Synthesis of chemically reactive ceria composite nanoparticles and CMP applications thereof

a composite nanoparticle, chemical reactive technology, applied in the direction of lanthanide oxide/hydroxide, manufacturing tools, other chemical processes, etc., can solve the problems of easy introduction of contaminants, difficult to obtain a narrow particle size distribution, and high energy consumption, so as to avoid the use of chemical oxidizers, reduce the risk of contamination, and reduce the effect of toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

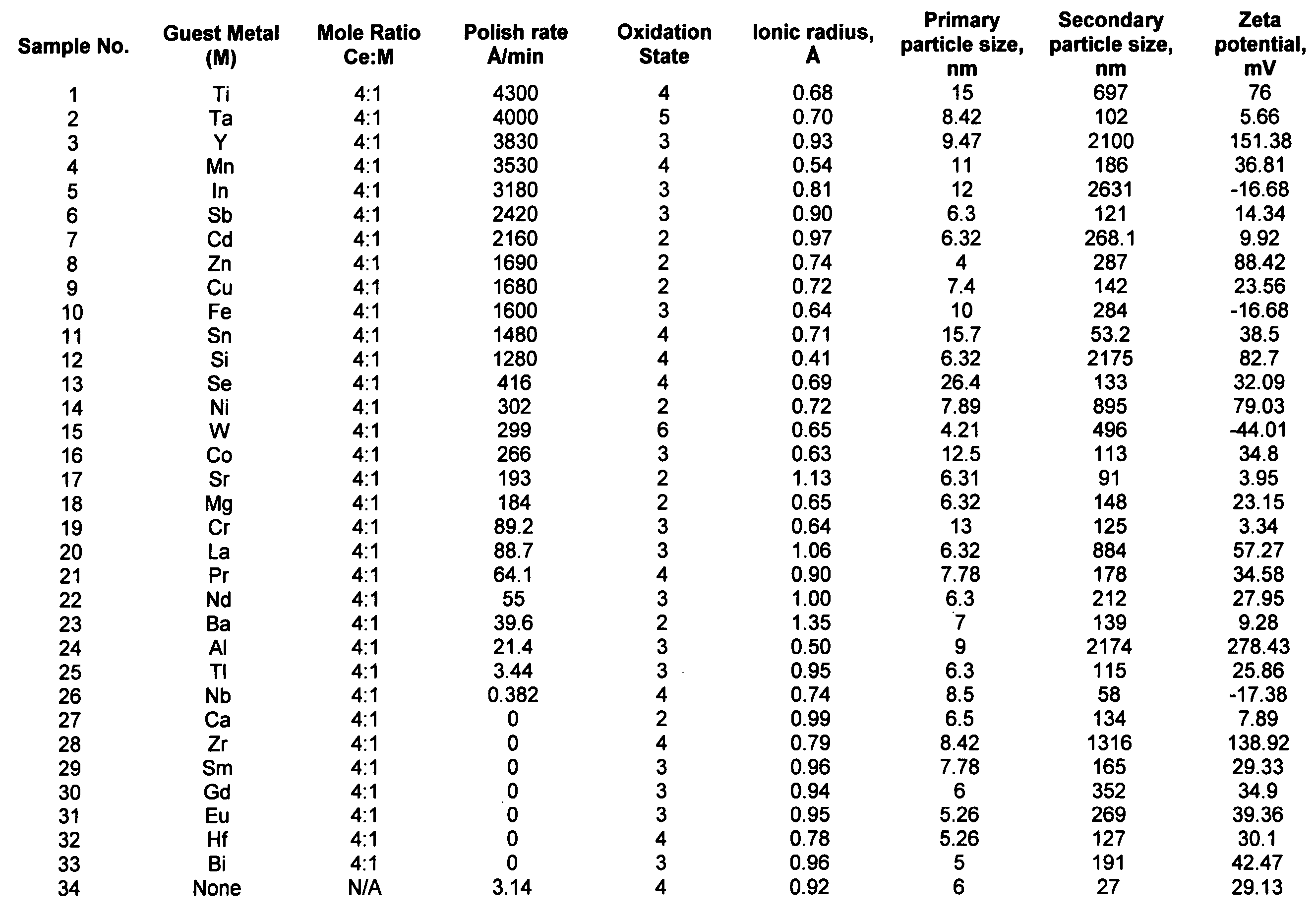

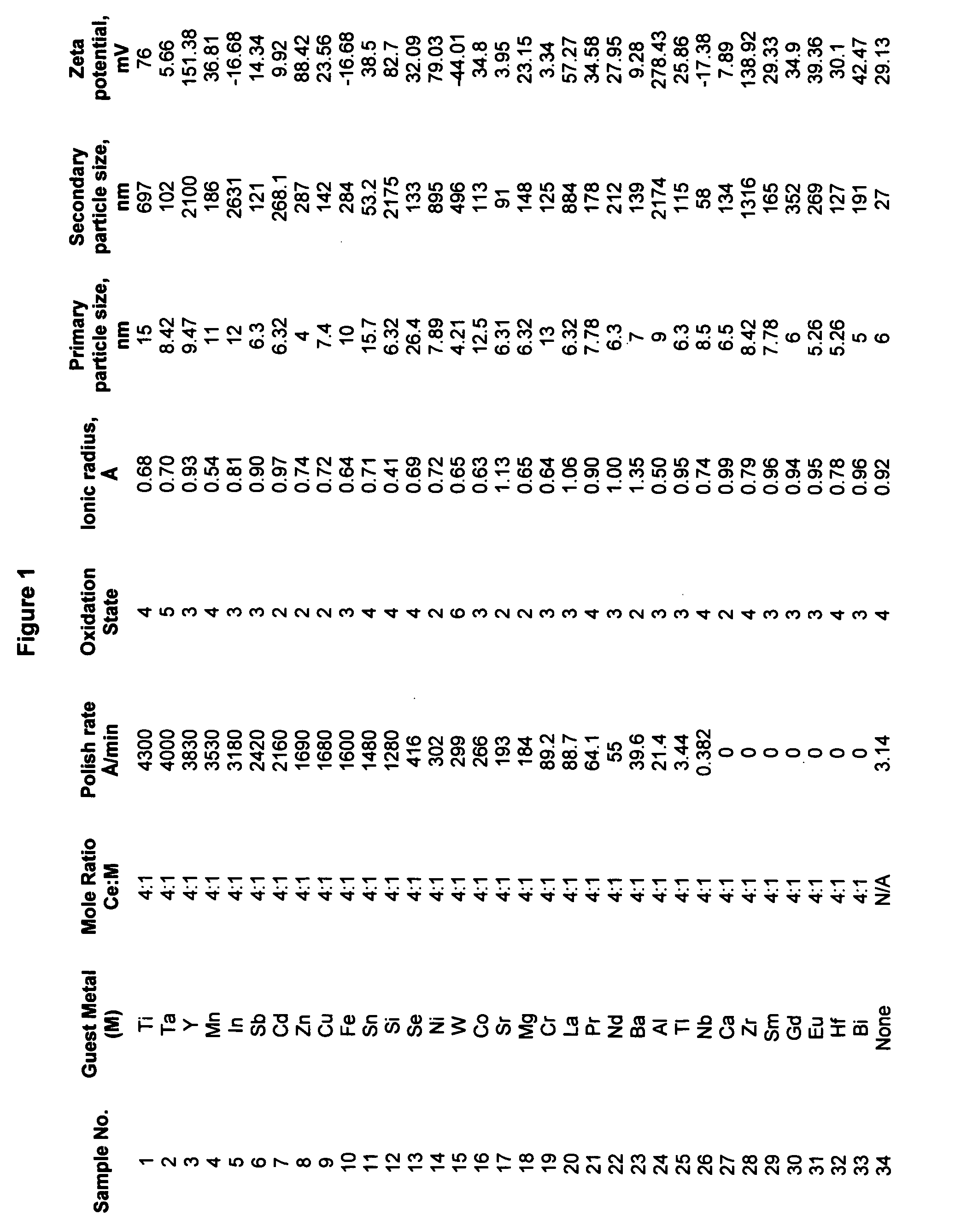

Image

Examples

example 1

[0036] An abrasive particle suitable for CMP was prepared by first dissolving 1854 g (3.38 mol) of Ce(NH4)2(NO3)6 in 3500 g of deionized water. To this solution, 100 g of Ti(isopropoxide)4 (0.35 mol) and 90 g of acetyl acetone was added. The cerium salt solution was mixed with a basic solution (containing 1000 g H2O and 1043 g of KOH) using a controlled double jet injection method with constant stirring. The slurry thus formed was diluted to a volume of 8330 mL with deionized water, and heated in a sealed stainless steel vessel, i.e., a hydrothermal reactor, at 300° C. for 6 hours with agitation. After the slurry was discharged from the hydrothermal reactor, the slurry was decanted several times before being subjected to cross-flow washing until a conductivity of 0.075 mS was achieved. The slurry was then subjected to a Dual-Frequency Reactor (Advanced Sonic Processing Systems) for sonification at a flow rate of about 50 ml / minute. The resultant final CeO2 particles exhibited a prim...

example 2

[0037] In a 500 ml beaker, 85.16 g of cerium ammonium nitrate Ce(NH4)2(NO3)6 was dissolved in 300 ml deionized water, and 6.34 grams (0.0157 mol) of ferric nitrate nonahydrate (Fe(NO3)3.9H2O) was added with stirring. The solution was diluted further by addition of 350 ml of deionized water. A basic solution was formed by dissolving 48.72 grams of potassium hydroxide (KOH) in 350 ml deionized water. The solutions (1) containing cerium ammonium nitrate and ferric nitrate and (2) the base were simultaneously introduced under stirring into a 1000 ml beaker via a controlled double jet injection method. After the solutions were added together, the resulting solution was stirred for 5 minutes and then ultrasonicated for 15 min. The solution was transferred to a sealed 1000 ml stainless steel reaction cylinder, and then placed in a preheated oven at 300° C. for 4 hours. The reaction cylinder was removed from the oven, cooled to room temperature, and the contents were transferred to a 1000 m...

example 3

[0038] A dispersion of cerium oxide-copper oxide composite nanoparticles was formed using the same materials and procedure set forth in Example 1, except that 13.36 g of copper nitrate hemipentahydrate (Cu(NO3)2.2.5H2O) was used instead of ferric nitrate nonahydrate. The Cu CMP was performed under the same conditions as in Example 1. A Cu removal rate of 2021 Å / min was obtained, indicating that Ce—Cu composite nanoparticles are chemically more active than pure CeO2 particles. The particle distribution is (d10) 158 nm, (d50) 316 nm, and (d90) 747 nm, with a crystallite size of 7.4 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com