Patents

Literature

67results about "Caprolactum production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

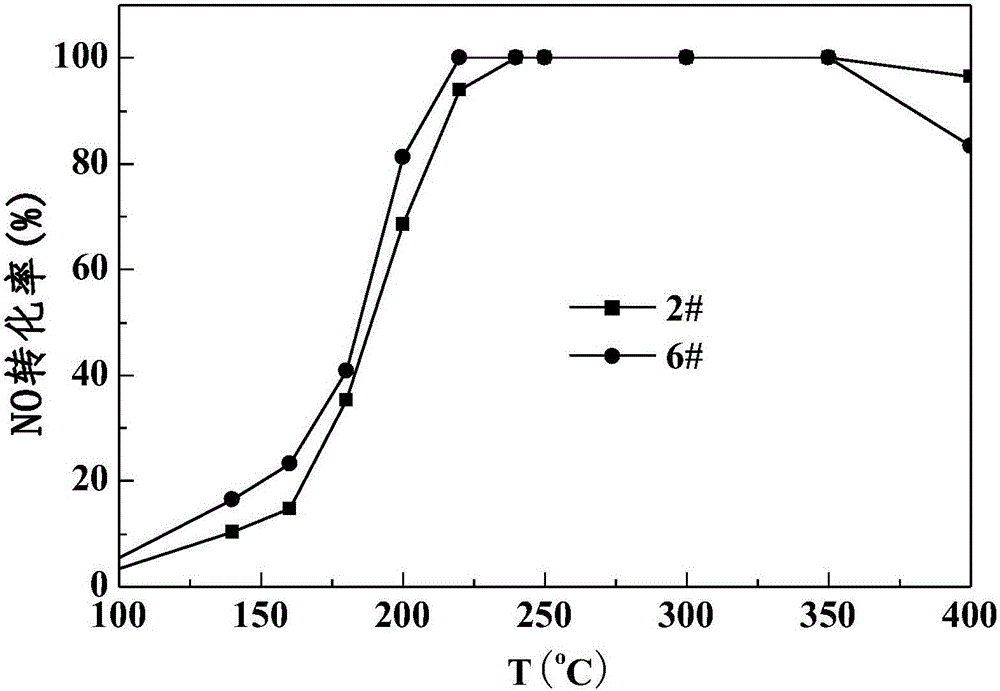

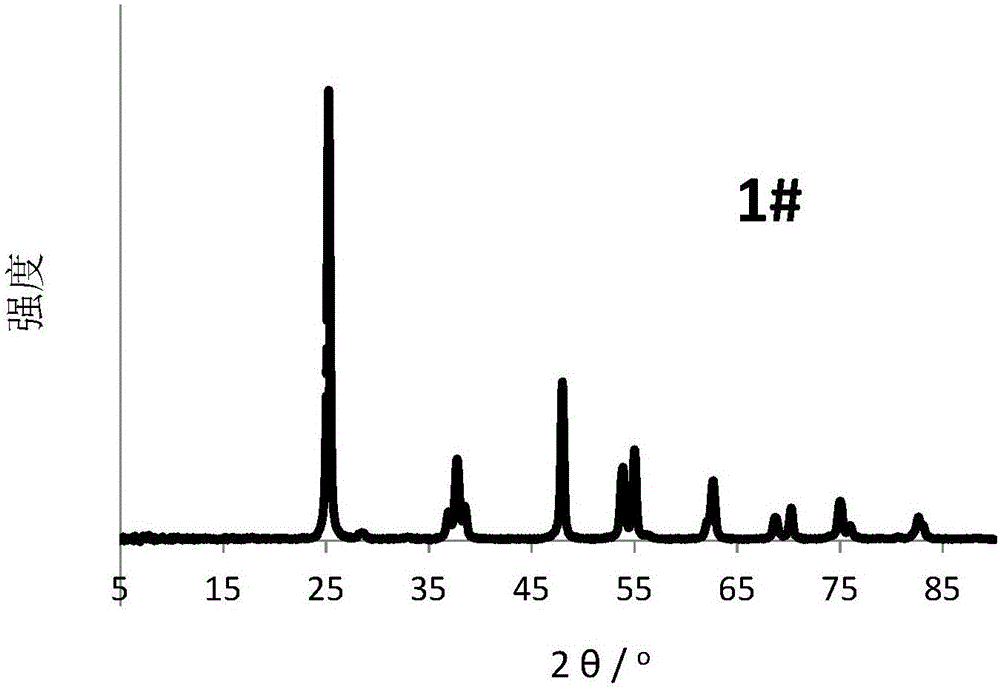

Method for preparing CeO2/TiO2 low-temperature SCR catalyst by using Ce-MOF as cerium precursor

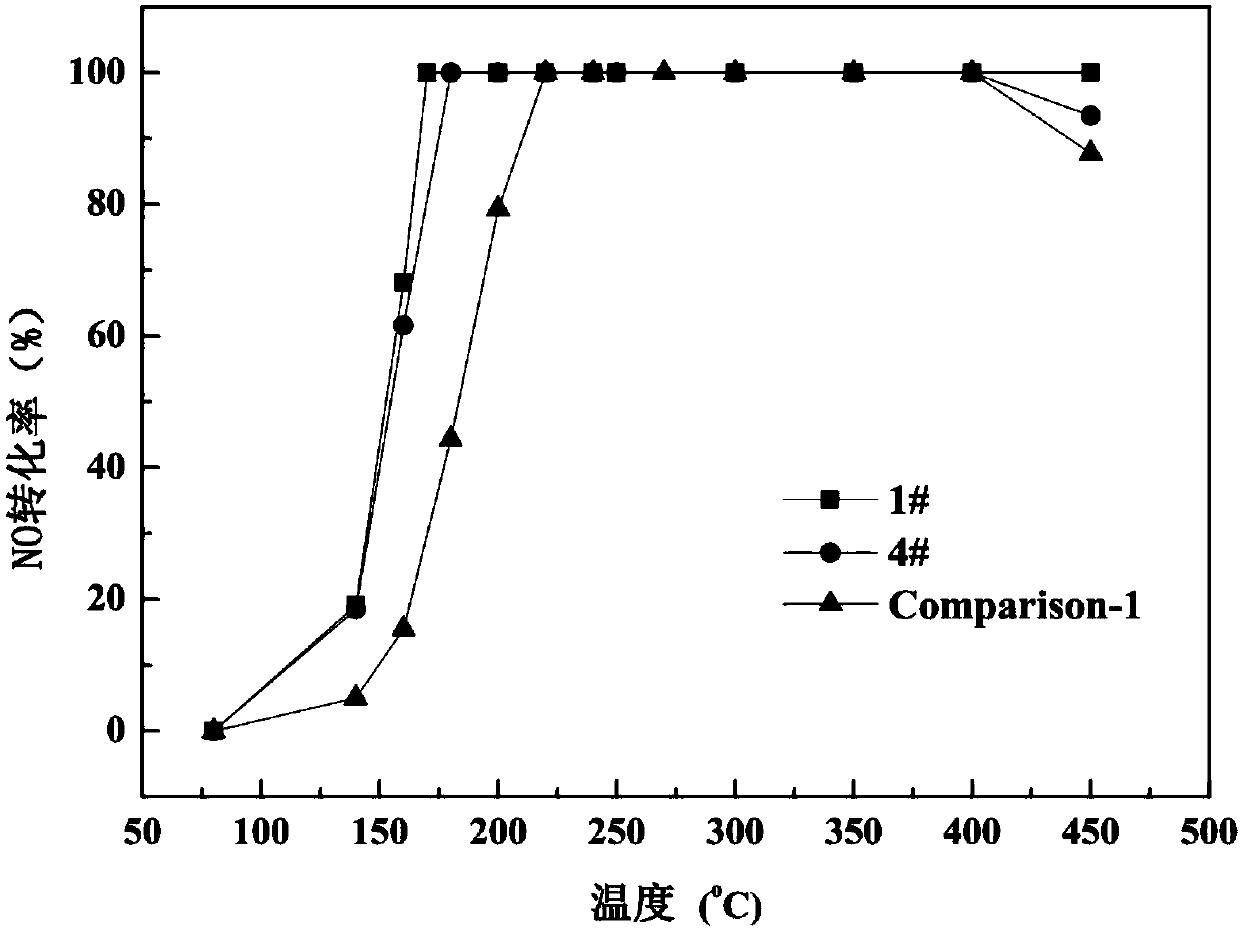

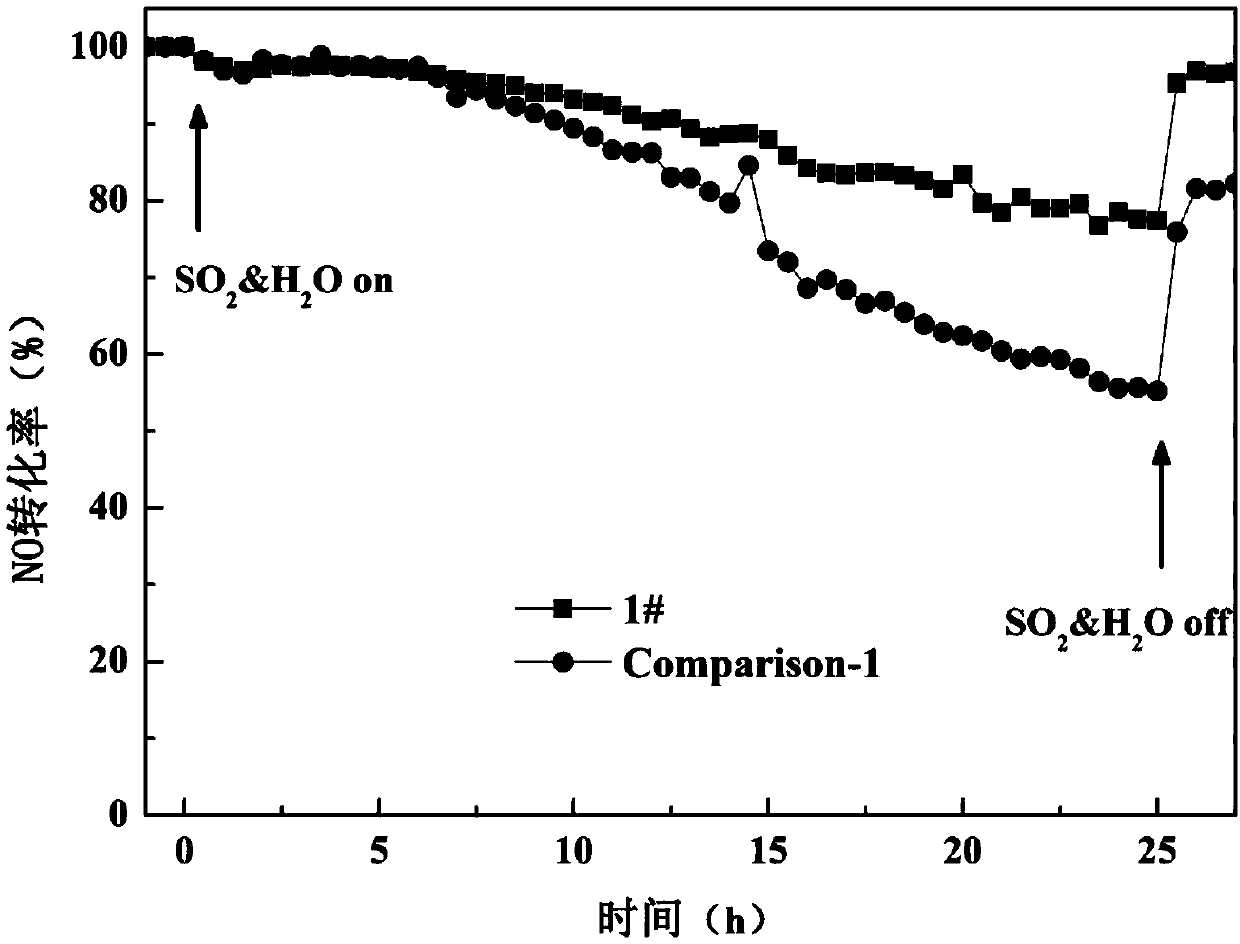

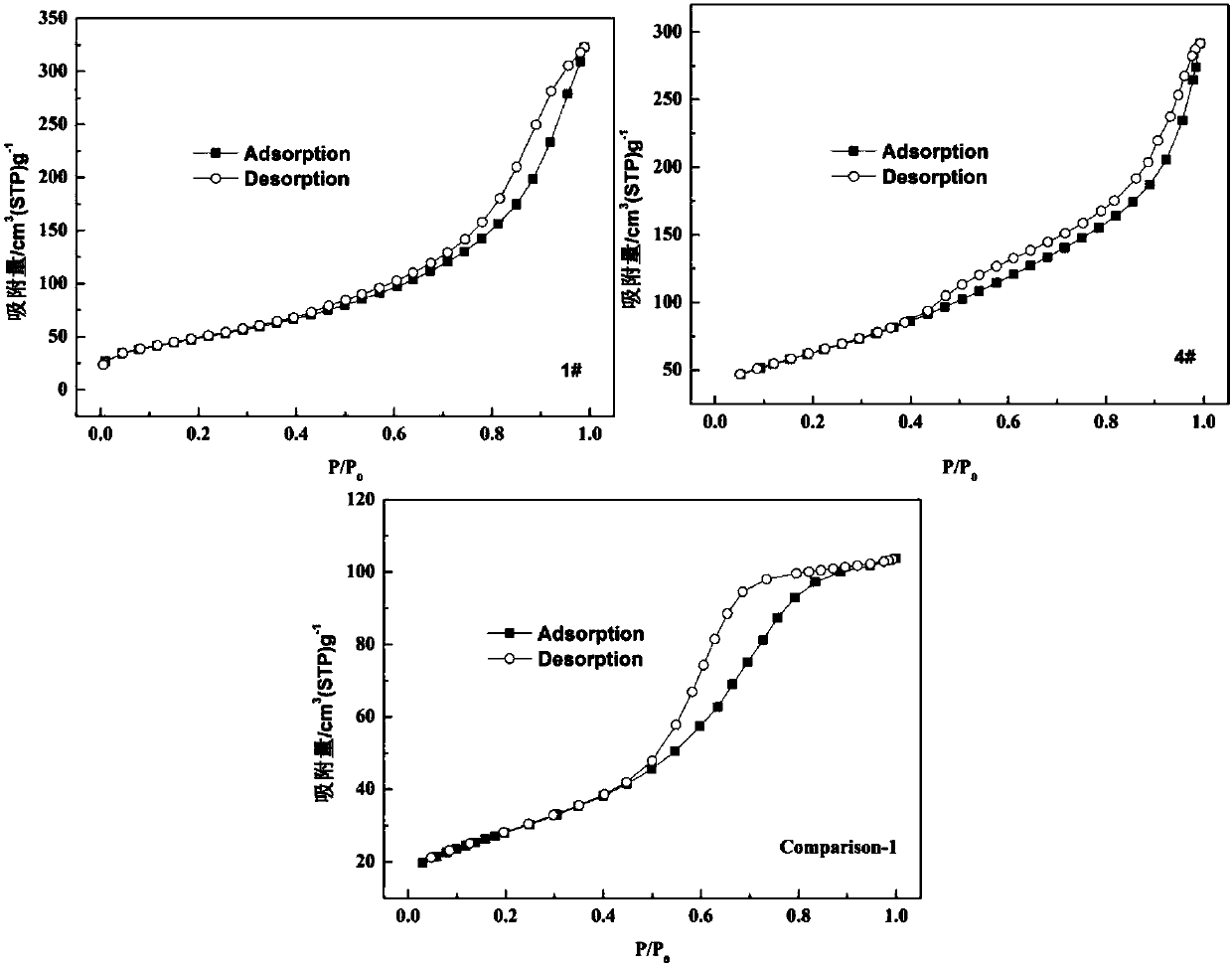

ActiveCN107824177AHigh specific surface areaLarge specific surface areaDispersed particle separationCatalyst activation/preparationSulfurMetal-organic framework

The invention relates to a method for preparing a CeO2 / TiO2 low-temperature SCR catalyst by using Ce-MOF as a cerium precursor, and belongs to the technical field of catalyst preparation. The preparation method comprises the following steps: (1) weighing a fixed quantity of a cerium source and an organic ligand, dissolving the cerium source and the organic ligand in a proper amount of a solvent, and preparing a cerium-based metal organic framework material (Ce-MOF) by adopting a solvothermal method; (2) weighing and dissolving a fixed quantity of a soluble titanium source in a certain solvent,adding the Ce-MOF prepared in the step (1), and preparing a catalyst precursor by adopting a coprecipitation method; (3) putting the catalyst precursor obtained in the step (2) into a muffle furnacefor calcination treatment. Therefore, the CeO2 / TiO2 low-temperature SCR catalyst prepared by using the Ce-MOF as a cerium precursor can be obtained. According to the preparation method provided by the invention, the preparation condition is easy to control, the preparation process is simple, and the prepared catalyst has excellent catalytic activity and good sulfur resistance and water resistancefor NH3-SCR reaction.

Owner:BEIJING UNIV OF TECH

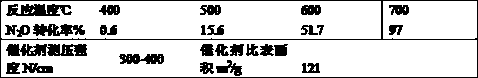

Catalyst for decomposing nitrous oxide and preparation method of catalyst

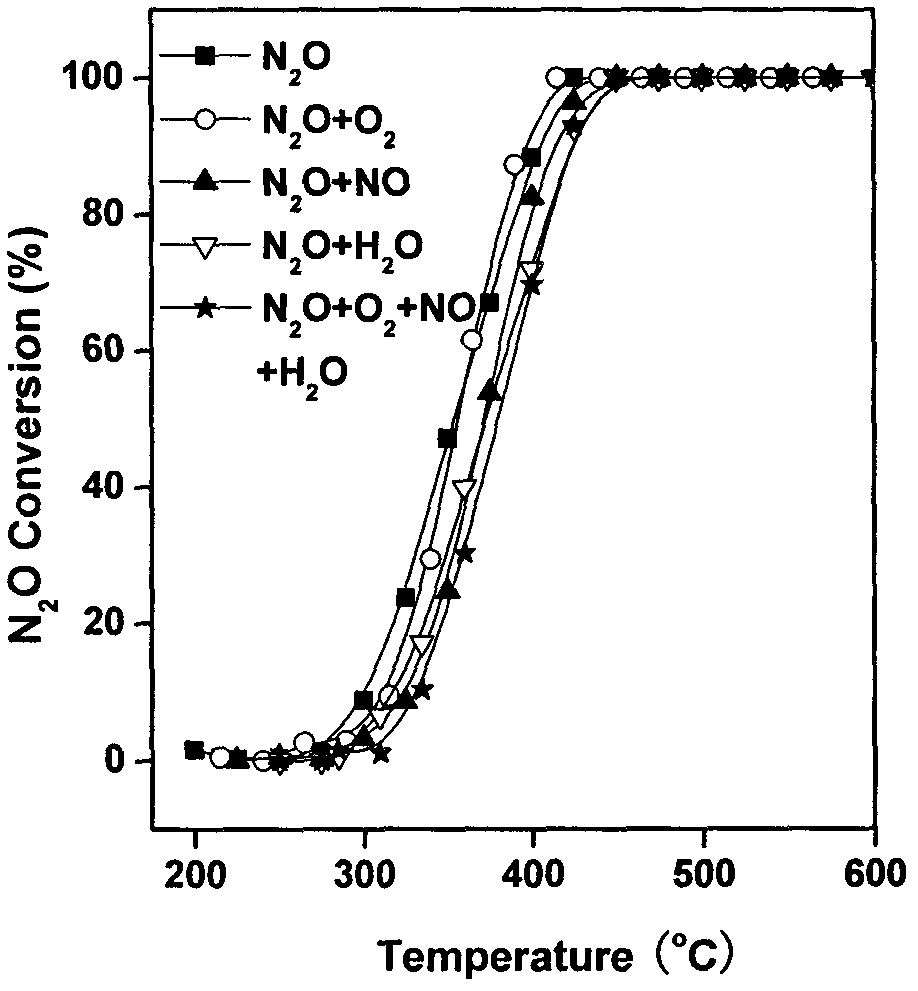

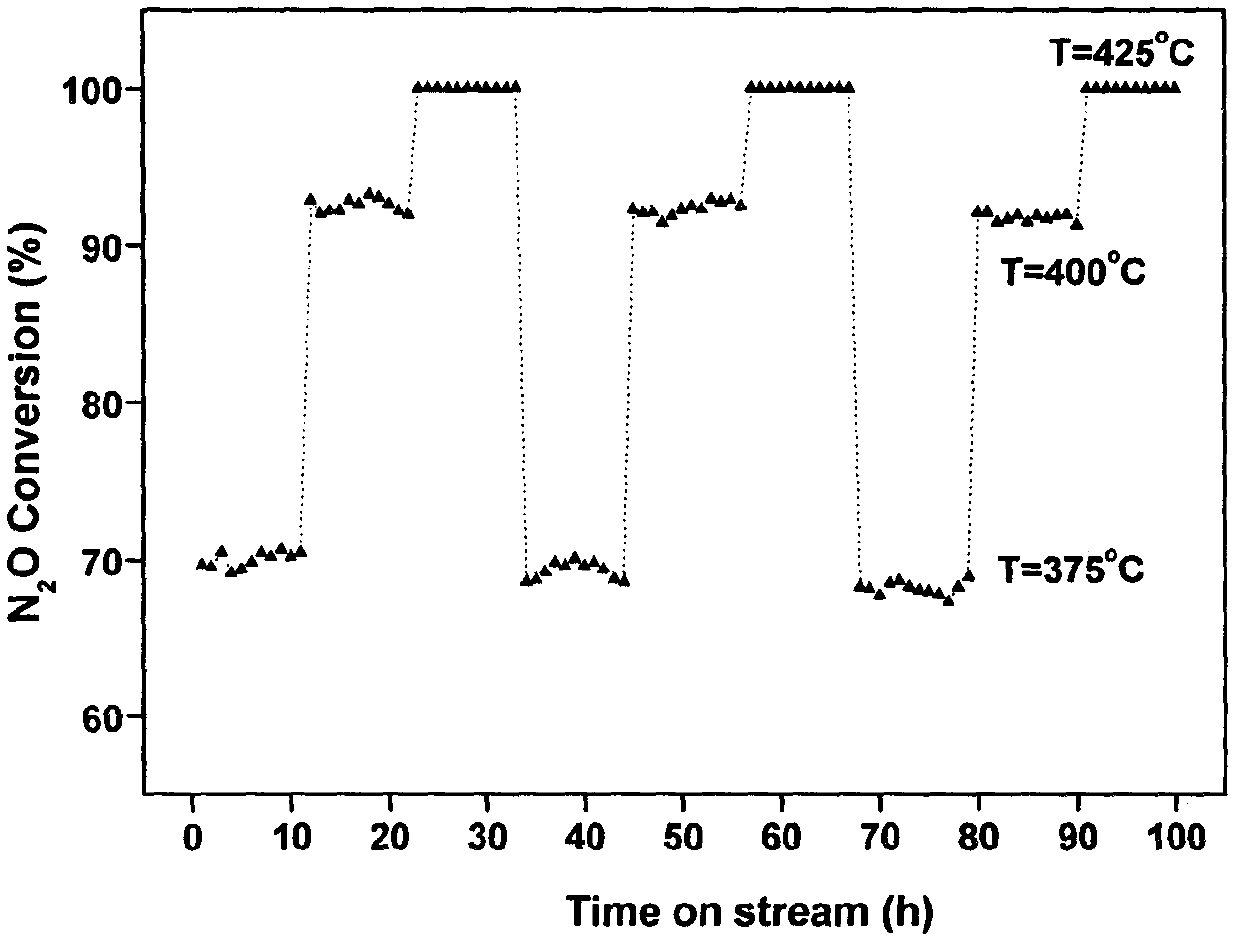

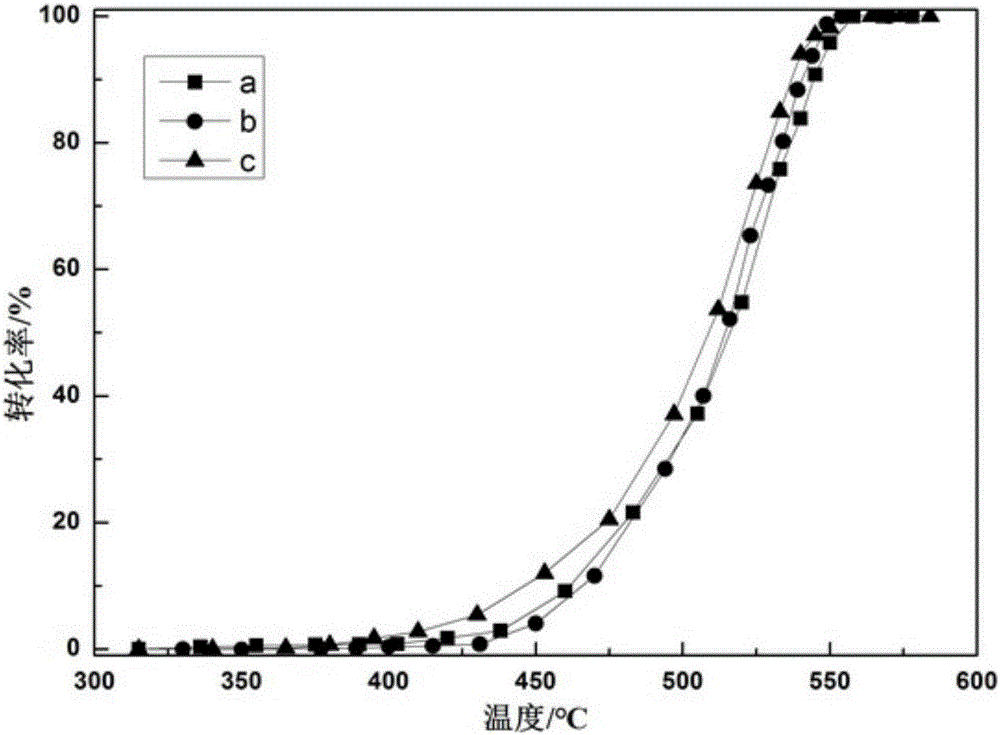

InactiveCN104437499AHigh activityIncreased reactive sitesNitrous oxide captureDispersed particle separationReaction temperatureAdipic acid

The invention discloses a catalyst for decomposing nitrous oxide and a preparation method of the catalyst. The catalyst is prepared by the deposition precipitation method. The method comprises the processes of preparing a deposit, washing, forming a deposit, activating through the catalyst, etc.; the catalyst comprises active ingredients, a carrier which is zirconium oxide, and additives, wherein the active ingredients include one or more than two of Co, Ni, Fe and Mn; the additives include one or more of cerium oxide, lanthanum oxide and barium oxide. A catalyst activity experiment shows that nitrous oxide can be completely catalytically decomposed into nitrogen and oxygen at the temperature ranging from 450 to 700 DEG C; therefore, the activation temperature is low, and the T50 (reaction temperature under conversion rate of 50%) is about 350 DEG C. The catalyst is high in activity and outstanding in heat resistance, has a wide operation window, and enables the concentration of nitrous oxide in industrial waste gas to be greatly reduced, and therefore, the environmental pollution is decreased; the catalyst is particularly suitable for N2O removal of a nitric plant and an adipic acid plant.

Owner:LANZHOU TIANYUE ENVIRONMENTAL PROTECTION TECH CO LTD

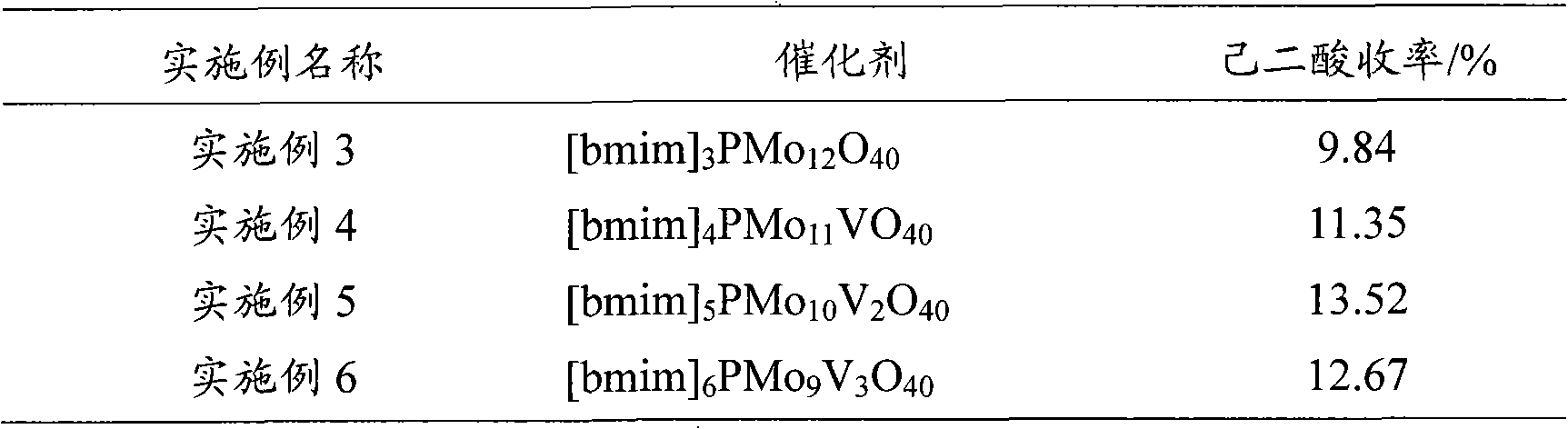

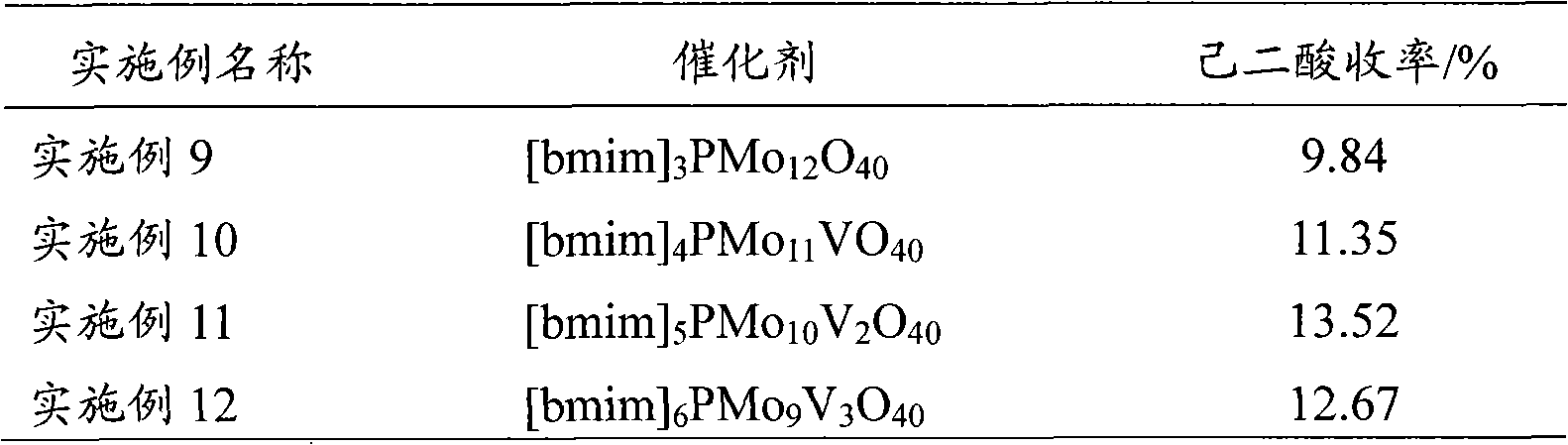

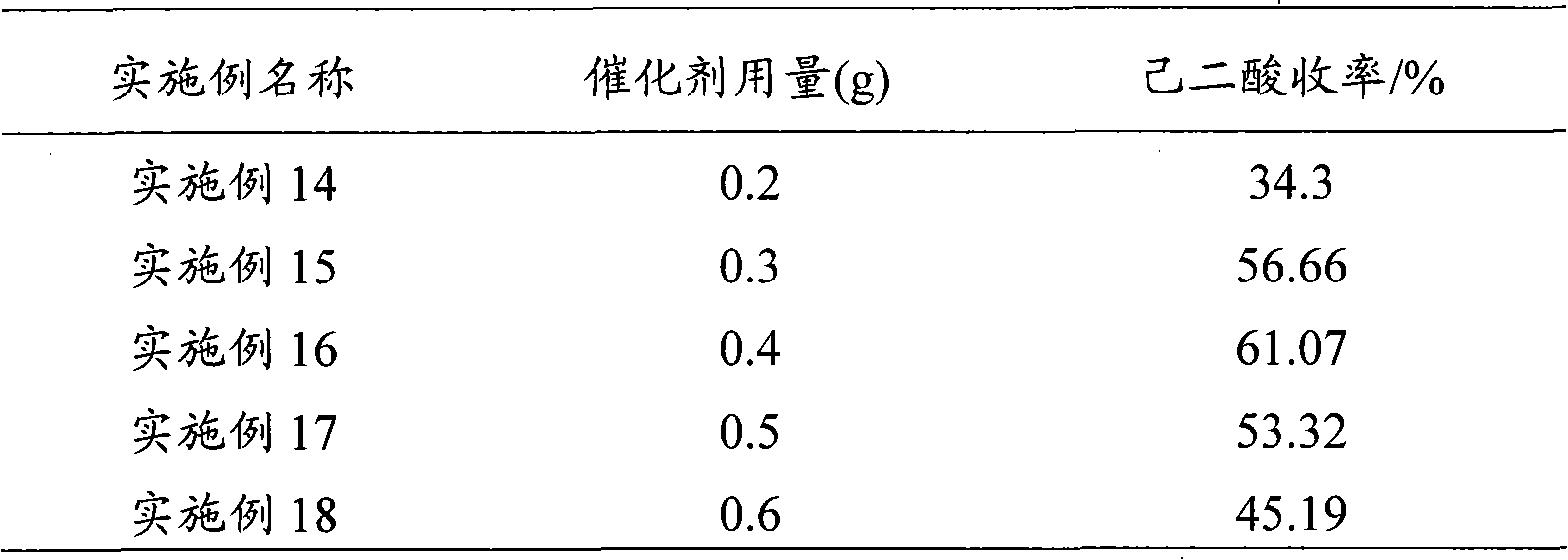

Method for preparing hexane diacid by liquid-phase catalytic oxidation of cyclohexanol

InactiveCN101302147AAvoid it happening againReduce usageOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPhosphomolybdic acidHeteropoly acid

The invention provides a method for preparing adipic acid through liquid-phase catalytic oxidation of cyclohexanol. H2O2 is taken as oxidant, a heteropoly acid imidazole salt is taken as catalyst, the cyclohexanol undergoes the catalytic oxidation to prepare the adipic acid, the catalyst can be phosphotungstic acid 1-butyl-3-methylimidazolium bmim3PW12O40, phosphomolybdic acid 1-butyl-3-methylimidazolium bmim3PMo12O40, and molybdovanadophosphoric heteropolyacid 1-butyl-3-methylimidazolium bmim3+xPMo12-xVxO40 (x is equal to between 1 and 3) and so on, and the bmim represents a 1-butyl-3-methyl-imidazolium cation. Compared with the method of preparing the adipic acid by industrially using nitric acid (nitrate) to oxidize the cyclohexanol, the method can not produce poisonous oxynitride N2O, and avoids the harm to the environment; and in a reaction system, phase shift catalyst and addition agent are not used, which avoids the potential environmental pollution and has apparent economic and social significance.

Owner:ZHEJIANG UNIV OF TECH

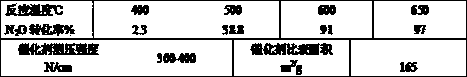

Efficient catalyst for decomposition of N2O and preparation method and application thereof

ActiveCN105363451AEconomicalHigh catalytic activityNitrous oxide captureDispersed particle separationDecompositionAdipic acid

The present invention provides an efficient catalyst for decomposition of N2O and a preparation method and application thereof. The catalyst comprises an active center and a carrier; the active center includes quantum dot oxide and spinel-type structural compound, and the carrier is a Al2O3 carrier; and the catalyst has a molecular formula L IIxO / M II1-xNIII2O4 / Al2O3, wherein: L II and M II are divalent metal cations, N III is a trivalent metal cation, and x equals to 0.01-1.0. The efficient catalyst for decomposition of N2O has high activity, good stability and low N2O decomposition temperature, is conducive to the purification of industrial waste gas from adipic acid plant; and the catalyst for decomposing N2O can significantly reduce the N2O concentration in industrial emission, reduce air pollution and protect the environment.

Owner:CHINA TIANCHEN ENG +1

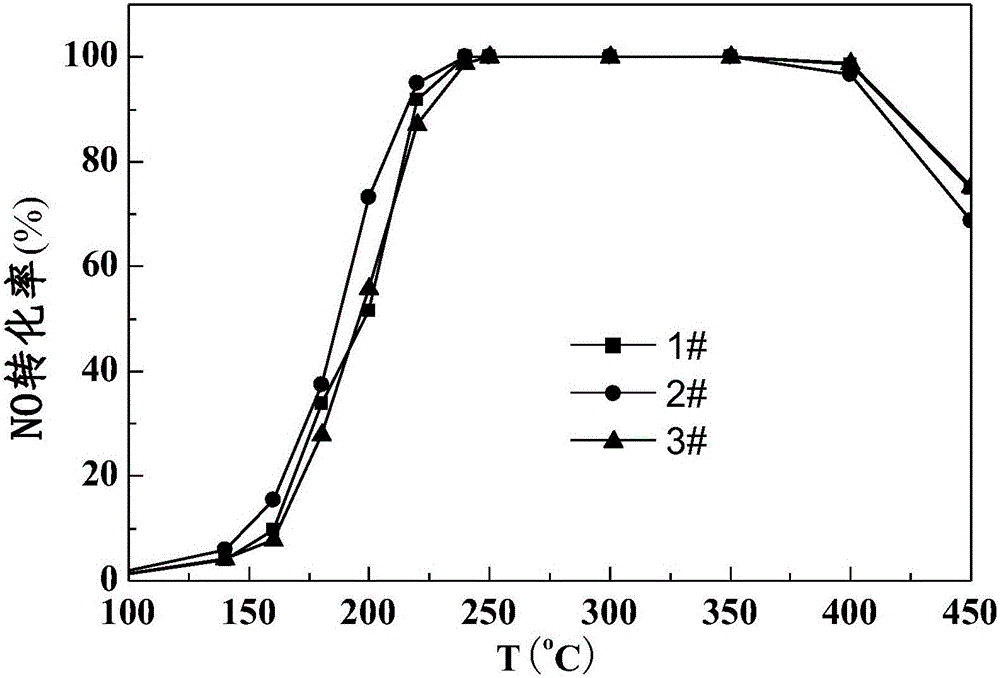

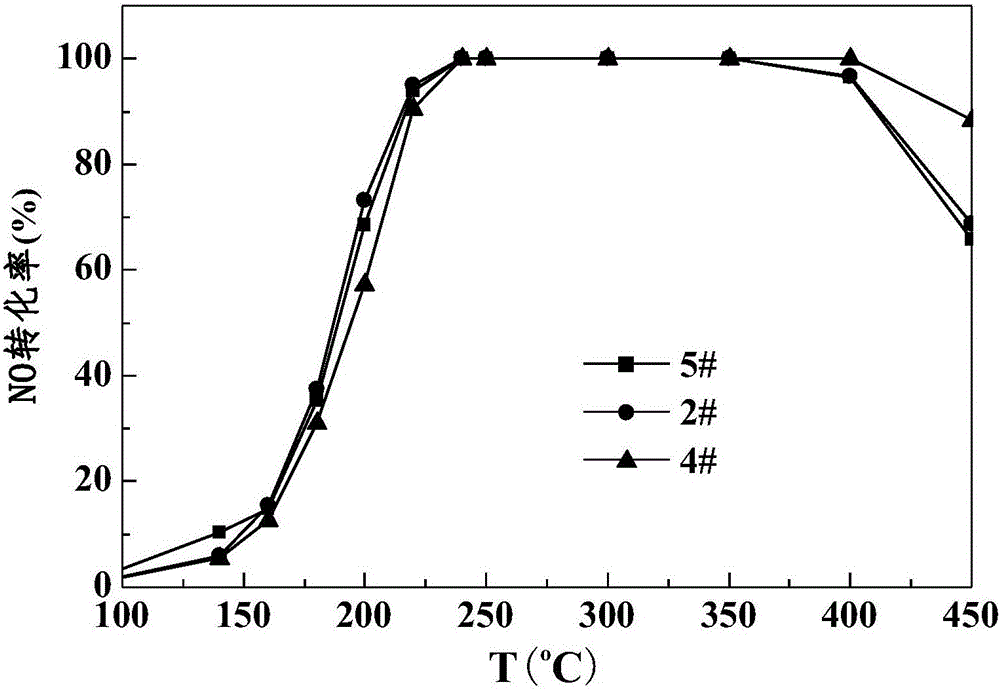

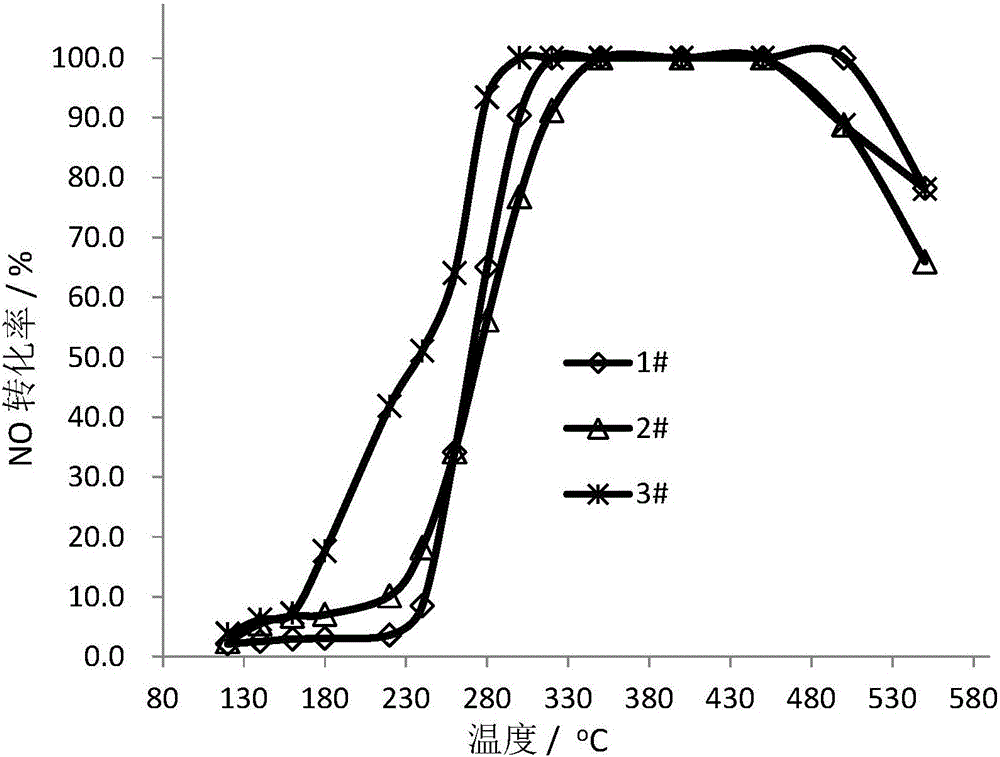

Preparation method of cerium-titanium composite oxide low-temperature SCR catalyst

ActiveCN106179301AGood dispersionHigh activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsOrganic solventCerium

The invention discloses a preparation method of a cerium-titanium composite oxide low-temperature SCR catalyst and belongs to the technical field of catalyst preparation. The preparation method particularly includes: placing a cerium precursor, an organic ligand, a carrier TiO2 and a small amount of organic solvent into a ball milling tank for ball milling to obtain well-mixed powder; calcining to obtain the CeO2-TiO2 composite oxide catalyst, wherein content of cerium oxide is 5-90wt%. Within a temperature range of 200-400 DEG C, NO conversion ratio of the catalyst is maintained higher than 95%. The preparation process is simple, preparation conditions are easy to control, and the preparation method is environment-friendly.

Owner:BEIJING UNIV OF TECH

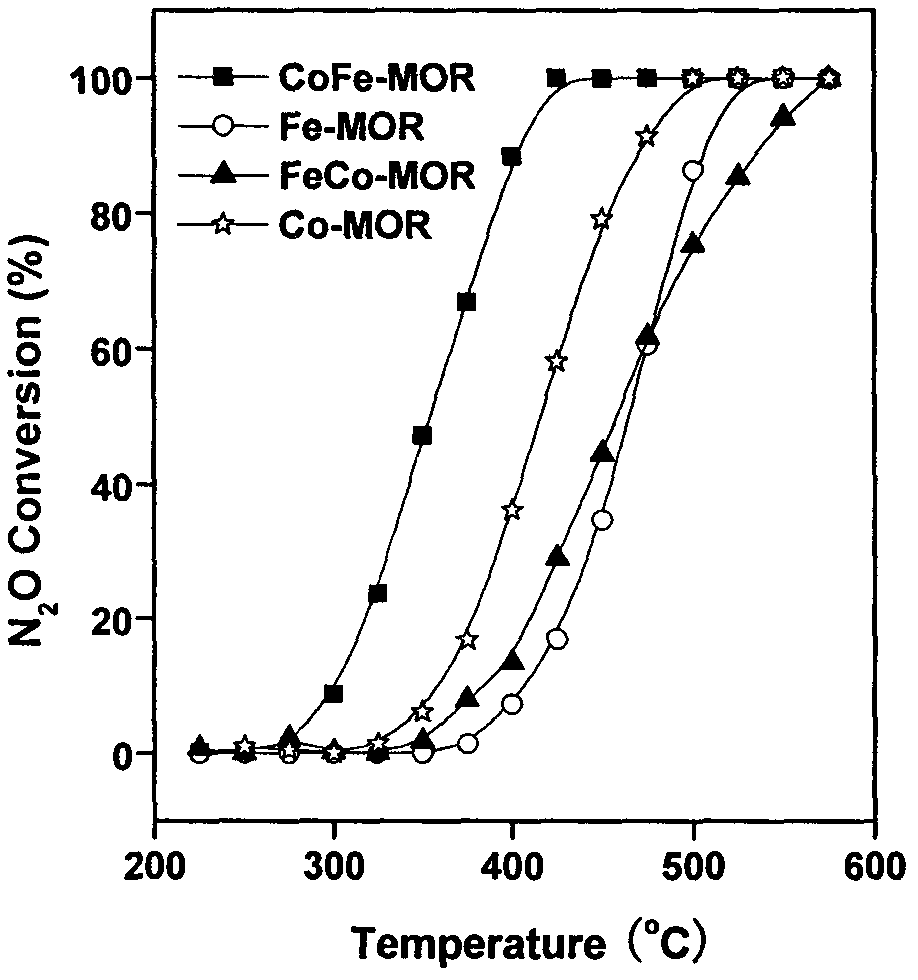

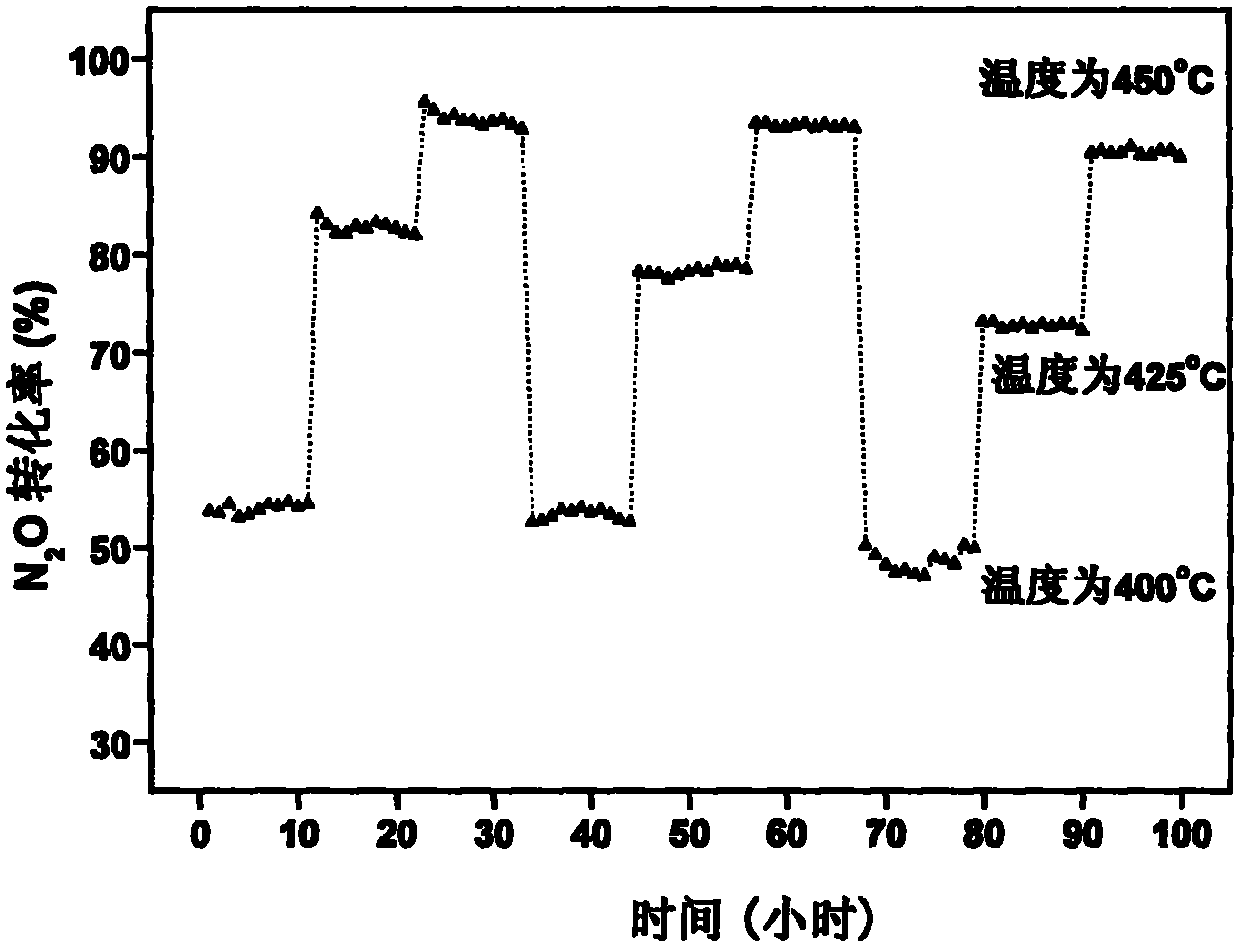

Ferro-cobalt bimetallic catalyst for catalyzing nitrous oxide (N2O) decomposition

InactiveCN102380410ANo significant decline in activityImprove stabilityNitrous oxide captureMolecular sieve catalystsDecompositionCatalytic oxidation

The invention provides a ferro-cobalt bimetallic load mordenite catalyst for catalyzing the nitrous oxide (N2O) decomposition and a preparation method. The catalyst can be used for decomposing most or all N2O in a pollution discharge system into N2 and O2 under the conditions that the space velocity is 30000h<-1>, the reaction temperature is 400 to 500 DEG C, the N2O concentration is 0.1 to 30 percent, and the H2O is 2 to 10 percent. In addition, the catalyst has high stability, and the activity of the catalyst is not decayed after 100h of the continuous nitric plant tail gas emission simulation. The catalyst has the advantages that the preparation process is simple, the cost is low, the catalyst is used for the catalytic N2O decomposition, the activity is high, and the stability is good. The technology has wide applicability, can be used for the N2O emission reduction process (such as processes of nitric acid production, adipate production and the like) of multiple industry sources and has wide application prospects.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

High-efficiency and energy-saving caprolactam recovery technology

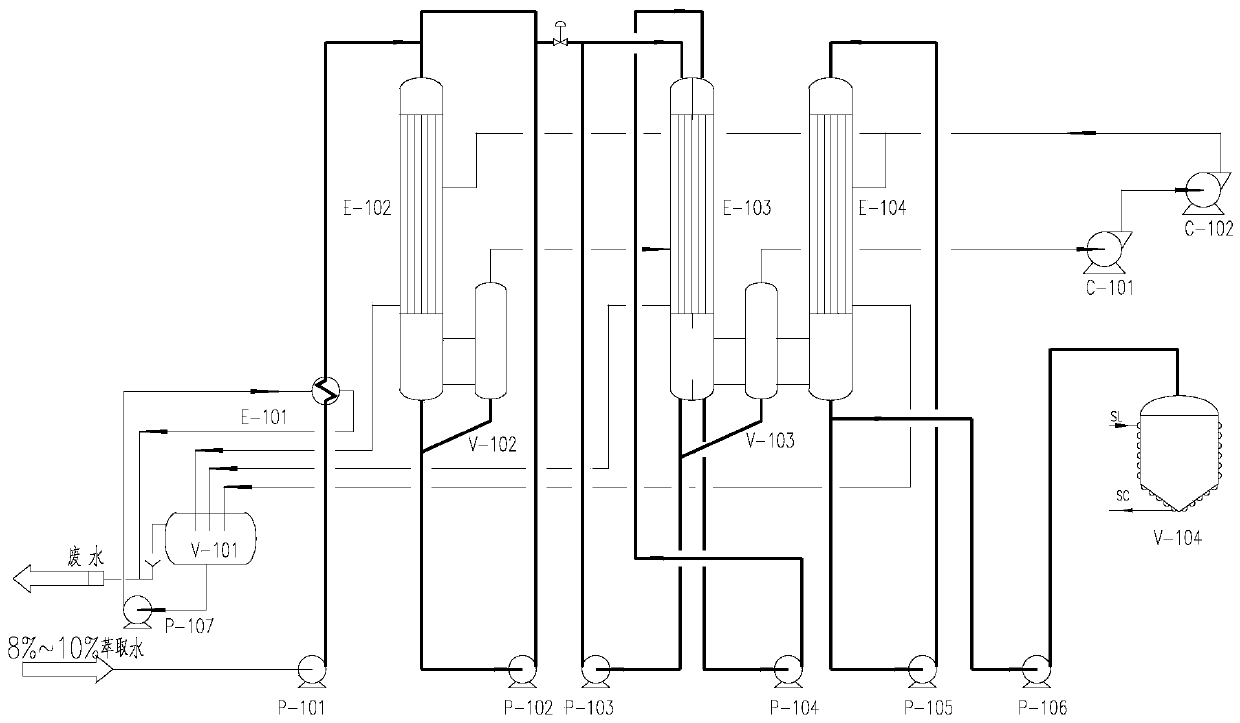

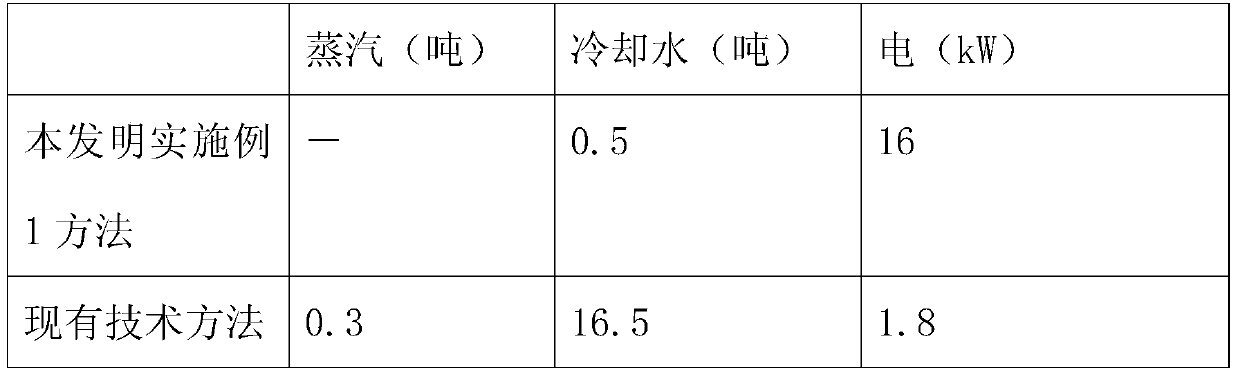

InactiveCN105498260ASmall footprintSave spaceOrganic chemistryMultiple-effect evaporationEnrichment methodsGravity flow

The invention relates to an aqueous caprolactam solution concentration method. The method comprises steps as follows: 1), extract water is preheated through a heat exchanger by the aid of a pump I, and enters an evaporation pipe through a top inlet of a single-effect falling-film evaporator; 2), the extract water is distributed by an in-tower liquid distributor, is distributed in a heat exchange pipe in a film-like mode and is subjected to thin film evaporation through steam heating outside the pipe when entering a pipe cavity by the aid of gravity flow, and the extract water and secondary steam in the pipe flow down to the bottom of an effect body and enter a single-effect separation tank for liquid-steam separation; 3), a concentrated solution at the bottom of the effect body and the bottom of the separation tank is sent to the top of a two-effect falling-film evaporator through a pump II, and the concentrated solution of the two-effect falling-film evaporator is subjected to liquid-steam separation through a pump III, a pump IV and a two-effect separation tank; 4), the concentrated solution is sucked by a pump V from the bottom of the effect body and sent into the top of a three-effect falling-film evaporator for circulating concentration, and the technological requirement is met.

Owner:BEIJING SANLIAN HOPE TEXTILE & CHEM TECH

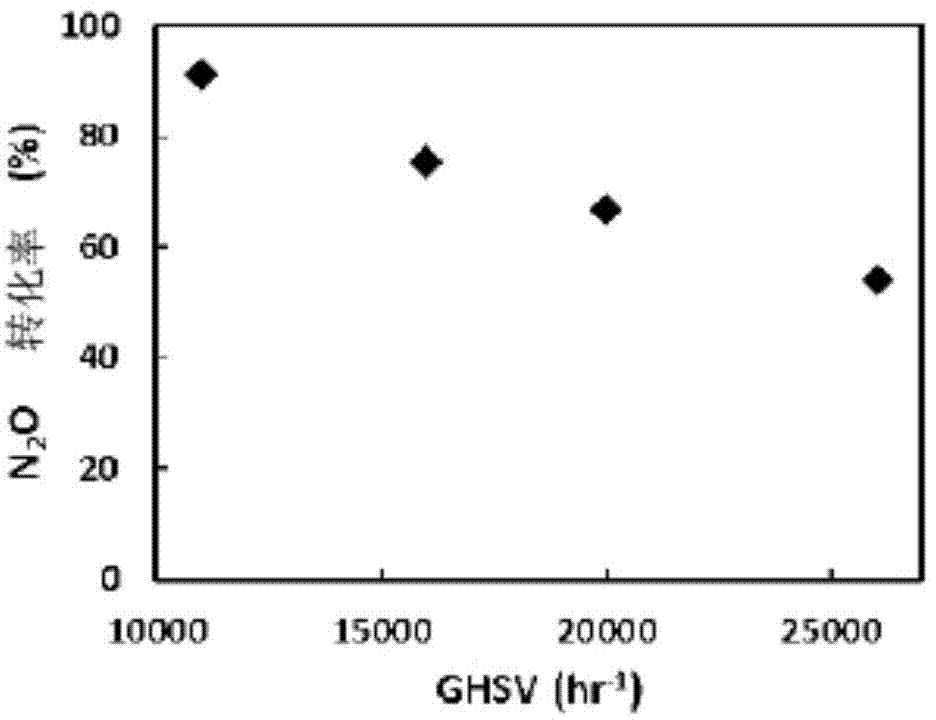

Formed catalyst for directly catalyzing N2O to decompose and manufacturing method thereof

InactiveCN103506128ASimple preparation processEasy to operateNitrous oxide captureDispersed particle separationAdipic acidChemistry

The invention relates to a preparation method for a formed catalyst for directly catalyzing N2O to decompose, and belongs to the technical field of environment protection catalytic materials and air pollution control. According to the catalyst, a compound material is used as a carrier to load metal oxide. The main active components are oxides of Zn and Ni, and one or two types from the oxides of Cu, Fe, Sr, La, Co, K, Na, Zr, Y or Ba are simultaneously loaded. The catalyst is characterized in that the compound material comprises two or more substances including clay, active carbon, bakelite powder, sesbania powder, special pseudo-boehmite powder, SiO2, TiO2, ZrO2, sandy soil and zinc oxide; the catalyst is columnar, clover-shaped or takes the shape of geranium nepalense sweet; the external diameter is 1-20 mm. The metal oxides accounts for 30-55% of the total weight of the catalyst, wherein the nickel oxide accounts for 1-5%, and the zinc oxide accounts for 30-45%. The catalyst can be widely used for removal and decomposing of N2O in a nitric plant, an adipic acid plant and other industrial process generating N2O.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Method for additionally impregnating active component for regeneration of denitration catalyst

ActiveCN105665036AEasy to operateLow costGas treatmentDispersed particle separationPtru catalystOrganosolv

The invention discloses a method for additionally impregnating an active component for the regeneration of a denitration catalyst. The method adopts two impregnation steps and comprises the following steps: firstly impregnating an inactivated denitration catalyst subjected to ash removal and chemical washing in an organic solvent insoluble in water, performing primary drying, and then re-impregnating a mixed solution containing active component elements, additive elements and a competitive absorbent. By adopting the method for additionally impregnating the active component, the active component and the additive component can be effectively loaded in ports of the denitration catalyst and can be intensively distributed at the outer layer of the denitration catalyst. By adopting the method, the denitration activity of the catalyst can be effectively restored, and the SO2 / SO3 conversion rate is inhibited.

Owner:DATANG NANJING ENVIRONMENTAL PROTECTION TECH

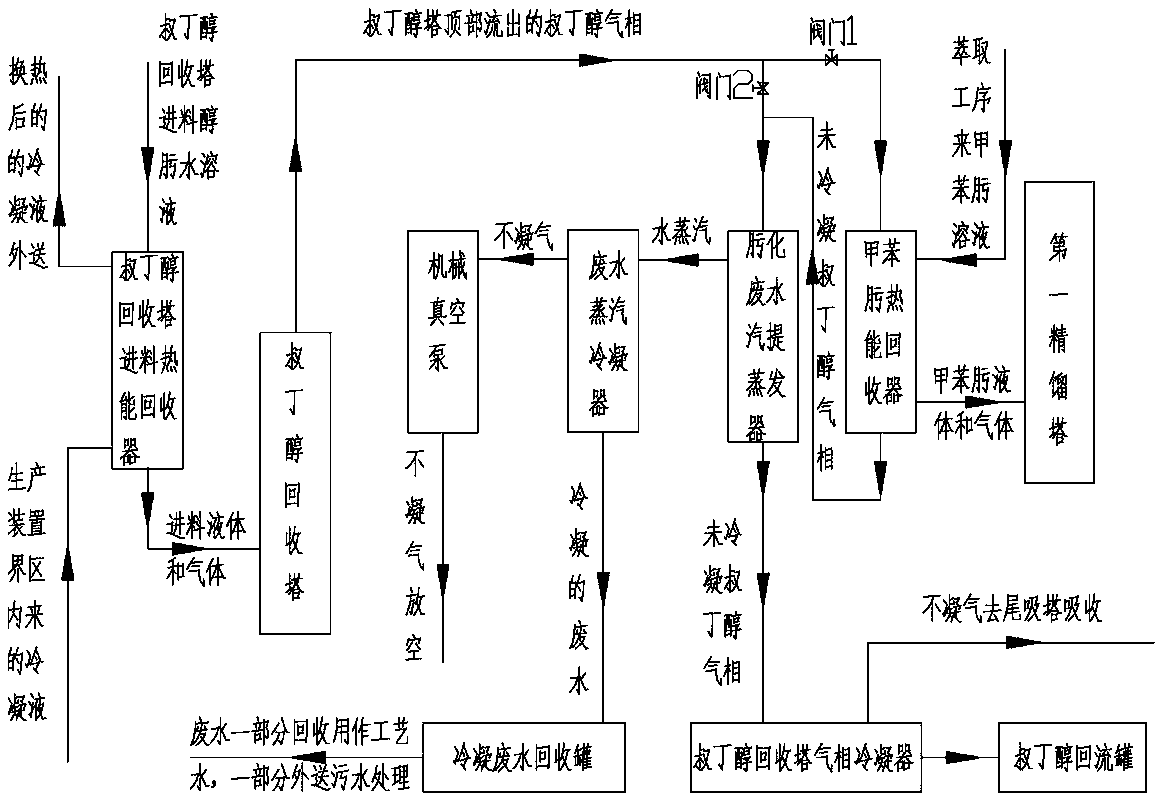

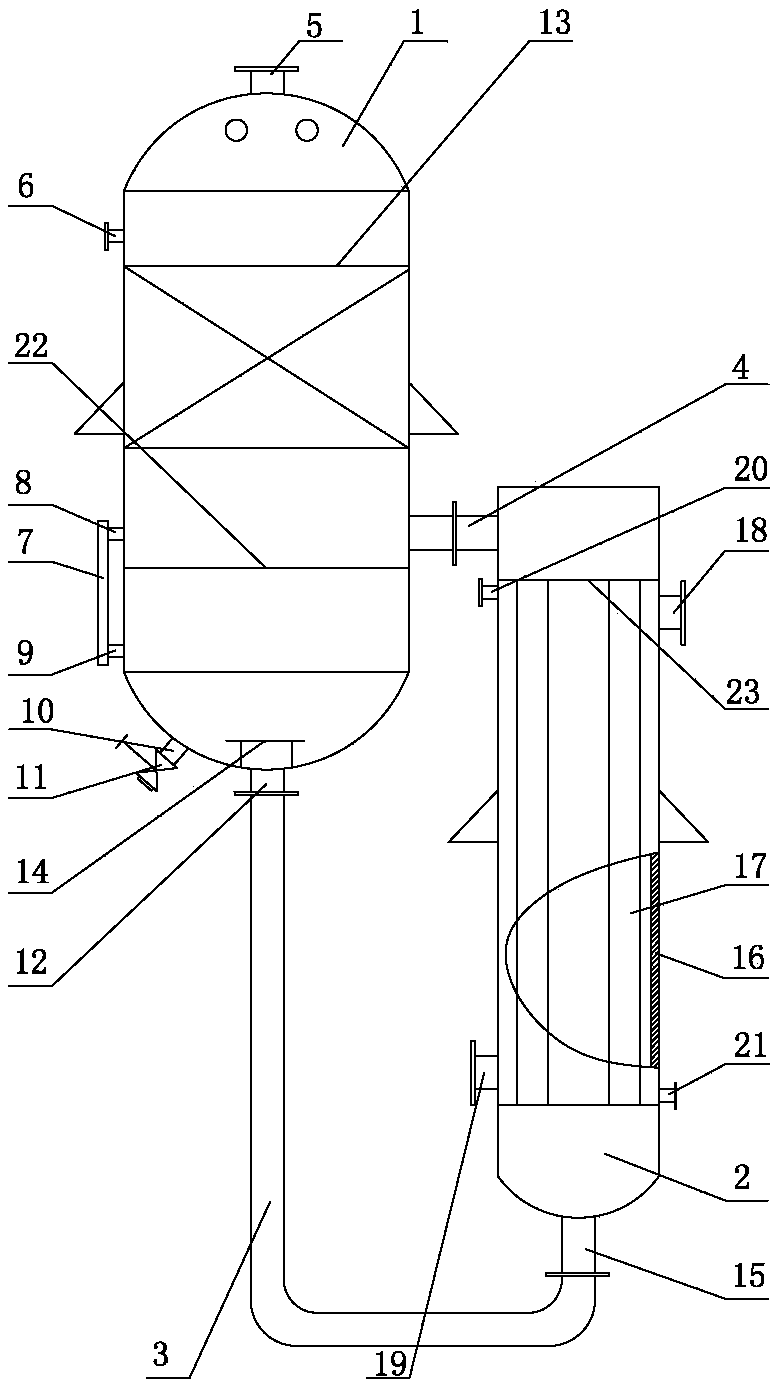

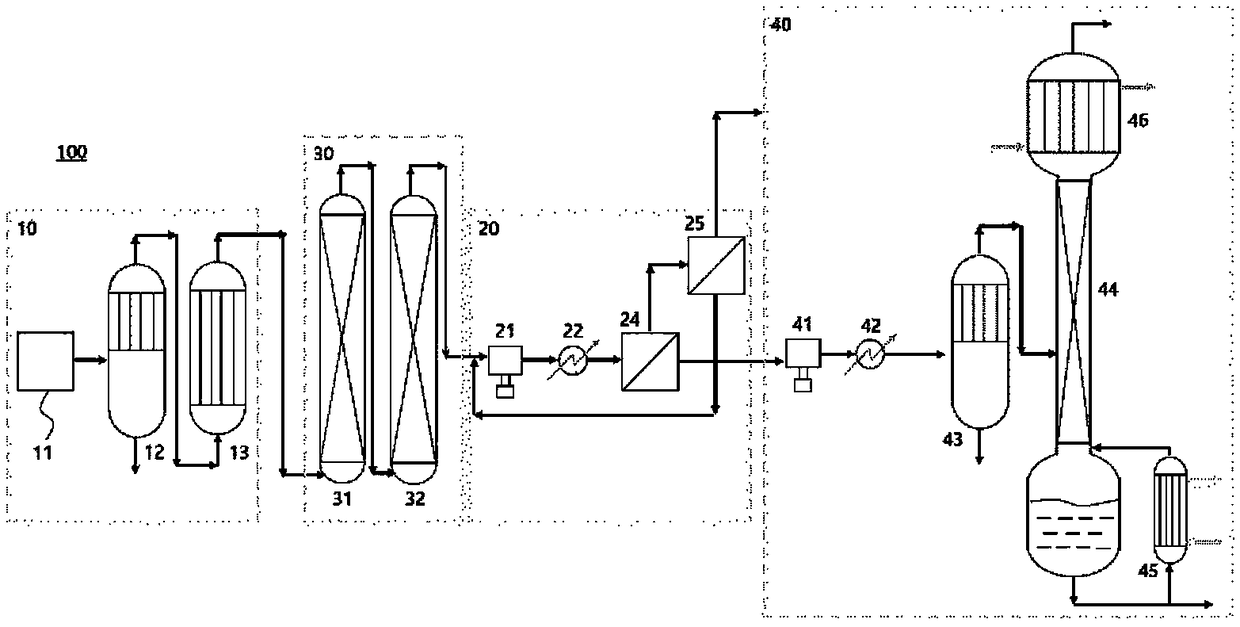

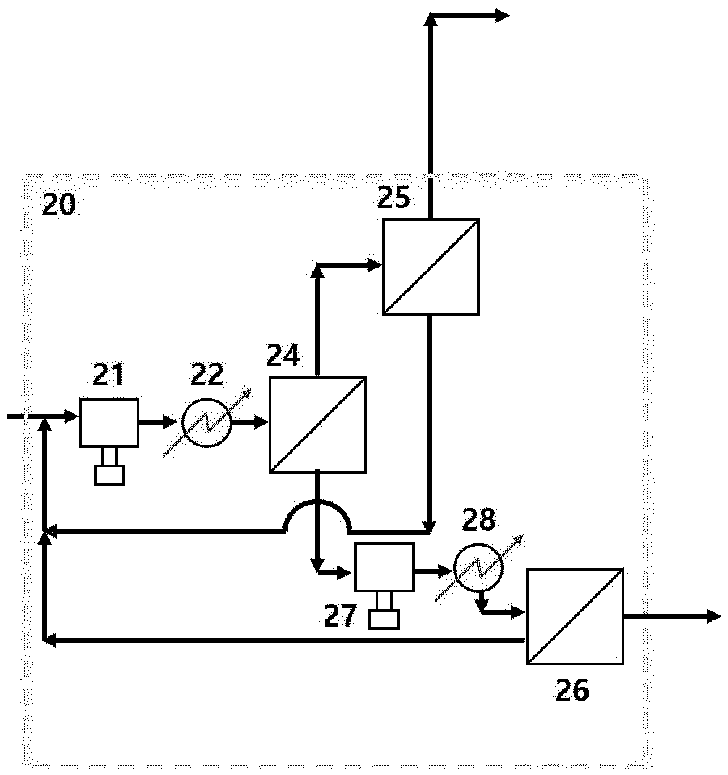

System and method for utilizing heat energy of oximation device

PendingCN108530317ALow costReduce usageLactams preparationOrganic compound preparationGas phaseEngineering

The invention discloses a system and a method for utilizing heat energy of an oximation device. The system comprises a TBA (Tert Butyl Alcohol) recovery tower feeding heat energy recoverer, a TBA recovery tower, a valve 1, a valve 2, an oximation wastewater steam stripping evaporator, a methylbenzene oximate heat energy recoverer, a first rectification tower, a TBA recovery tower gas-phase condenser, a TBA reflux tank, a wastewater steam condenser, a mechanical vacuum pump and a condensed wastewater recovery tank, wherein the oximation wastewater steam stripping evaporator and the methylbenzene oximate heat energy recoverer are in parallel and serial arrangement. According to the system and the method for utilizing the heat energy of the oximation device, disclosed by the invention, heat of high-temperature condensate during a production process of caprolactam can be recovered through the TBA recovery tower feeding heat energy recoverer, and heat of gas-phase steam flowing out of the TBA recovery tower can be recovered through the oximation wastewater gas stripping evaporator and the methylbenzene oximate heat energy recoverer which are in parallel and serial arrangement, so that the using amount of boiler steam is reduced; through the whole system and the method, the boiler steam can be saved by about 1.5 to 1.6 tons through the production of caprolactam per ton, the cost of steam is reduced from original 560 yuan to about 310 yuan, and huge economic benefit is gained.

Owner:宋心红

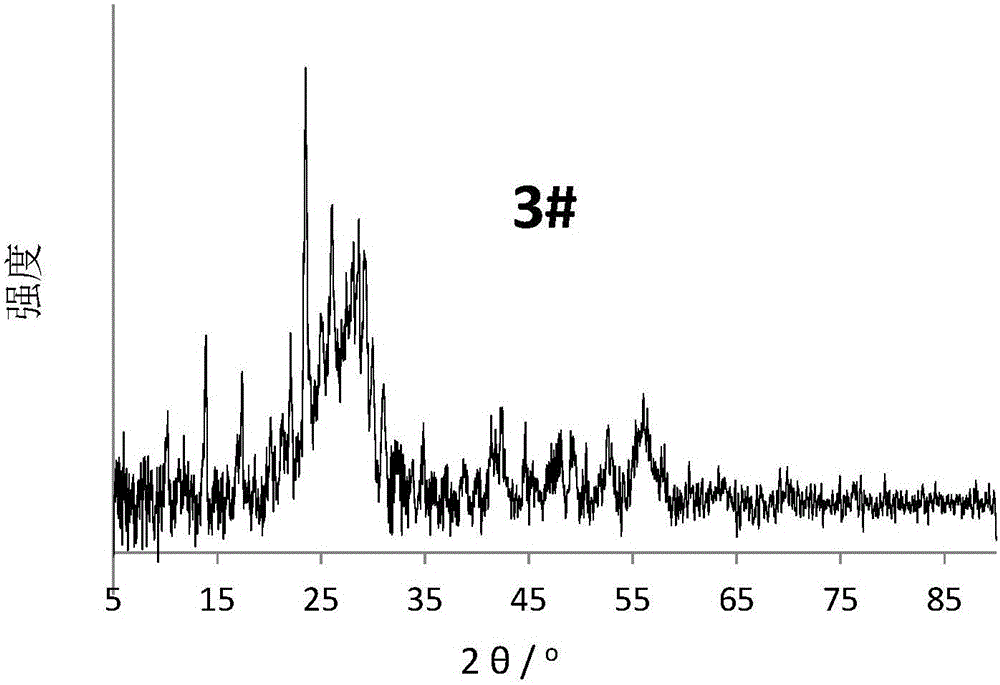

Preparation method of cerium-based sulfate catalyst for SCR (selective catalytic reduction) reaction

ActiveCN106622207AHigh catalytic activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsSulfateCerium

A preparation method of a cerium-based sulfate catalyst for SCR (selective catalytic reduction) reaction belongs to the technical field of preparation of a rare earth based SCR catalyst. The preparation method comprises the following steps: (1) weighing raw materials, mixing and ball-milling, wherein the Ce / Ti molar ratio is between 0.02 and 0.5; and (2) transferring the mixture to a muffle furnace, roasting at the temperature of 200 to 250 DEG C, preserving the temperature for 2 to 4 hours, and performing roasting at the temperature of 400 to 650 DEG C for 2 to 6 hours. The preparation method has the characteristics that the raw materials are cheap and easily available, the preparation process is simple, the preparation condition is easy to control, the preparation process is low in discharge and the like; and the obtained catalyst has high catalytic activity.

Owner:BEIJING UNIV OF TECH

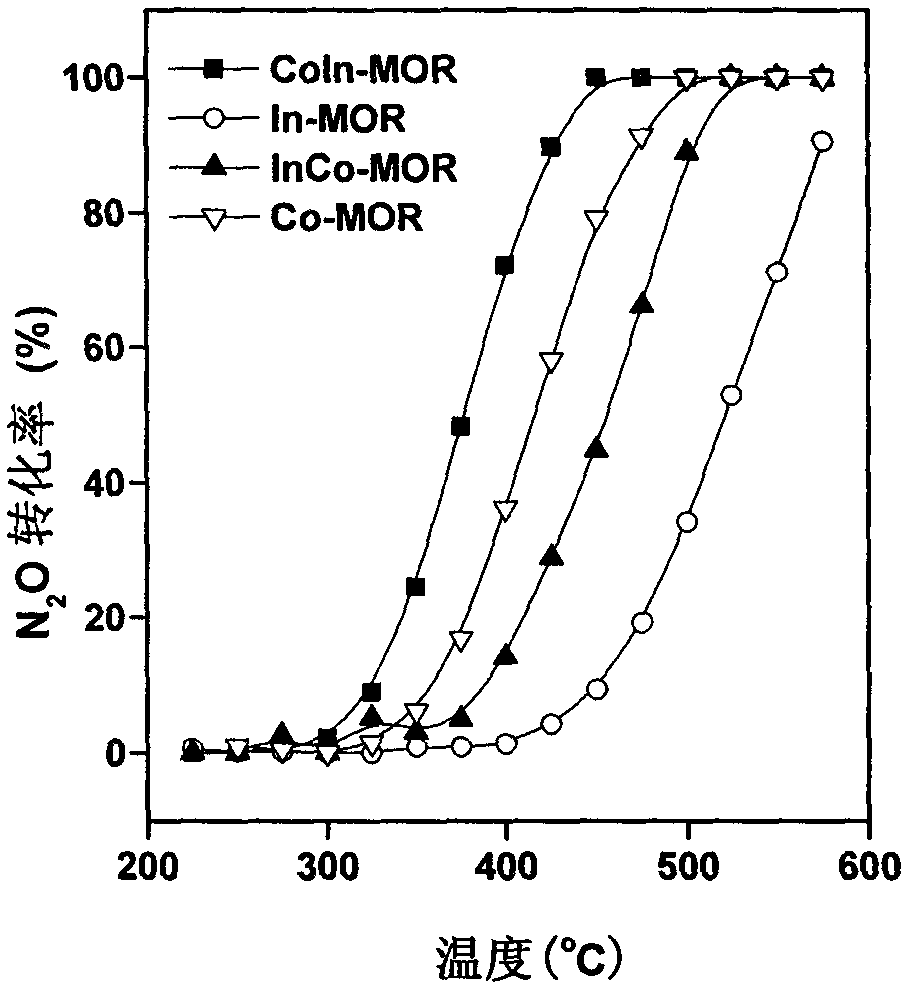

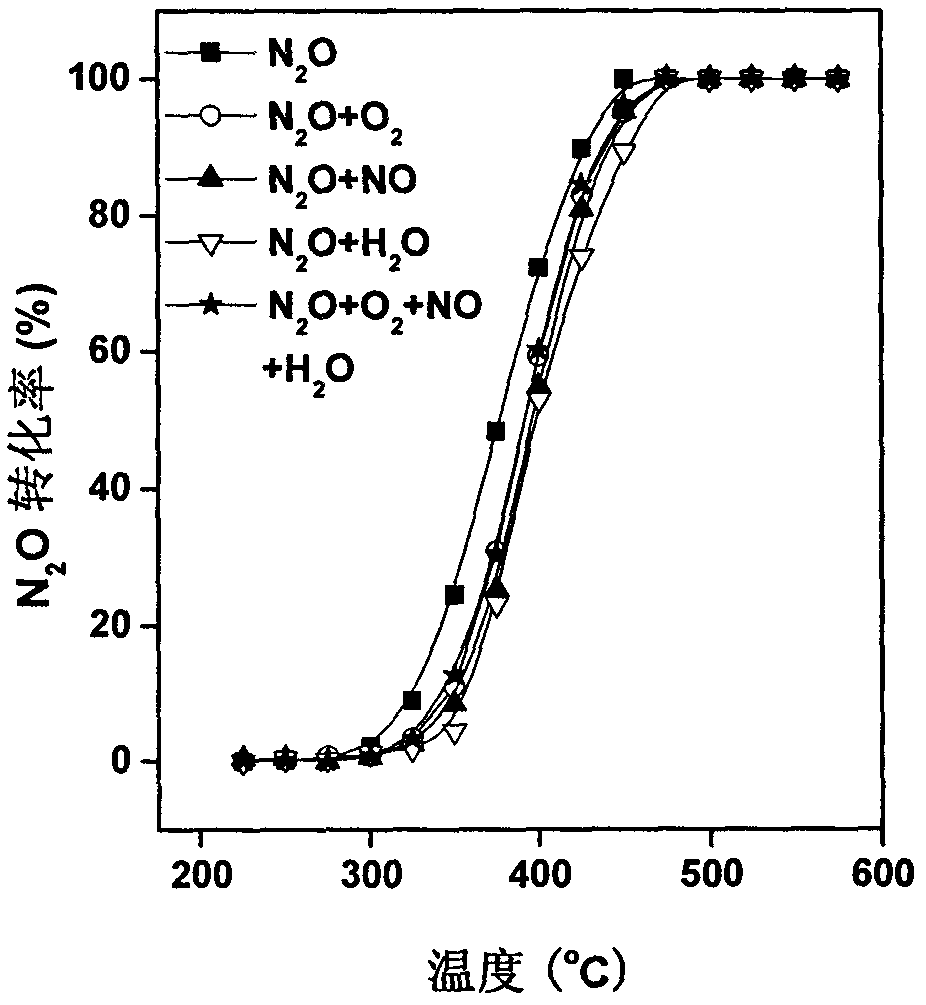

Catalyst for catalytic decomposition of nitrous oxide and a preparation method

InactiveCN102350370ANo significant decline in activityImprove stabilityNitrous oxide captureMolecular sieve catalystsIndiumCatalytic decomposition

The invention provides a cobalt-indium bimetal loaded mordenite catalyst used for catalytic decomposition of nitrous oxide and a preparation method thereof. Under the circumstances of a space velocity of 30,000h<-1>, a reaction temperature of 400-500DEG C, an N2O concentration of 0.1-30%, an H2O content of 2-10%, the catalyst can decompose most or all of N2O in a pollutant discharge system into N2 and O2. With high stability, the catalyst does not weaken in activity after a continuous simulation of nitric acid plant tail gas discharge for 100h. The catalyst of the invention has the advantages of simple preparation process, low cost, high activity in catalytic decomposition of nitrous oxide, and good stability. With wide applicability, the technology in the invention can be used in a lot of discharge reduction processes (like nitric acid production, adipic acid production and other processes) of N2O from industrial sources, thus boasting very wide application prospects.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

PPS (Polyphenylene Sulfite) microporous membrane with GO/TiO2 additive and low-temperature denitrification catalytic membrane

ActiveCN108211813AHigh porosityLarge specific surface areaMembranesSemi-permeable membranesPorosityHydrogen Sulfate

The invention provides a PPS (Polyphenylene Sulfite) microporous membrane with a GO / TiO2 additive and a low-temperature denitrification catalytic membrane. The PPS microporous membrane is prepared from the following raw materials in percentage by mass: 10 to 60 weight percent of polyphenylene sulfite, 30 to 80 weight percent of a compound diluting agent and 0.1 to 20 weight percent of the GO / TiO2additive. By adopting the PPS microporous membrane provided by the invention, the poisoning and inactivation problems of an existing low-temperature SCR (Selective Catalytic Reduction) catalyst are improved, and the catalytic membrane with water-resisting and sulfur-resisting functions is prepared. The polyphenylene sulfite membrane has high porosity, high specific surface area, good solvent resistance, environment resistance and hydrophobic property, so that the polyphenylene sulfite membrane can be used for effectively limiting combination of water steam and a catalyst and a high-performancecarrier is provided for the catalyst; a matrix is modified through TiO2-loaded graphene oxide to have good sulfur-resisting performance, so that the multifunctional catalytic membrane which can be used for effectively inhibiting the generation of ammonium sulfate and ammonium hydrogen sulfate on the surface of the catalyst, and furthermore, damages, caused by SO2, to the activity of the catalystare resisted and the service life of the catalyst is prolonged.

Owner:TIANJIN POLYTECHNIC UNIV

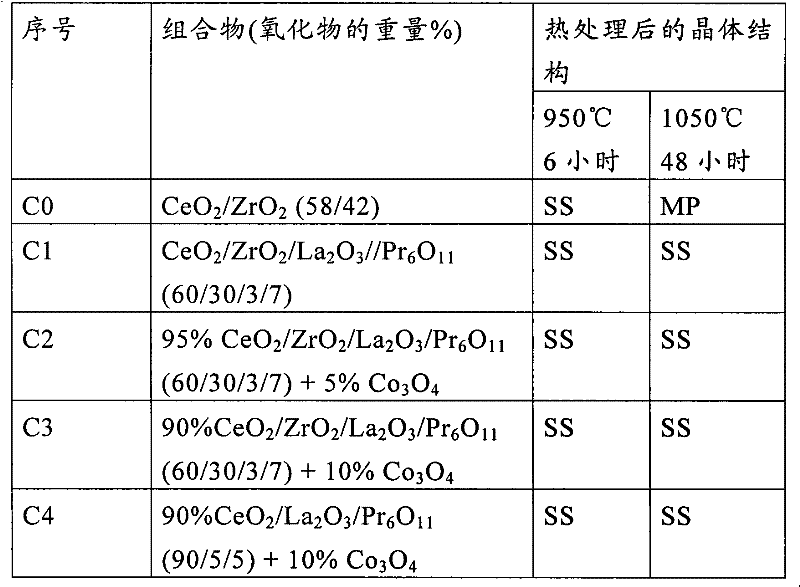

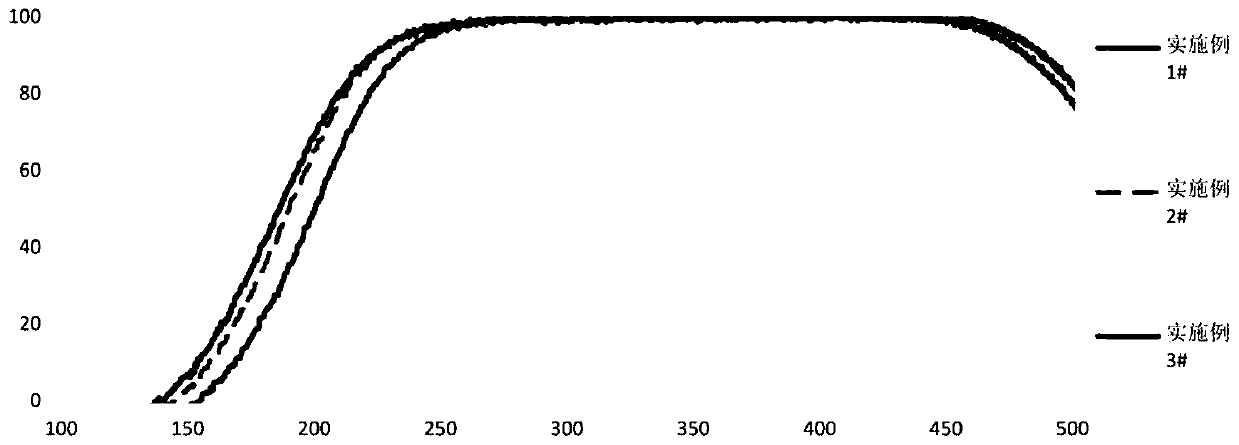

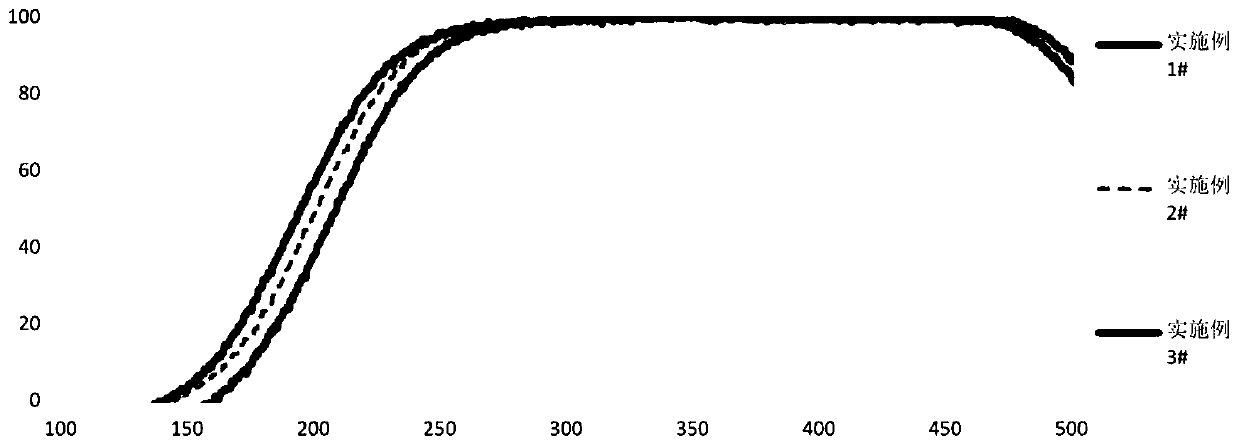

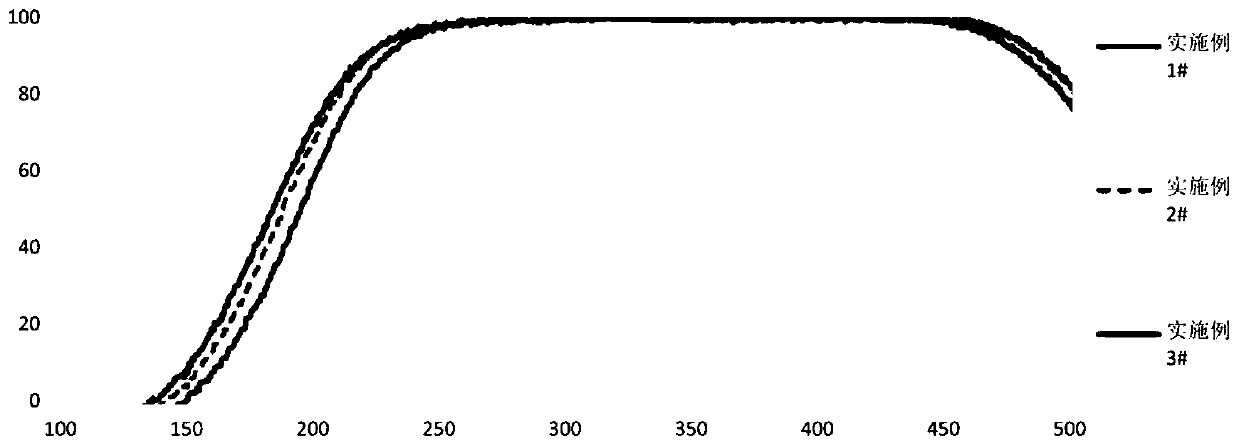

Method of decomposing n2o using a catalyst based on a cerium lanthanum oxide

The invention relates to a method for decomposing N2O. This method is characterized in that it uses, as catalyst, an oxide based on cerium and lanthanum which further includes at least one oxide of an element chosen from zirconium and rare earths other than cerium and lanthanum. This catalyst is more stable, enabling it to be used at high temperature.

Owner:RHODIA OPERATIONS SAS +1

Catalyst for low-temperature V2O5-WO3/TiO2NH3 selective reduction catalysis of NO and preparation method thereof

PendingCN111036229AGood thermal stability at high temperatureLarge specific surface areaHeterogenous catalyst chemical elementsDispersed particle separationPtru catalystPhysical chemistry

The invention discloses a catalyst for low-temperature V2O5-WO3 / TiO2NH3 selective reduction catalysis of NO and a preparation method of the catalyst, and relates to the technical field of preparationof oxide low-temperature SCR catalysts. According to the catalyst for NH3 selective reduction catalysis of NO, cordierite (2MgO.2Al2O<3>.5SiO2) is used as an inert carrier, cerium-modified titanium dioxide with a high specific surface area is used as a second carrier, and an active component is oxide of vanadium; the catalyst for NH3 selective reduction catalysis of NO comprises, by weight, 100 parts of TiO2, 1 to 5 parts of V2O5, 10 to 60 parts of CeO2, 5 to 20 parts of WO3 and 1 to 5 parts of auxiliary agent oxide.

Owner:SHIYAN HUIBO ENVIRONMENTAL SCI & TECHCO

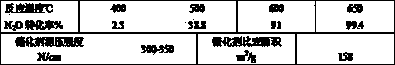

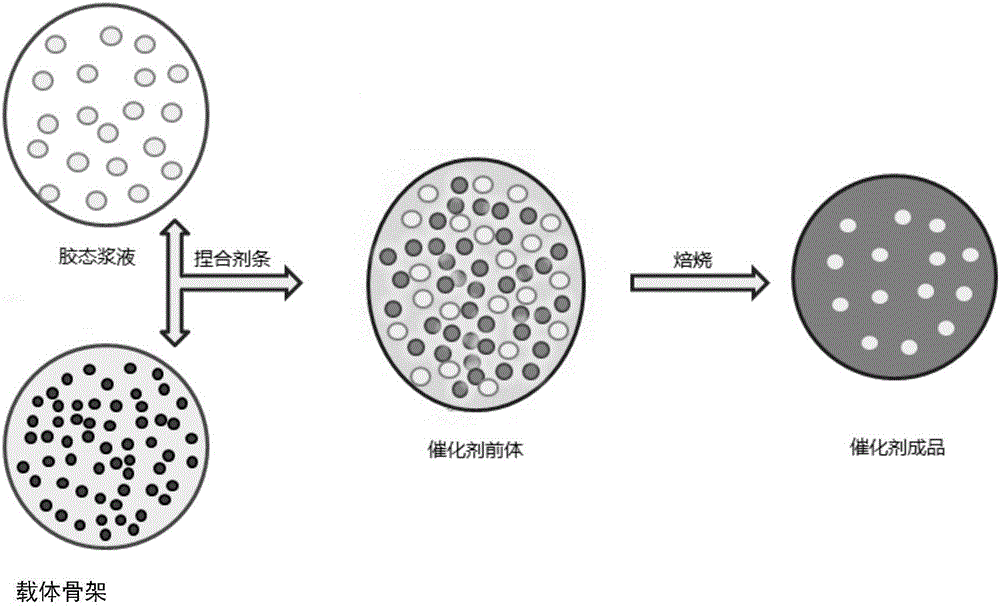

High-efficiency catalyst for purifying tail gas of adipic acid device, and forming technology method of catalyst

ActiveCN106179359AAvoid uneven loadHigh activityNitrous oxide captureGas treatmentActive componentDivalent metal

The invention provides a high-efficiency catalyst for purifying tail gas of adipic acid device, and a forming technology method of the catalyst. The high-efficiency catalyst is prepared from the following components in percentage by mass: 80-90% of carrier skeletons, 5-20% of active components, and 0.1-5% of promoter, wherein the active components contain divalent metal elements and trivalent metal elements. The concentration of N2O in industrial waste gas can be efficiently reduced. In addition, the catalyst can be directly formed and produced in batches, thus providing effective guarantee for the industrial application of the catalyst.

Owner:CHINA TIANCHEN ENG +1

Industrial catalyst for direct catalytic decomposition of N2O, and preparation method thereof

InactiveCN106512997AHigh activityHigh strengthNitrous oxide captureGas treatmentCatalytic decompositionAdipic acid

The invention discloses an industrial catalyst for direct catalytic decomposition of N2O, and a preparation method thereof. According to the catalyst, gamma-Al2O3 is adopted as a carrier, the main active components are the oxides of Cu and Co, and the catalyst supports one or two oxides of Ce, Fe, Mn and Ni. The catalyst preparation method comprises: (1) dissolving a main catalyst and a co-catalyst by using nitric acid, adding uniformly mixed materials such as pseudo boehmite, a binder and magnesium nitrate, and kneading into a plasticized form; (2) making the catalyst have a rod-like, a clover or a five-leaf grass solid or hollow shape; and (3) carrying out drying calcination to prepare the catalyst. According to the present invention, the catalyst has advantages of low raw material cost, simple preparation process, regular appearance, high strength, good catalytic activity and no secondary pollution, and especially provides good decomposition ability for the removal of the N2O in the production tail gas in adipic acid plants and nitric acid plants.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY +1

Method for simultaneously removing nitrous oxide and nitric oxide in exhaust gas of chemical plant by utilizing catalyst

InactiveCN104841273ASimple processLow running costNitrous oxide captureDispersed particle separationReaction temperatureNitric oxide

The invention relates to a method for simultaneously removing nitrous oxide and nitric oxide in the exhaust gas of a chemical plant by utilizing a catalyst. According to the method, a zeolite catalyst, infiltrated in iron ions, is put in a catalytic reactor. Inside the catalytic reactor, the ammonia is adopted as a reducing agent, and the operation conditions supplied from the catalytic reactor to the exhaust gas is controlled. In this way, during the generation process of nitric acid, adipic acid, caprolactam and the like, nitrous oxide and nitric oxide can be generated out of the exhaust gas of the chemical plant at the same time at a low reaction temperature of 300-400 DEG C.

Owner:KOREA INST OF ENERGY RES

Vanadium-free denitration catalyst and preparation method thereof

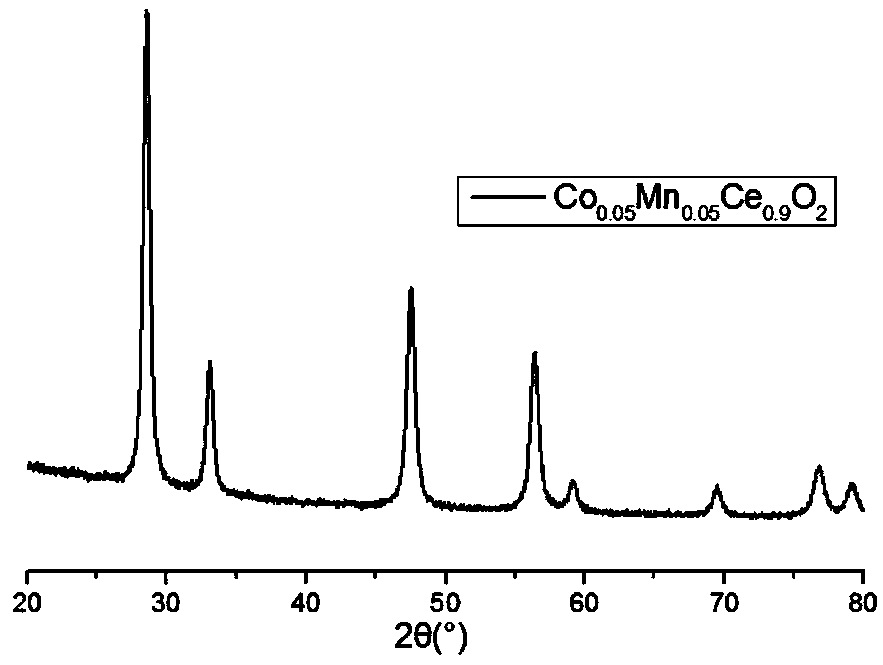

InactiveCN108745345AWide catalytic activity temperature windowHigh catalytic efficiencyHeterogenous catalyst chemical elementsDispersed particle separationHuman healthSolvent

The invention discloses a vanadium-free denitration catalyst, wherein a CeO2 nanosheet is used as a matrix, and transition metal elements are uniformly incorporated into a CeO2 lattice. A preparationmethod of the vanadium-free denitration catalyst is further disclosed. The method includes: conducting chelation reaction in a water and ethanol mixed solution with cerium oxide as a main body, the transition metal elements as a dopant, a common alkali metal solution as a regulator and phthalic acid, biphenyldicarbox ylic acid, trimesic acid, pyromellitic acid or the like as a ligand; drying a product of the chelation reaction, calcining the product for 2-5h at the temperature of 400-700DEG C to obtain the vanadium-free denitration catalyst. The method has the advantages of being simple in production process, capable of obtaining raw materials easily and easy to industrialize, adopting non-toxic harmless components and being harmless to the environment and human health. The vanadium-free denitration catalyst prepared by the method has wide catalytic activity temperature window and high catalytic efficiency, and can be used for denitration of both fixed source industry and mobile sourceexhaust gas.

Owner:杭州同久净颢科技有限责任公司

Regeneration method of SCR (selective catalytic reduction) catalyst

ActiveCN104548935ATargetedImprove efficiencyDispersed particle separationAdipic acid productionActive componentOrganic chemistry

The invention discloses a regeneration method of an SCR (selective catalytic reduction) catalyst. According to the method, the catalyst is cleaned through two steps and is loaded with active components after complete cleaning, blocking materials are more thoroughly cleaned, and the active components are more uniformly loaded. An adopted cleaning fluid formula belongs to a low-toxic or even non-toxic material, so that environmental pollution is reduced; a weak acidic or weak basic solution is adopted, and loss of the active components in the catalyst is avoided in a cleaning process, and the method further has the characteristics of high pertinence and high efficiency. The activity of the catalyst cleaned in a separated manner recovers to higher than 95% of the activity of a fresh catalyst.

Owner:CHINA HUADIAN ENG +1

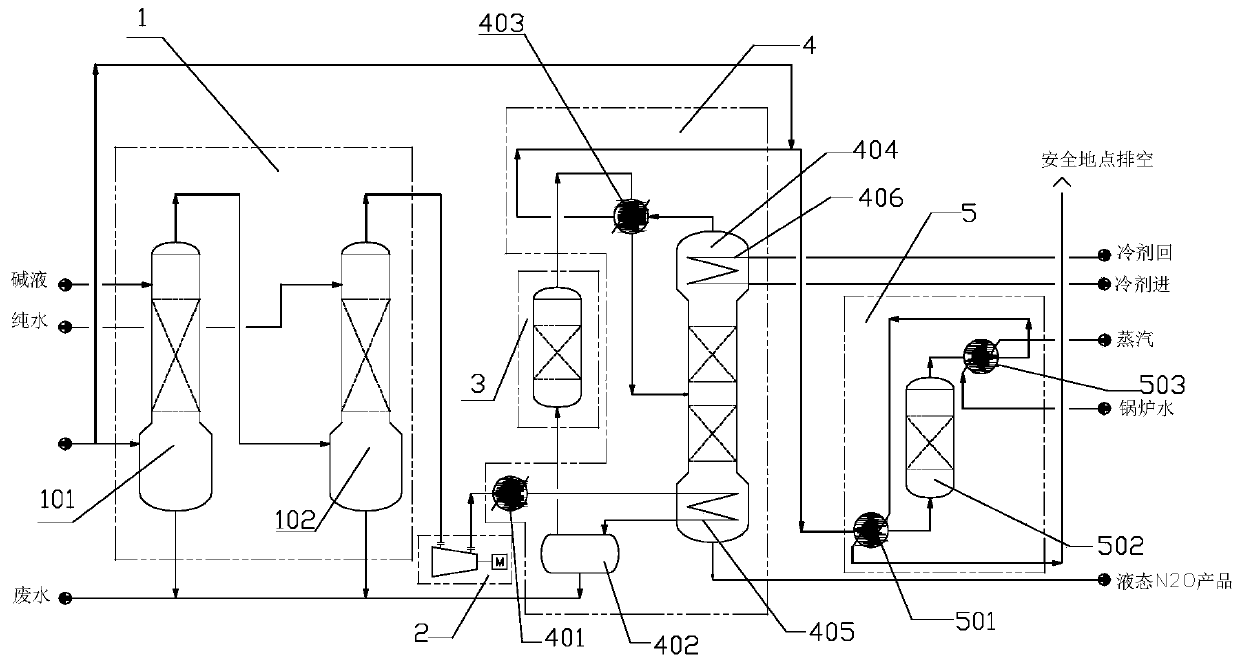

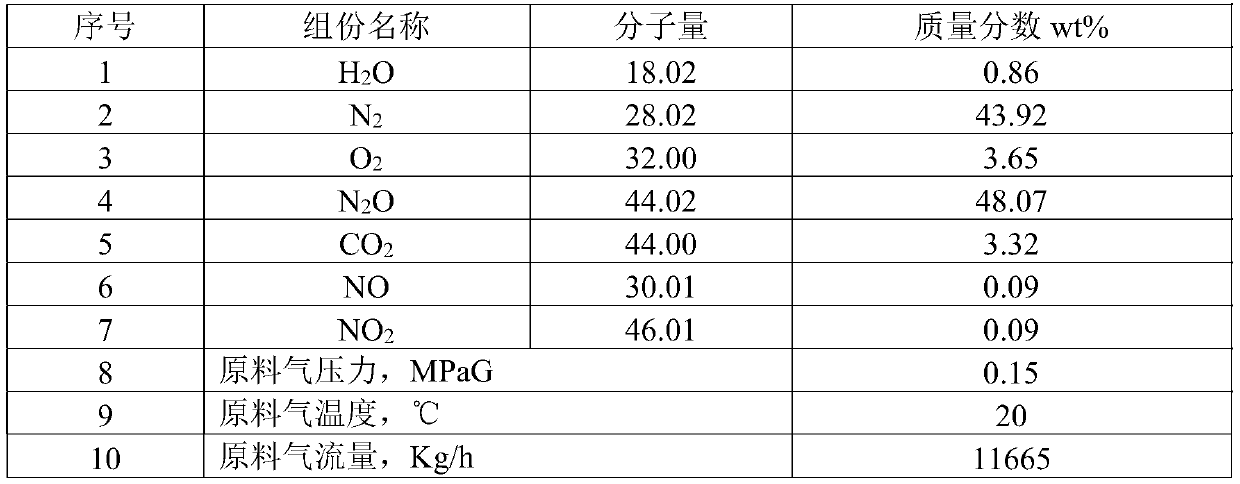

Process for recovery and purification of nitrous oxide from nitrous oxide-containing gas mixture

The present invention relates to a process for recovering and purifying nitrous oxide from a gas mixture generated in industrial processes, such as a nitrous oxide (N2O) production process by pyrolysis of ammonium nitrate, an adipic acid production process, a nitric acid production process, and a caprolactam production process.

Owner:KOREA RES INST OF CHEM TECH

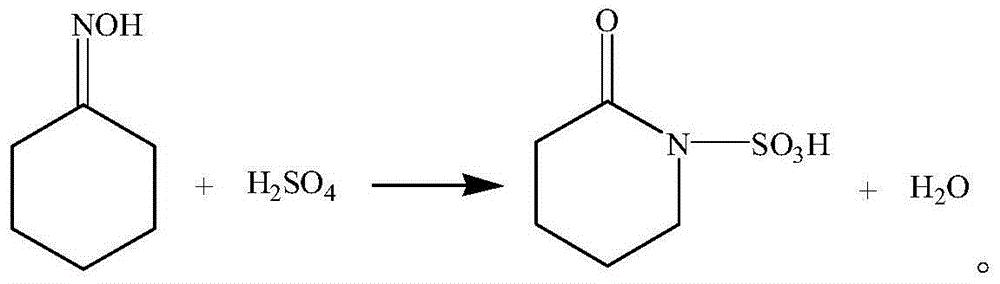

Preparation method for caprolactam

InactiveCN105837507AHigh yieldIncrease annual outputLactams preparationBulk chemical productionBeckmann rearrangementOrganic solvent

Owner:HUBEI JINXIANGNING CHEM ENG TECHENOLOGY CO LTD +1

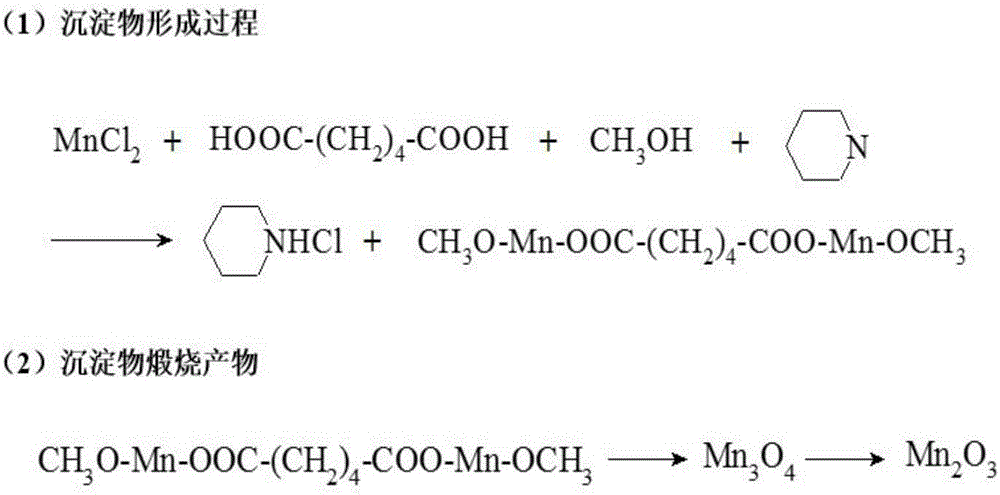

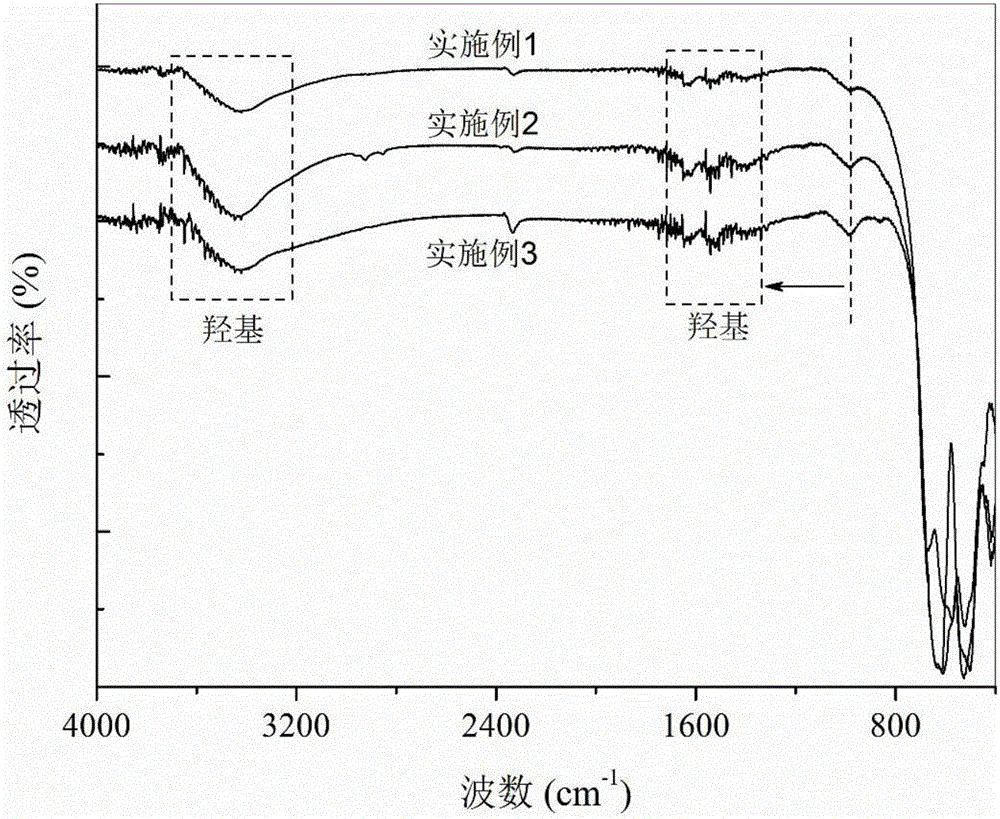

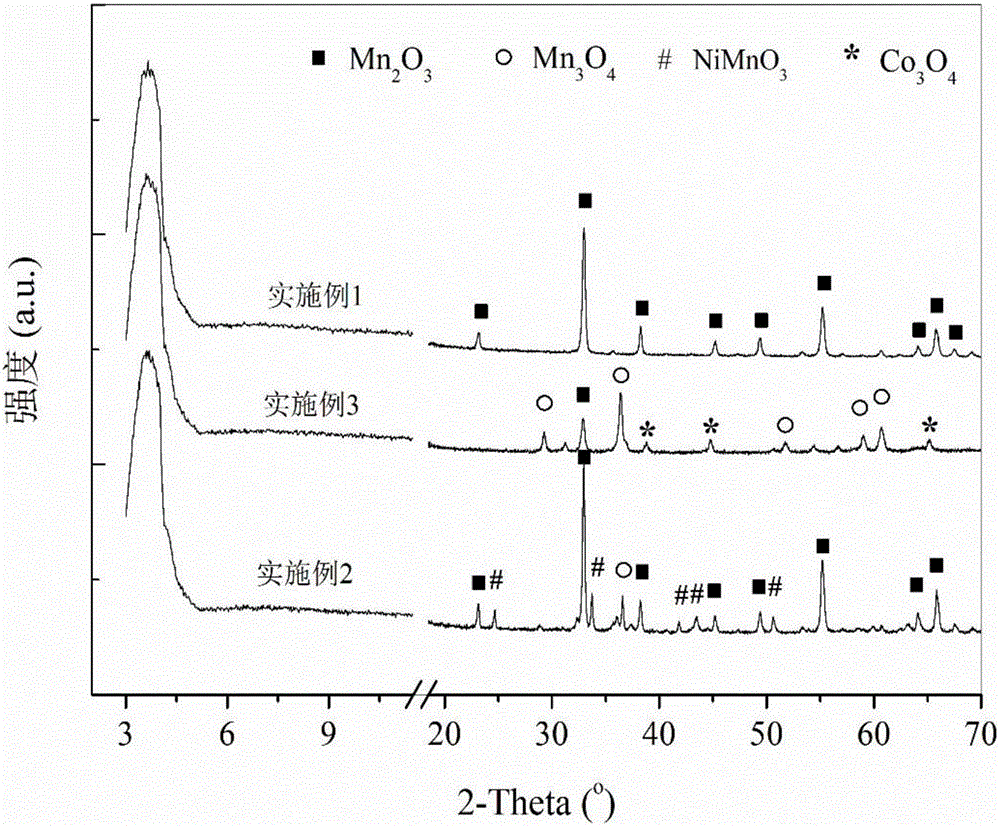

Hydroxyl-containing manganese-series catalyst used for low-temperature flue gas denitration and preparation method thereof

InactiveCN106492789AImprove purification efficiencyImprove anti-sulfur poisoning performanceGas treatmentDispersed particle separationManganeseCarboxylic acid

The invention provides a hydroxyl-containing manganese-series catalyst used for low-temperature flue gas denitration and a preparation method thereof, belonging to the field of flue gas denitration and environmental catalysis. According to the invention, dicarboxylic acid is used as a template agent; a metal chloride is used as ligand; methanol is used as a complexation aid and a solvent; piperidine is used as a proton and chloride ion capturing agent; and the hydroxyl-containing manganese-series catalyst is prepared through an esterification reaction and metal ion complexation, and is applicable to NH3-SCR denitration. The dicarboxylic acid comprises one selected from a group consisting of oxalic acid and propane diacid to dodecanedioic acid, i.e., HOOC-(CH2)n-COOH (wherein n is no less than 0 and no more than 10). The hydroxyl-containing manganese-series catalyst has high low-temperature nitrogen oxide (NOx) purifying effect and good nitrogen (N2) selectivity, wherein the removal rate of NOx in a temperature range of 150 to 250 DEG C is as high as 80 to 100% and the selectivity of N2 reaches 75% or above; and the catalyst has certain resistance to SO2 poisoning. The method is easy to operate, simple in process and convenient for realization of industrial production. The prepared catalyst is applicable to removal of nitrogen oxides in low-temperature flue gas from coal-fired power plants, industrial kilns, pellet sintering, the coking industry, etc.

Owner:UNIV OF SCI & TECH BEIJING

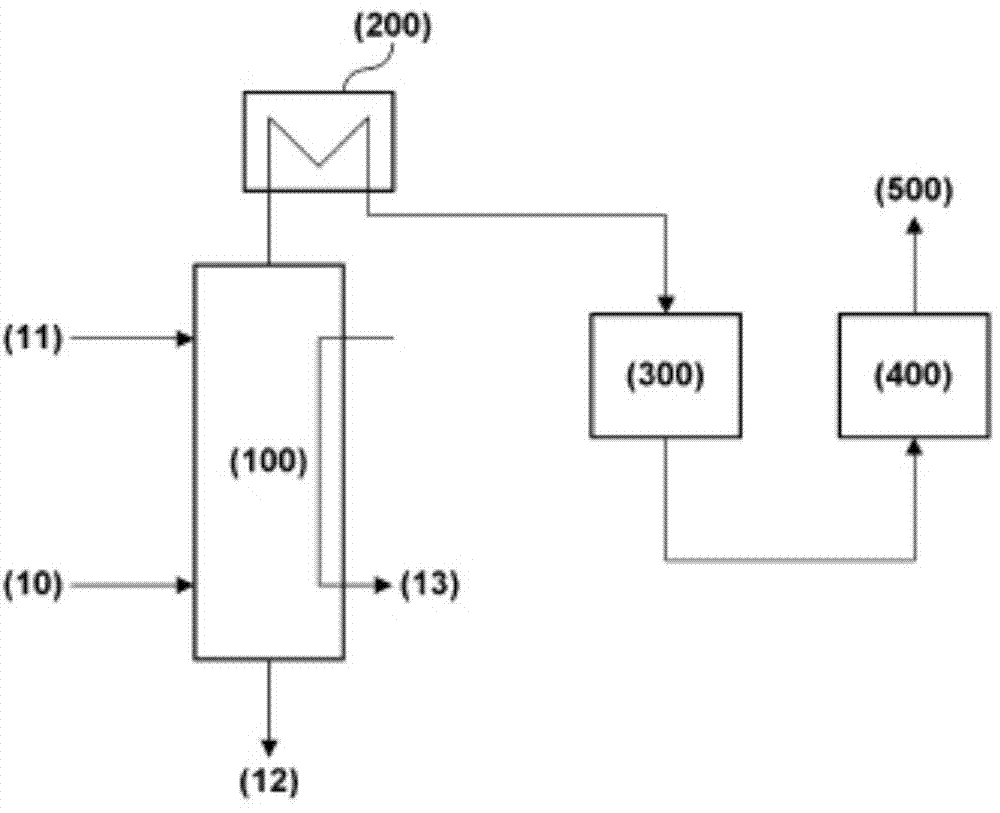

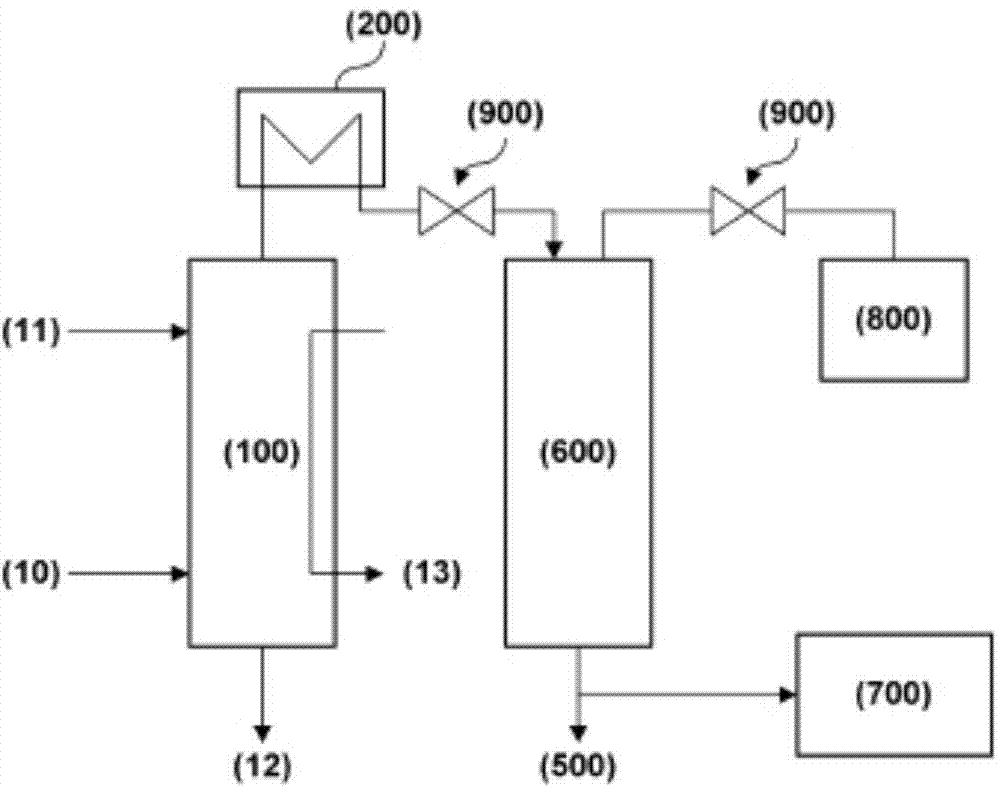

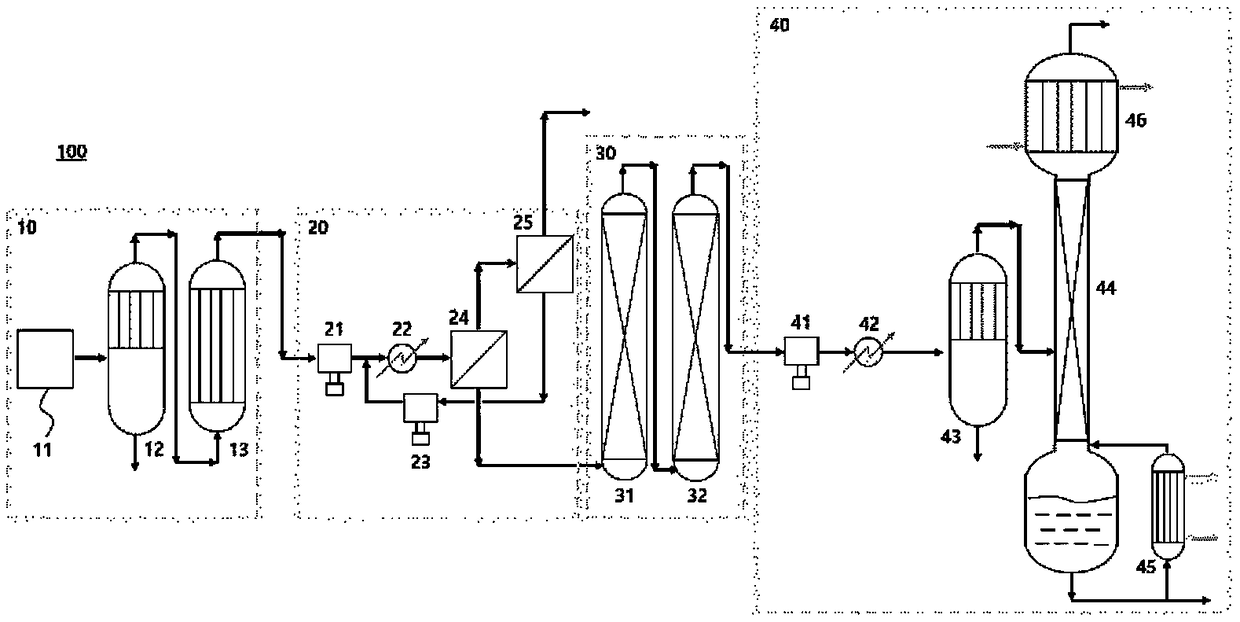

Adipic acid production device tail gas treatment device and method

PendingCN111013382AReach friendlyEfficient recyclingNitrous oxide captureGas treatmentCatalytic decompositionProcess engineering

The invention provides an adipic acid production device tail gas treatment device and a method. The adipic acid production device tail gas treatment device comprises a preceding-stage pretreatment system, a tail gas pressurization system, a purification system, a low-temperature rectification system and a catalytic decomposition system; wherein the preceding-stage pretreatment system is connectedwith the tail gas pressurization system through a pipeline, and a gas outlet of the tail gas pressurization system is communicated with a reboiling coil at the lower end of a rectification tower in the low-temperature rectification system; the other end of the reboiling coil is communicated with a liquid separation tank, an outlet of the liquid separation tank is communicated with an inlet of thepurification system, and an outlet of the purification system is communicated with an inlet of the rectification tower through a pipeline; and a liquid N2O discharge pipeline is arranged at the bottomof the rectification tower, and an outlet at the top of the rectification tower is communicated with the catalytic decomposition system. According to the method, N2O in the adipic acid production device tail gas can be effectively recycled, the blank in adipic acid process is filled up, and the aims of maximizing economic benefits and being environmentally friendly are achieved.

Owner:CHINA TIANCHEN ENG

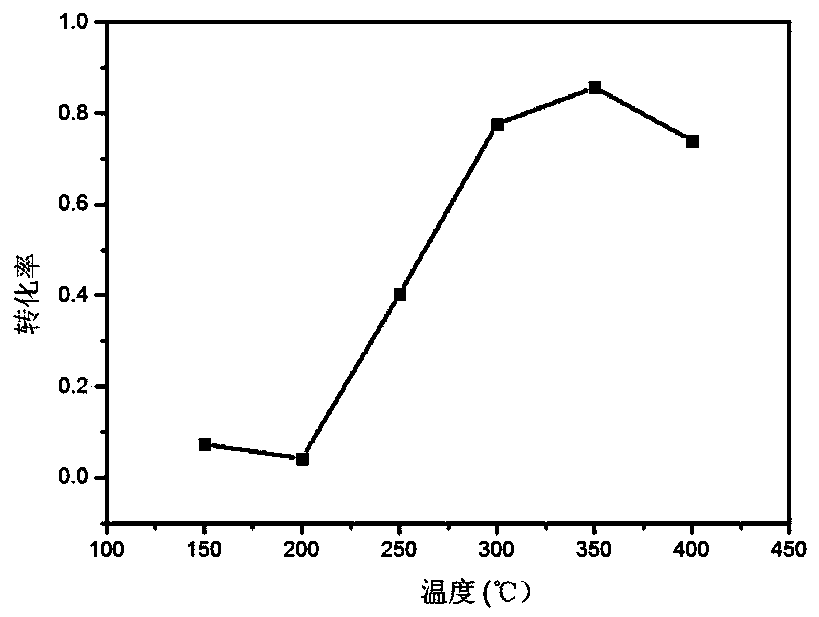

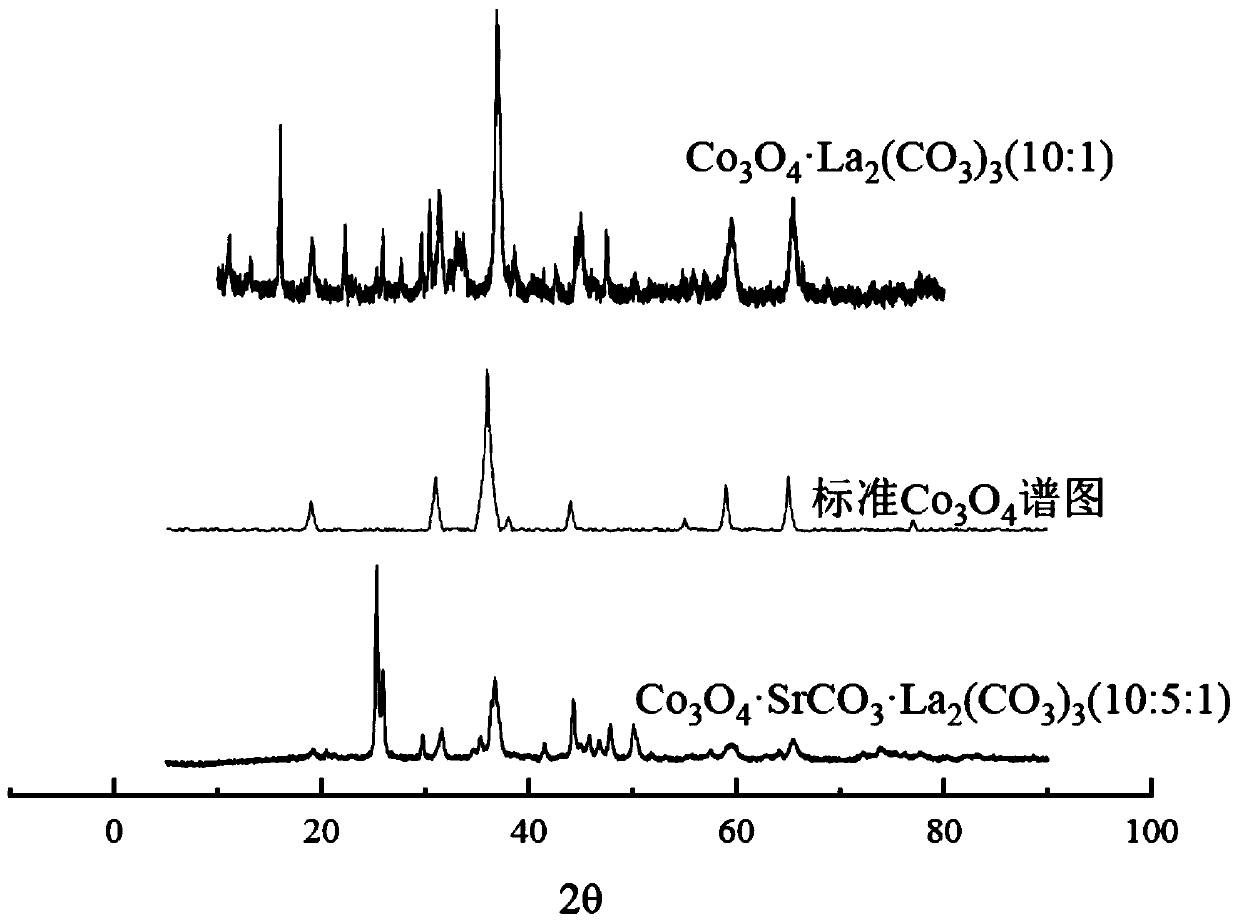

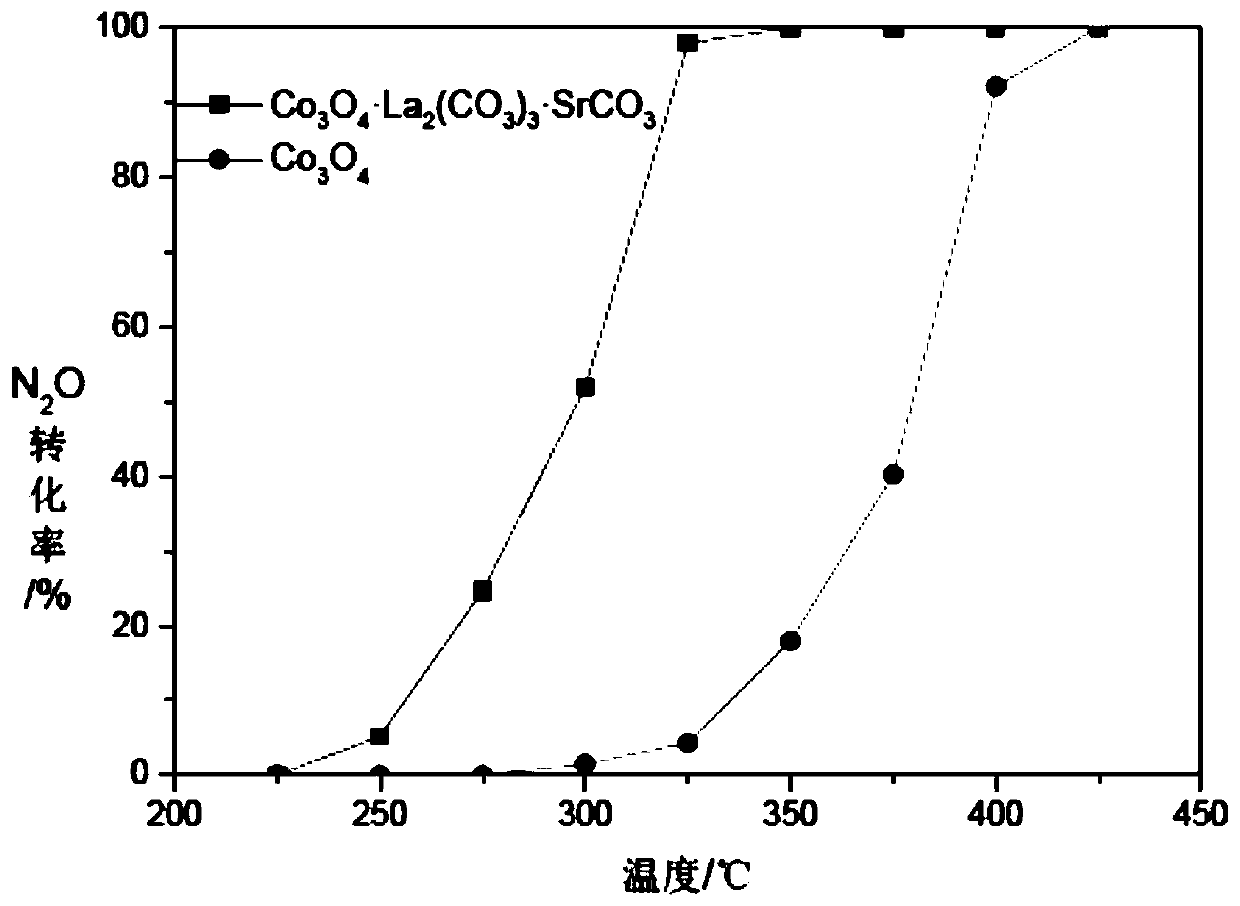

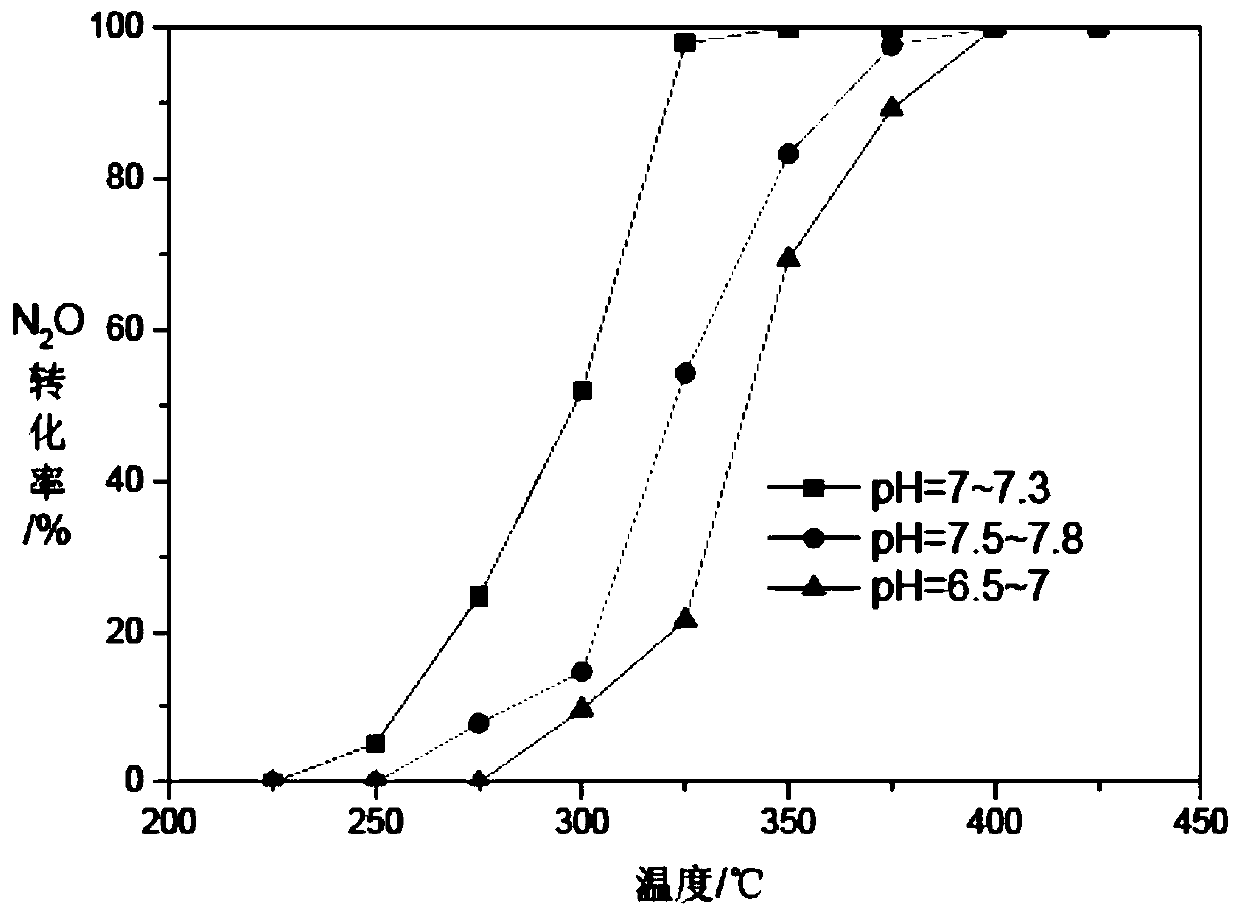

Preparation method and application of nitrous oxide decomposition reaction catalyst

InactiveCN111359645AEmission reductionLow costNitrous oxide captureGas treatmentAlkaline earth metalPtru catalyst

The invention discloses a preparation method and an application of a nitrous oxide decomposition reaction catalyst, and belongs to the technical field of waste gas purification treatment. The catalystcomprises a carrier, an auxiliary agent and an active substance; the catalyst is a compound of Co3O4 and a carbonic acid compound of any one or more metal elements selected from alkali earth metal Aor / and La; and the main active component in the metal oxide is Co3O4, and meanwhile, the alkali earth metal A such as Cs, Ba and other metal carbonates are used as a matrix or / and metal La carbonatesare used as a matrix to assist in dispersing Co3O4 and further reduce the cost. The catalyst can be used in the field of tail gas treatment in adipic acid production or nitric acid production. The catalyst disclosed by the invention can realize catalytic decomposition reaction of N2O, is simple in preparation process and wide in raw material source, and can provide an effective catalyst for the field of environmental governance.

Owner:BEIJING UNIV OF CHEM TECH +2

Preparation method of eggshell laughing gas decomposition catalyst

InactiveCN106807431AHigh activitySolution to short lifeNitrous oxide captureGas treatmentHigh concentrationEggshell

The invention discloses a preparation method of a shell catalyst for catalytic decomposition of laughing gas and belongs to the field of environmental catalyst materials. The method of the catalyst comprises the steps of taking a beta molecular sieve, ZSM-5 or activated aluminum oxide after surface pretreatment as a carrier and taking metal oxides such as Fe, Co and Cu as active components of the catalyst, adding an appropriate amount of assistant, enriching the active components on an outer layer of the carrier by a controlled quick drying method to form a shell structure. The activity and the service life of the catalyst are improved and prolonged. The catalyst is applicable to treatment of high-concentration laughing gas such as adipic acid exhaust gas and can perform complete catalytic decomposition of the 5000-15000ppm laughing gas under conditions of pressure of 0.18MPa, temperature of 500-600 DEG C and airspeed of 6000-10000h<-1>.

Owner:TANGSHAN KAILUAN CHEM TECH CO LTD

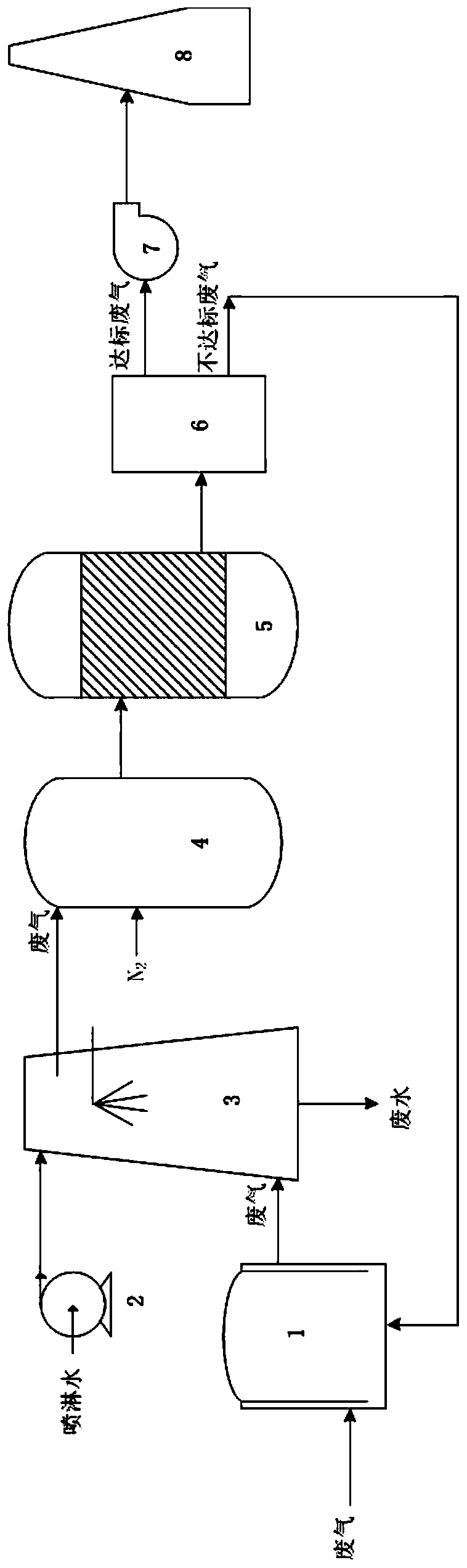

System and method for co-processing N2O and VOC in caprolactam production waste gas

PendingCN110538570AEasy to handleTo achieve the purpose of treating waste with wasteNitrous oxide captureGas treatmentFlue gasRedox

The invention discloses a system for co-processing N2O and VOC in caprolactam production waste gas. According to the flow direction of the waste gas, the system includes a gas storage device, a waterwashing device, a gas dilution device, a catalytic reaction device, a flue gas monitoring device, and a gas discharging device. The invention also discloses a method for co-processing the N2O and theVOC in the caprolactam production waste gas by using the system. The caprolactam production waste gas enters the water washing device from the gas storage device, after pretreatment is performed, thepretreated product enters the catalytic reaction device, a redox reaction is performed under the action of a catalyst, various indexes of the products are detected by the flue gas monitoring device, and discharge is performed through the gas discharging device. The method utilizes oxidability of the N2O in the caprolactam production waste gas for the first time to synergistically treat tert-butanol in the caprolactam production waste gas, the conversion rate of the N2O is 99.95-99.98%, the conversion rate of the tert-butanol is 99.96-99.99%, and the purpose of treating waste with waste is realized; and the system and the method are technological innovation in the field of energy conservation and environmental protection, and have economic, practical and industrial application prospects.

Owner:HENAN SHENMA NYLON CHEM +3

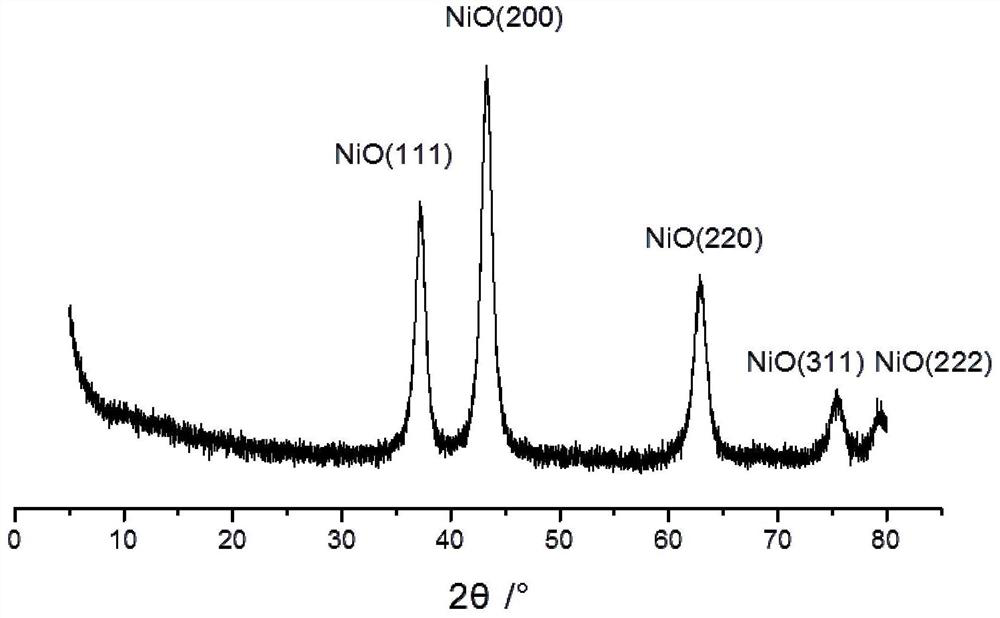

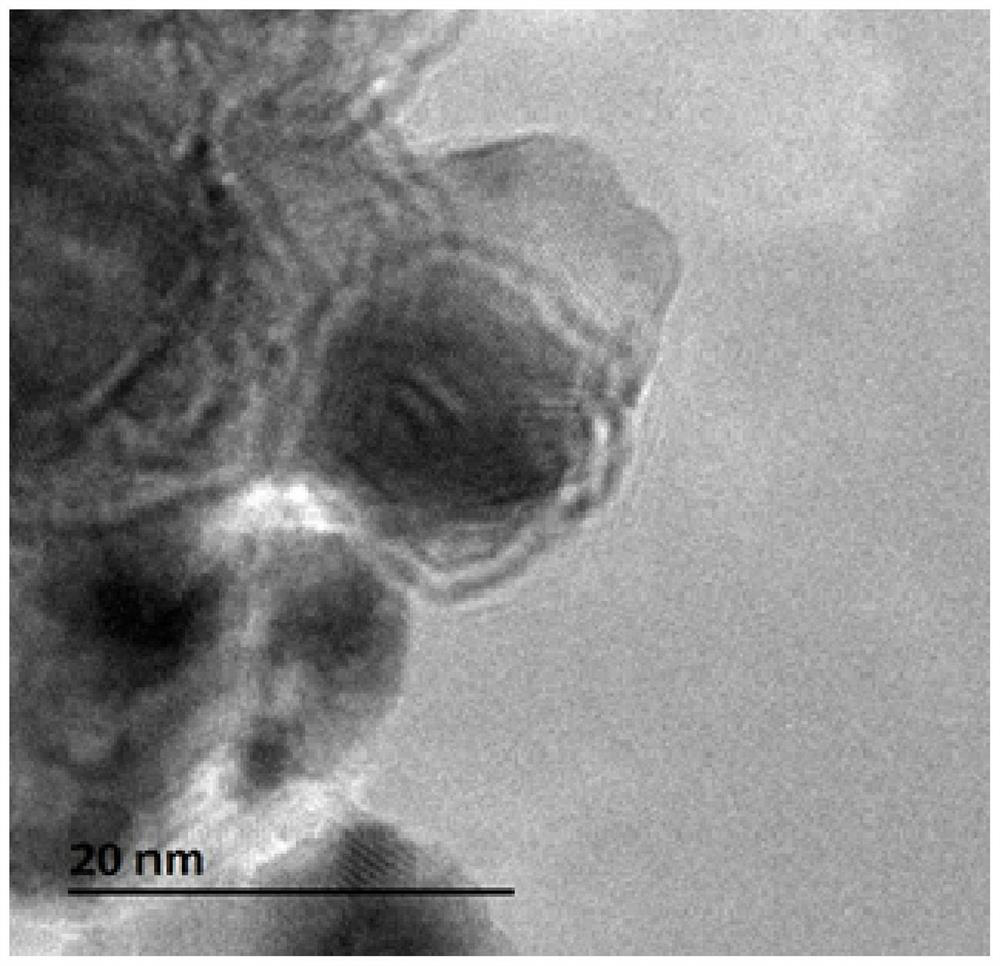

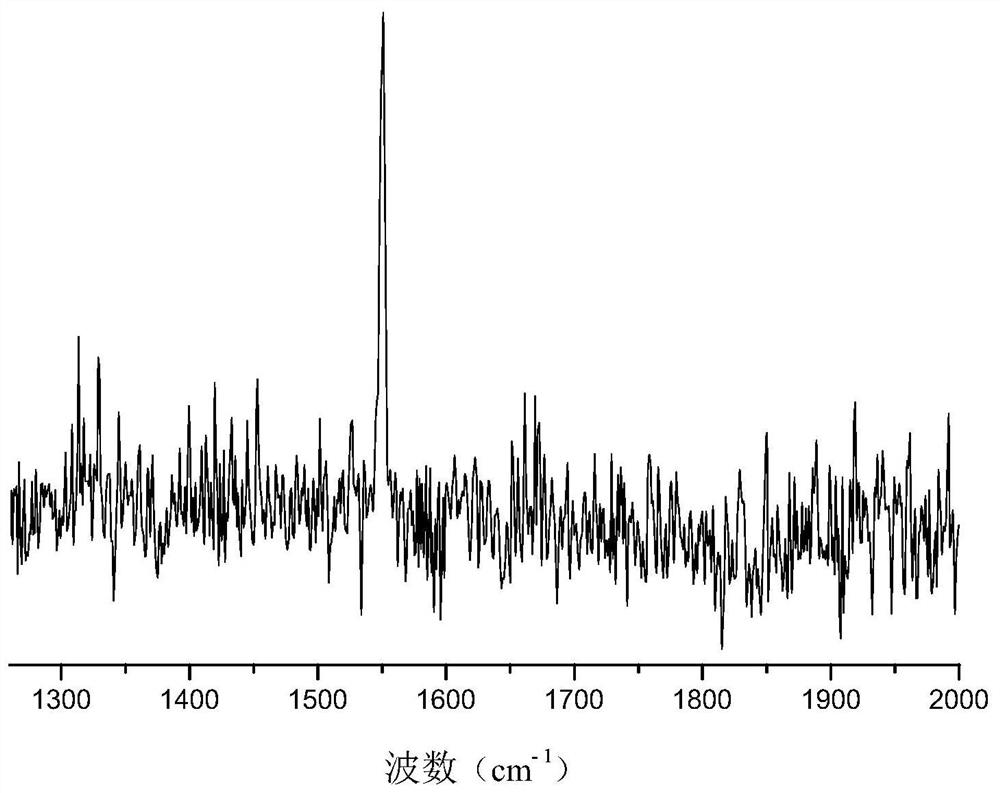

Carbon-coated nickel oxide nano composite material and preparation method and application thereof

ActiveCN113751042AReduce pollutionHigh activityNitrous oxide captureGas treatmentPtru catalystCatalytic decomposition

The invention provides a carbon-coated nickel oxide nano composite material and a preparation method and application thereof, including a method for catalyzing nitrous oxide decomposition by utilizing a catalyst containing the nano composite material and a method for preparing adipic acid by utilizing the catalyst containing the nano composite material to catalyze and oxidize cyclohexane. The nano composite material comprises a nuclear membrane structure with an outer membrane and an inner core, the outer membrane is a nitrogen-doped graphitized carbon membrane, the inner core comprises nickel oxide nano particles, and the carbon content accounts for not more than 5 wt% of the nano composite material. As a catalyst active component, the nano composite material can effectively catalyze and decompose nitrous oxide, and is beneficial to solving the problem of eliminating high-concentration N2O generated in the production process of adipic acid plants, nitric acid plants and the like. In addition, the nitrogen-doped carbon-coated nickel oxide nanocomposite can catalyze cyclohexane oxidation under mild conditions, can realize high-conversion-rate and high-selectivity one-step preparation of adipic acid from cyclohexane, and has a good industrial application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

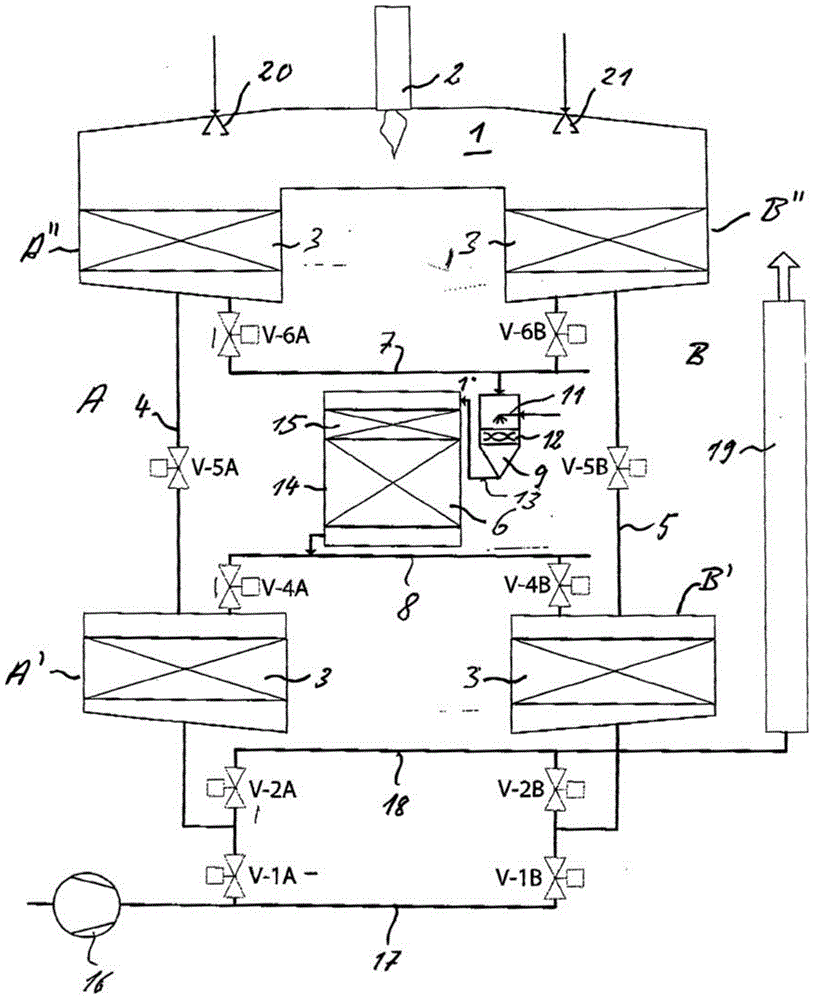

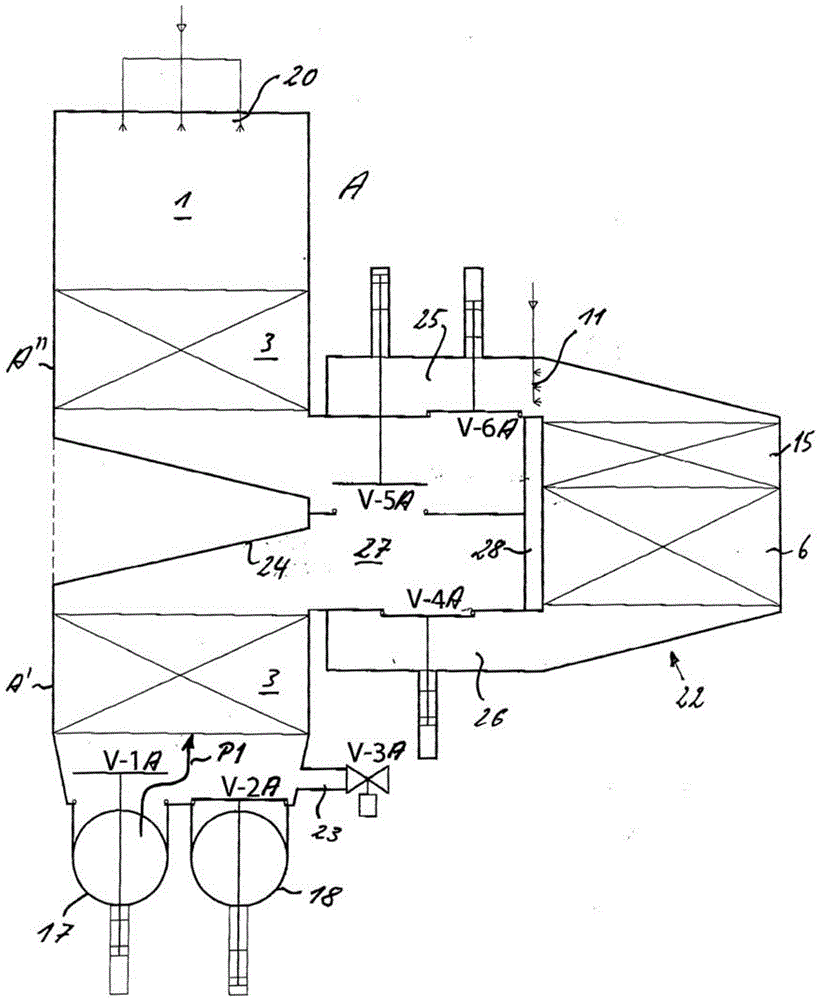

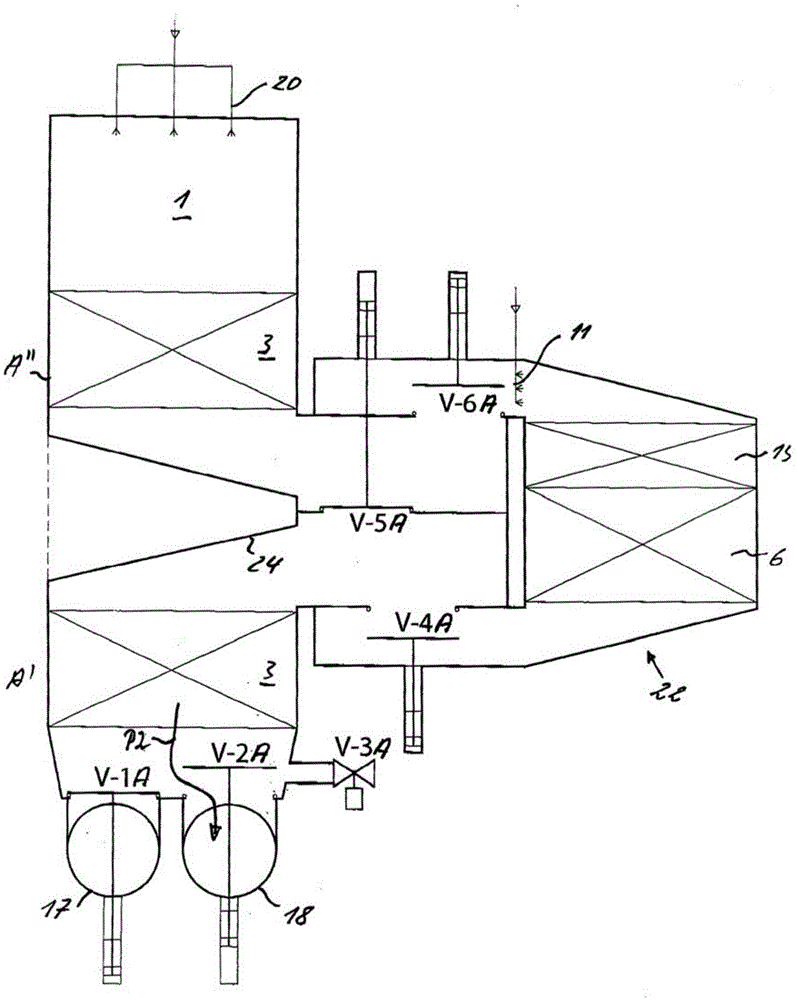

Method and for purifying exhaust gas

InactiveCN104930525AReduces alternating thermal stress loadsReliable and Efficient PurificationNitrous oxide captureDispersed particle separationCombustion chamberAdipic acid

In order to purify exhaust gas containing nitrogen oxide combined with CO, VOC or nitrous oxide, especially exhaust gas generated during the production of cement clinker, nitric acid, adipic acid, fertilizer and uranium trioxide, a regeneration-type post-heat burning system equipped with at least two regenerators (A, B) is employed and the CO, VOC and nitrous oxide are purified thermally in a combustor (1) under the temperature from 800 DEG C to 1000 DEG C through the system. The thermal recovery of oxynitride is achieved through the adding of a hydronitrogen SCR catalyst (6), wherein the purified exhaust gas is removed out at a proper position from the corresponding two regenerators (A, B) under the temperature of about 300 DEG C. and is guided in a fixed flowing direction through the hydronitrogen SCR catalyst (6) and then fed back to the remaining sections (A', B') of the two regenerators (A, B).

Owner:化学热处理技术有限责任公司

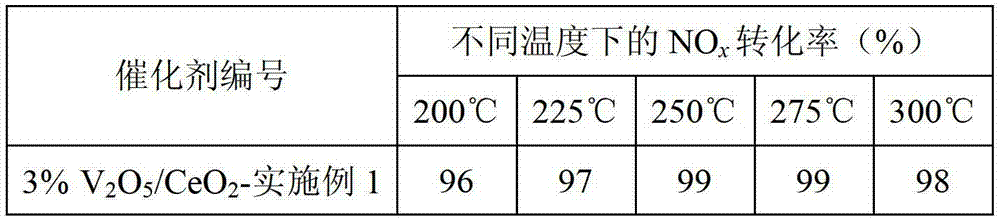

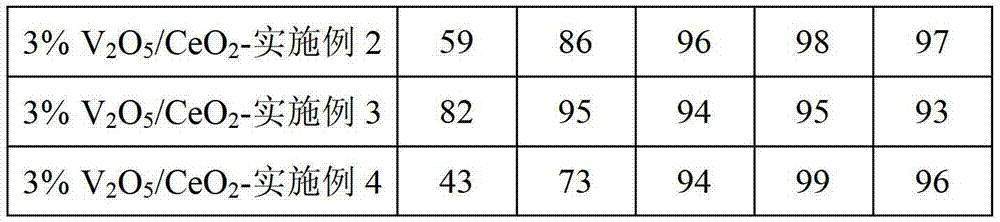

Vanadium-cerium oxide catalyst as well as preparation method and purpose thereof

InactiveCN103170326ANH

<sub>3</sub>

-Good SCR activityNH

<sub>3</sub>

-Excellent SCR activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCerium oxideVanadium

The invention relates to a vanadium-cerium oxide catalyst. The catalyst consists of the following chemical components: V2O5 / CeO2, wherein the mass percentage of V2O5 in the vanadium-cerium oxide catalyst is 1%-10%. The invention further discloses a preparation method of the vanadium-cerium oxide catalyst. The vanadium-cerium oxide catalyst disclosed by the invention has NOx purification efficiency as high as 100% within 0-200 DEG C, has excellent SO2 intoxication resistance and can be operated within a wide temperature range.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com