Preparation method of cerium-titanium composite oxide low-temperature SCR catalyst

A technology for SCR catalysts and composite oxides, which is applied in the field of preparation of cerium-titanium composite oxide low-temperature SCR catalysts, can solve problems such as narrow temperature window, high working temperature, and cumbersome process, and achieves a green and environmentally friendly preparation method and easy control of preparation conditions , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

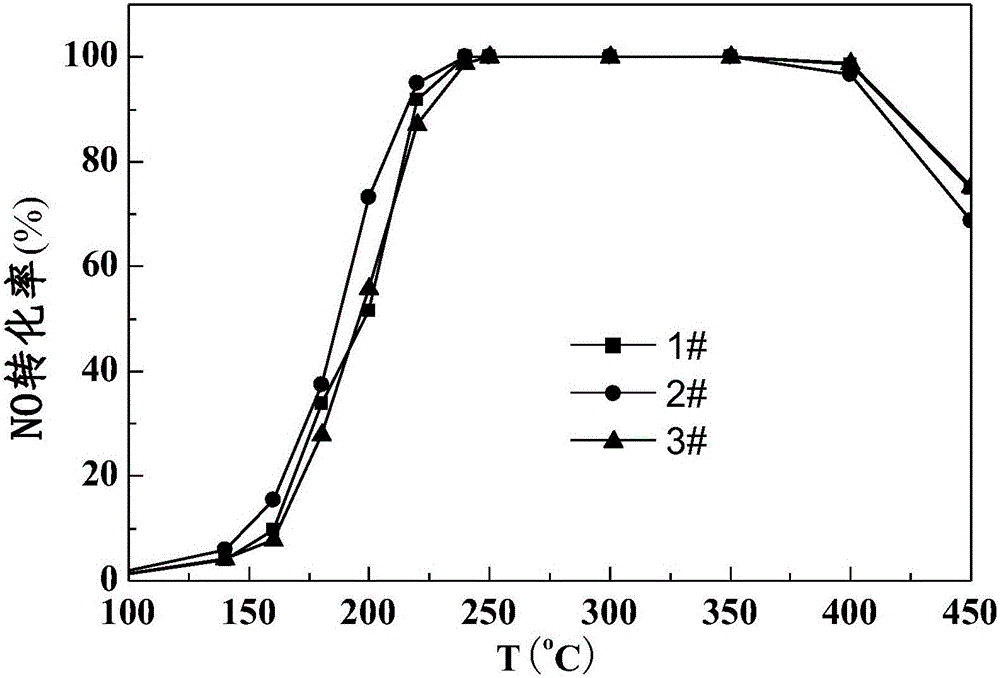

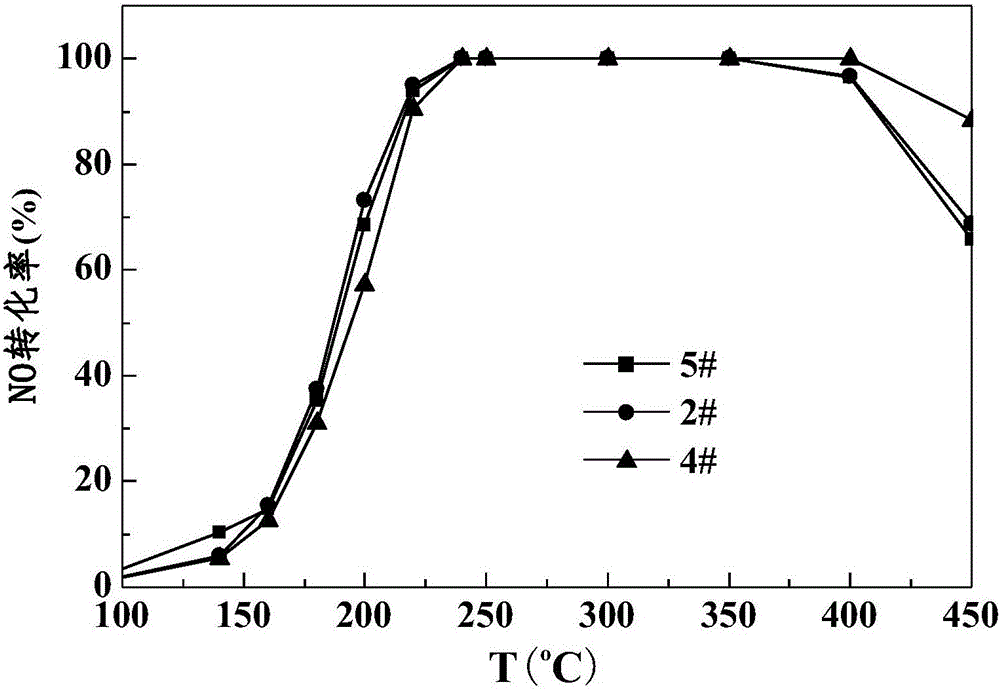

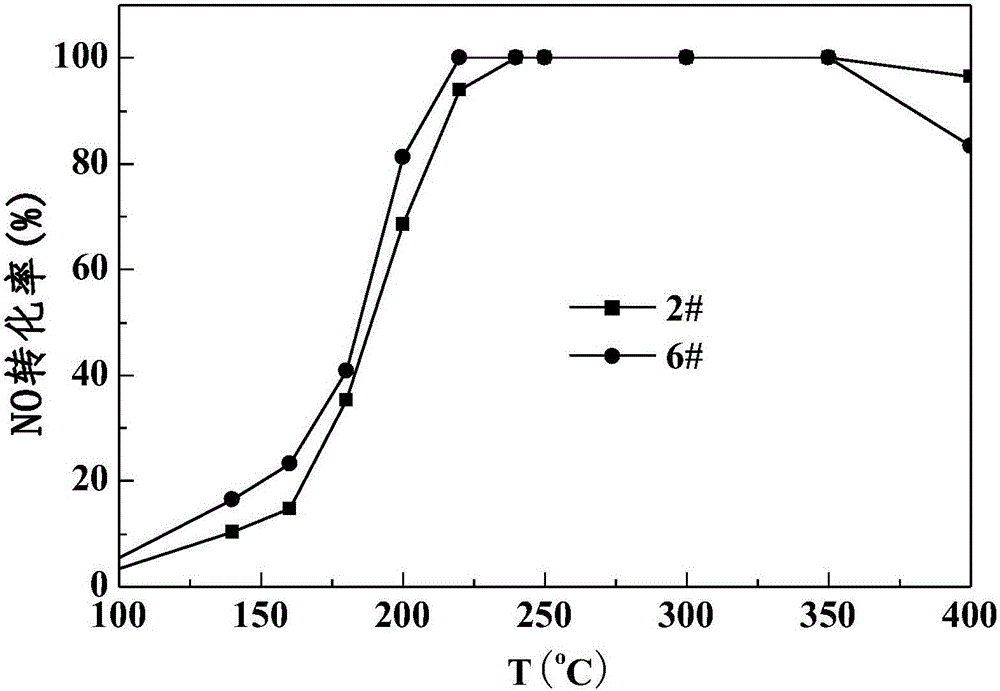

Embodiment 1

[0031] Weigh 10.1g of cerium nitrate hexahydrate, 5.05g of adipic acid, TiO 2 Put 16g into a ball mill jar, then add a certain number of agate balls of 20mm, 15mm and 10mm, the ratio of ball to material is 10:1, put it into a planetary ball mill, and grind for 0.5h. The uniformly mixed powder was put into a muffle furnace, and calcined at 250° C. for 2 hours and at 450° C. for 2 hours in an air atmosphere to obtain 1# catalyst sample.

Embodiment 2

[0033] Weigh 10.1g of cerium nitrate hexahydrate, 5.05g of adipic acid, TiO 2 Put 16g into the ball mill pot, then add a certain number of agate balls of 20mm, 15mm and 10mm, the ratio of ball to material is 10:1, put it into the planetary ball mill, grind for 1h, put the evenly mixed powder into the muffle furnace , in an air atmosphere, calcined at 250°C for 2 hours, and at 450°C for 2 hours to obtain the 2# catalyst sample.

Embodiment 3

[0035] Weigh 10.1g of cerium nitrate hexahydrate, 5.05g of adipic acid, TiO 2 Put 16g into the ball mill jar, then add a certain number of agate balls of 20mm, 15mm and 10mm, the ratio of ball to material is 10:1, put it into the planetary ball mill, grind for 2h, put the evenly mixed powder into the muffle furnace , in an air atmosphere, calcined at 250°C for 2 hours, and at 450°C for 2 hours to obtain 3# catalyst sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com