Nitrogen-doped graphene hydrogel, preparation method and applications thereof

A nitrogen-doped graphene and hydrogel technology is applied in the field of graphene to achieve the effects of simple synthesis and regulation, no pollution, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

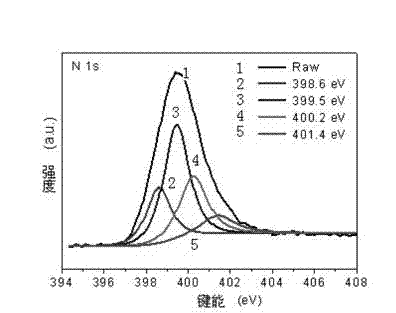

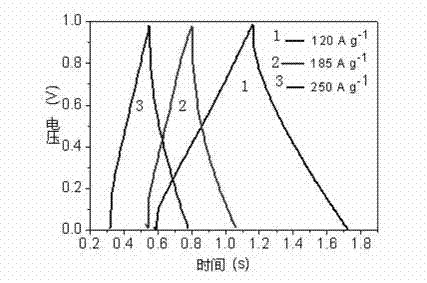

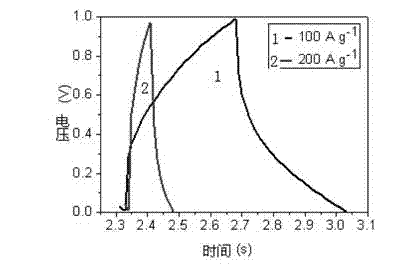

[0038] Graphene oxide was chemically synthesized by the Hummars method, and graphite oxide was added to water for ultrasonic dispersion to obtain a graphene oxide aqueous solution with a concentration of 2.7 mg / mL; 30.0 μL ethylenediamine was slowly added dropwise to 17 mL of graphene oxide aqueous solution, and The speed of diamine dripping is 50uL / min, after stirring for 15 minutes, put into the reaction kettle of 23mL and carry out reaction, and hydrothermal reaction temperature is 200 ℃, time 12h. The product was washed with water. Photos of the obtained product are attached figure 1 shown. From attached figure 1 It can be seen that the product has certain mechanical properties. figure 2 SEM photographs of the obtained product. image 3 According to the photoelectron spectrum (N1s) of the obtained product, it can be seen that pyridinic and pyrrole nitrogen exist in the product. Figure 6 It is the charge-discharge performance that the obtained product has as the supe...

Embodiment 2

[0040] Graphene oxide was chemically synthesized by the Hummars method, and graphite oxide was added to water for ultrasonic dispersion to obtain a graphene oxide aqueous solution of 2.0 mg / mL; 2.5 μL of ethylenediamine was slowly added dropwise to 17 mL of graphene oxide aqueous solution, and ethylenediamine was dropped The speed of adding is 100uL / min, after stirring for 15 minutes, put it into a 23mL reactor for reaction, the hydrothermal reaction temperature is 200°C, and the time is 10h. The product was washed with water, and the results are shown in Table 1.

Embodiment 3

[0042] Graphene oxide was chemically synthesized by the Hummars method, and graphite oxide was added to water for ultrasonic dispersion to obtain a graphene oxide aqueous solution of 2.7 mg / mL; 5.0 μL of ethylenediamine was slowly added dropwise to 17 mL of graphene oxide aqueous solution, and ethylenediamine was dropped The speed of adding is 250uL / min, after stirring for 15 minutes, put it into a 23mL reactor for reaction, the hydrothermal reaction temperature is 200°C, and the time is 12h. The product was washed with water, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com