Catalyst for low-temperature V2O5-WO3/TiO2NH3 selective reduction catalysis of NO and preparation method thereof

A V2O5-WO3, catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. The effect of improving the ability of sulfur to resist water poisoning, good low temperature activity and high temperature activity, and broadening the working temperature window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

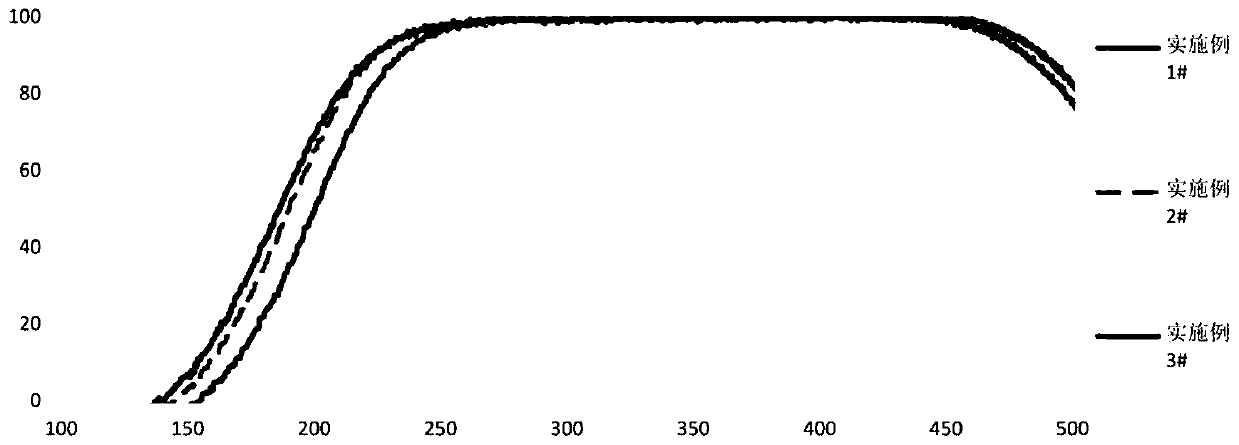

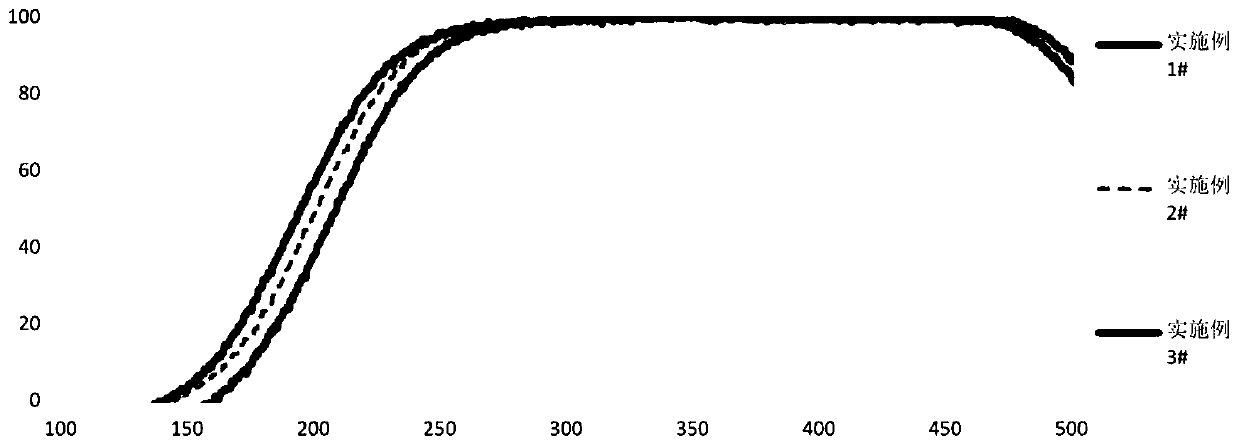

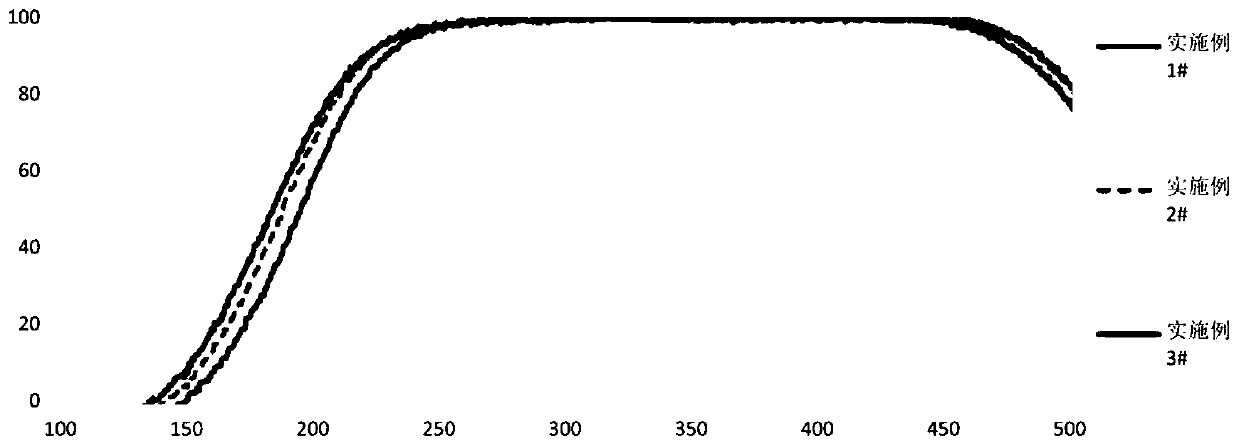

Examples

preparation example Construction

[0027] The present invention also provides a kind of above-mentioned NH 3 The preparation method of selective reduction catalytic NO catalyst comprises the following steps:

[0028] Step S1. Weigh the stoichiometric dispersant and cerium precursor respectively, the molar mass ratio of the dispersant to the cerium precursor is 0.1-2.0:1, then add an appropriate amount of deionized water to prepare a solution, and impregnate TiO after aging 2 Powder (titanium dioxide), TiO 2 TiO in powder 2 Content is 80~95wt%, WO 3 The content is 5~20wt%, TiO 2 The weight ratio of the powder to the solution is 1:2, and the Ce-doped modified TiO is obtained by drying and roasting. 2 Powder not; the aging time is greater than 2 hours, preferably 2-4 hours. The immersion time is preferably 4-6 hours, and the drying conditions are preferably drying at 60-120°C for 4-7 hours, and then baking at 400-600°C for 3-6 hours, so as to realize the dispersion and curing of the active components on the s...

Embodiment 1

[0037] Take by weighing 56 grams of cerium nitrate, add 27 grams of dispersing agent citric acid, 5 grams of dispersing agent polyethylene glycol, add deionized water and be mixed with 40% cerium nitrate solution, after aging for 3 hours, 74 grams containing 10wt% WO 3 Anatase titanium dioxide is added to the above solution for stirring, wherein the weight of titanium dioxide and the solution is 1:2, and finally dried and roasted, the drying temperature is 90°C, the drying time is 5h, the calcination temperature is 500°C, and the roasting temperature is 500°C. The time is 3h, and 100 grams of Ce-doped modified TiO are obtained 2 Powder is not.

[0038] Weigh 15 grams of oxalic acid, add 79 grams of deionized water to dissolve, and then add 6 grams of ammonium metavanadate to prepare a 6 wt % ammonium metavanadate solution. 100 grams of Ce-doped modified TiO obtained above 2 The powder was immersed in 21 grams of 6wt% ammonium metavanadate solution, ultrasonically dispersed a...

Embodiment 2

[0042] Take by weighing 56 grams of cerium nitrate, add 27 grams of dispersing agent citric acid, 5 grams of dispersing agent polyethylene glycol, add deionized water and be mixed with 40% cerium nitrate solution, after aging for 3 hours, 74 grams containing 10wt% WO 3 Anatase titanium dioxide is added to the above solution for stirring, wherein the weight of titanium dioxide and the solution is 1:2, and finally dried and roasted, the drying temperature is 90°C, the drying time is 5h, the calcination temperature is 500°C, and the roasting temperature is 500°C. The time is 3h, and 100 grams of Ce-doped modified TiO are obtained 2 Powder is not.

[0043] Weigh 15 grams of oxalic acid, add 79 grams of deionized water to dissolve, and then add 6 grams of ammonium metavanadate to prepare a 6 wt % ammonium metavanadate solution. 100 grams of Ce-doped modified TiO obtained above 2 The powder was immersed in 21 grams of 6wt% ammonium metavanadate solution, ultrasonically dispersed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com