Patents

Literature

125 results about "No conversion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite catalyst flue gas denitrating under low-temperature condition and method of preparing the same

InactiveCN101254464ALarge specific surface areaImprove thermal stabilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsManganeseCerium

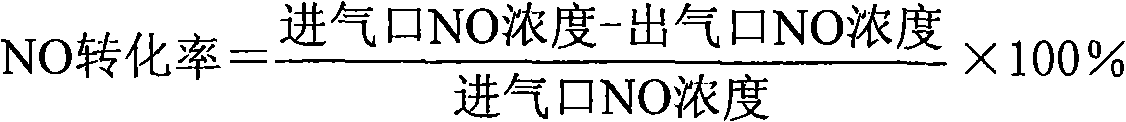

The invention relates to a composite catalyst used for denitrification of flue gases under low-temperature conditions. The catalyst contains a Ti / Zr composite oxide as carrier, an oxide of manganese as catalytically-active component, and at least one oxide of vanadium, chromium, iron, copper, nickel and cerium as auxiliary agent. The Ti / Zr composite oxide is prepared by coprecipitation method and loads the catalytically-active component and the auxiliary agent by immersion method, wherein the mole ratio of Ti / Zr in the composite oxide is controlled in a range from 0.25 to 4, the oxide of manganese accounts for 1-15% of the weight of the Ti / Zr composite oxide, and the auxiliary agent accounts for 1-5% of the weight of the Ti / Zr composite oxide. The catalyst has good catalytic activity at low temperature and high NO conversion rate up to 100% at 100-300 DEG C, and has good prospect in industrial application.

Owner:NANJING UNIV OF TECH

Image Processor, Image Processing Method, And Vehicle Including Image Processor

InactiveUS20090322878A1Less susceptible to camera installation errorWide fieldTelevision system detailsGeometric image transformationVisibilitySupporting system

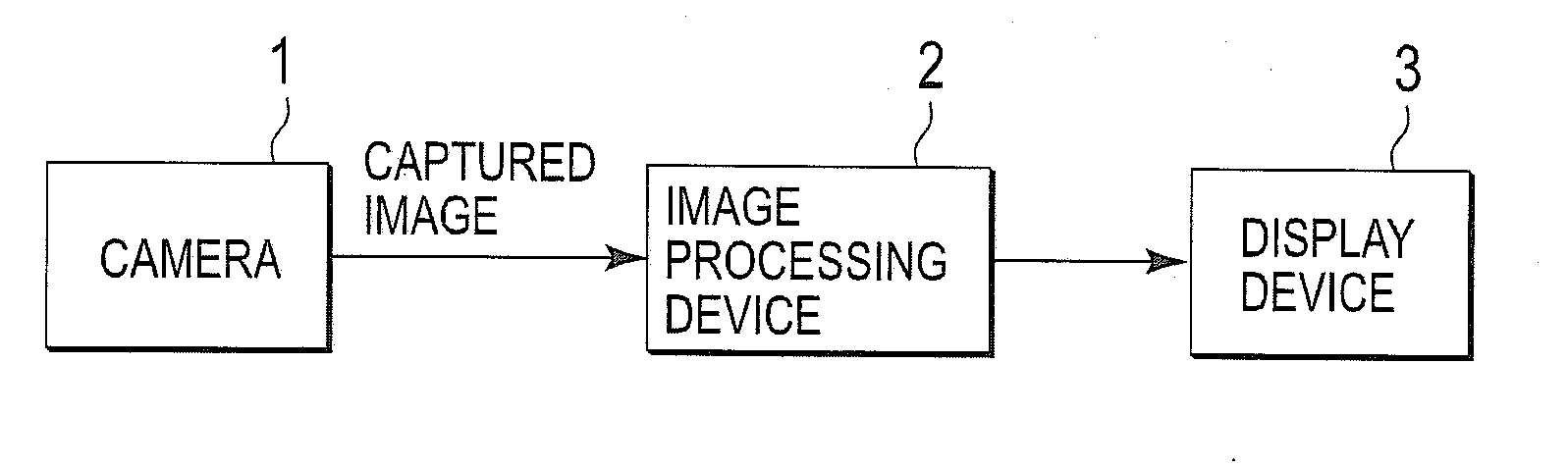

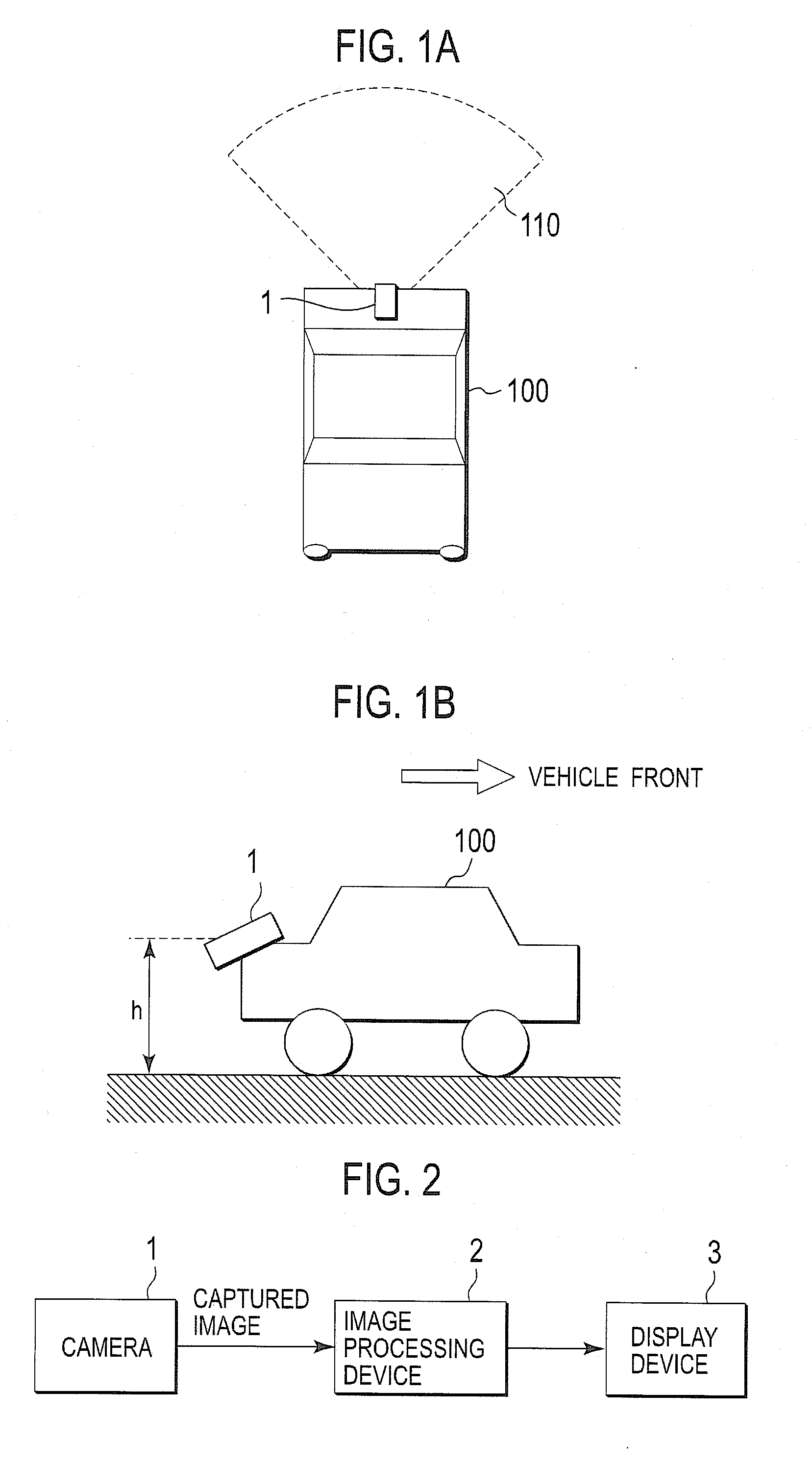

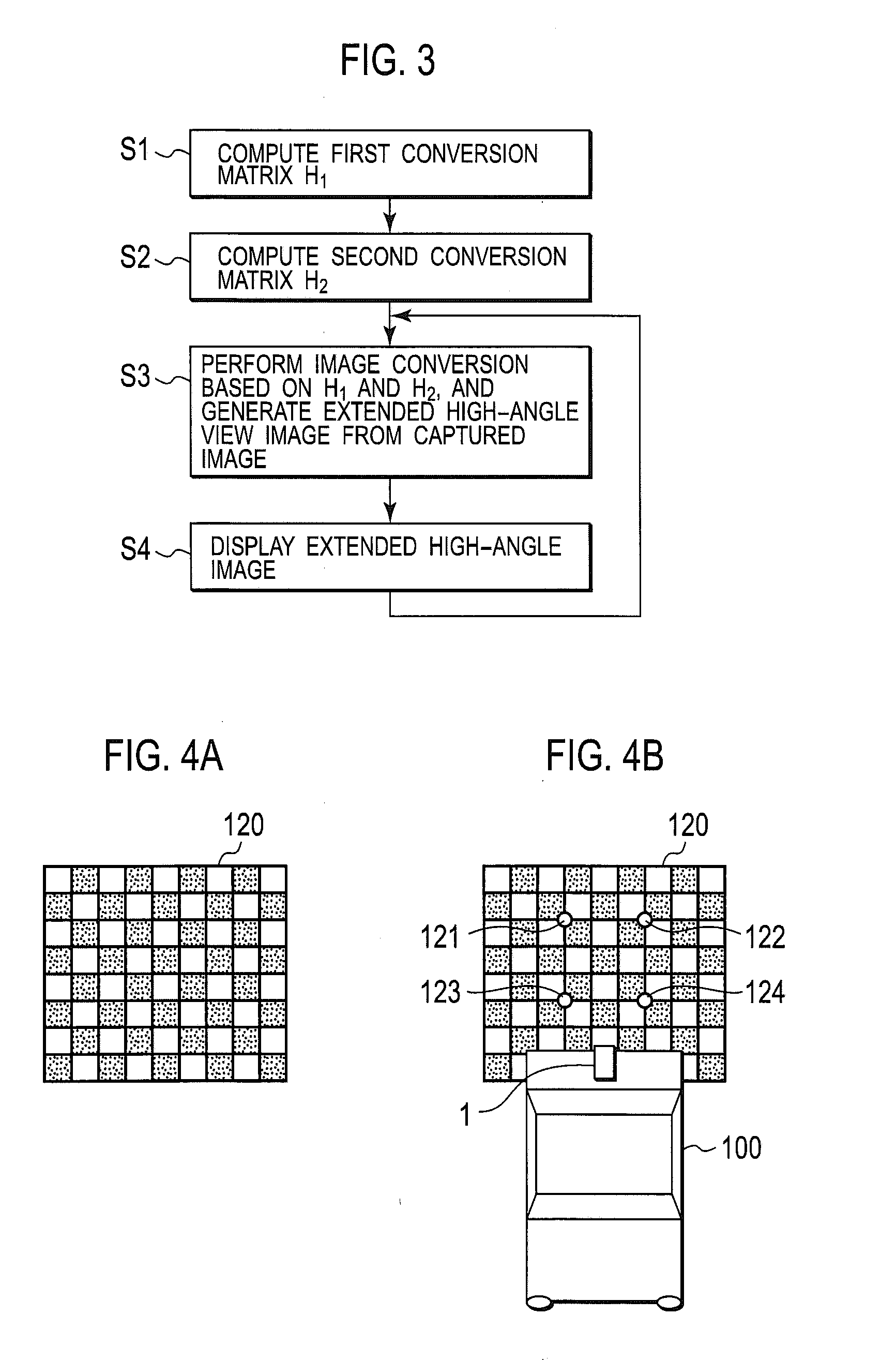

A visibility support system is provided which displays a wide field of view while absorbing camera installation errors. The visibility support system obtains a first conversion matrix H1 for projecting a captured image onto the ground, while a second conversion matrix H2 for projecting the captured image on a plane different from the ground (e.g. no-conversion unit matrix) is set. An extended high-angle view image is divided into a first region corresponding to the vehicle periphery and a second region corresponding to farther away from the vehicle, and a high-angle view image based on H1 is displayed in the first region, whereas an image based on a weight-added conversion matrix in which H1 and H2 are weight-added is displayed in the second region. Weight for the weight-addition is varied according to a distance from the border of the first and second regions to seamlessly join the images in both regions.

Owner:SANYO ELECTRIC CO LTD

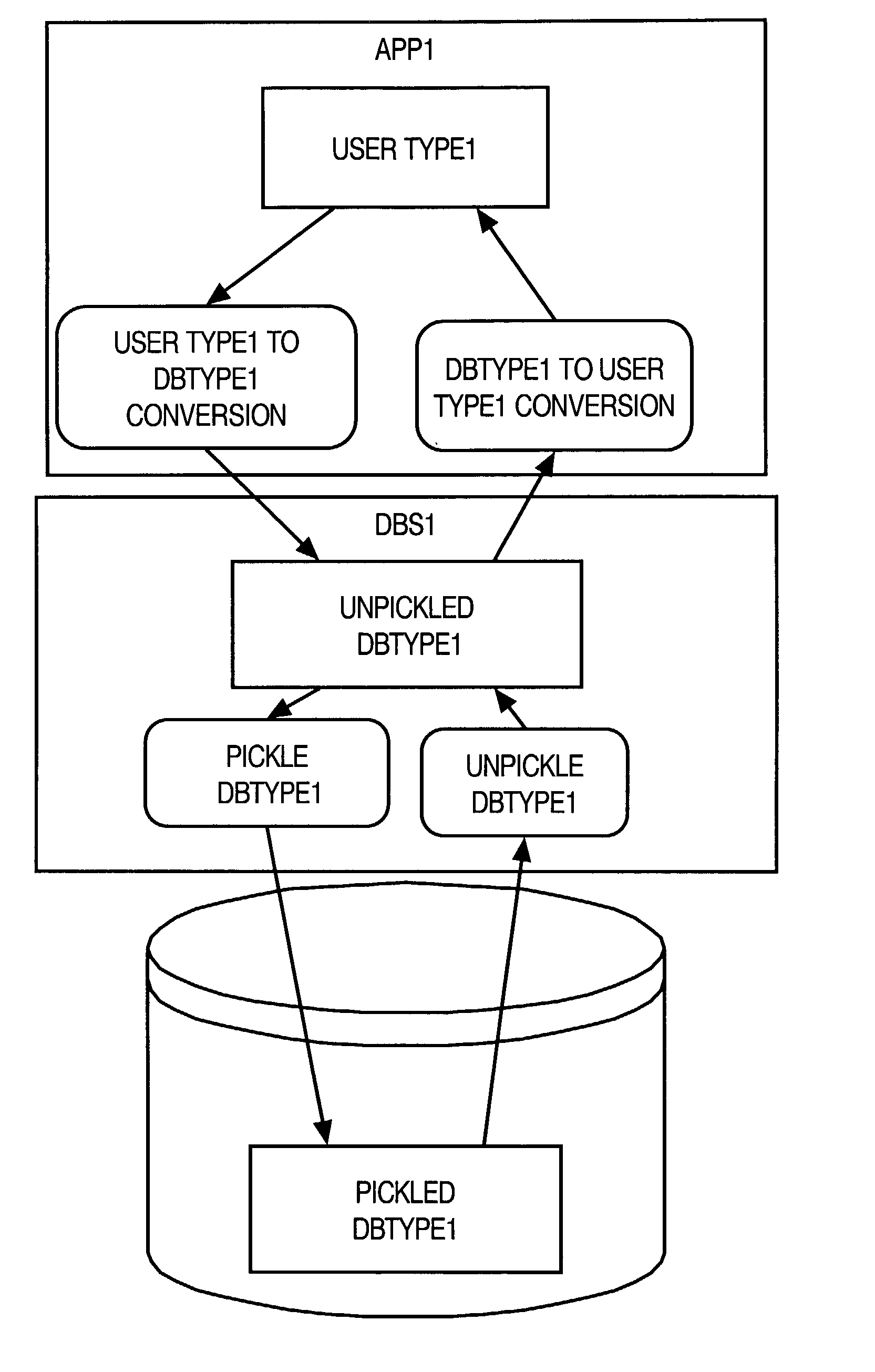

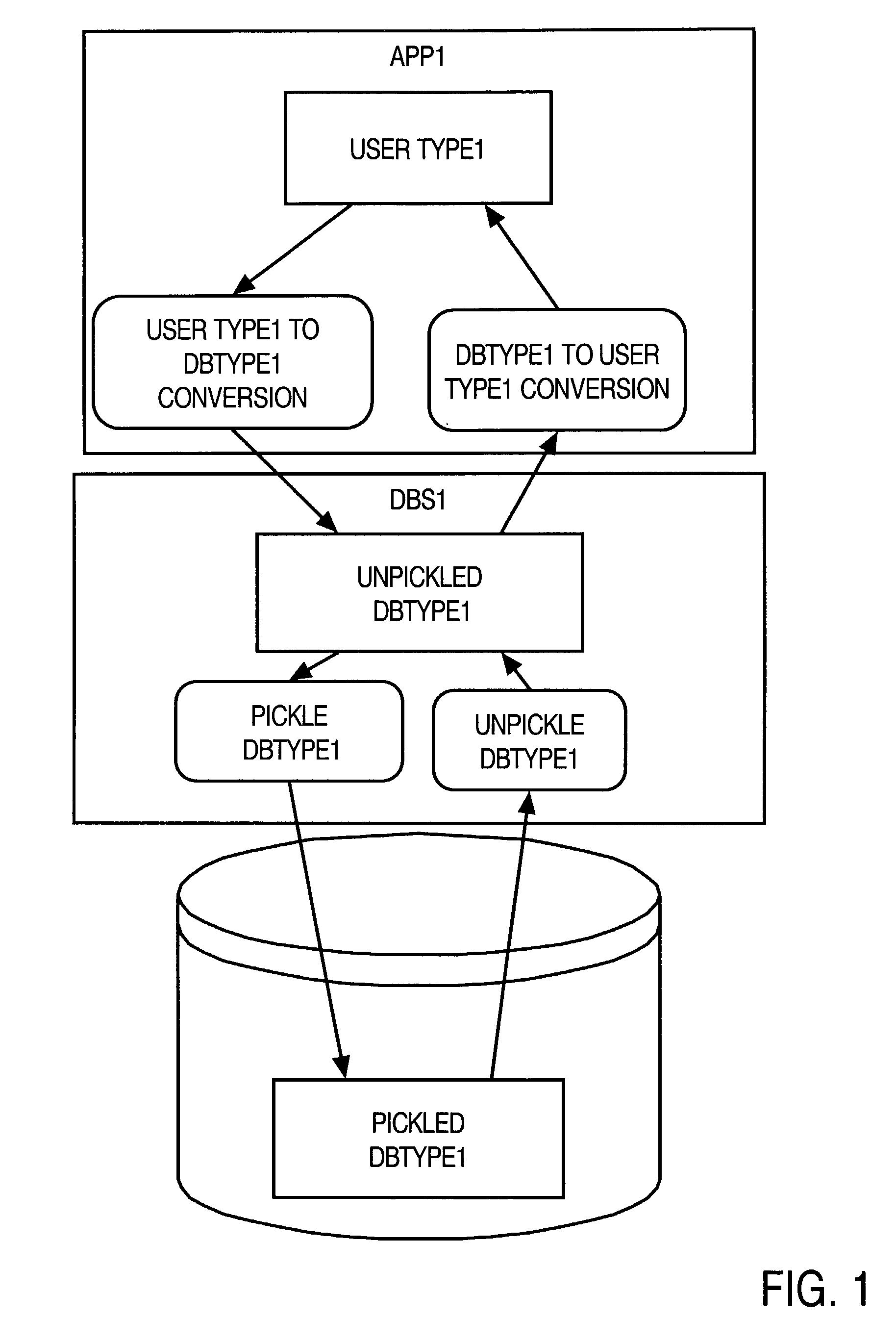

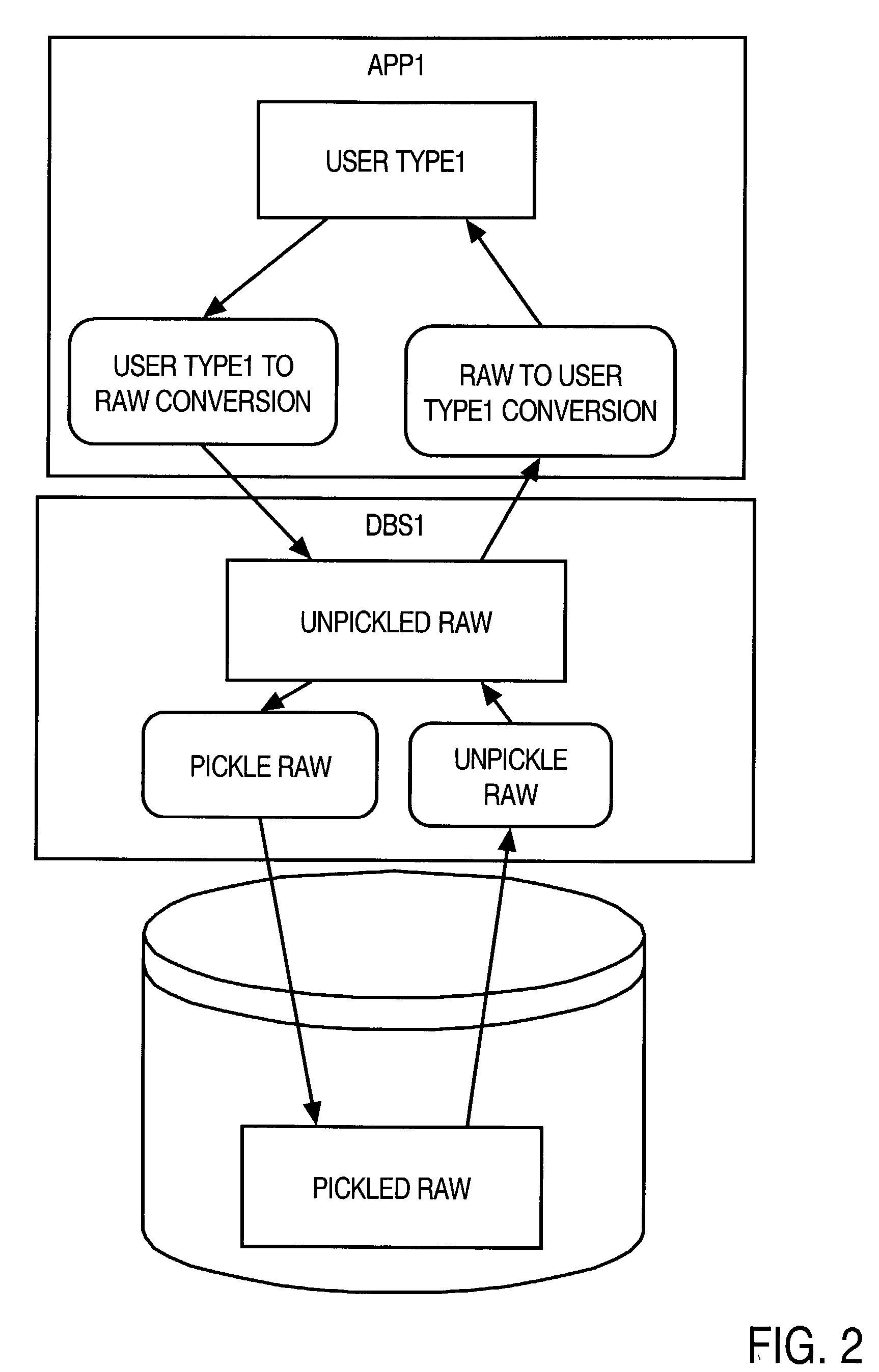

Opaque types

InactiveUS20020174128A1Data processing applicationsDigital data processing detailsNative structureSystem call

A method and apparatus are provided for handling within a database system data items that are associated with data types whose native structure is not known to the database system. The data items are stored within the database system in their native structure, even though it is not understood by the database system. To store the data items, the database system calls a pickling routine that is provided by the user, or by the runtime subsystem of the programming environment that is native to the data item. To retrieve the routine from storage, the database system calls an unpickling routine, also provided by the user or the appropriate runtime subsystem. Because the database maintains the data items in their native format, no conversions are required as the data items are passed between the database system and external routines that manipulate the data items.

Owner:ORACLE INT CORP

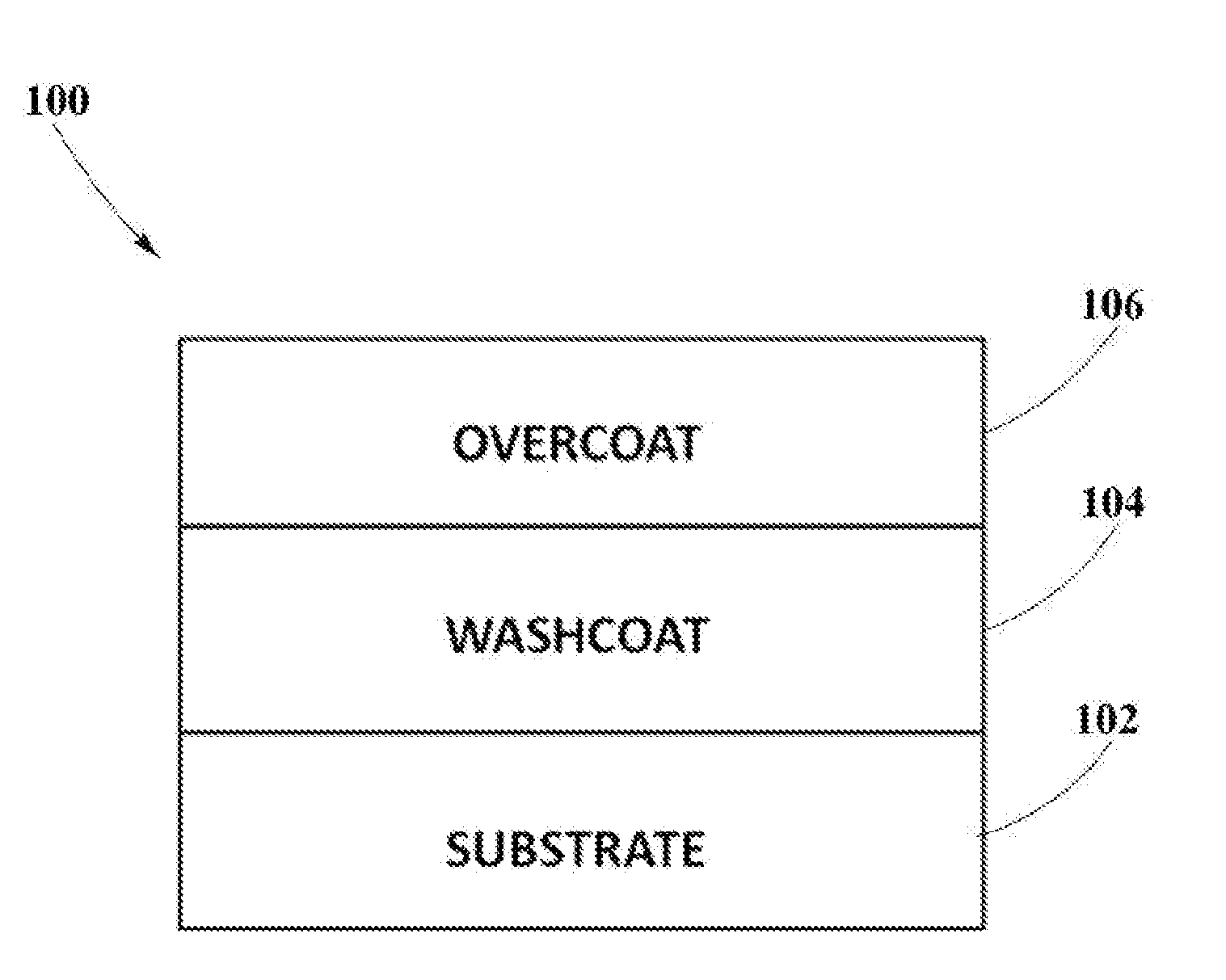

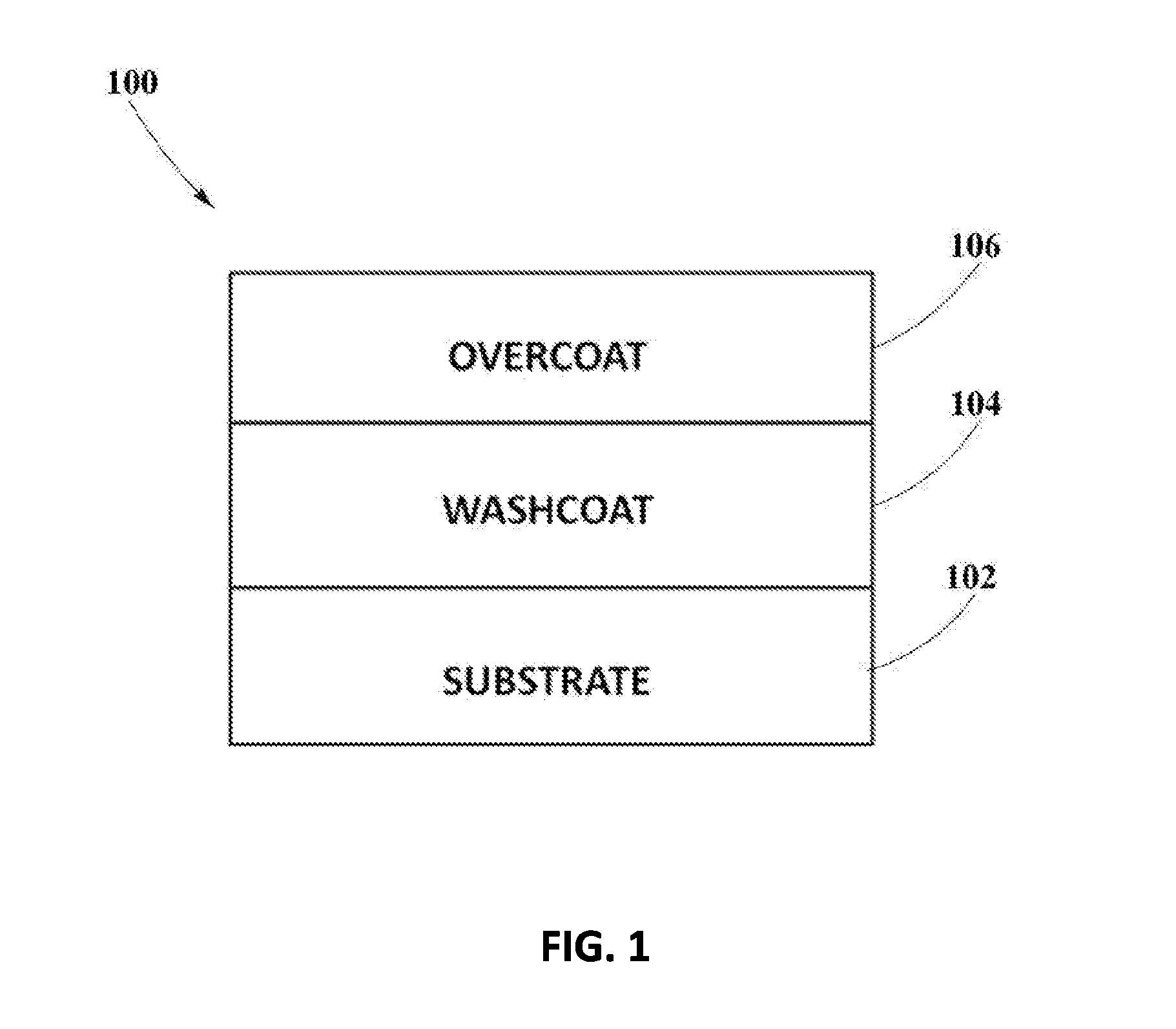

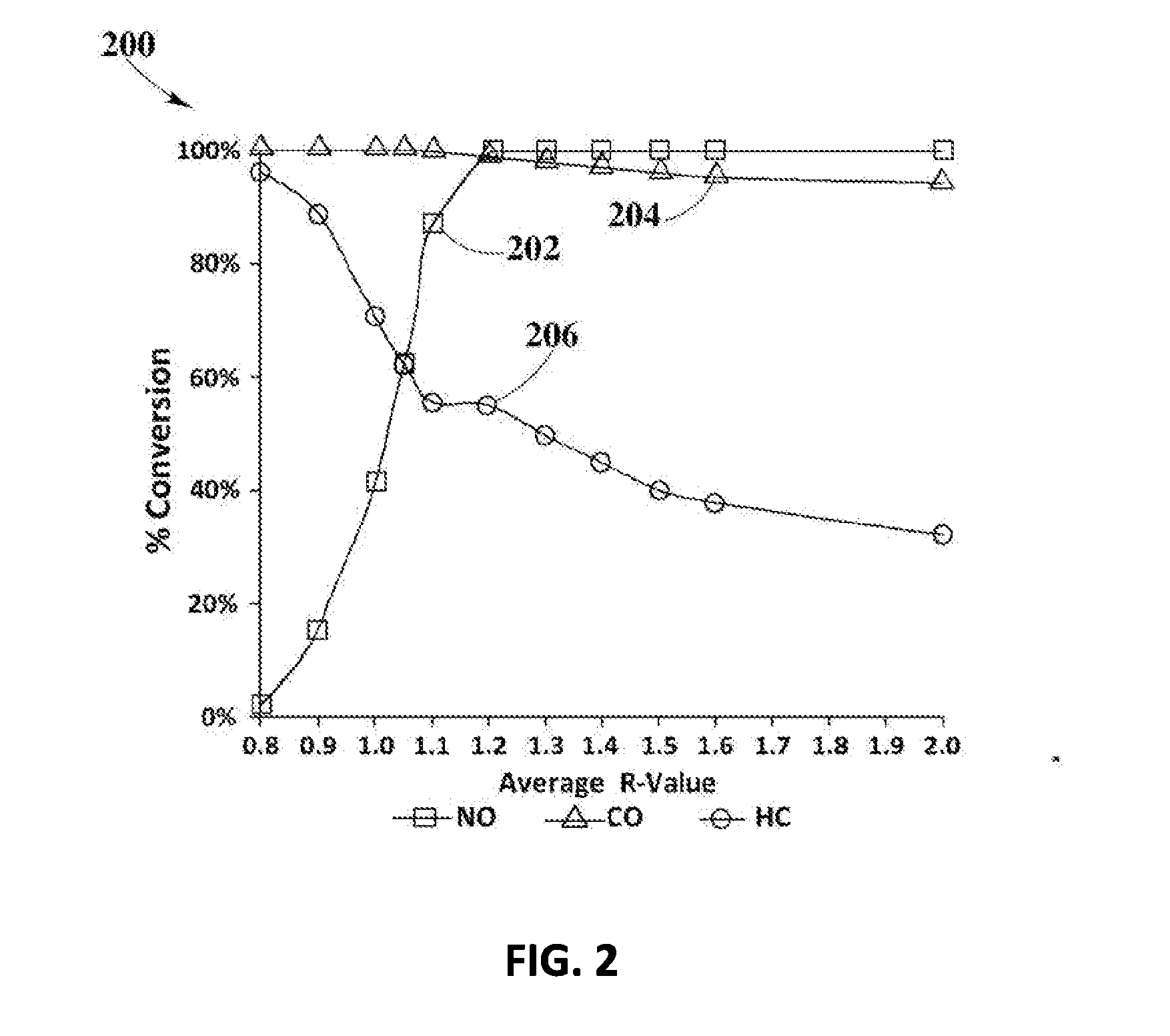

Optimal Composition of Copper-Manganese Spinel in ZPGM Catalyst for TWC Applications

InactiveUS20140271387A1High catalytic activityImprove thermal stabilityCombination devicesInternal combustion piston enginesChemical compositionSpinel

It is an object of the present disclosure, to provide an optimized catalyst composition with variations of Cu and Mn molar ratio, which may include a formulation CuxMn3-xO4 spinel, with a plurality of molar ratio variations for selecting the optimal Cu—Mn molar ratio for TWC application. The formulation may include a support oxide, such as Nb2O5—ZrO2. Employing this optimized Cu and Mn ratio in spinel as overcoat may achieve optimal NO conversion, high catalyst activity, and enhanced thermal stability, having a chemical composition substantially free from PGM and rare earth metals. According to principles of the present disclosure, the disclosed Cu—Mn spinel on Nb—Zr support oxide for TWC applications may require a washcoat of alumina, and overcoat of Cu—Mn spinel on Nb—Zr support oxide.

Owner:CLEAN DIESEL TECHNOLOGIES

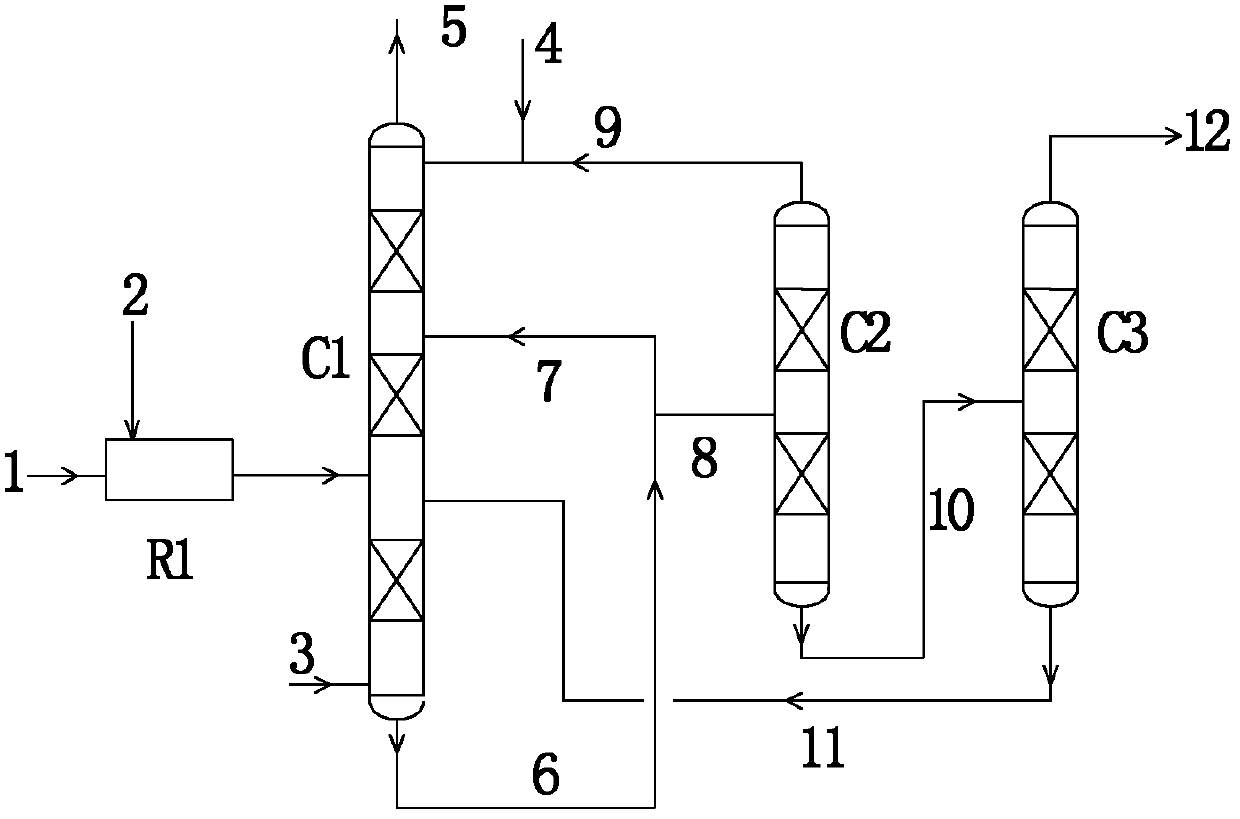

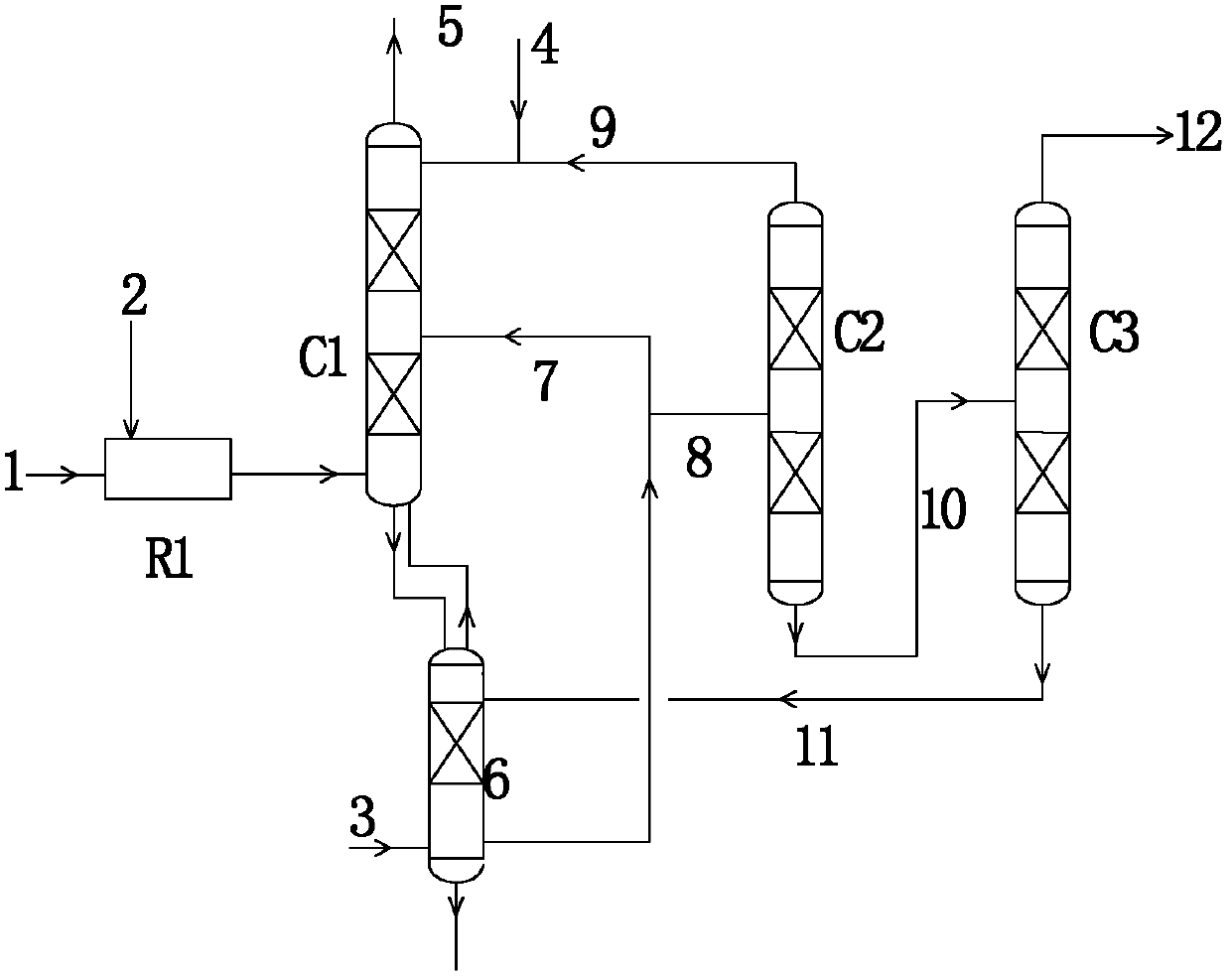

Preparation method for methyl nitrite

ActiveCN103373925AReduce heat supplyHigh yieldNitrous acid preparation ester preparationWastewaterNo conversion

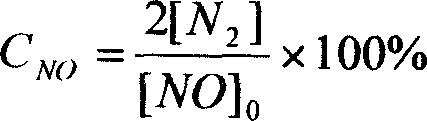

The invention relates to a preparation method for methyl nitrite. The preparation method is characterized by comprising the following steps of: taking NO-containing gas, O2 and methanol as raw materials, inputting the NO-containing gas, the O2 and the methanol into at least one esterification column, reacting to obtain methyl nitrite, and recycling nitric acid and the residual methanol, wherein the residual methanol is recycled in at least one methanol recycling column, and the nitric acid is recycled in at least one nitric acid recycling column. Compared with the prior art, the preparation method for the methyl nitrite has the advantages that MN can be effectively generated, the NO conversion rate can be improved, the yield of the MN can be increased, the heating capacity of the bottom of the esterification column can be reduced, and the wastewater discharged from a system does not contain the nitric acid; the problem of the nitric acid wastewater generated in a process for generating methyl nitrite from NO is thoroughly solved, and the preparation method is beneficial to environmental protection and has a good practical application value and production significance.

Owner:PUJING CHEM IND SHA +1

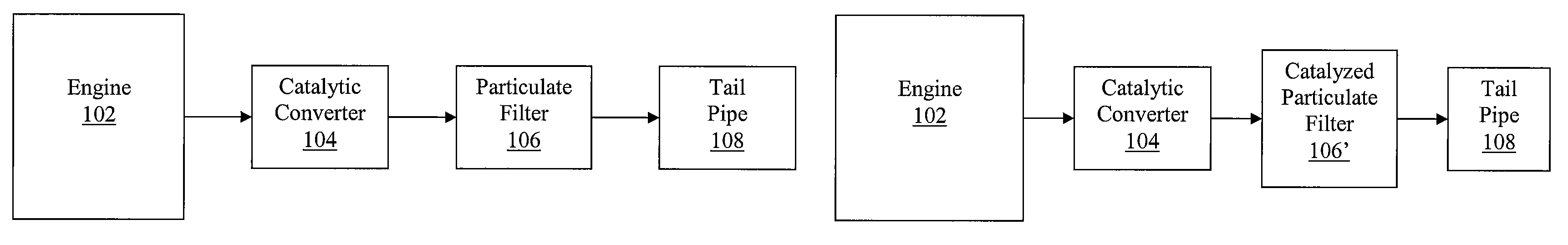

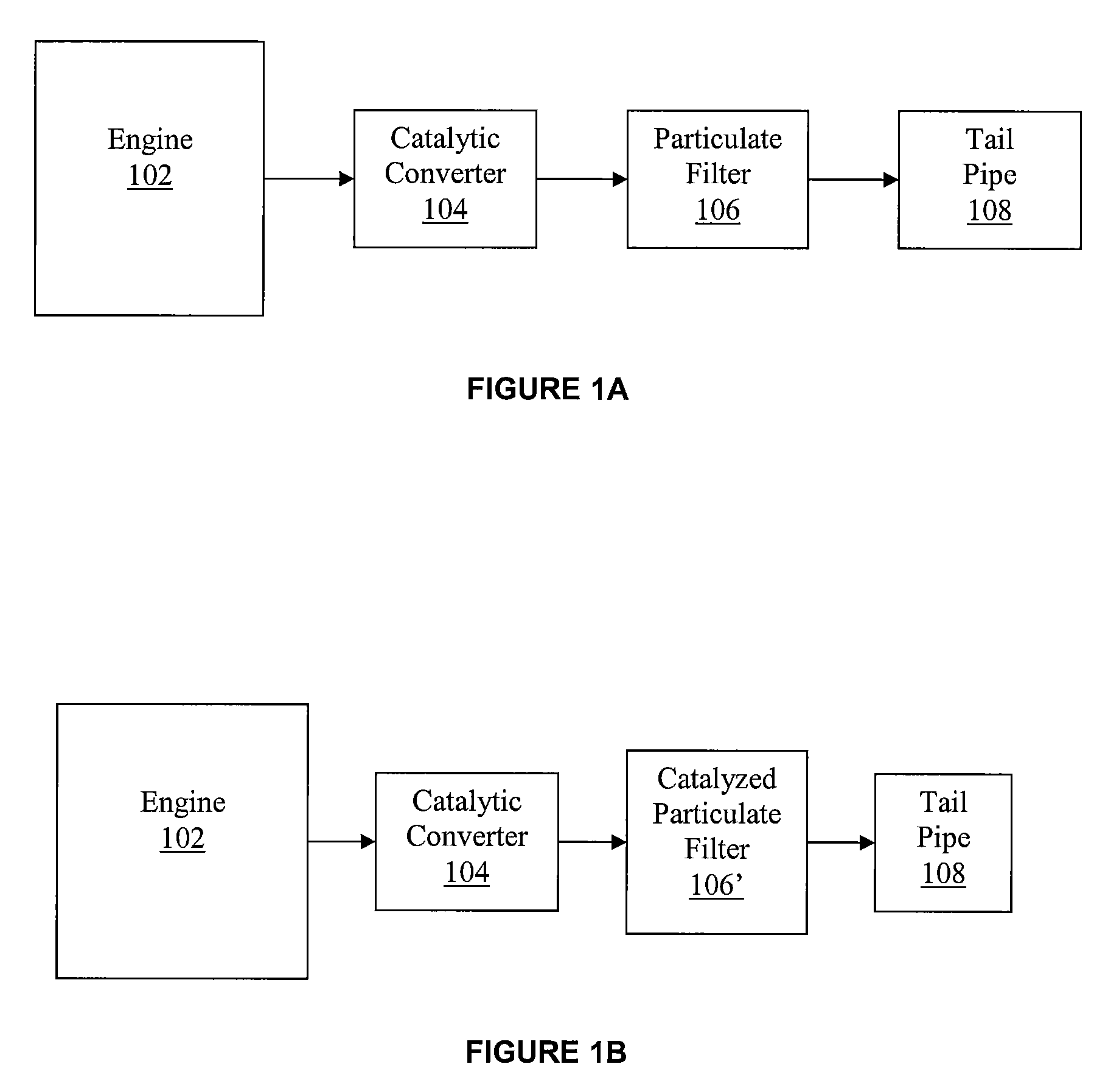

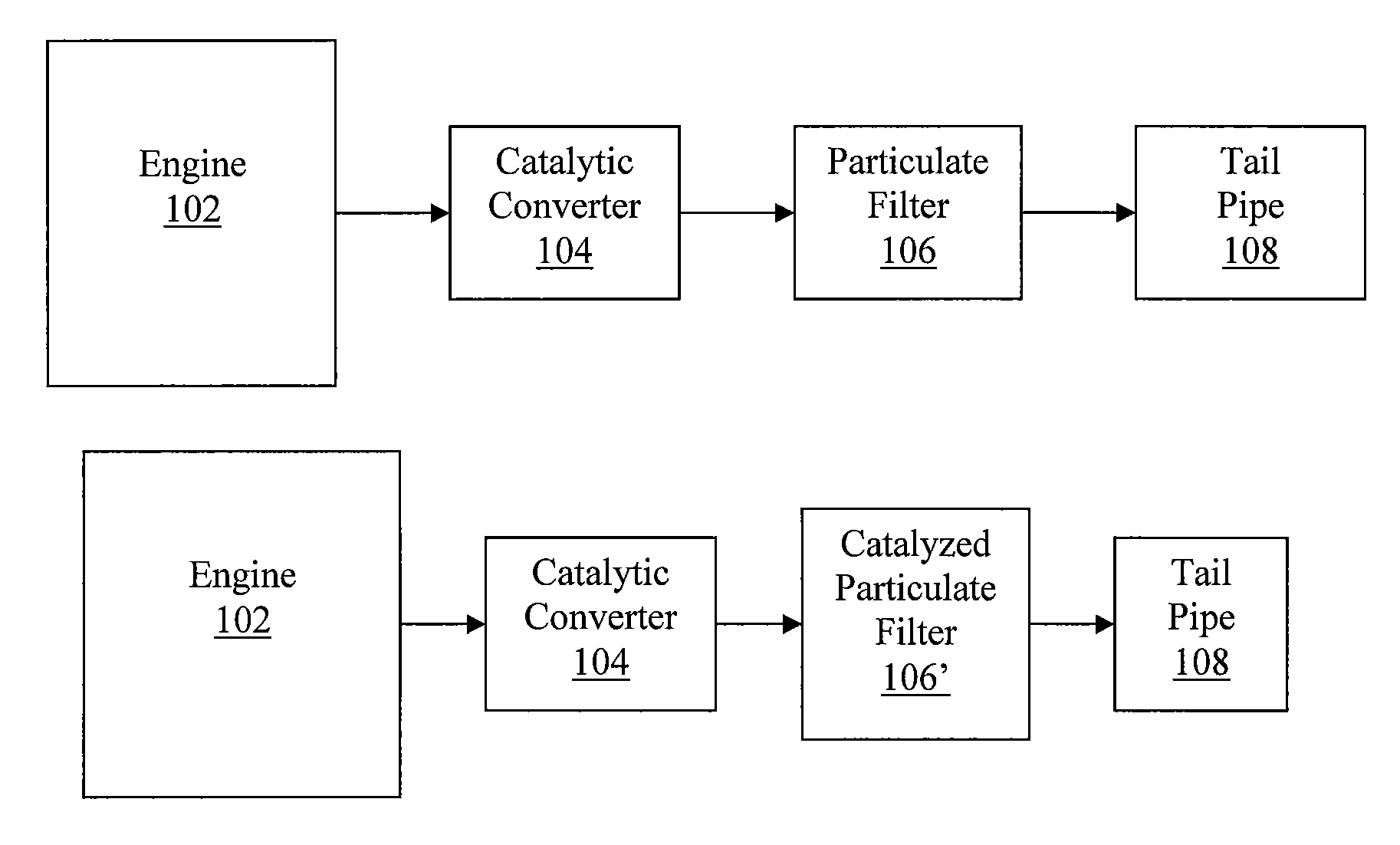

Platinum-bismuth catalysts for treating engine exhaust

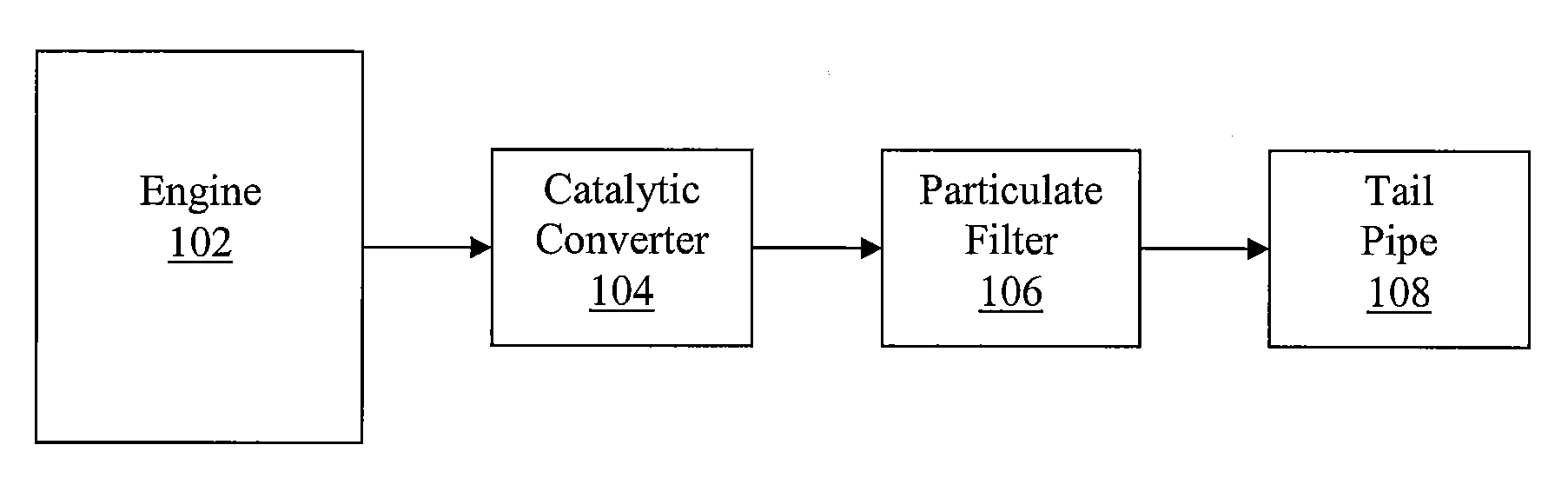

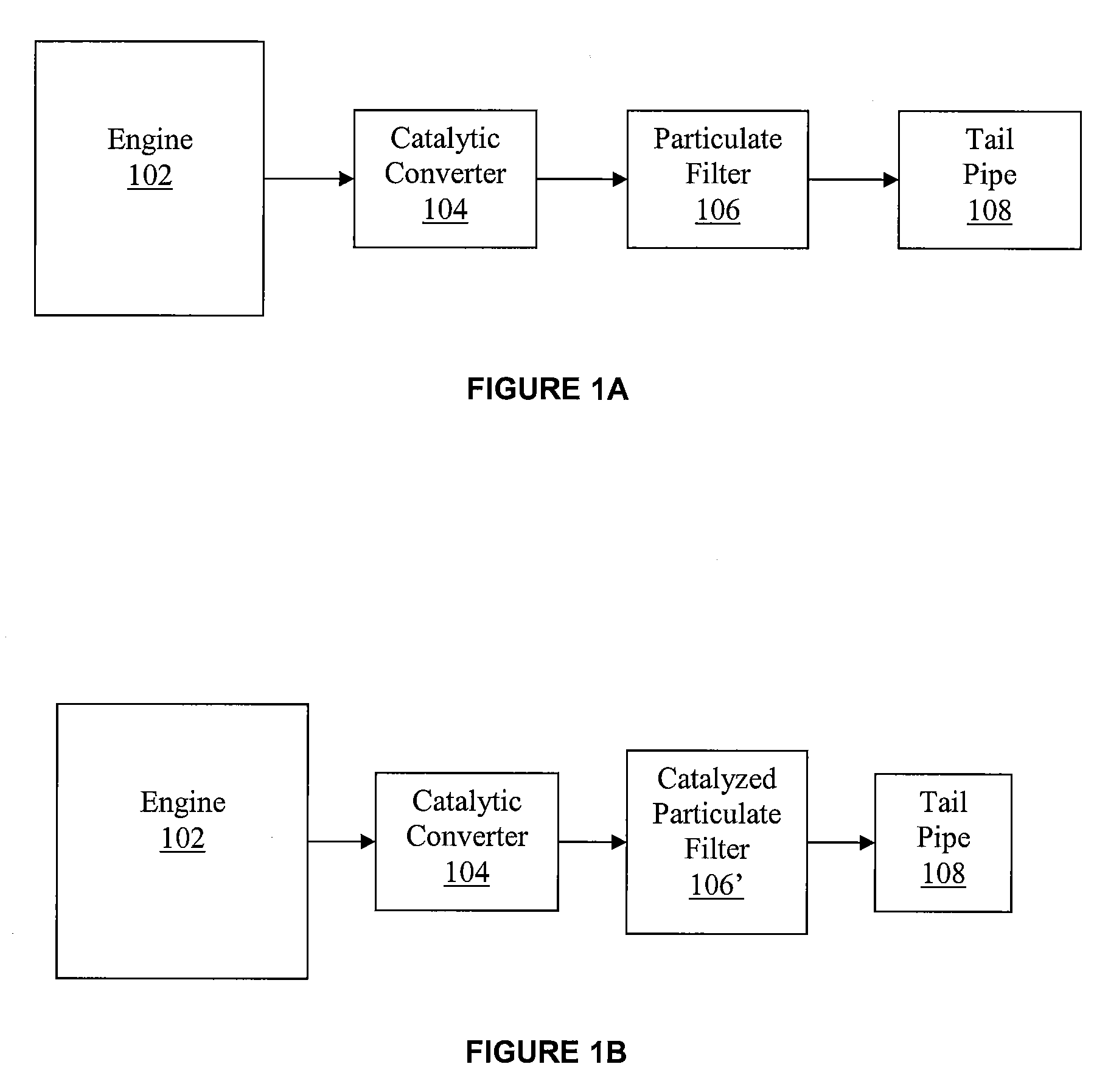

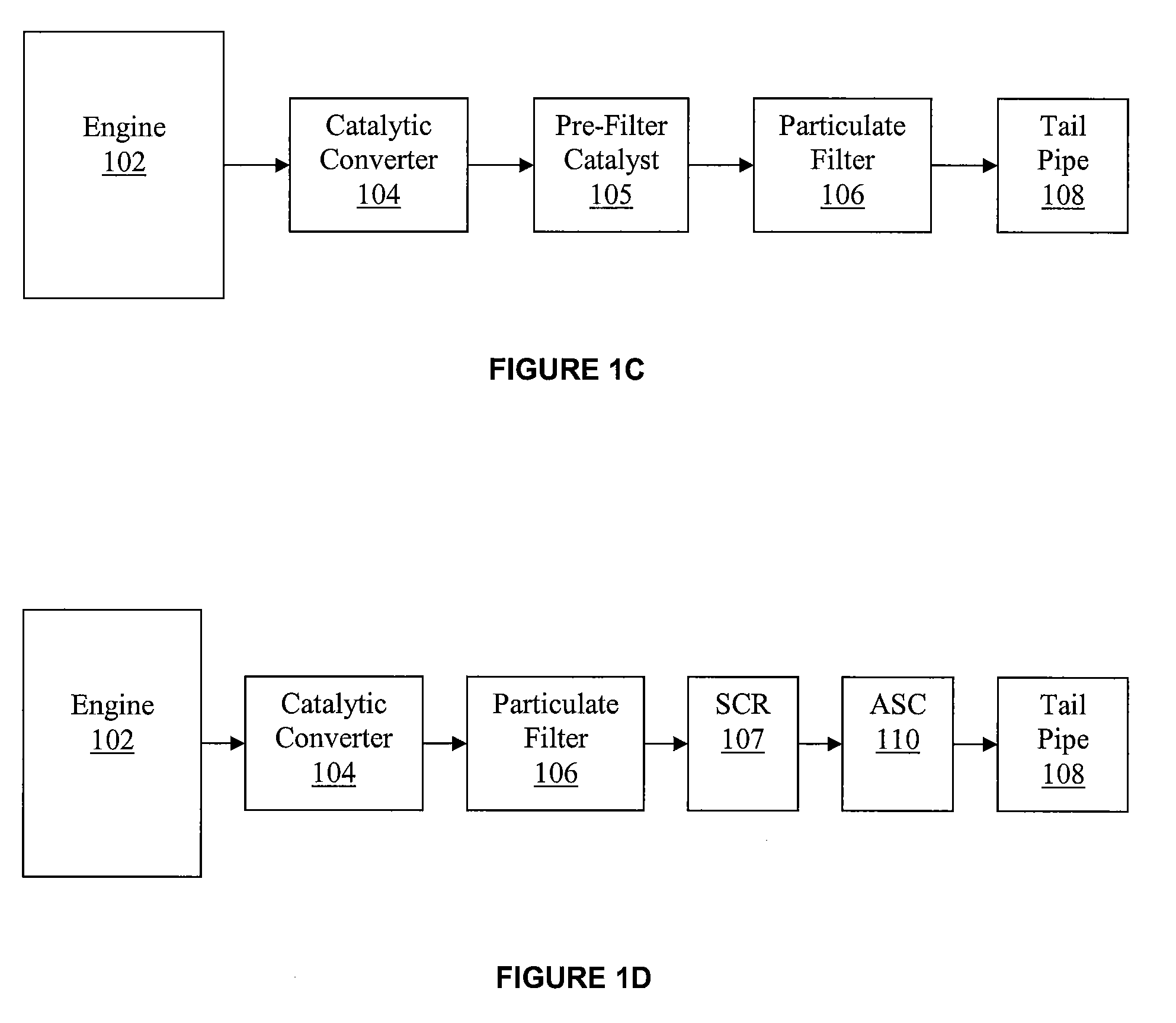

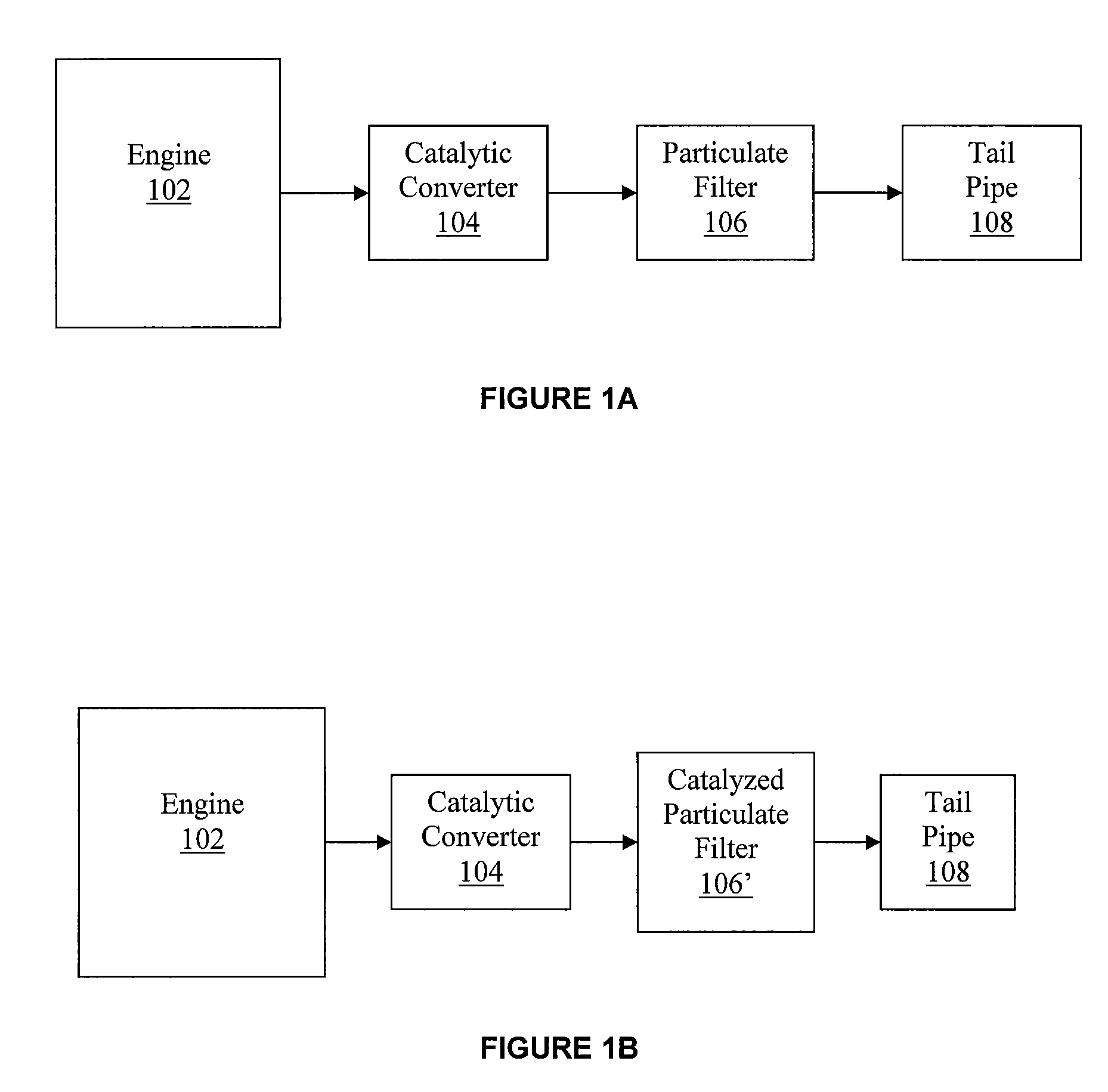

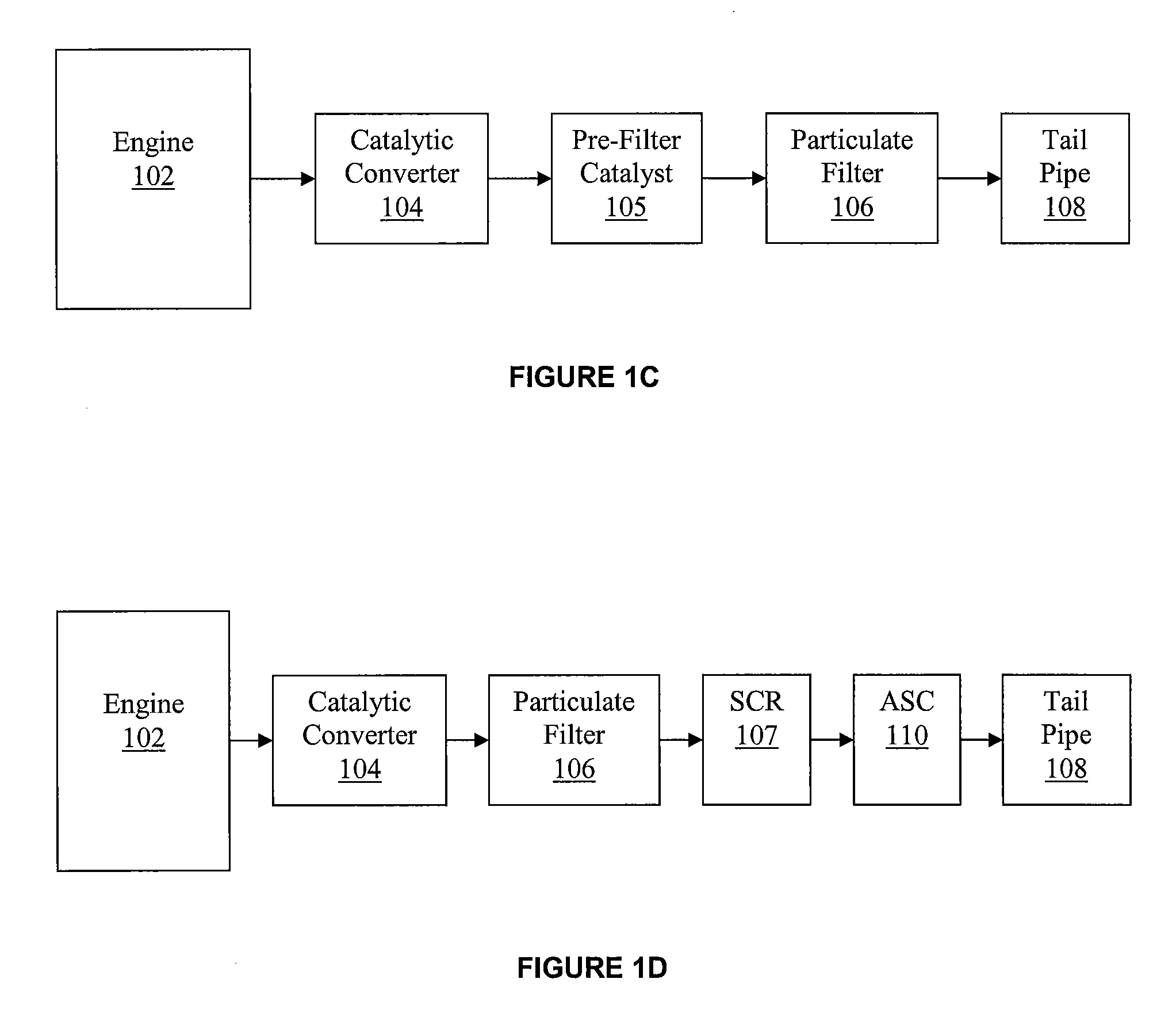

InactiveUS7611680B2Improve oxidation capacityQuantity minimizationCombination devicesNitrogen compoundsParticulatesPlatinum

An engine exhaust catalyst containing precious metal nanoparticles is promoted with bismuth. The bismuth promotion improves the catalyst's CO oxidation performance. Also, by varying the amount of bismuth that is added, the NO conversion rate that can be realized with the catalyst can be controlled. The control over the NO conversion rate is important because the passive regenerative performance of a particulate filter used in engine exhaust systems is based on the amount NO2 that is present in the exhaust stream that reaches the particulate filter. The amount of NO2 being produced needs to be optimized (not necessarily maximized) so that adequate particulate filter regeneration performance can be maintained while avoiding unused, toxic NO2 from being exhausted into the atmosphere.

Owner:SHUBIN

Platinum-Bismuth Catalysts For Treating Engine Exhaust

InactiveUS20080003155A1Improve oxidation capacityQuantity minimizationCombination devicesNitrogen compoundsPlatinumParticulates

An engine exhaust catalyst containing precious metal nanoparticles is promoted with bismuth. The bismuth promotion improves the catalyst's CO oxidation performance. Also, by varying the amount of bismuth that is added, the NO conversion rate that can be realized with the catalyst can be controlled. The control over the NO conversion rate is important because the passive regenerative performance of a particulate filter used in engine exhaust systems is based on the amount NO2 that is present in the exhaust stream that reaches the particulate filter. The amount of NO2 being produced needs to be optimized (not necessarily maximized) so that adequate particulate filter regeneration performance can be maintained while avoiding unused, toxic NO2 from being exhausted into the atmosphere.

Owner:SHUBIN

Glutamine extracting process from fermented liquid

InactiveCN1432559AAvoid conversionReduce dosageCarboxylic acid amide separation/purificationStrong acidsImpurity

The present invention belongs to the field of medicine and health care article amino acid, and includes pre-treatment of the fermented liquid to eliminate thallus, partial protein, pigment and polysaccharide, controlling the pH value of the fermented liquid after pre-treatment; electrodialysis to eliminate inorganic salt and regulating pH value again; leading in processed OH type anionic exchangecolumn to adsorb impurities and separate glutamine; decoloring, vacuum concentration, isoelectric crystallization, washing coarse crystal in organic solvent and drying. The said process has low exchange resin consumption, no conversion of glutamine in strong acid and strong alkali environment, low production cost and high total glutamine extracting rate up to 70%, and is suitable for industrial production.

Owner:TSINGHUA UNIV

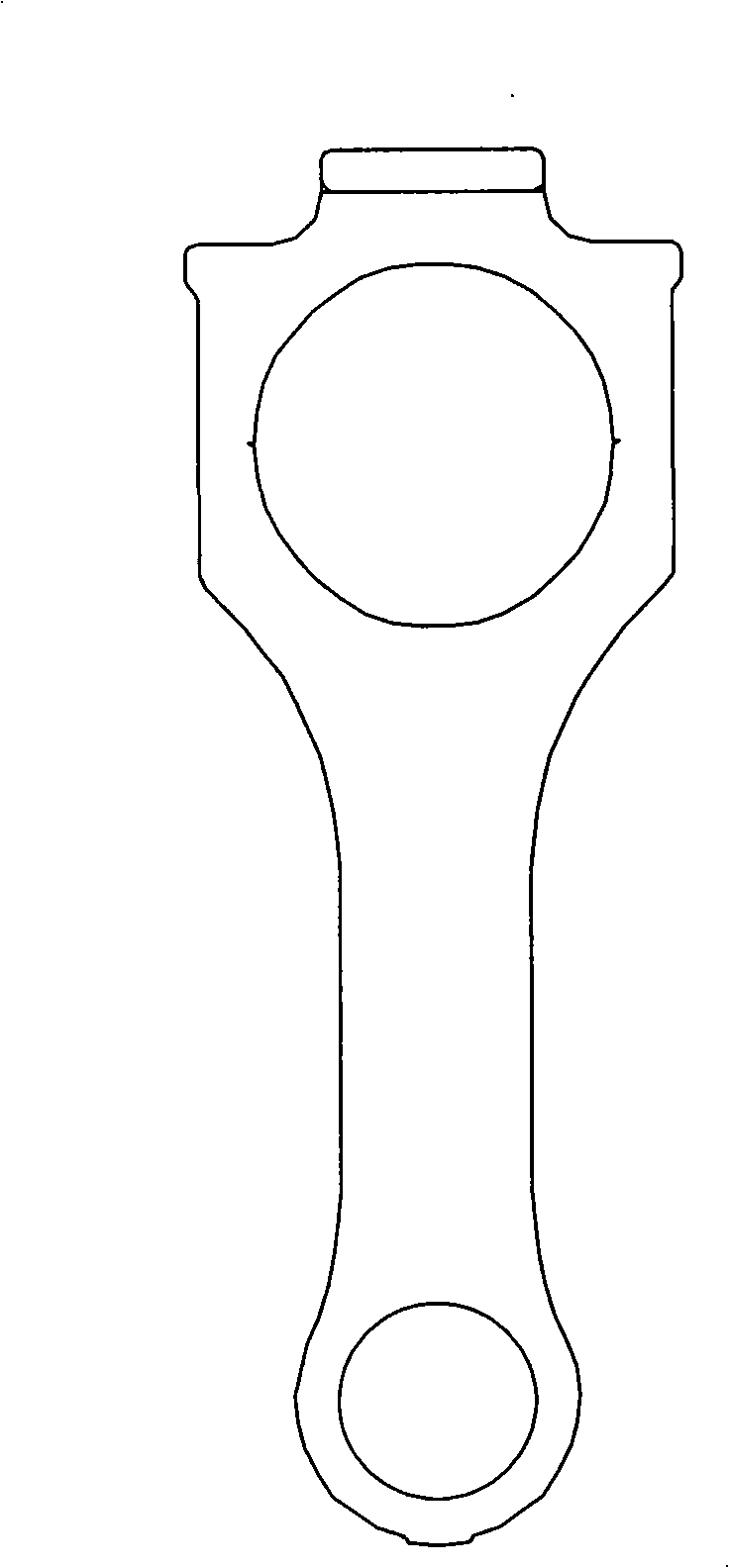

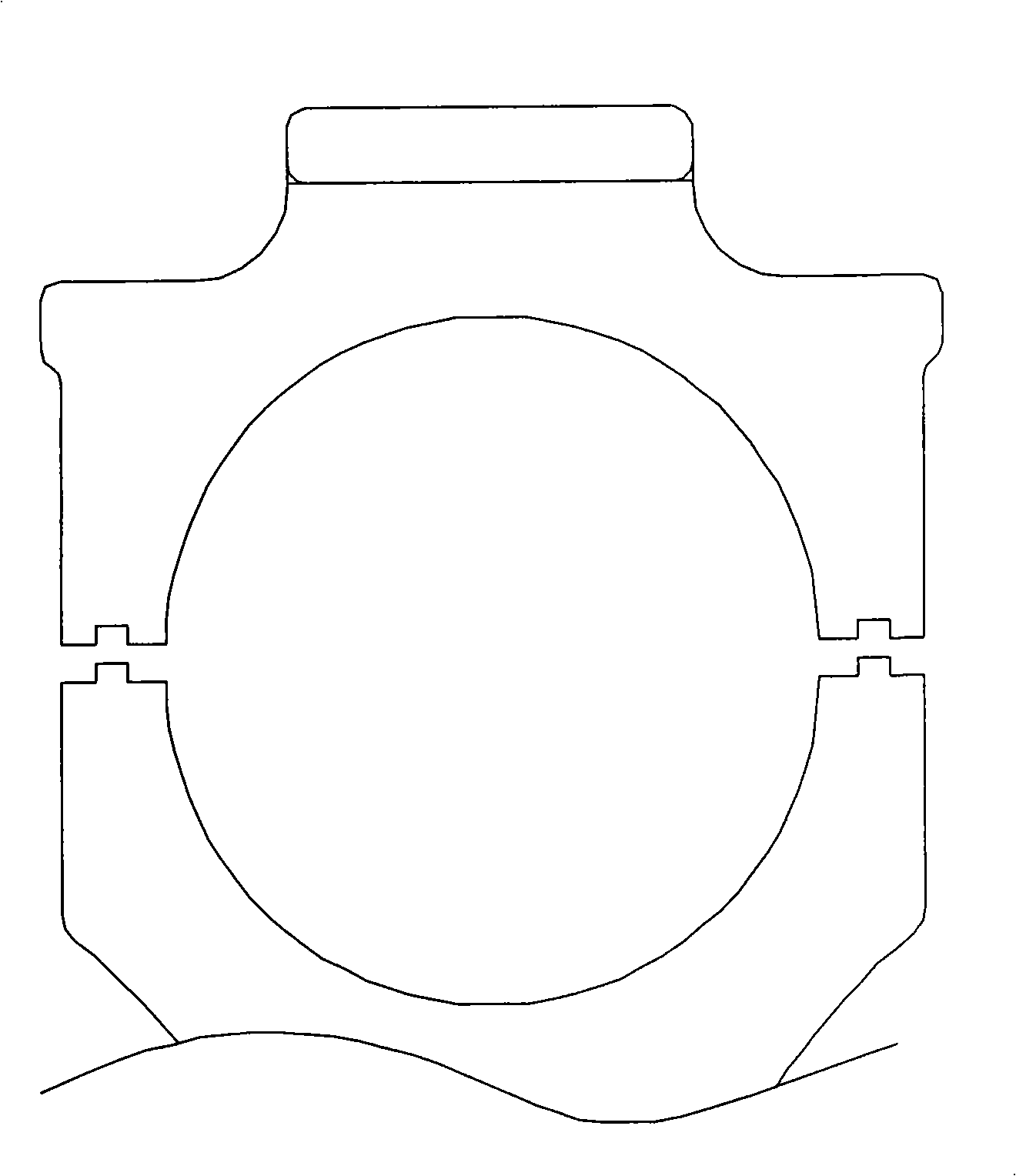

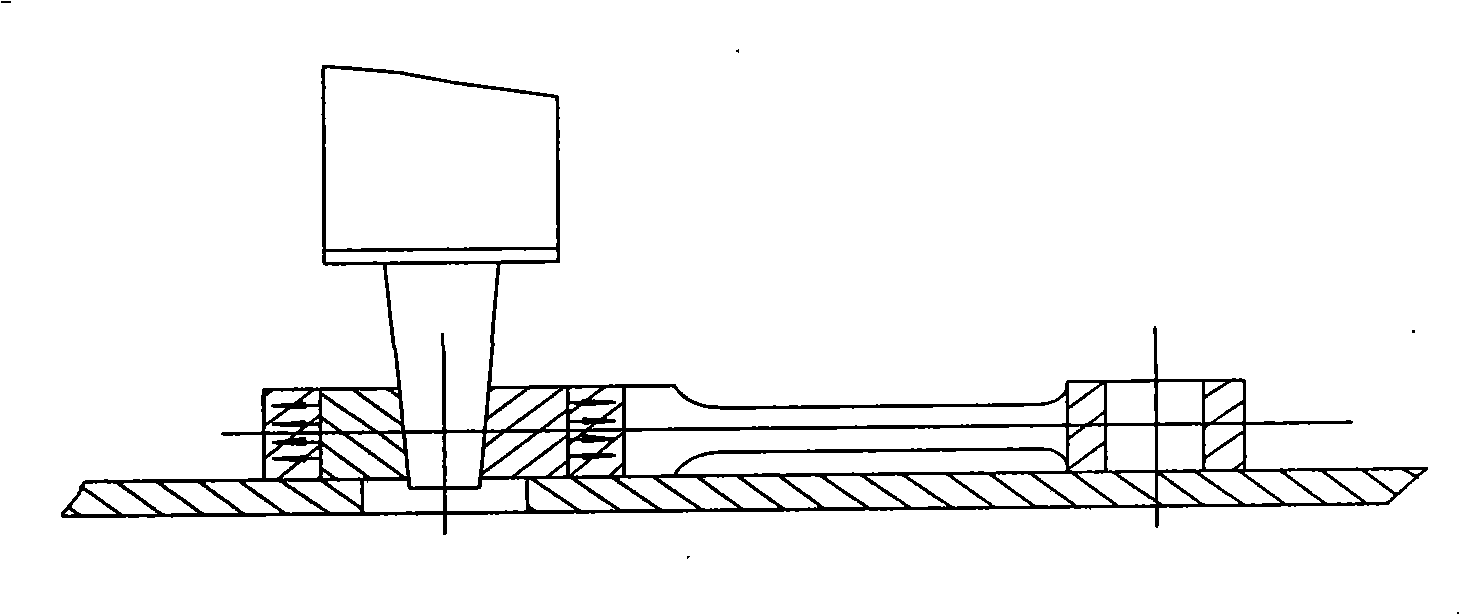

High intensity alloyed steel linkage rod deep cooling embrittlement bulge-breaking process

InactiveCN101307796AChange ductilityAchieve brittle fractureConnecting rodsHigh intensityLiquid nitrogen

The invention provides a process for deep-cooling, embrittling and broken-expanding of a connecting rod of high-rigid alloy steel, relating to an improvement of the process for processing engine components. The process comprises the following steps of: a. putting the connecting rod in liquid nitrogen for deep cooling for more than 5 minutes; basically deep cooling of the connecting rod to a test piece core part after ending of heat exchange; and measuring temperature at a fracture of the cracked test piece same as surface temperature of the test piece; b. keeping the deep cooling temperature to be lower than 156 DEG C below zero; c. placing an expanding sleeve in a macropore of the connecting rod and fixing the connecting rod on an operating board of a pressure machine, and punching the expanding sleeve by an expanding head to expand the connecting rod to be broken. The process has the advantages of changing tractility of the connecting rod of a high-power engine, and ensuring radically no conversion of mechanical performance before deep cooling and after deep cooling through utilizing the deep cooling technology. The technology is popularized and used in the high-power engine manufacture field of our country, which can combine seven or ten steps of key steps of the process for producing the connecting rod into one or two steps, thereby reducing much precision equipment for carrying out precise broaching and form grinding and so on.

Owner:CHANGCHUN EQUIP TECH RES INST

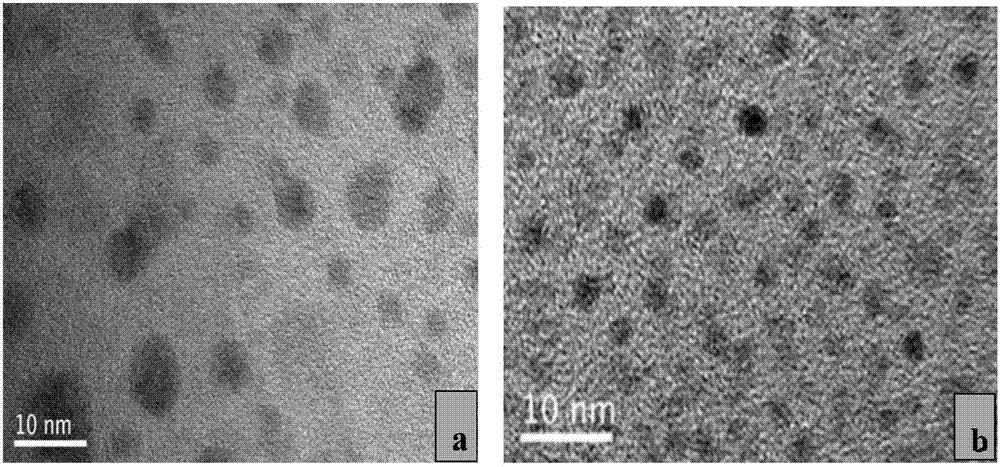

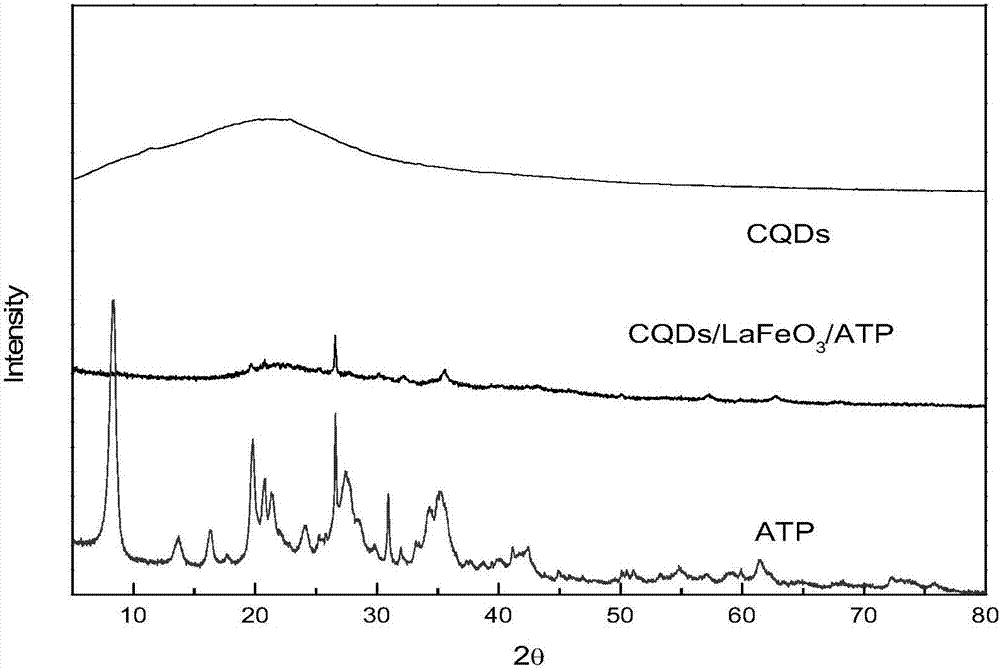

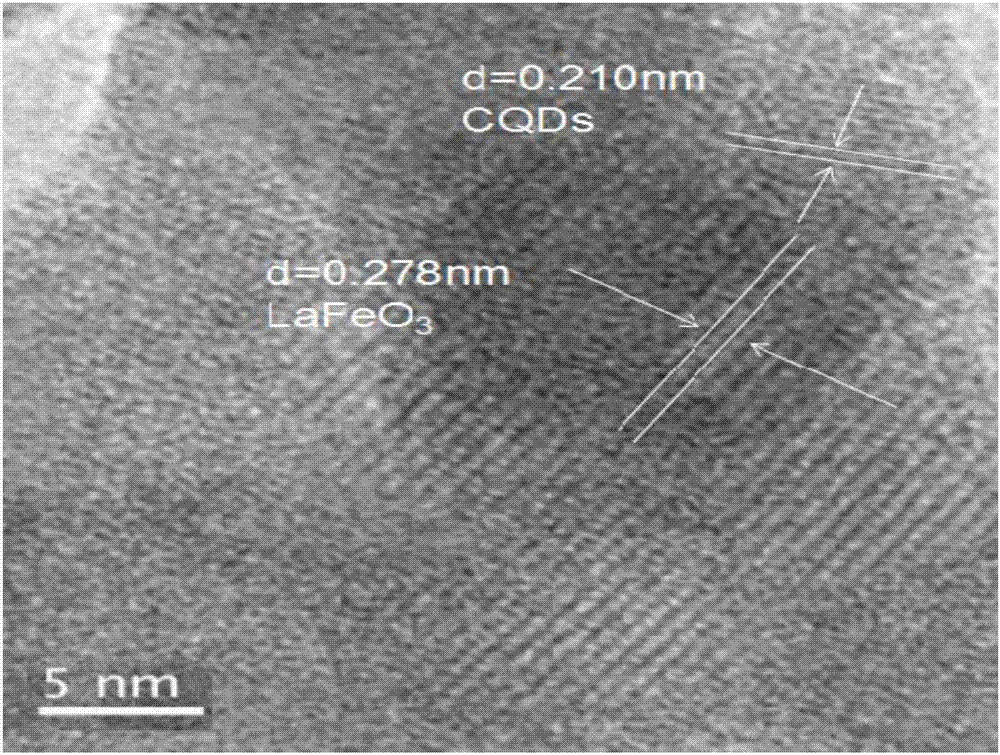

Carbon quantum dot modified lanthanum ferrite/attapulgite nanocomposite material and preparation method and application thereof

ActiveCN106964358ASmall particle sizeAvoid uneven loadDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater bathsEvaporation

The invention belongs to the technical field of denitration catalyzed production in environmental protection and particularly relates to a carbon quantum dot modified lanthanum ferrite / attapulgite nanocomposite material and a preparation method and application thereof. Lanthanum nitrate, ferric nitrate, citric acid and attapulgite are added into deionized water for full mixing, then the mixture is transferred to a water bath pot, evaporation is performed at the temperature of 50-100 DEG C to obtain wet gel, drying and calcination is performed, then the mixture is impregnated a carbon quantum dot solution, and drying and grinding are performed. The composite material is adopted as a catalyst to perform photocatalytic denitration. Compared with traditional SCR denitration, the energy consumption is greatly reduced, the NO conversion efficiency is obviously improved at low temperature.

Owner:CHANGZHOU UNIV

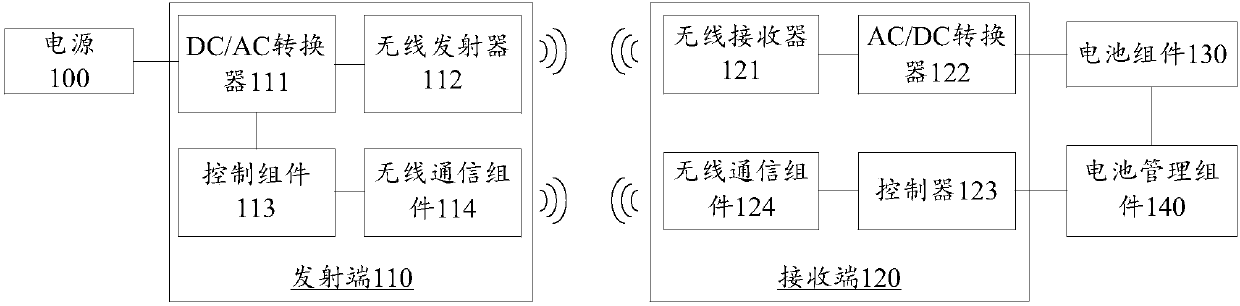

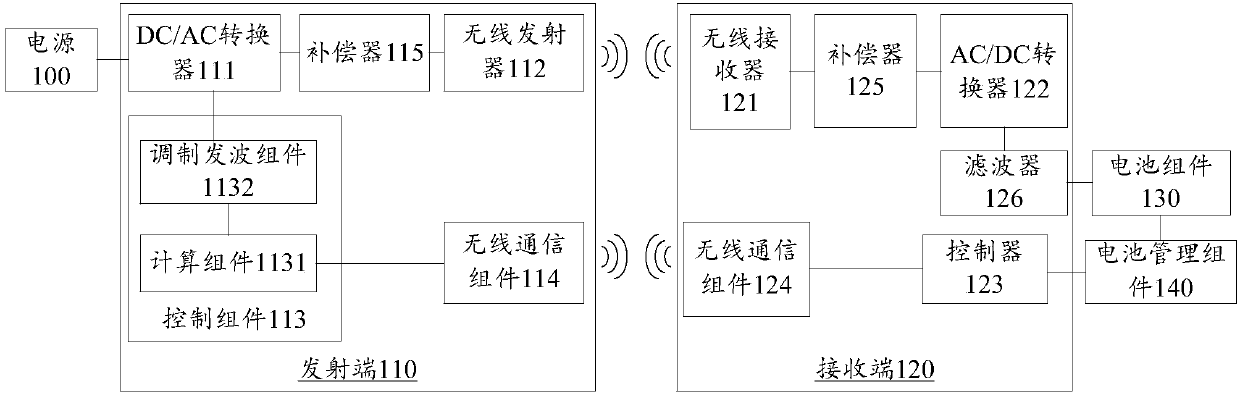

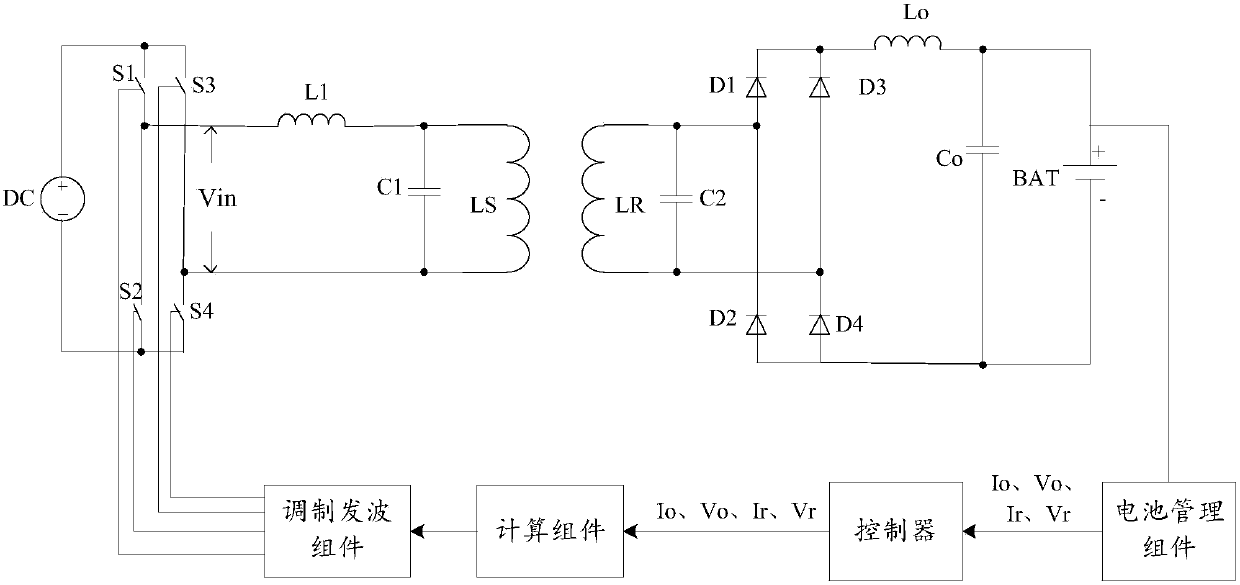

Wireless charging circuit, wireless charging system and circuit control method

InactiveCN107623344AAvoid damageNear-field transmissionBatteries circuit arrangementsComputer moduleDc voltage

The invention discloses a wireless charging circuit, a wireless charging system and a circuit control method, and belongs to the technical field of wireless charging. The wireless charging circuit comprises a DC / AC converter, a wireless transmitter, a control component and a wireless communication component. The wireless communication component is used for receiving the charging parameters fed back by a receiving side. The control component is used for transmitting a first driving signal or a second driving signal to the DC / AC conversion module according to the charging parameters. The DC / AC converter is used for being in the work state under the control of the first driving signal and converting the DC voltage in the work state and being in the work stop state under the control of the second driving signal and performing no conversion of the DC voltage in the work stop state. The problem of increasing of the circuit cost and the size of the present output power adjustment method can be solved so that the effects that the average power of the actual load of the receiving side is enabled to be equal to or close to the needed power of the load and the efficiency and the power densityof the wireless charging system can be enhanced can be achieved.

Owner:HUAWEI TECH CO LTD

Method for denitrifying NO by directly decomposing NO catalytically by using supported metal oxide catalyst

ActiveCN104474890AImprove removal efficiencyNo secondary pollutionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsDecompositionCerium

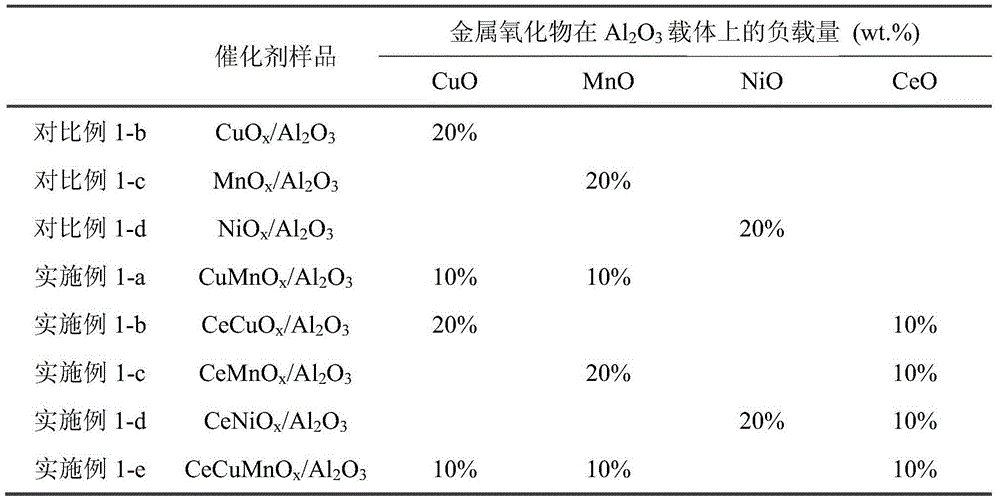

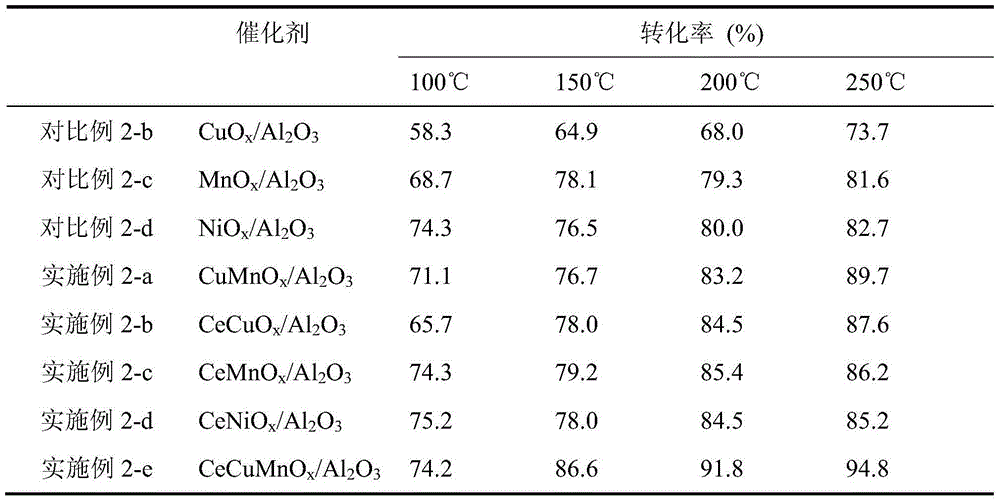

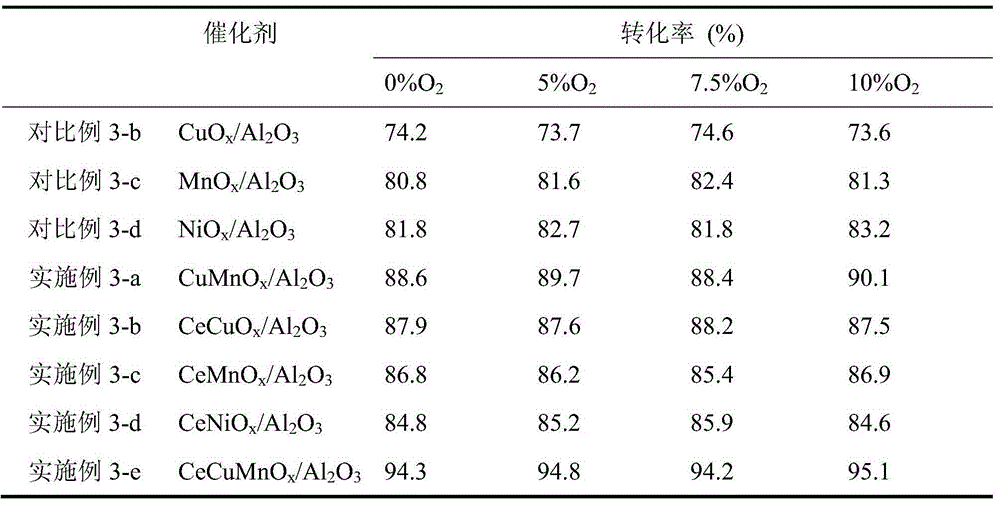

The invention provides a method for denitrifying NO by directly decomposing NO catalytically by using a supported metal oxide catalyst. The method is carried out in a microwave field. The catalyst is a supported mixed metal oxide catalyst which is characterized in that a mixed metal oxide MOx is supported on an Al2O3 carrier, wherein M is selected from two or three of cerium, copper, manganese and nickel; preferably, the catalyst is selected from CeCuOx / Al2O3, CeMnOx / Al2O3, CeNiOx / Al2O3 and CeCuMnOx / Al2O3. The method has the advantages that secondary pollution is avoided through microwave catalytic direct NO decomposition reaction; the process is simple, is convenient to operate and easy to control, is high in NO removal efficiency (the NO conversion rate can be 95.1%), strong in oxidation resistance and low in operating temperatures, is energy-saving and environment-friendly and is low in operating cost; the flue gases or waste gases treated by using the method can be directly up to the national emission standard.

Owner:XIANGTAN UNIV

Method for catalytic oxidation of nitric oxide with low-temperature plasma modified catalyst

InactiveCN101822945AImprove conversion efficiencyIntroduction to the processAmmonium nitratesDispersed particle separationCatalytic oxidationNitric oxide

The invention relates to a method for catalytic oxidation of nitric oxide with a low-temperature plasma modified catalyst. In the method, a catalyst is arranged in a plasma reactor to be modified under certain condition, thereby significantly improving the property of the catalyst for low-temperature catalytic oxidation, and the NO conversion rate can reach 80-86 percent at 50-150 DEG C. The NO in mixture can be oxidized into NO2 and enter into an ammonia absorption bottle along with the gas, thereby obtaining an ammonium nitrate product which can be used as a raw material of a fertilizer. The catalyst is mainly used for purifying NOX in the industrial waste gas emitted from coal-based power plants and other fixed sources. The invention can significantly improve the low-temperature oxidation activity of the catalyst, and facilitate the increase of the purification efficiency in the following liquid-phase absorption.

Owner:KUNMING UNIV OF SCI & TECH

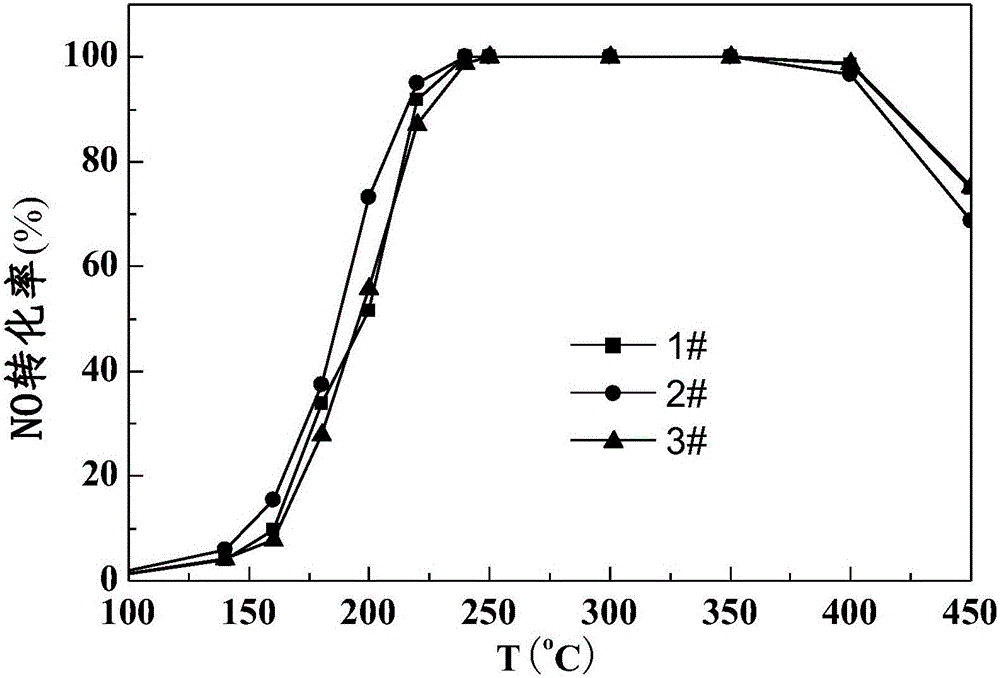

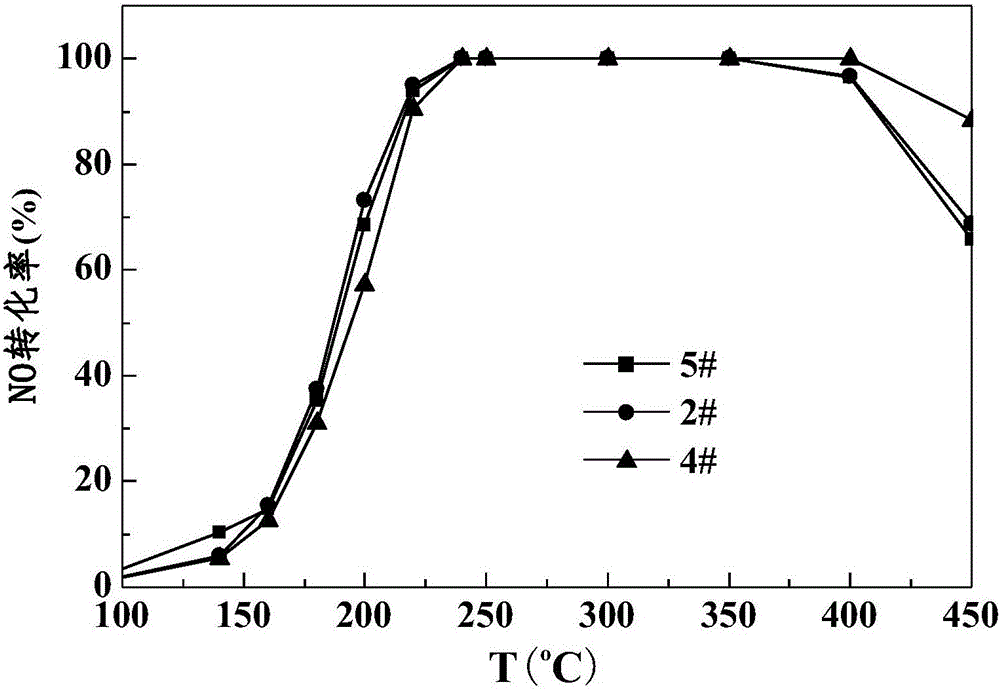

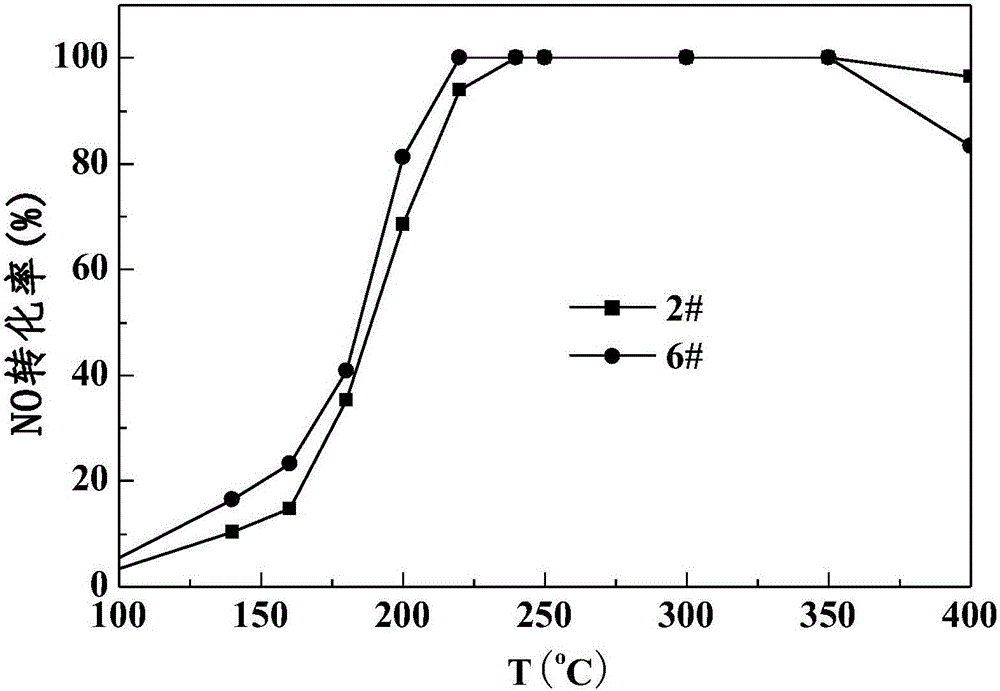

Preparation method of cerium-titanium composite oxide low-temperature SCR catalyst

ActiveCN106179301AGood dispersionHigh activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsOrganic solventCerium

The invention discloses a preparation method of a cerium-titanium composite oxide low-temperature SCR catalyst and belongs to the technical field of catalyst preparation. The preparation method particularly includes: placing a cerium precursor, an organic ligand, a carrier TiO2 and a small amount of organic solvent into a ball milling tank for ball milling to obtain well-mixed powder; calcining to obtain the CeO2-TiO2 composite oxide catalyst, wherein content of cerium oxide is 5-90wt%. Within a temperature range of 200-400 DEG C, NO conversion ratio of the catalyst is maintained higher than 95%. The preparation process is simple, preparation conditions are easy to control, and the preparation method is environment-friendly.

Owner:BEIJING UNIV OF TECH

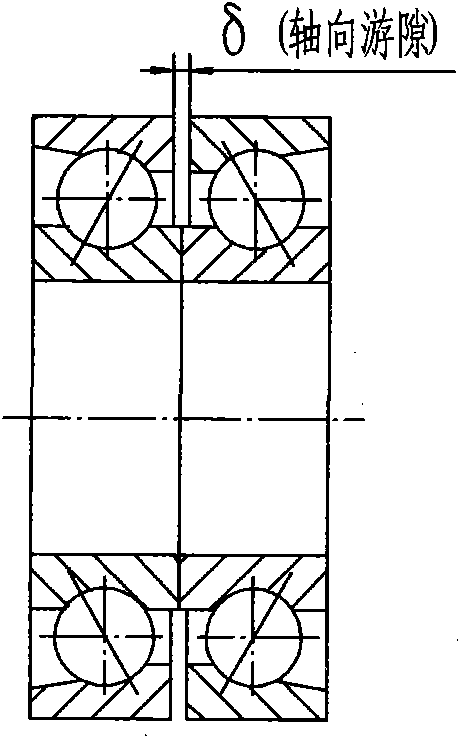

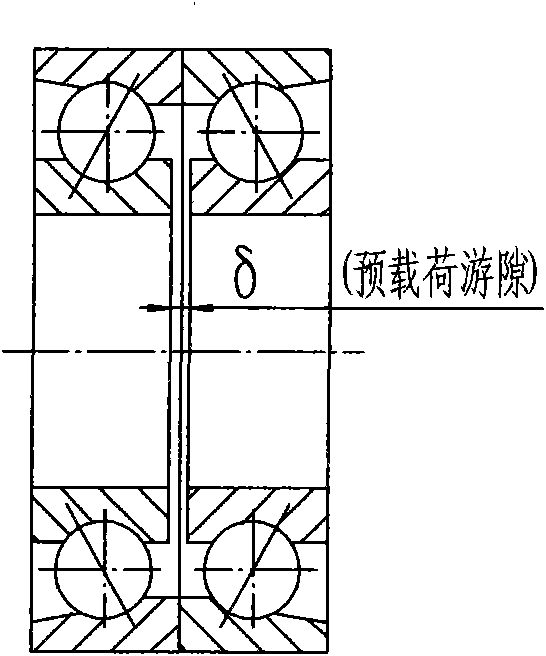

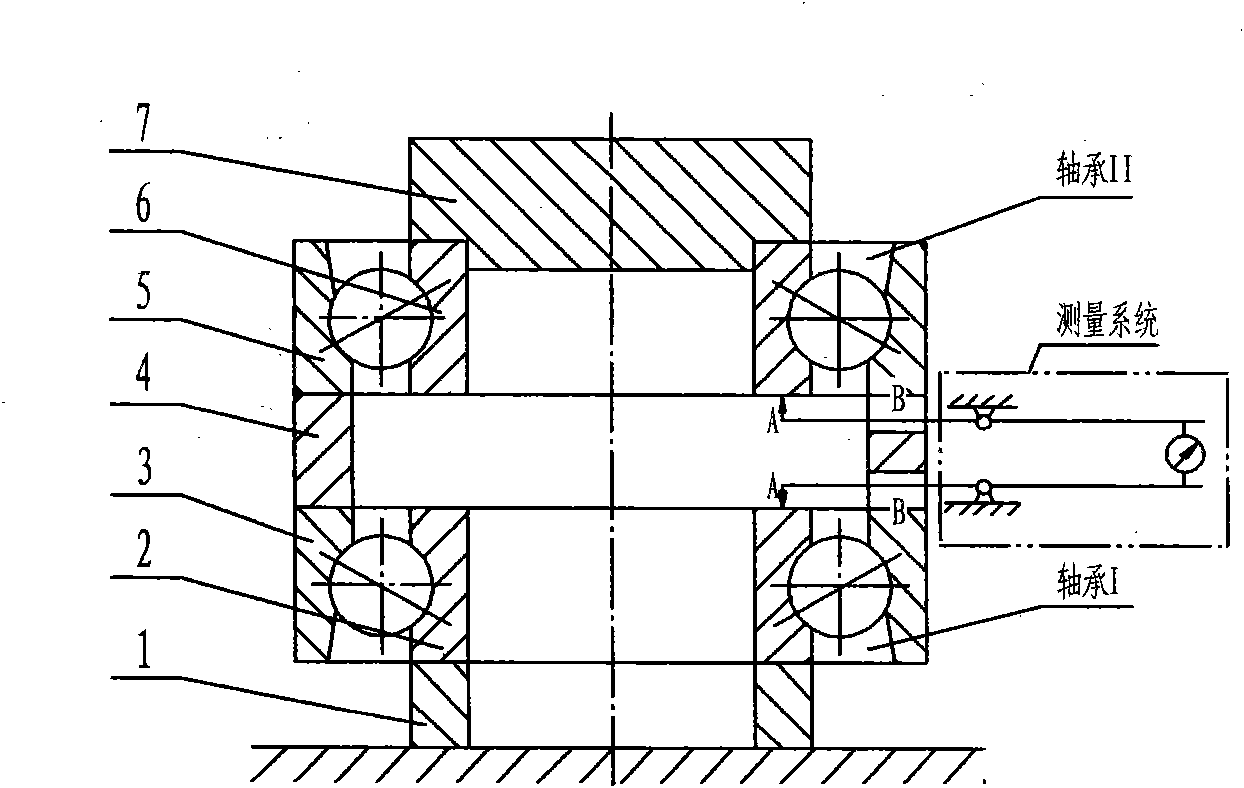

Method for measuring axial clearance and preload clearance of back-to-back angular contact ball bearings

InactiveCN101922906AEliminate the effects ofGuaranteed accuracyMechanical clearance measurementsBall bearingEngineering

The invention discloses a method for measuring the axial clearance or the preload clearance of back-to-back angular contact ball bearings, which comprises the steps of firstly manufacturing an outer ring spacer bush (4), a gasket (1), an inner diameter load block (7) and a measurement system and then correcting measurement instruments, wherein the inner ring (2) of a bearing I is arranged on the gasket, the bearing I and a bearing II are arranged on the outer ring spacer bush back to back, the inner diameter load block is arranged in the inner ring (6) of the bearing II; and during the correction of instruments, one end of each of the two equilong levers, which is provided with a right-angle measuring head, extend into an inner ring space bush through each notch groove of the inner ring spacer bush. During the measurement, the inner diameter load block of a balance weight applies axial load to the bearing I and the bearing II, the two right-angle measuring heads respectively align to the center points A and B of the bearing I and the bearing II, wherein A-B=delta, if the delta is a negative value, the bearing I and the bearing II are in axial clearance, and if the delta is a positive value, the bearing I and the bearing II are in preload clearance. The invention has the advantages of simple operation, no complicated conversion for obtaining measurement result, visually readable values A and B, and no conversion and cumulative errors.

Owner:LUOYANG BEARING RES INST CO LTD

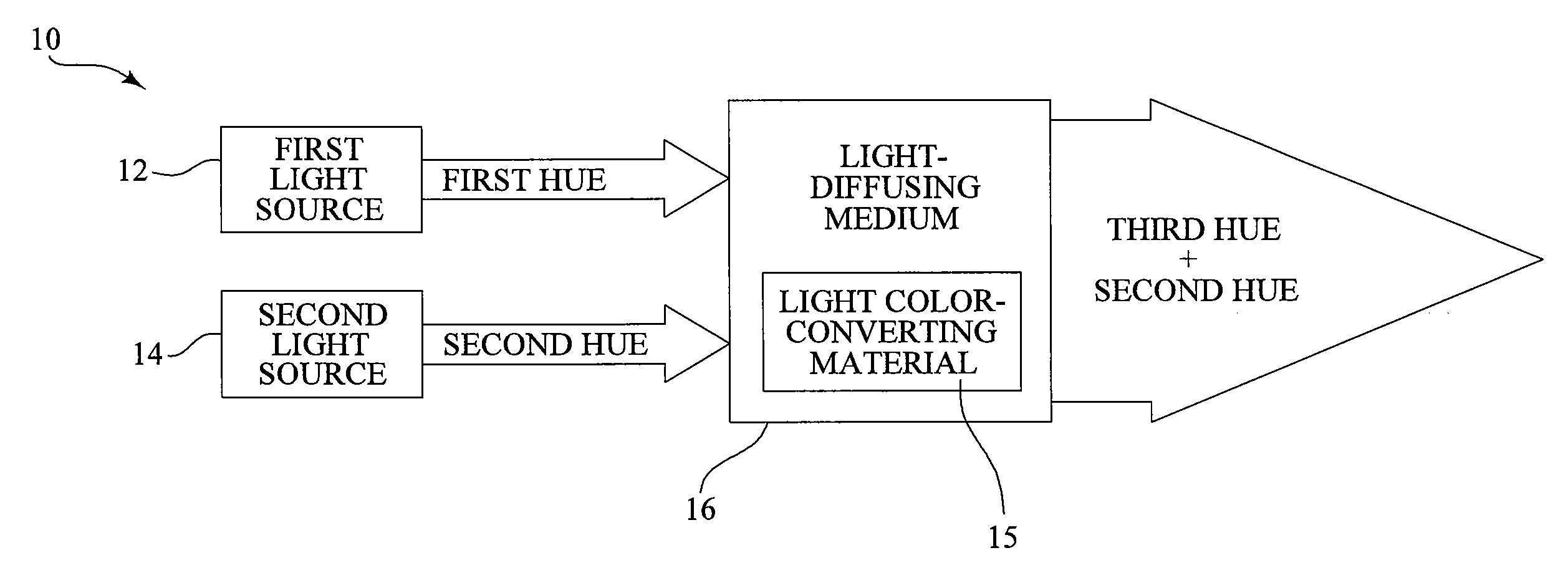

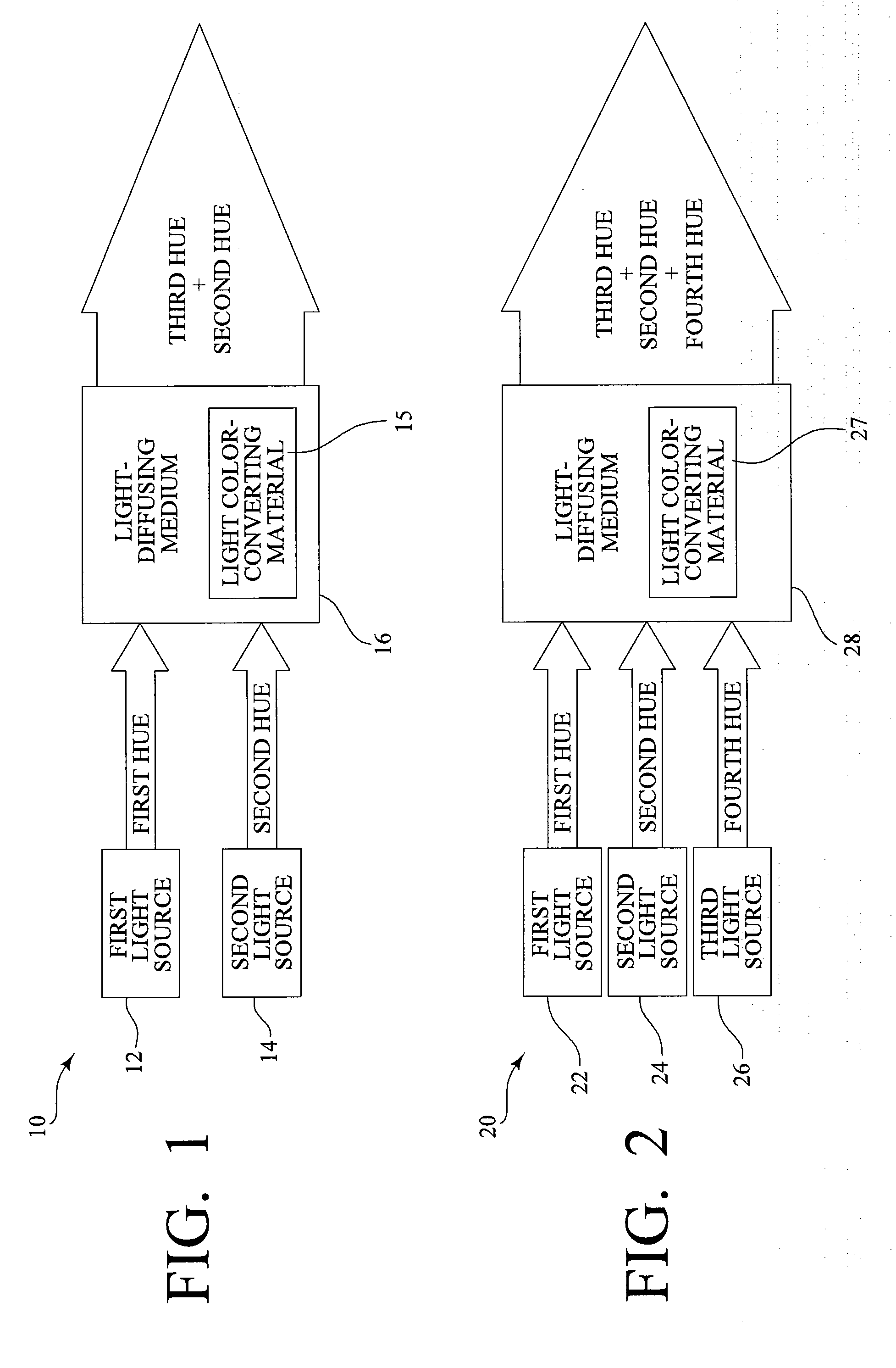

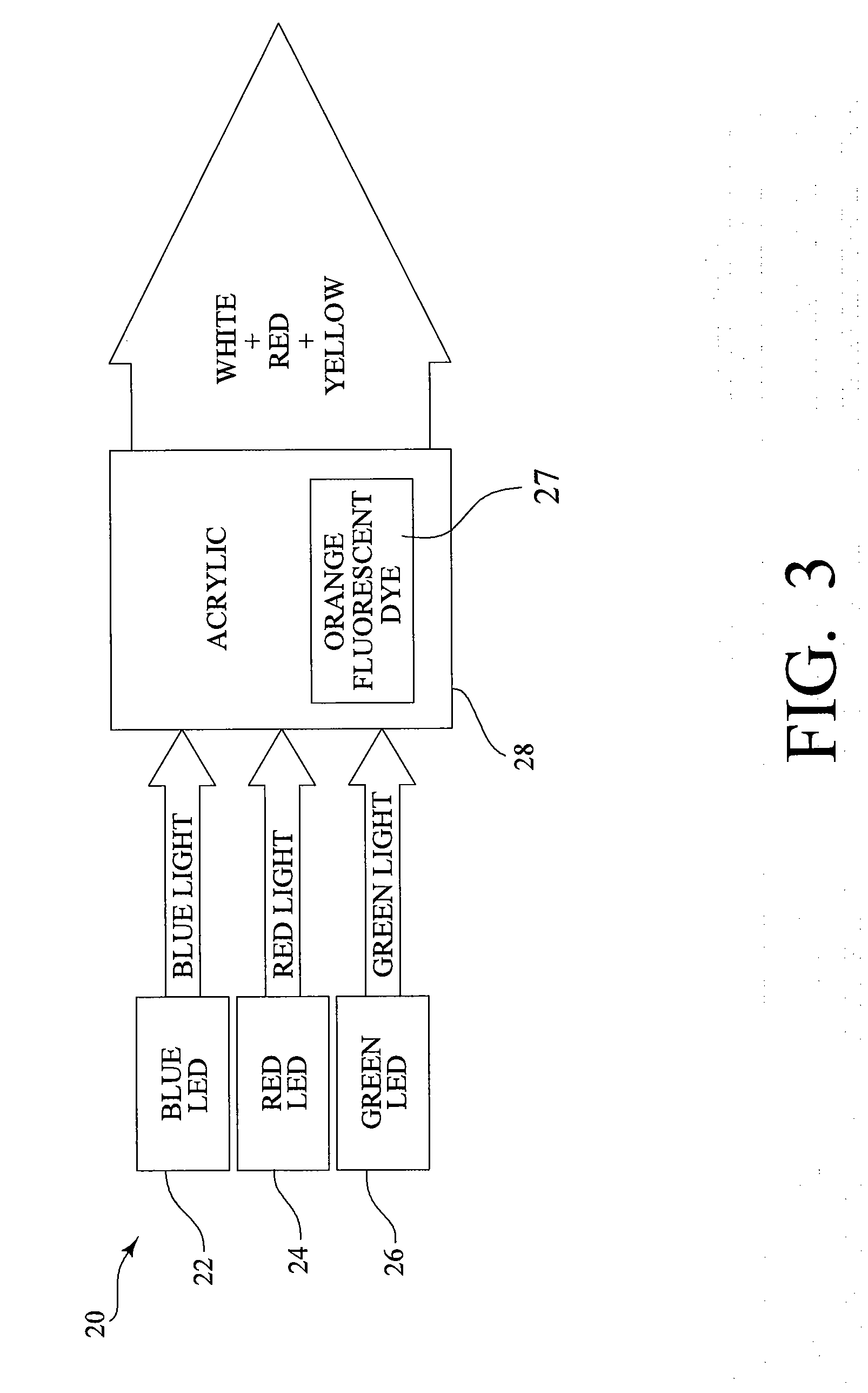

Illumination device with hue transformation

InactiveUS20070133204A1Easy to tuneReadily transformed and tunedNon-electric lightingPoint-like light sourceRelative intensityOptoelectronics

An illumination device includes a first light source, a second light source, and a light-diffusing medium. The first light source emits light of a first hue, and the second light source emits light of a second hue. The light-diffusing medium receives light emitted from the first and second light sources. The light-diffusing medium is composed of a light-transmitting material and a light color-converting material. The light color-converting material is selected to convert the light of a first hue into a light of a third hue, and to pass the light of the second hue with substantially no conversion. The light-diffusing medium thus emits light of a perceived hue that is a combination of the light of the third hue and the light of the second hue. By adjusting the relative intensities of the light emitted by the first and second light sources, the perceived hue can be readily transformed or tuned.

Owner:ILIGHT TECH INC

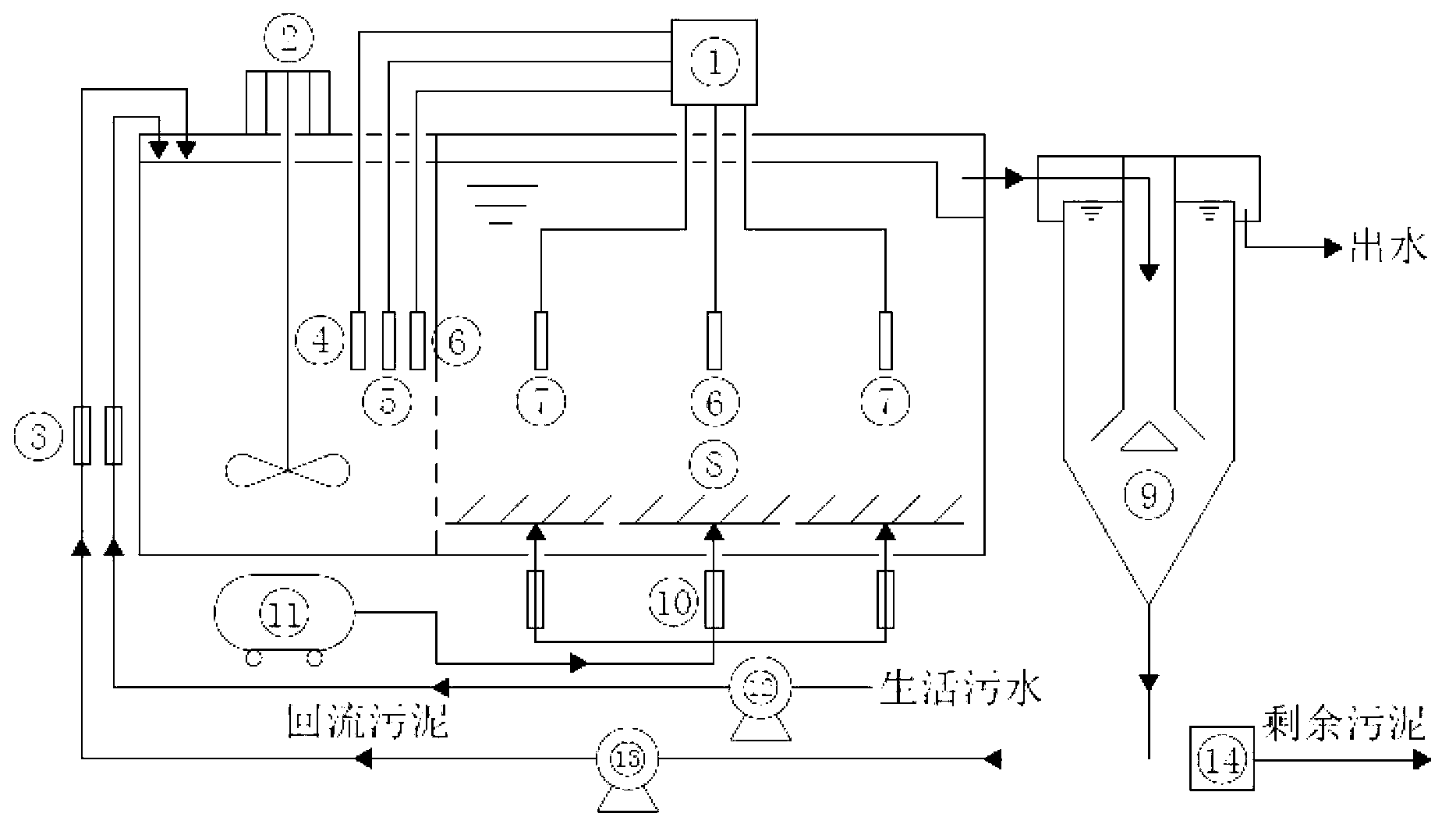

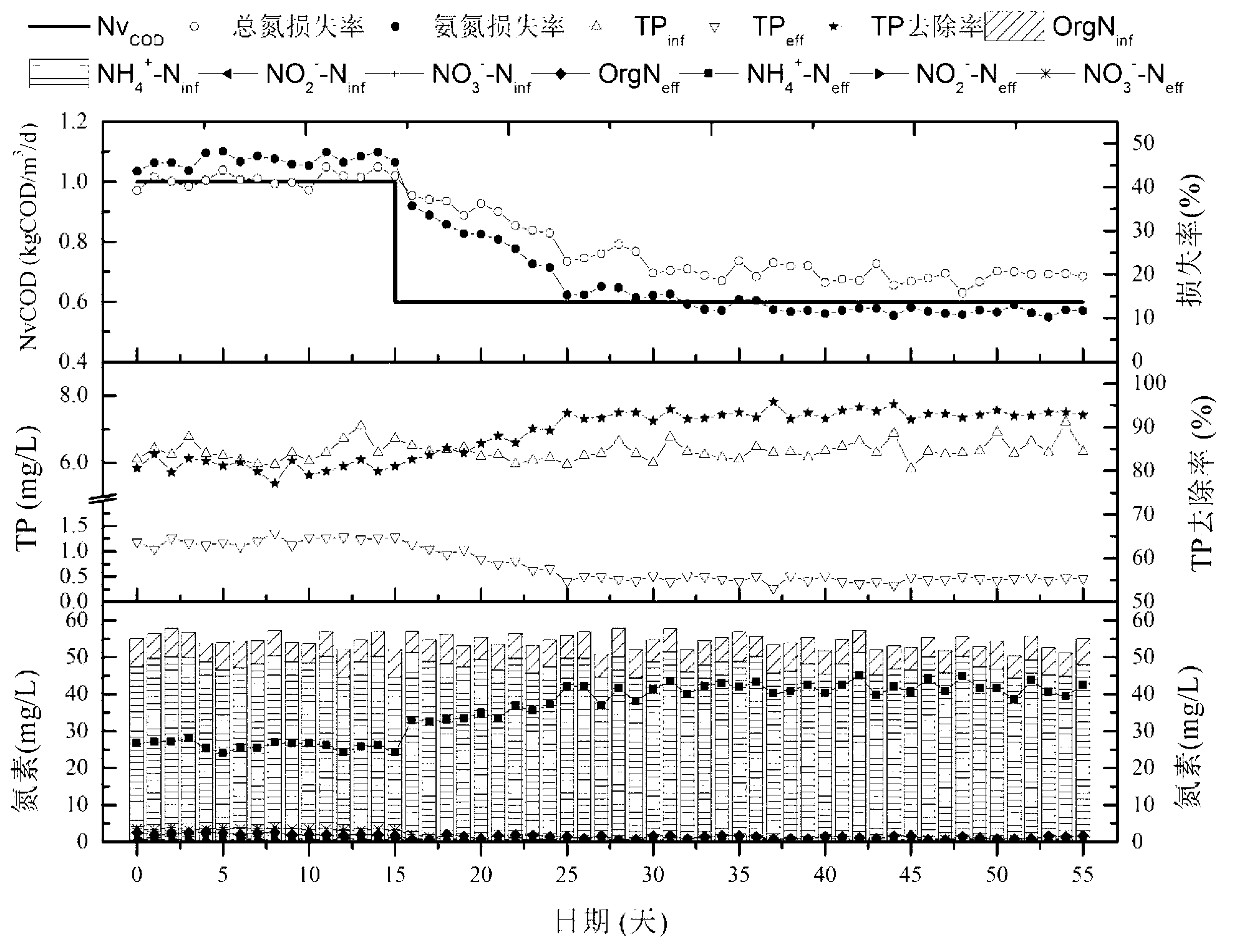

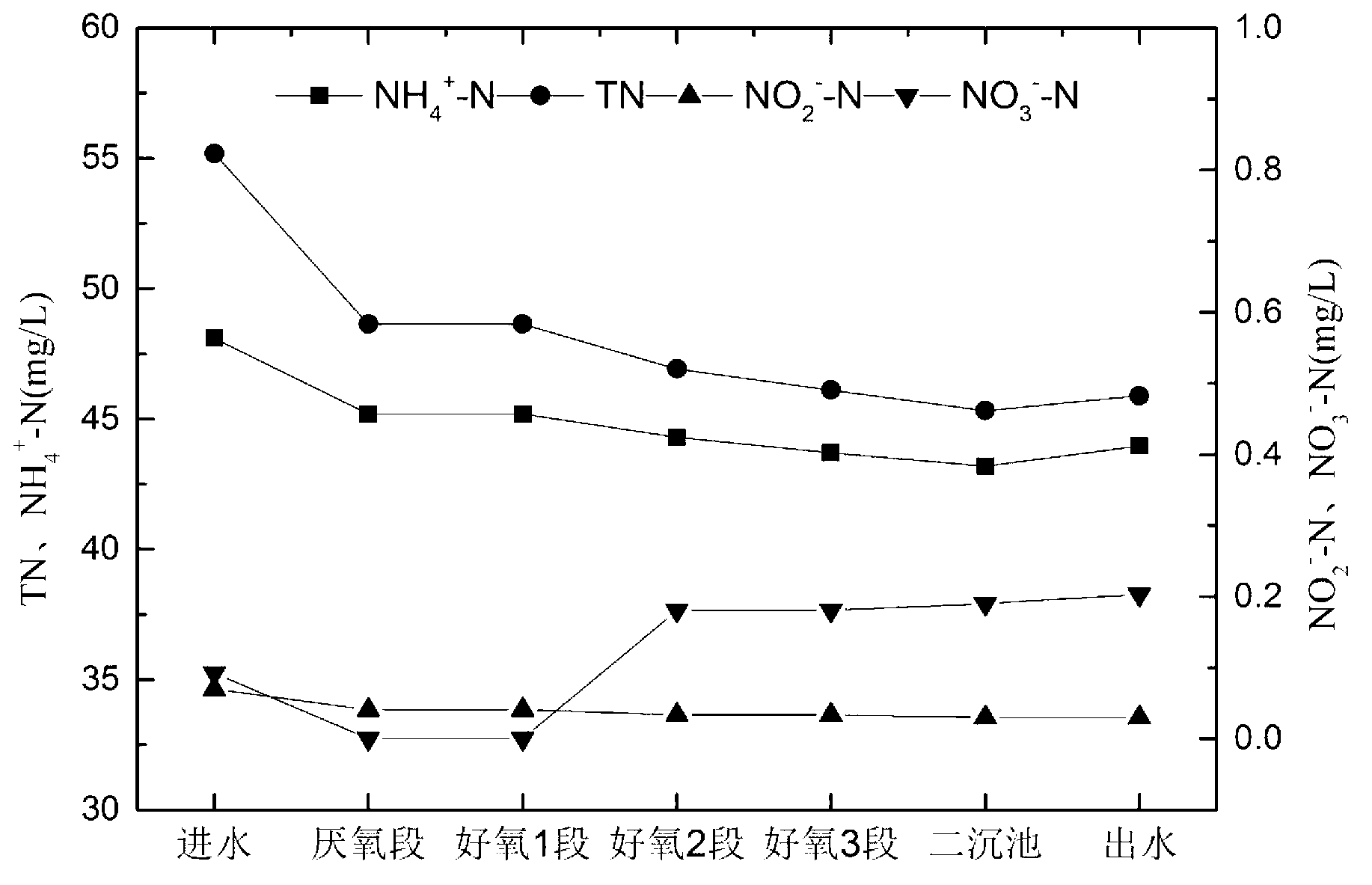

Anaerobic-aerobic process control method for efficient phosphorus removal and nitrogen reservation of municipal domestic sewage

ActiveCN103058375AEfficient phosphorus removalReduce lossesTreatment with aerobic and anaerobic processesLow nitrogenOxygen

An anaerobic-aerobic process control method for the efficient phosphorus removal and nitrogen reservation of municipal domestic sewage belongs to the municipal domestic sewage processing and recycling fields. A complete sewage regeneration flow represented by using anaerobic-aerobic processes to remove phosphorus and organic matters and using an autotrophic nitrogen removal technology to remove nitrogen is an effective approach for realizing the low-carbon and high-efficiency processing of the sewage; and the subsequent autotrophic nitrogen removal technology has no phosphorus removal function and treats ammonia nitrogen as inlet water, so the total phosphorus content of the outlet water of the anaerobic-aerobic process in the complete flow is less than 0.5mg / L and reaches a first order A standard, and nitrogen reservation, no conversion and low loss are reached. The anaerobic-aerobic process efficient phosphorus removal and low nitrogen operation is realized through treating the domestic sewage as base water, carrying out gradient oxygen limitation, strictly controlling the sludge age and inhibiting ammoxidation and denitrification through providing the anaerobic-aerobic process control parameters at different temperatures under a normal temperature condition.

Owner:BEIJING UNIV OF TECH

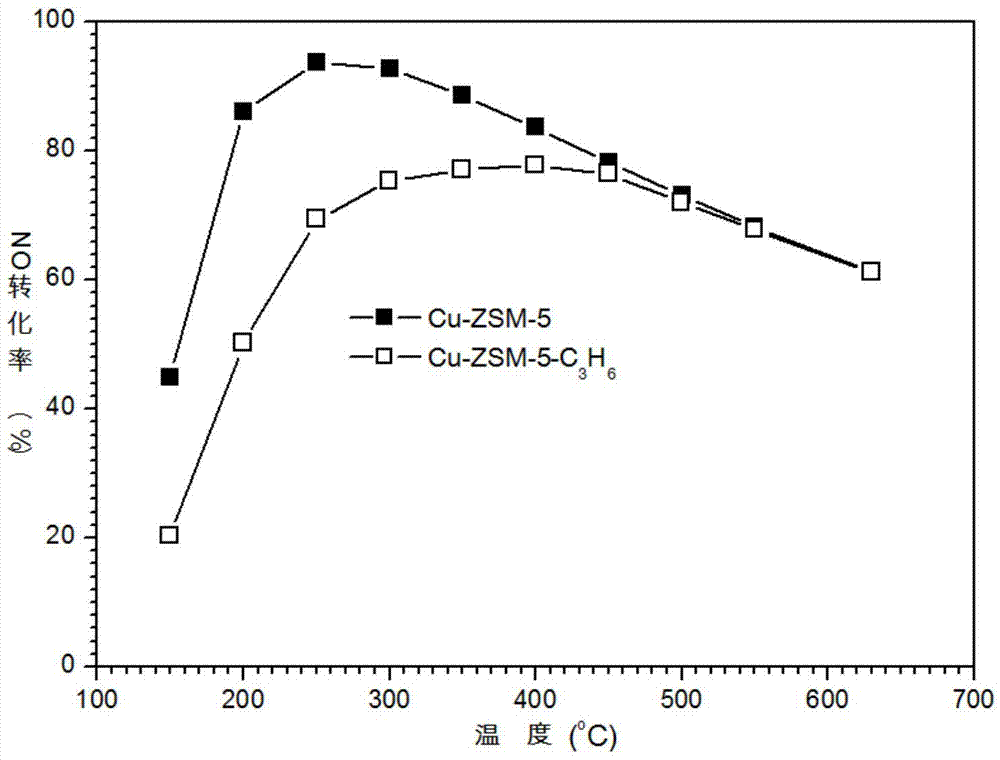

Catalyst for selective reduction of No by propylene in oxygen-rich condition and preparation method thereof

InactiveCN1762591ADispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsHydrothermal synthesisNitric oxide

The invention provides a catalyst for propylene to selective reduce NO on oxygen-enriched condition, which comprises: the La2O3-ZrO2-Al2O3 as complex carrier composed of 9-11% ZrO2, 3-5% La2O3 and 84-88% Al2O3; and 1-5wt% Cu2+ as active constituent. Wherein, the carrier is prepared by: synthesizing by hydrothermal method, dipping to modify by SO42-, drying, baking, dipping with Cu2+ solution, drying, and baking. This invention has NO conversion more than 84%, well moisture-proof and heat-proof properties and wide temperature operation range, and provides a practical approach to tail gas decontamination facility.

Owner:SHANTOU UNIV

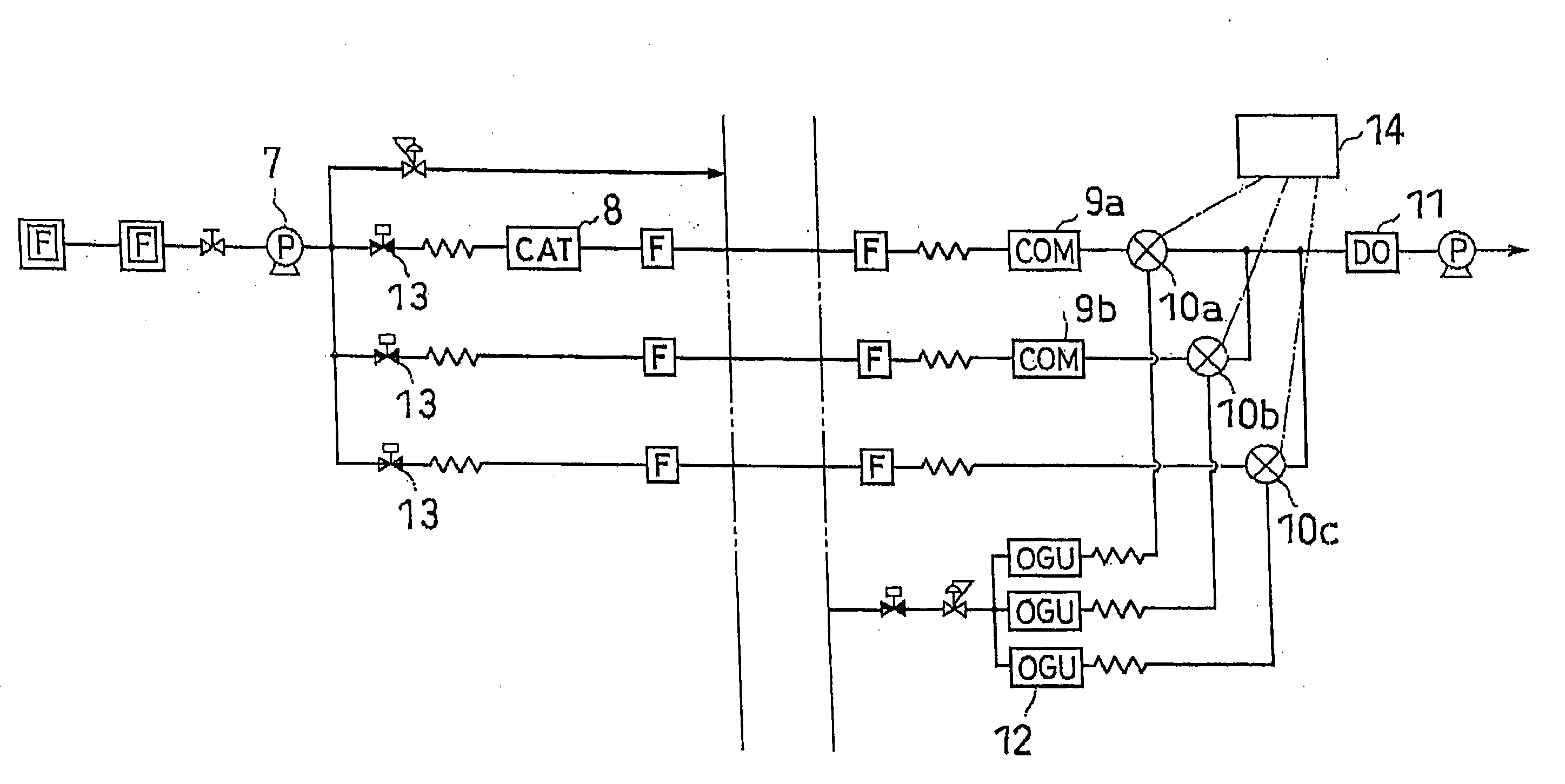

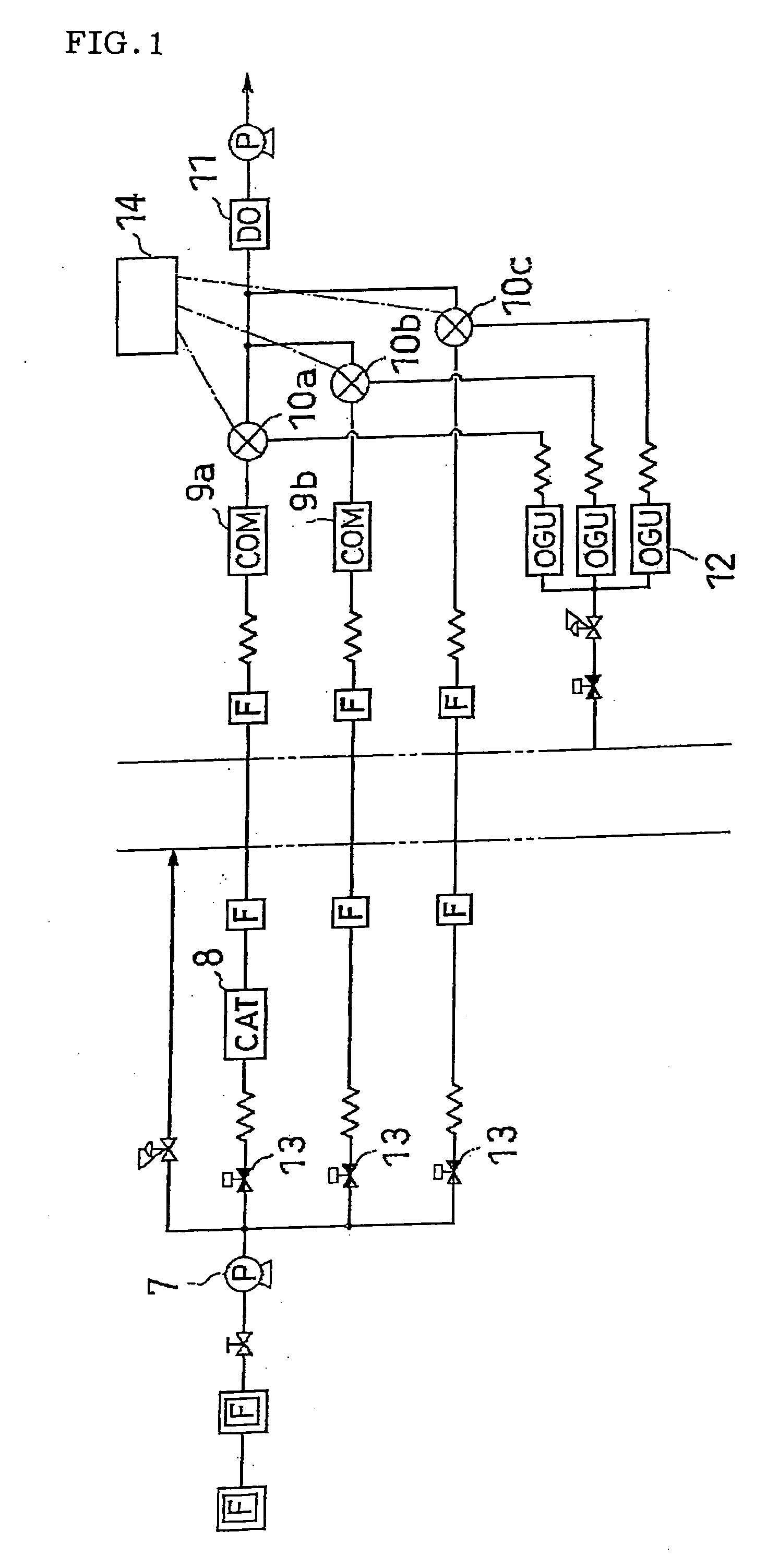

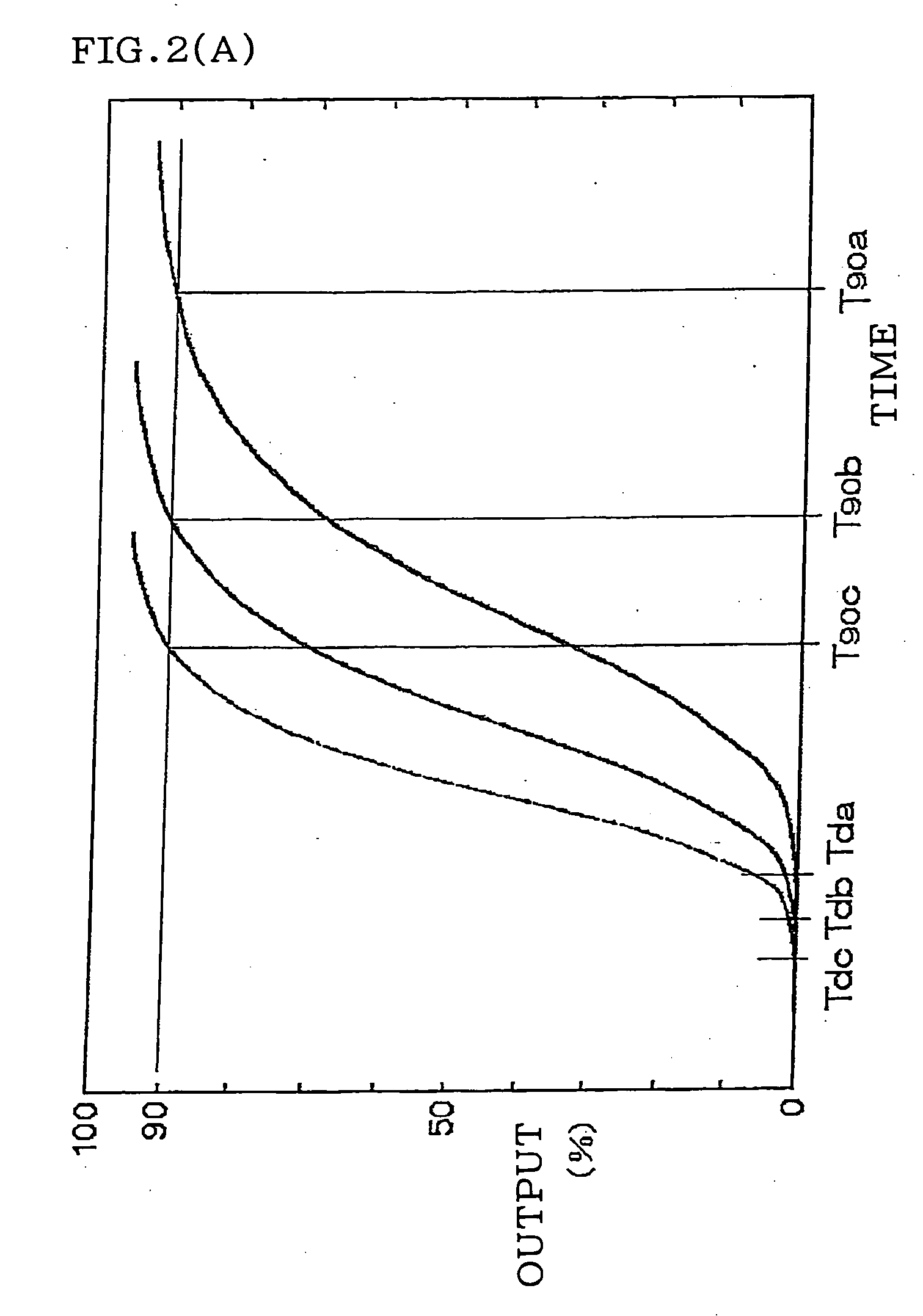

Concentration monitor of fluid samples

InactiveUS20060039826A1Heating fastHigh speed responseBiological testingParticle suspension analysisNitric oxideTreatment system

There is provided a nitrogen compound analyzer capable of easily and accurately measuring the two components NH3 and NO2 or each nitrogen compound component in a single sample. The nitrogen compound analyzer includes: a plurality of sample treatment systems by which a single sample is divided and which includes (A) a treatment system having oxidation means for oxidizing ammonia in the sample and conversion means for converting nitrogen dioxide in the sample to nitrogen monoxide, (B) a treatment system having conversion means for converting nitrogen dioxide in the sample to nitrogen monoxide, and (C) a treatment system in which no conversion treatment is performed on a specific component in the sample; changeover means capable of providing a specific combination of any of the treatment systems (A), (B) and (C); and at least one measurement means for continuously measuring nitrogen monoxide in the sample.

Owner:HORIBA LTD

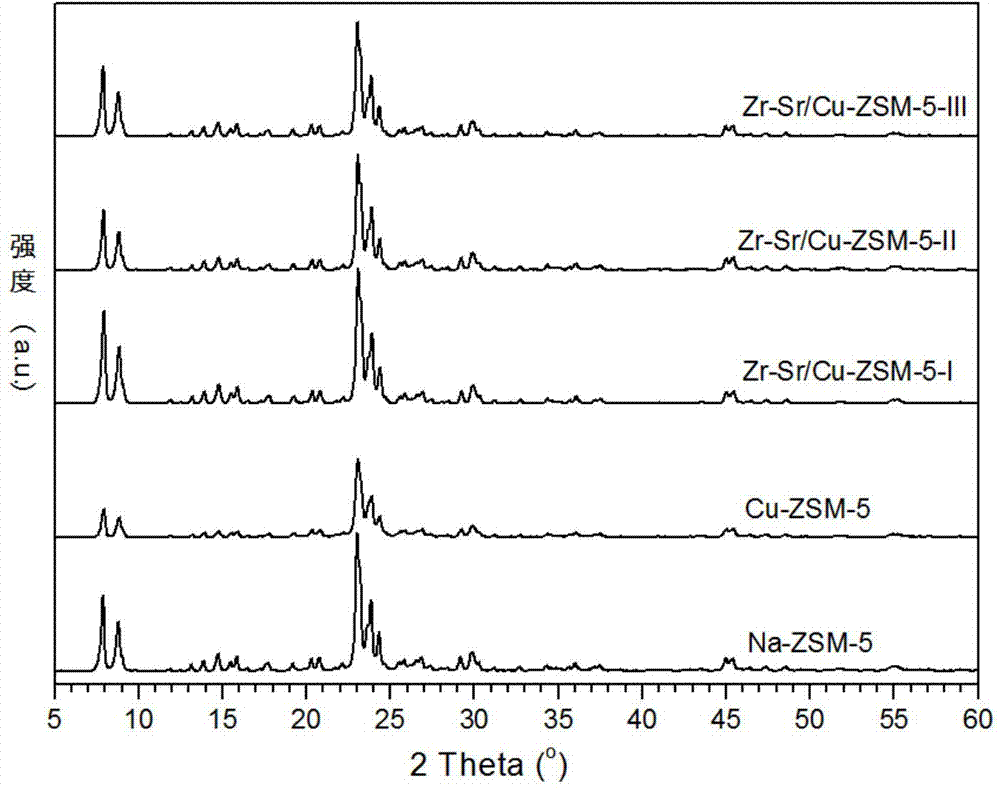

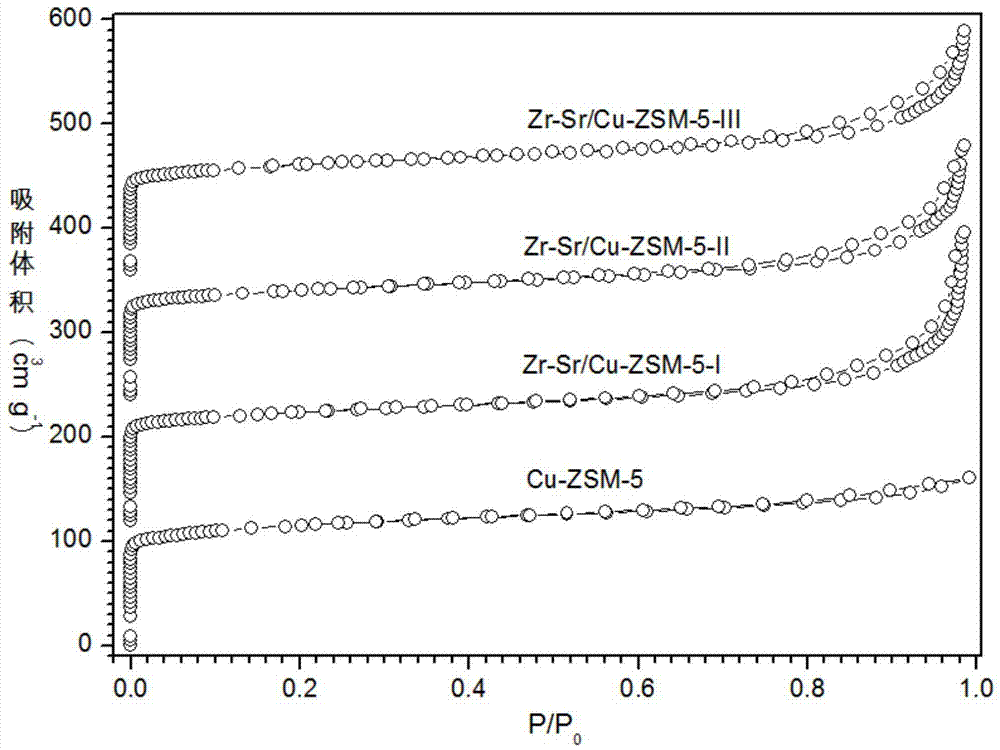

Preparation method and application of Cu-ZSM-5 doped Zr and Sr composite catalyst

InactiveCN104741143AHigh activityReduced activityMolecular sieve catalystsDispersed particle separationIon exchangeCopper

The invention provides a preparation method and an application of a Cu-ZSM-5 doped Zr and Sr composite catalyst. The composite Zr-Sr / Cu-ZSM-5 catalyst which is high in specific surface area (350-400m2 / g) is prepared by the following steps: exchanging a Na-ZSM-5 molecular sieve with NH4Cl to prepare an amino type NH4-ZSM-5 molecular sieve; then, adding a copper acetate solution to the NH4-ZSM-5 molecular sieve, preparing a Cu-ZSM-5 molecular sieve by virtue of an ion exchange method, and doping little Zr and Sr by virtue of an impregnation method. Within a relatively wide temperature range, the catalyst has a high catalytic elimination effect (NO conversion rate is 50-97%) for pollutants which are high in space velocity (120,000-360,000mL.(g.h)-1), high in O2 concentration (10-20vl%), high in H2O content (5-10wt%) and low in NO concentration (300-1000ppm). By adding a hydrocarbon compound (100-300ppm propylene) to a reaction system, the catalyst is high in anti-carbon-deposition performance.

Owner:BEIJING UNIV OF TECH

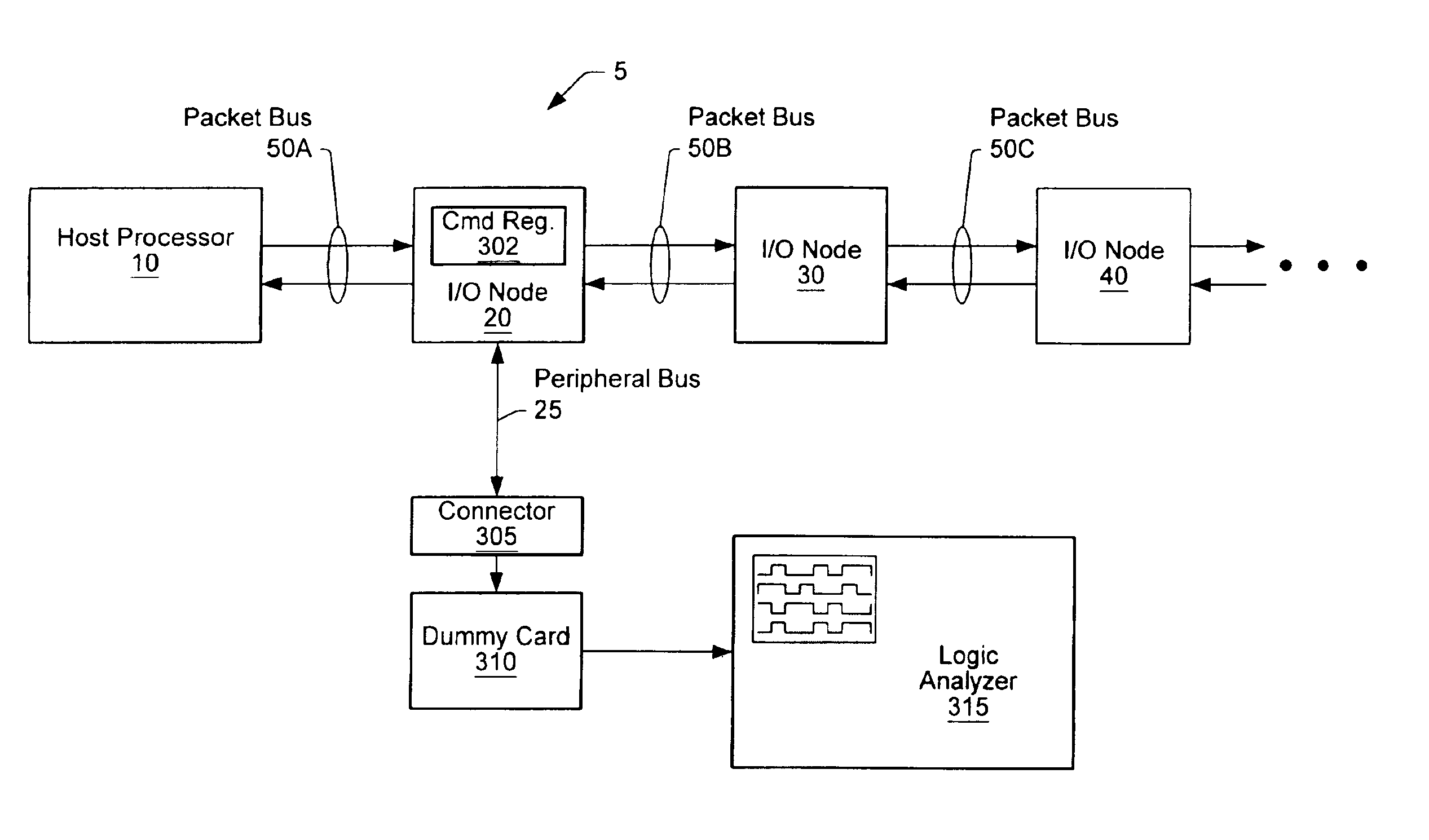

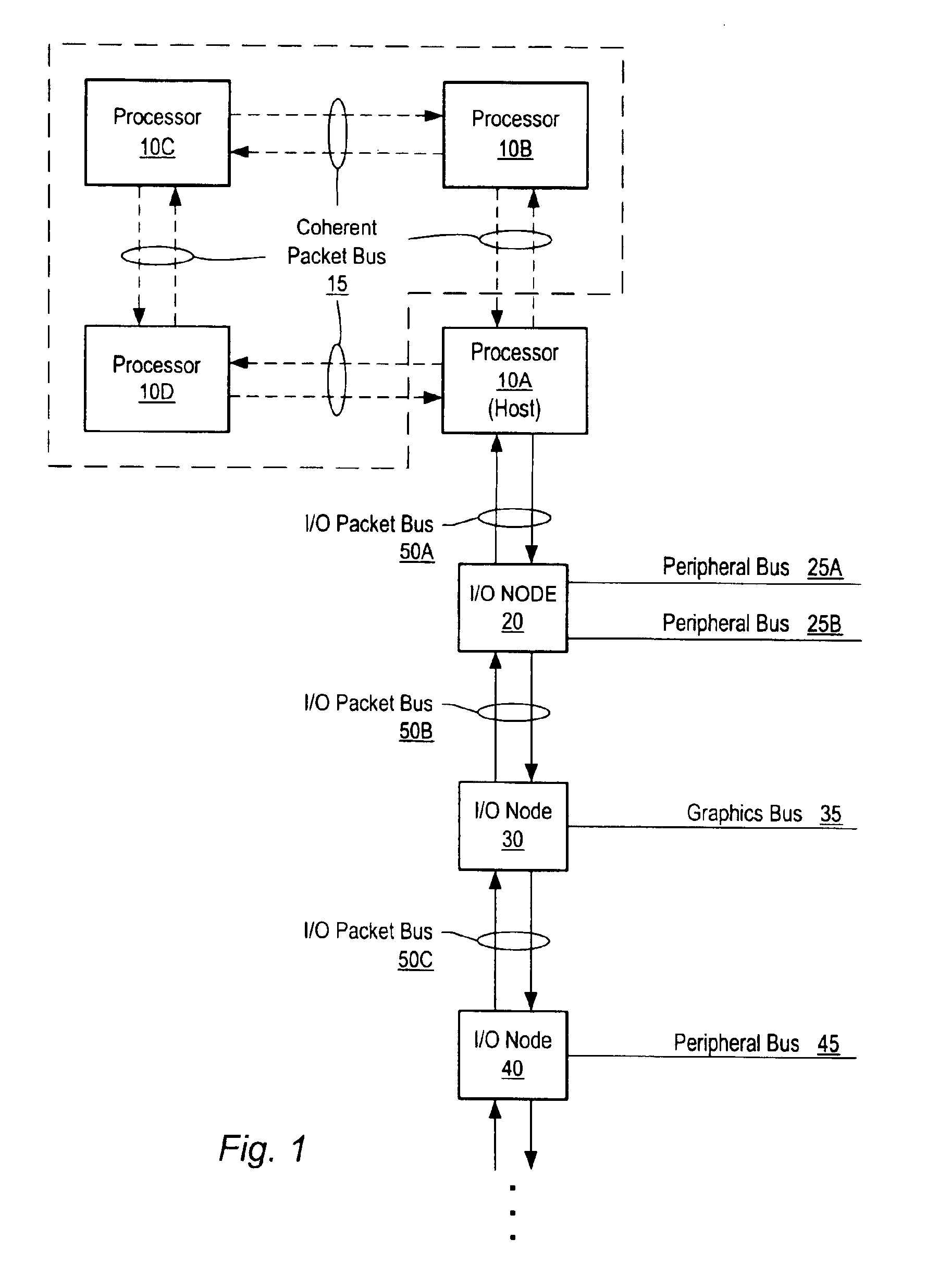

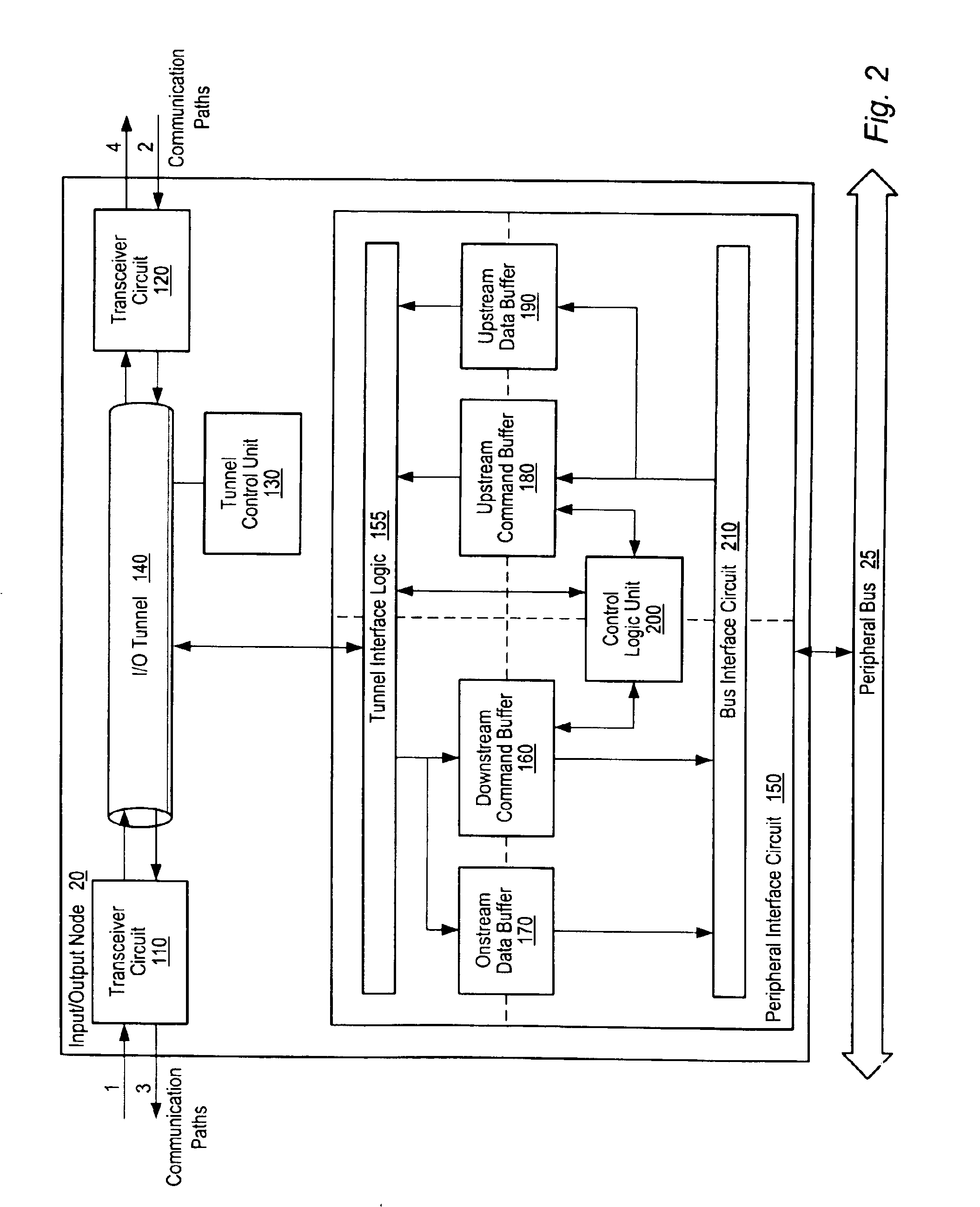

System and method for analyzing bus transactions

InactiveUS6862647B1Digital data processing detailsError detection/correctionSignal analyzerComputerized system

A system and method for observing transactions on a packet bus is disclosed. In one embodiment, a computer system includes a plurality of input / output (I / O) nodes serially coupled to a processor. Each of the I / O nodes may be configured to operate in a first (normal) mode, and a second (analysis) mode. During the normal mode, packets may be selectively conveyed through an I / O tunnel in the I / O node, and particular packets may be selectively conveyed to a peripheral bus interface in the I / O node. In the analysis mode, electrical signals corresponding to packets conveyed through the I / O tunnel may be replicated on a peripheral bus coupled to the peripheral bus interface. No conversion from the packet bus protocol to the peripheral bus protocol. A signal analyzer may be coupled to the peripheral bus, thereby allowing observation of the electrical signals.

Owner:ADVANCED MICRO DEVICES INC

Flue gas denitrification catalyst and preparation method thereof

InactiveCN104383912AStrengthen anti-sulfur and anti-water poisoning abilityIncrease concentrationDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWater vaporMolybdenum trioxide

The invention discloses a flue gas denitrification catalyst and a preparation method thereof. The flue gas denitrification catalyst comprises a carrier component TiO2, an active component CeO2 and an assistant MoO3, wherein the mass of the CeO2 accounts for 5-20wt percent of that of the TiO2, and the mass of the MoO3 accounts for 1-20wt percent of that of the TiO2. According to the flue gas denitrification catalyst, anatase type titanium dioxide is used as a carrier, and by adopting a sol-gel method, the active component cerium oxide and a cocatalyst molybdenum trioxide are loaded on the carrier. The catalyst is a selective reduction denitrification catalyst with the good activity, in a range of 300-450 DEG C, the NO conversion rate of more than 90 percent can be maintained and relatively high water-resisting and sulphur-resisting performances are obtained; at a temperature of 350 DEG C, after sulfur dioxide and water vapor are introduced for 7.5h, the NO conversion rate can be kept more than 80 percent, and after the introduction of the sulfur dioxide and the water vapor is stopped, the NO conversion rate is recovered to be 97 percent.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

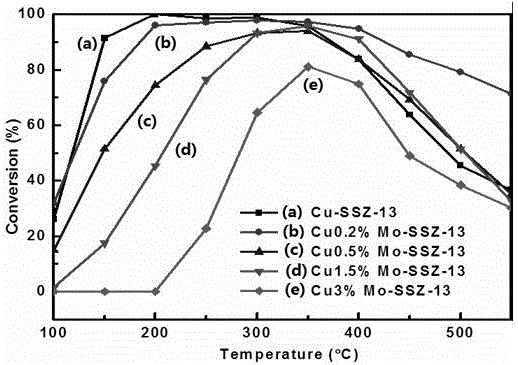

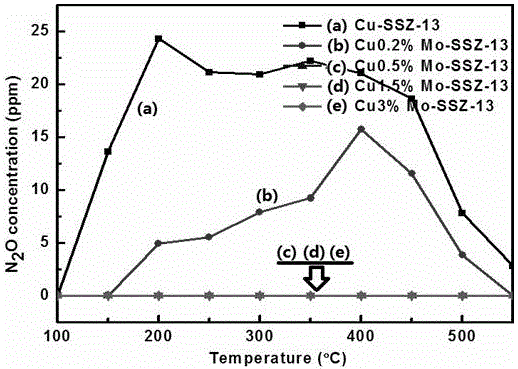

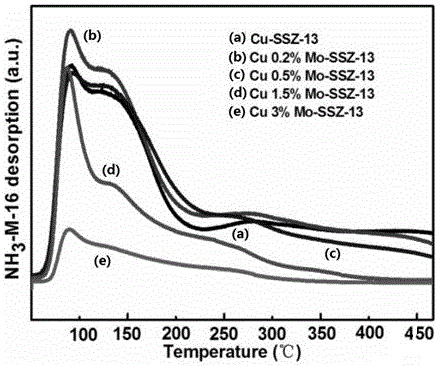

Preparation method of Mo modified Cu-SSZ-13 catalyst

InactiveCN106334577AEasy to prepareEasy to operateNitrous oxide captureGas treatmentActive componentCopper nitrate

The invention discloses a preparation method of a Mo modified Cu-SSZ-13 catalyst. Ammonium molybdate tetrahydrate and copper nitrate are taken as precursors and are directly dipped and loaded to an H-SSZ-13 (SiO2:Al2O3=10:1) molecular sieve. In the Mo modified Cu-SSZ-13 catalyst, the mass percent of Cu is 4 percent, and the mass percent of Mo is 0.2 to 3 percent. Active components are transition metal Cu<2+>, a Bronsted acidic locus and a Lewis acidic locus. The transition metal catalyzes the NO oxidation, and all the acidic loci take charge of ammonia activation. When the addition of Mo is 0.2 percent, a NO conversion rate temperature window is widened; when the addition of Mo is 0.5 percent or more, a NOx conversion rate temperature window is reduced. Through the adoption of the Mo modified Cu-SSZ-13 catalyst, the discharge of NOx can be reduced, and meanwhile the generation of a by-product N2O can be reduced.

Owner:NANCHANG UNIV

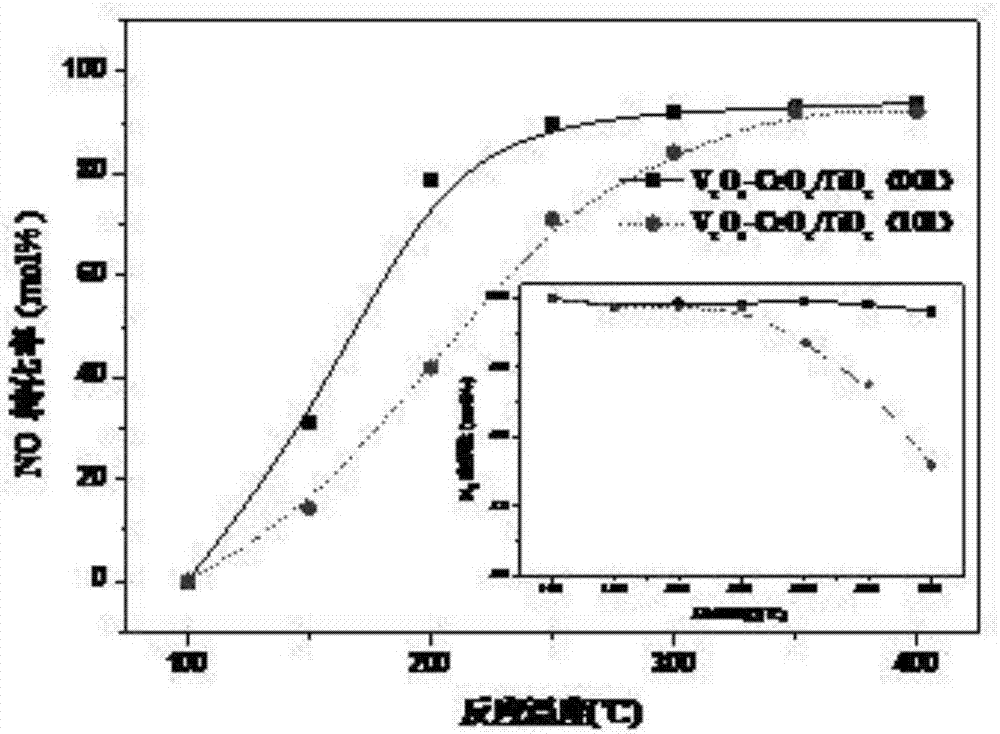

Catalyst for removing nitric oxide in flue gas under low temperature, and preparation method and application thereof

InactiveCN107413327AHigh selectivityGas treatmentHeterogenous catalyst chemical elementsFlue gasSulfur

The invention discloses a catalyst for removing nitric oxide in flue gas. The catalyst is a supported V2O5-CeO2 / TiO2 catalyst, the catalyst adopts anatase titanium dioxide of which a 001 crystal face is preferentially exposed as a supporter, Ce and V are supported in sequence by using an impregnation method, and the catalyst contains the following components in percentage by mass: 1 to 10 percent of CeO2 and 1 to 10 percent of V2O5. The catalyst has good denitration activity within medium and low temperature ranges (200 to 300 DEG C), the NO conversion ratio is up to 90 percent, the conversion ratio is nearly 100 percent, and the catalyst has good water resistance and sulfur resistance. The invention discloses a preparation method thereof.

Owner:NANJING UNIV

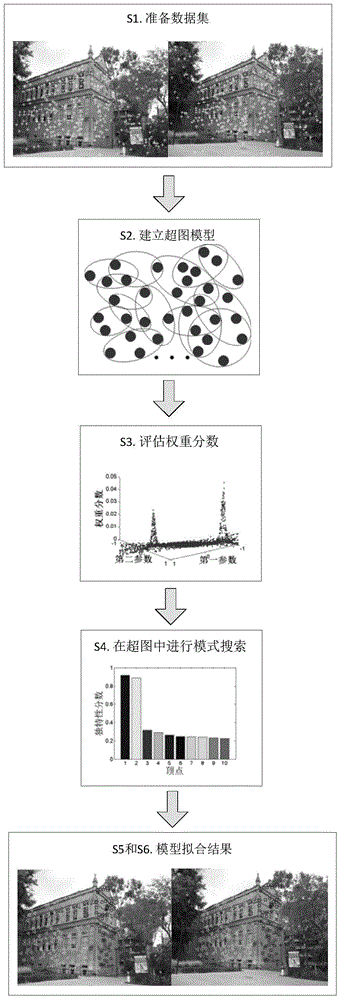

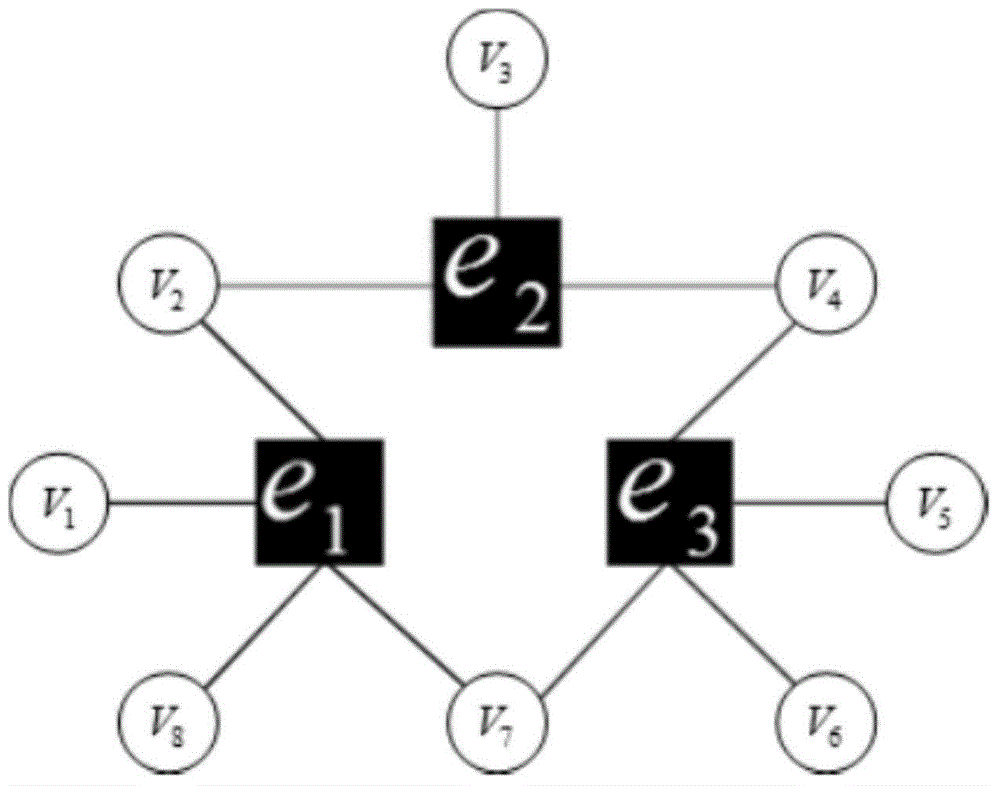

Robustness model fitting method based on supermap mode search

ActiveCN104835174AEfficient detectionReduce sensitivityImage enhancementImage analysisSearch problemData set

A robustness model fitting method based on supermap mode search relates to the computer visual technology; the method comprises the following steps: preparing a dataset; setting up a supermap model G-(V, E), one model assumption corresponds to one peak v of the supermap, and a data point corresponds to a super edge e, so each peak is connected with an inner point of the corresponding model assumption, i.e., the super edge; using a non-parameter kernel density estimation method to evaluate a weight fraction w (v) of each peak v, so a model fitting problem can be converted into a mode search problem in the supermap; providing mode search through searching weight peak in the supermap; determining inner points and parameters of each structure through searched mode and supermap model; cutting an image according to the parameters and inner points of each structure so as to complete model fitting. The robustness model fitting method can alleviate data distribution sensitivity, and the set supermap needs no conversion, and can be directly applied to mode search.

Owner:XIAMEN UNIV

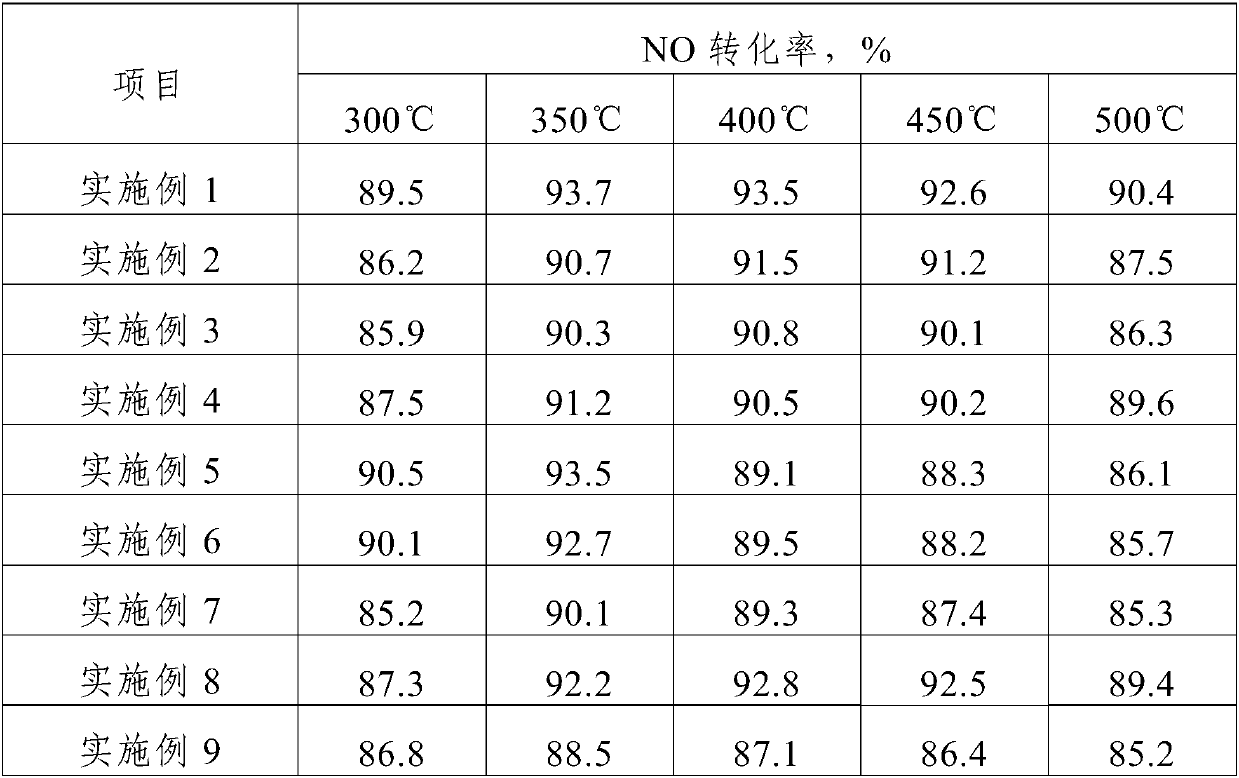

Preparation method of supported medium and high temperature denitration catalyst

InactiveCN107754849ANot easy to pulverizeExtended service lifeMolecular sieve catalystsDispersed particle separationMolecular sieveHot Temperature

The invention discloses a preparation method of a supported medium and high temperature denitration catalyst. The method comprises the following steps: 1, dissolving a soluble active metal component precursor salt and a soluble auxiliary metal component precursor salt into deionized water to obtain a transparent impregnation solution; 2, impregnating a molecular sieve carrier for 6h-24h, filtering, drying at temperature of 80-120 DEG C for 12h-24h to obtain a catalyst precursor; 3, putting the catalyst precursor in a heat treatment furnace, heating to 300 DEG C-400 DEG C, calcining while introduction of air for 1h-3h, heating up to 600-800 DEG C, calcining for 2h-6h, and cooling to obtain the supported medium and high temperature catalyst. The supported medium and high temperature denitration catalyst prepared by the method has high strength, is not easy to pulverize, has long service life, and has low catalyst bulk density. The catalyst has a NO conversion rate of 85% or more at a suitable application temperature of 300 to 500 DEG C.

Owner:XIAN ORIGIN CHEM TECH

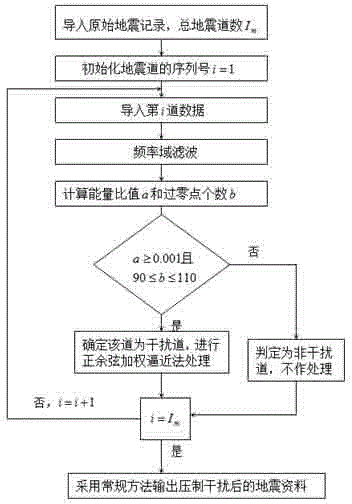

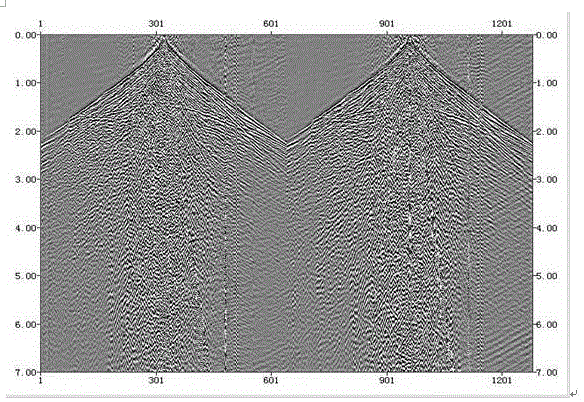

Method for automatically identifying and removing industrial interface based on dual factors

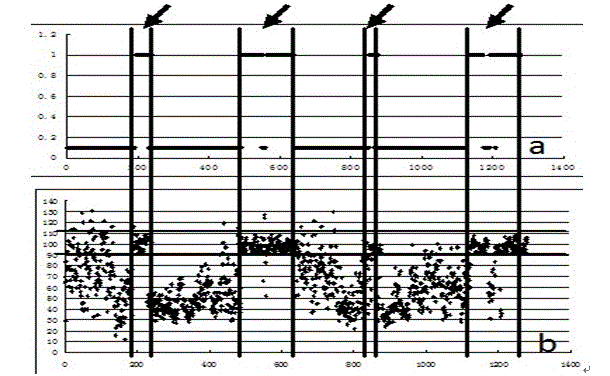

ActiveCN104570118AAvoid Effective Signal Fidelity IssuesImprove stabilitySeismic signal processingTime domainOriginal data

The invention discloses a method for automatically identifying and removing industrial interface based on dual factors. The method comprises the following steps: after seismic data are acquired, carrying out frequency domain filtering on each channel of data, respectively calculating energy A (y(t)) of a filtering result and energy A (x(t)) of original data, and dividing A (x(t)) by A (y(t)); if the ratio is greater than 0.001 and the filtering result passes through a zero point for 90-110 times within 1 s, judging that the channel has 50 Hz industrial interference, otherwise judging that no industrial interference exists; processing the channel with the industrial interference by a sine and cosine weighing approach method to obtain seismic data subjected to interference removal. According to the method, the industrial interference is detected and suppressed within a time domain of original shot data, so that no conversion to a detection point or a frequency domain is needed, and the time and the space are greatly saved; furthermore, only records with the interference are processed, so that the signal-to-noise ratio of the seismic data can be effectively increased, and the method is an efficient fidelity processing technology.

Owner:CHINA PETROLEUM & CHEM CORP +1

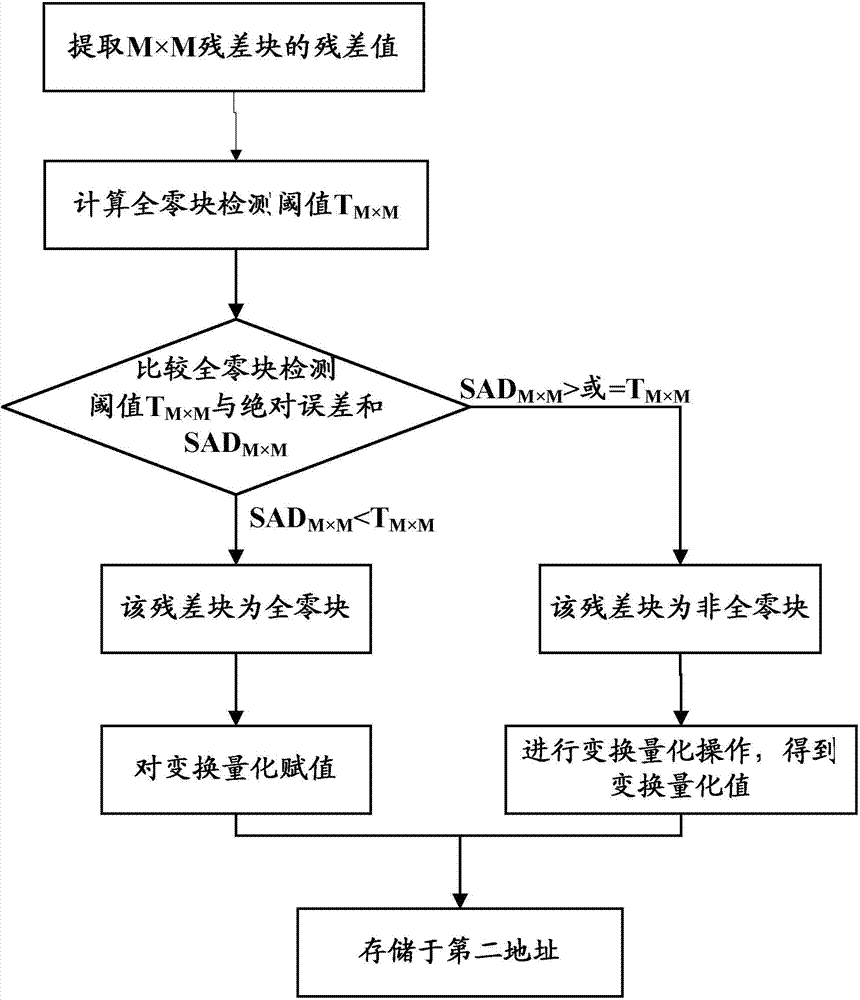

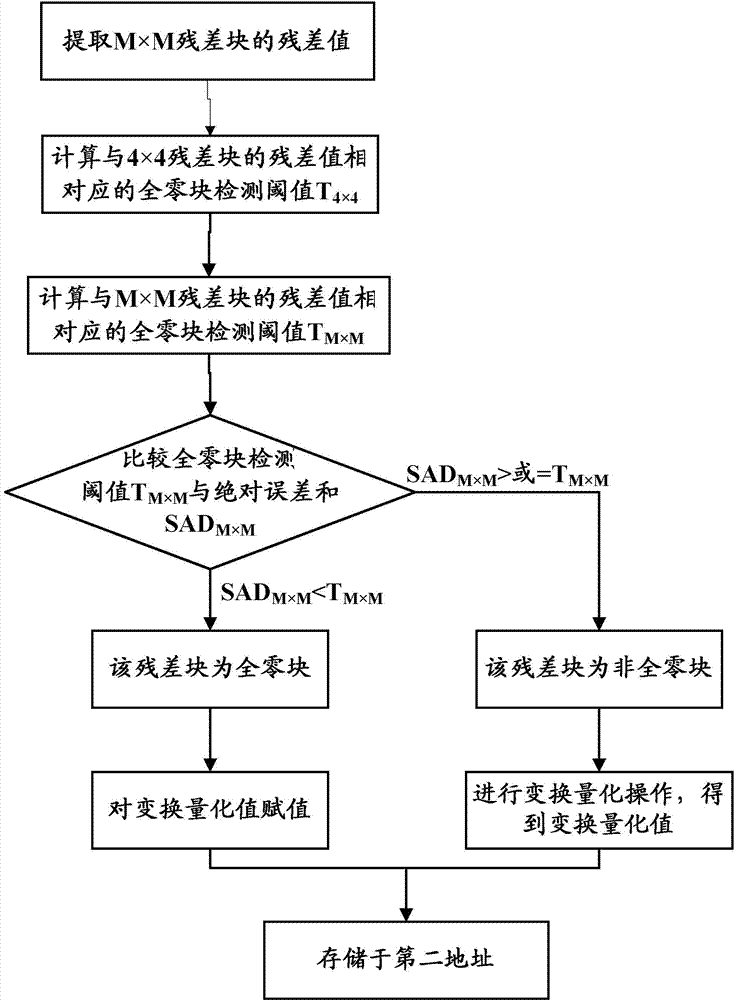

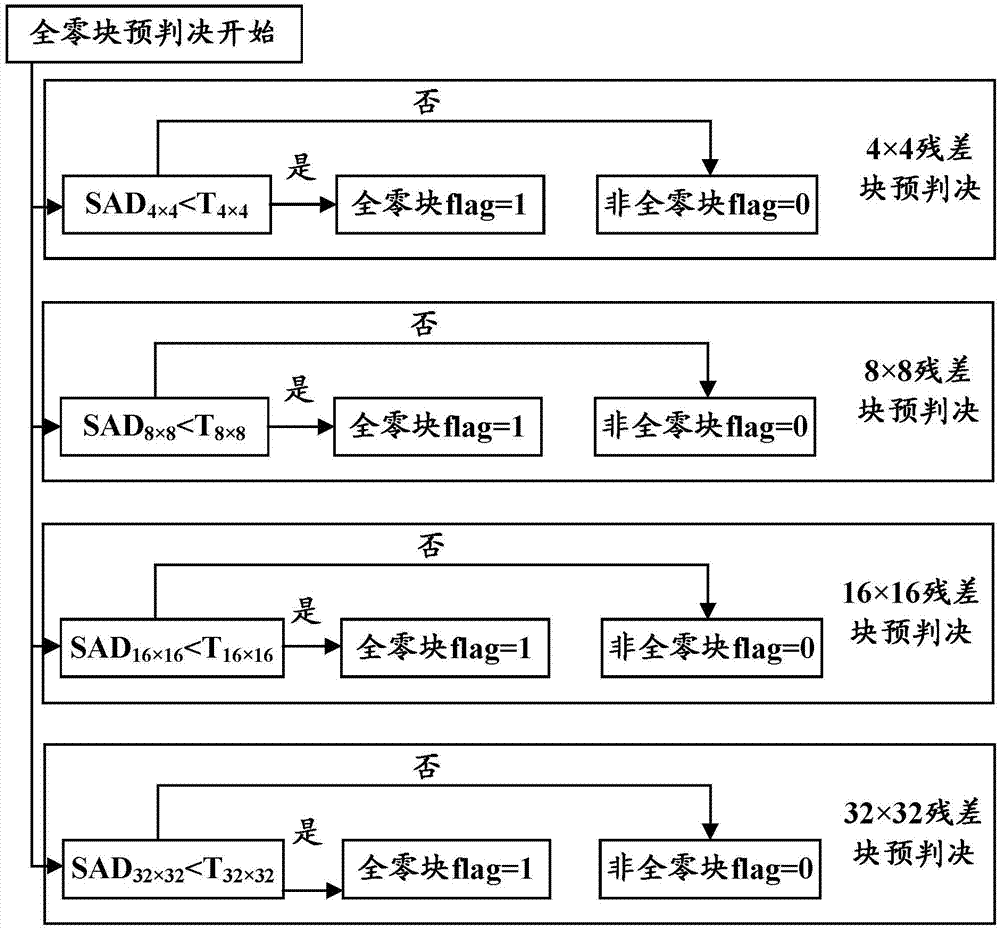

A conversion quantification method is HEVC video coding and a video coding device

InactiveCN104247418AReduce operational complexityAvoid transform and quantization operationsDigital video signal modificationVideo encodingTheoretical computer science

The invention relates to a conversion quantification method is HEVC video coding and a video coding device. The method comprises the steps of detecting a residual value of an M*M residual block generated in computing of original image data and interframe forecast image data from a first address; computing an all-zero-block detection threshold value T[M*M] corresponding to the residual value; comparing the computed all-zero-block detection threshold value T[M*M] with an absolute error of the residual value and SAD[M*M]; if SAD[M*M] <T[M*M], the M*M residual block is an all-zero-block, and the residual value of the M*M residual block is subjected to conversion quantization value assignment and then stored at a second address; otherwise, the M*M residual block is not an all-zero-block; the residual value of the M*M residual block is detected from the first address and subjected to conversion quantization operation; and then a conversion quantization value is stored at a second address. During HEVC video coding, the residual value which is the all-zero-block is directly skipped, and no conversion quantization operation is carried out on the all-zero-block, so that the computing complexity degree is lowered; the coding efficiency is raised; and the coding time is reduced.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

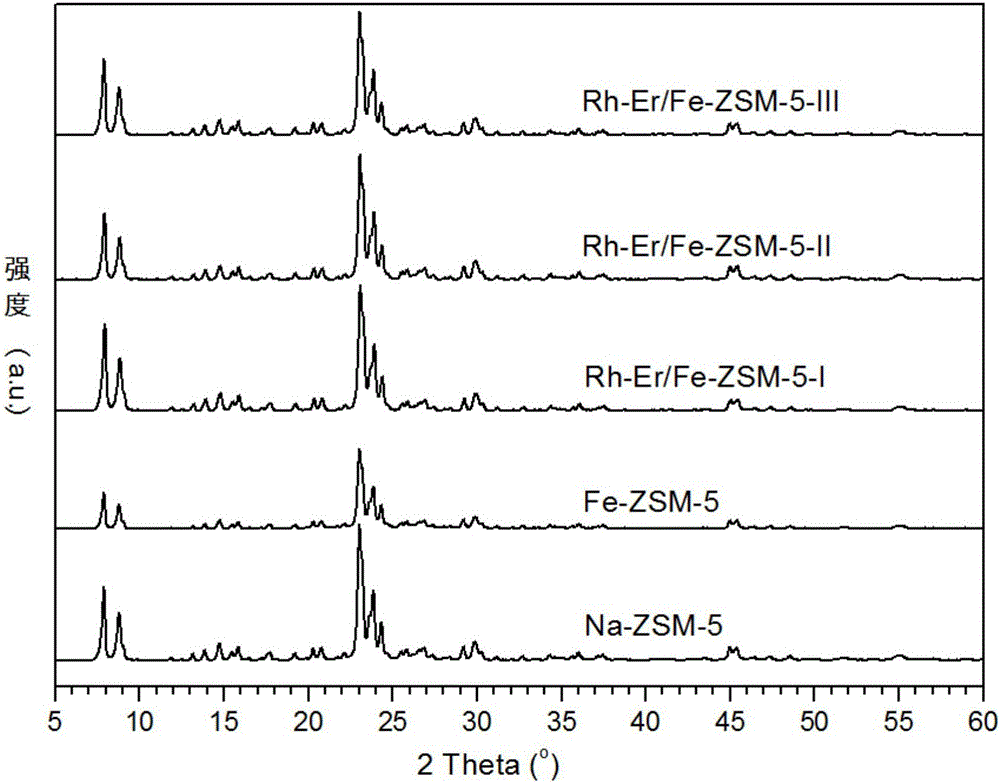

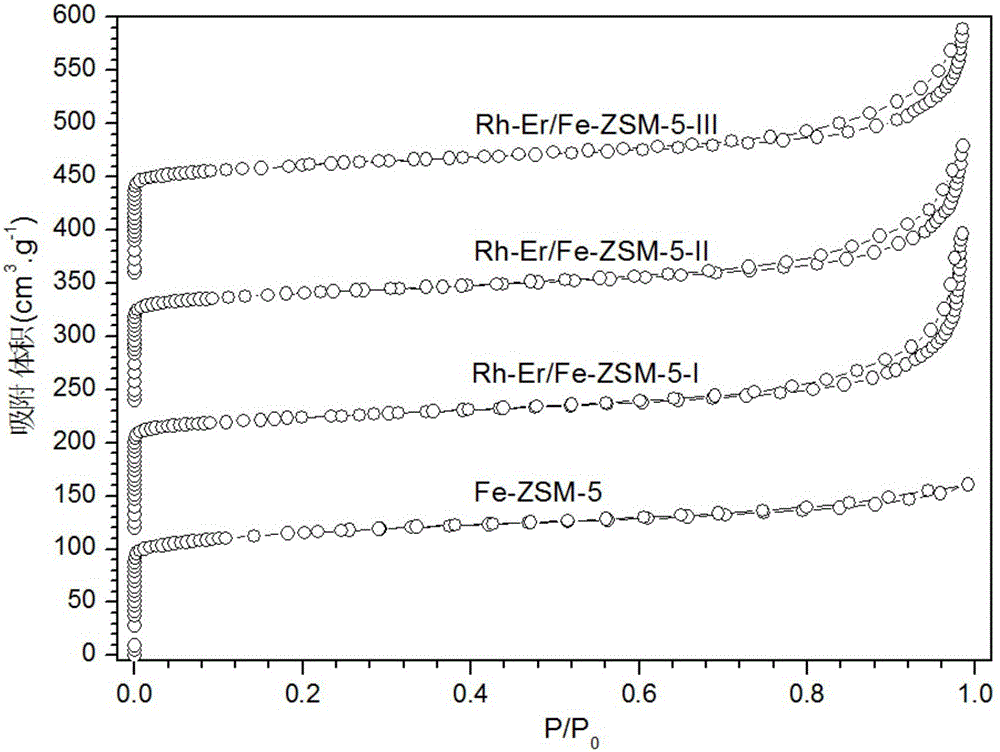

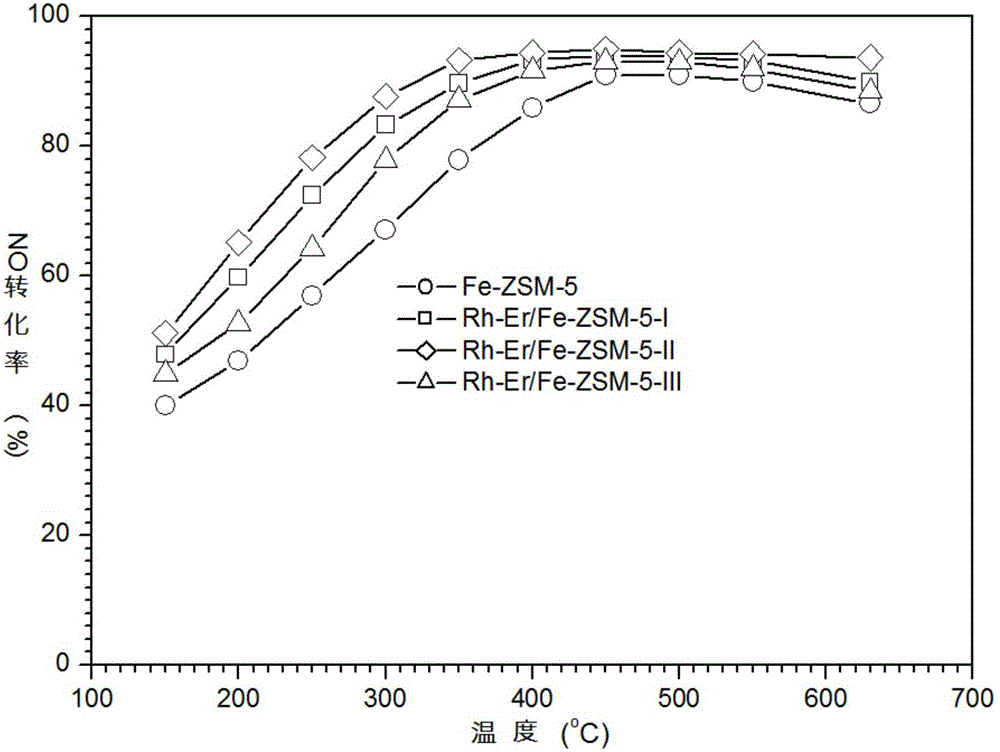

Preparation method and application of Fe-ZSM-5 doped Rh and Er composite catalyst

InactiveCN105964292AImprove stabilitySimple preparation processGas treatmentMolecular sieve catalystsIon exchangeSilicon

The invention provides a preparation method and application of a Fe-ZSM-5 doped Rh and Er composite catalyst. The preparation method comprises the following steps: preparing a sodium type high-silicon-aluminum-rate Na-ZSM-5 molecular sieve by virtue of a hydrothermal method, exchanging the sodium type high-silicon-aluminum-rate Na-ZSM-5 molecular sieve and NH4Cl to prepare an ammonium type NH4-ZSM-5 molecular sieve, adding the NH4-ZSM-5 molecular sieve into a ferric nitrate solution, preparing a Fe-ZSM-5 molecular sieve by virtue of an ion exchange method, and doping a small amount of Rh and Er to prepare a high-silicon-aluminum-rate (350 to 420m<2> / g) composite Rh-Er / Fe-ZSM-5 catalyst by virtue of an impregnation method. The prepared catalyst has good catalytic removal effects (NO conversion rate of 45 to 95 percent) on high-airspeed, high-O2-concentration, high-H2O-content and low-NO-concentration (300 to 1,000ppm) pollutants within a wider temperature (150 to 650 DEG C) range. Moreover, the initial NO conversion rate of the catalyst within 100 hours within the wide temperature range (150 to 650 DEG C) is maintained.

Owner:BEIJING UNIV OF TECH

Platinum-bismuth catalysts for treating engine exhaust

InactiveUS7605109B1Improve oxidation capacityQuantity minimizationGas treatmentInternal combustion piston enginesParticulatesPlatinum

An engine exhaust catalyst containing precious metal nanoparticles is promoted with bismuth. The bismuth promotion improves the catalyst's CO oxidation performance. Also, by varying the amount of bismuth that is added, the NO conversion rate that can be realized with the catalyst can be controlled. The control over the NO conversion rate is important because the passive regenerative performance of a particulate filter used in engine exhaust systems is based on the amount NO2 that is present in the exhaust stream that reaches the particulate filter. The amount of NO2 being produced needs to be optimized (not necessarily maximized) so that adequate particulate filter regeneration performance can be maintained while avoiding unused, toxic NO2 from being exhausted into the atmosphere.

Owner:SHUBIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com