Catalyst for selective reduction of No by propylene in oxygen-rich condition and preparation method thereof

A catalyst and condition technology, which is applied in the preparation field of the above-mentioned catalyst, can solve the problems of low activity of the supported copper catalyst and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Example 1: Cu / Al 2 o 3 The catalytic effect of the catalyst

[0026] Al 2 o 3 Preparation of supported copper catalyst:

[0027] 1. Al(NO 3 ) 3 9H 2 O was made into a 0.5 mol / L solution with deionized water, placed in a 50°C water bath and continued to stir, slowly dripped ammonia water until the solution pH ≈ 9, continued to stir at constant temperature for 2 hours, and aged at room temperature for 12 hours. Then suction filter, dry, and bake at 600°C for 4 hours to obtain Al 2 o 3 .

[0028] 2. The Al prepared above 2 o 3 With 0.62mol / L Cu(NO 3 ) 2 solution immersion for 24 hours, so that the Cu 2+ The loading amount is 3%, dried at 80°C for 6 hours, and then calcined at 500°C for 2 hours to obtain Al 2 o 3 Supported copper catalyst (abbreviated as Cu / Al 2 o 3 ).

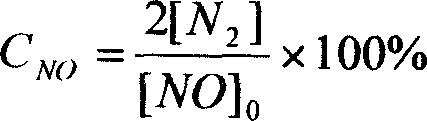

[0029] The Cu / Al containing copper 3% prepared by the above-mentioned method 2 o 3 Catalyst, the reaction temperature is 100-600°C, the space velocity is 20000h -1 , The reaction was c...

example 2

[0032] Example 2: Cu / ZrO 2 -Al 2 o 3 The catalytic effect of the catalyst

[0033] Al(NO 3 ) 3 9H 2 O is made into a 0.5mol / L solution with deionized water, and then 0.2mol / L of ZrOCl is added 2 ·8H 2 O solution, stirred evenly, placed in a 50°C water bath and continued to stir, slowly dripped ammonia water to the solution pH≈9, then put the prepared sol in an autoclave, kept the temperature at 115°C for 24 hours, took it out and put It is steamed in a water bath at 60°C until it becomes viscous, dried at 115°C, and then calcined at 600°C for 4 hours to obtain ZrO 2 (10%)-Al 2 o 3 , and then loaded with 3% Cu according to the method of Example 1 2+ and make ZrO 2 -Al 2 o 3 Supported copper catalyst (abbreviated as Cu / ZrO 2 -Al 2 o 3 ).

[0034] The reaction conditions of propylene selective reduction NO under oxygen-enriched conditions are the same as example 1, and the conversion rate of NO is as table 2 under each reaction temperature

[0035] Reac...

example 3

[0037] Example 3: Cu / La 2 o 3 -ZrO 2 -Al 2 o 3 The catalytic effect of the catalyst

[0038] Al(NO 3 ) 3 9H 2 O was made into a 0.5mol / L solution with deionized water, and then 0.2mol / L of ZrOCl was added 2 ·8H 2 O solution and 0.1mol / L La(NO 3 ) 3 ·6H 2 O solution, stir well. Place in a water bath at 50°C and continue to stir continuously, slowly drop ammonia water until the solution pH is 9, then put the prepared sol in an autoclave, keep the temperature at 115°C for 24 hours, take it out and evaporate it in a water bath at 60°C until viscous, dried at 115°C, and then roasted at 600°C for 4 hours to obtain La 2 o 3 (4%)-ZrO 2 (10%)-Al 2 o 3 (86%) composite carrier, then by the method loading of example 1 on 3% Cu 2+ , and make La 2 o 3 -ZrO 2 -Al 2 o 3 Supported copper catalyst (abbreviated as Cu / La 2 o 3 -ZrO 2 -Al 2 o 3 ).

[0039] The reaction conditions for the selective reduction of NO by propylene under oxygen-enriched conditions are the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com