-10 hours, and carrying out vacuum drying until moisture is dried to obtain the supported bimetallic catalyst; a dried product is obtained; (2) carrying out high-temperature roasting on the dried product at 400-1000 DEG C in an inert atmosphere, a hydrogen atmosphere or a vacuum state for 2-20 hours to obtain a roasted product; and (3) reducing the temperature to 100-180 DEG C, and treating the roasted product in an air atmosphere for 4-10 hours to prepare the supported carbon-coated bimetallic catalyst. The catalyst prepared by the invention has a complete carbon layer wrapping metal active component with a proper structure and thickness, is used for preparing alkoxy substituted or phenolic hydroxyl substituted aniline compounds by hydrogenation rearrangement of nitrobenzene compounds, and has high stability and high target product selectivity.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com