Pd/SiO2@Al2O3 (palladium/silicon dioxide@aluminum oxide) nanocrystalline material and preparation method and application thereof

A nanocrystalline material and nanocrystalline technology, applied in chemical instruments and methods, fuels, gas fuels, etc., can solve problems such as restrictions on popularization and application, achieve good application prospects, and improve the thermal stability of high-temperature catalytic reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] The present invention also provides a Pd / SiO 2 @Al 2 o 3 The preparation method of nanocrystalline material comprises the following steps:

[0074] A) After mixing polyvinylpyrrolidone, reducing agent, auxiliary agent, nano-silica, water and palladium source compound for reaction, Pd / SiO is obtained 2Nanocrystalline;

[0075] B) Pd / SiO obtained by combining trimethylaluminum and water in the above steps 2 After deposition on the nanocrystalline surface, Al 2 o 3 Coated Pd / SiO 2 nanocrystalline materials;

[0076] C) the Al obtained by the above steps 2 o 3 Coated Pd / SiO 2 After the nanocrystalline materials were heat-treated in oxidizing and reducing atmospheres, Pd / SiO 2 @Al 2 o 3 nanocrystalline material.

[0077] The present invention is to Al in the above-mentioned preparation method 2 o 3 Coated Pd / SiO 2 The selection and requirements of nanocrystalline materials, as well as the corresponding optimization principles, are similar to those of the afo...

Embodiment 1

[0126] Cubic Pd{100} / SiO 2 Synthesis of Nanocrystals

[0127] Take 105mg of polyvinylpyrrolidone (Mw=55000), 60mg of ascorbic acid, 75mg of KBr, and 141mg of KCl and dissolve them in 7ml of ultrapure water in a single-necked flask with a capacity of 25ml, keep the temperature in an oil bath at 80°C for 10min, and then add 1ml of SiO 2 Suspension (150mg / ml) was kept at constant temperature for 5 minutes, and 3ml of 65mmol / L Na was added again 2 PdCl 4 The aqueous solution reacted for 3h. Finally, centrifuge washing and vacuum drying at room temperature for 24 hours, and then the three-dimensional Pd{100} / SiO with PVP protective agent on the surface was obtained. 2 Nanocrystalline.

[0128] The cubic Pd{100} prepared in Example 1 of the present invention was characterized.

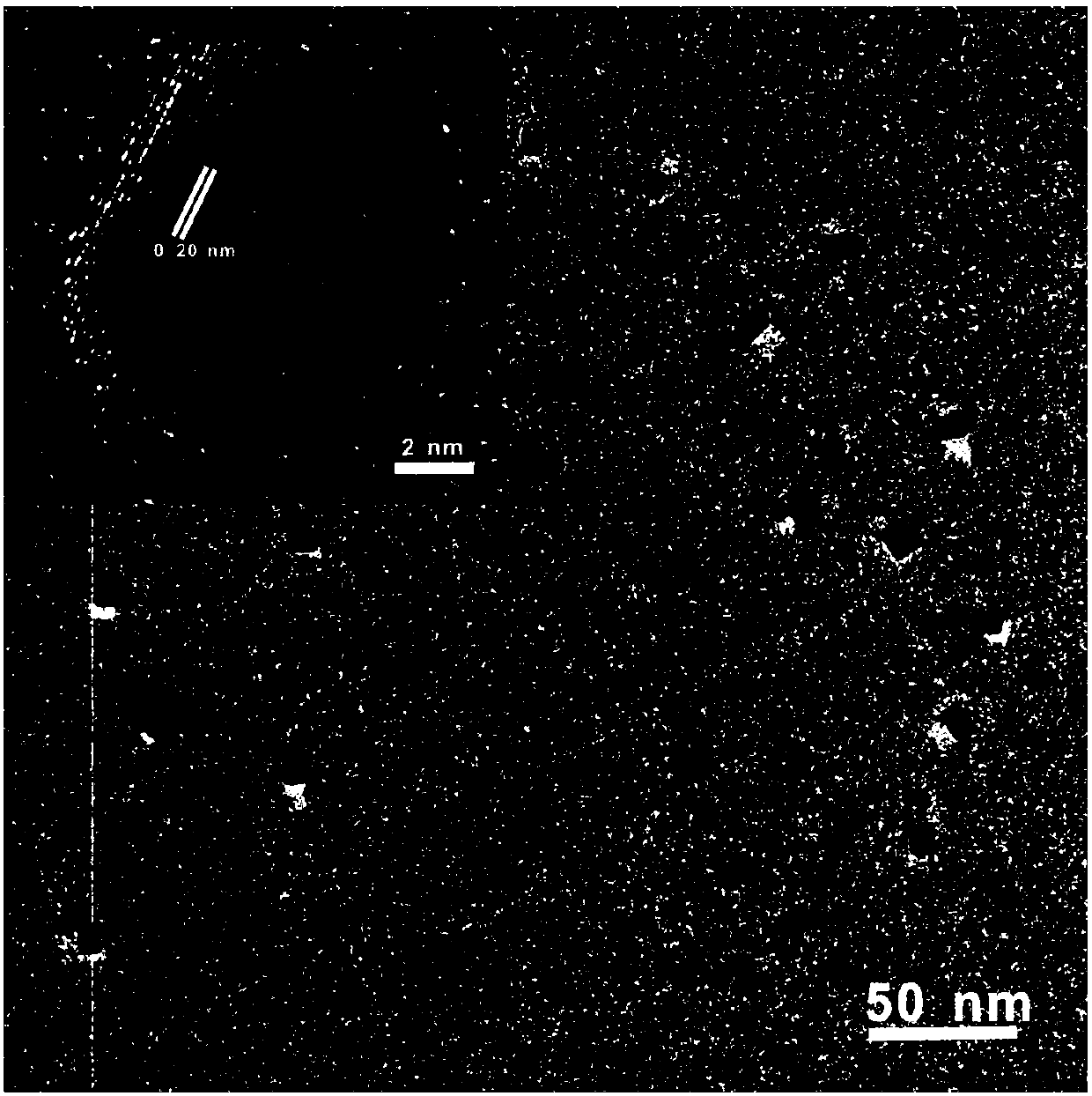

[0129] see figure 1 , figure 1 TEM image of cubic Pd nanocrystals prepared in Example 1 of the present invention.

[0130] Depend on figure 1 It can be seen that the present invention prepares cubic...

Embodiment 2

[0136] Octahedral Pd{111} / SiO 2 Synthesis of Nanocrystals

[0137] Take 105mg of polyvinylpyrrolidone (Mw=55000), 180mg of citric acid, and 3ml of ethanol and dissolve them in 4ml of ultrapure water in a single-necked flask with a capacity of 25ml, keep the temperature in an oil bath at 80°C for 10min, and then add 1ml of SiO 2 The suspension (150mg / ml) was kept at a constant temperature for 5min, and 3ml of 65mmol / L Na 2 PdCl 4 The aqueous solution reacted for 3h. Finally, centrifuge washing and vacuum drying at room temperature for 24 hours, and then the octahedral Pd{111} / SiO with PVP protective agent on the surface was obtained. 2 Nanocrystalline.

[0138] The octahedral Pd{100} prepared in Example 2 of the present invention was characterized.

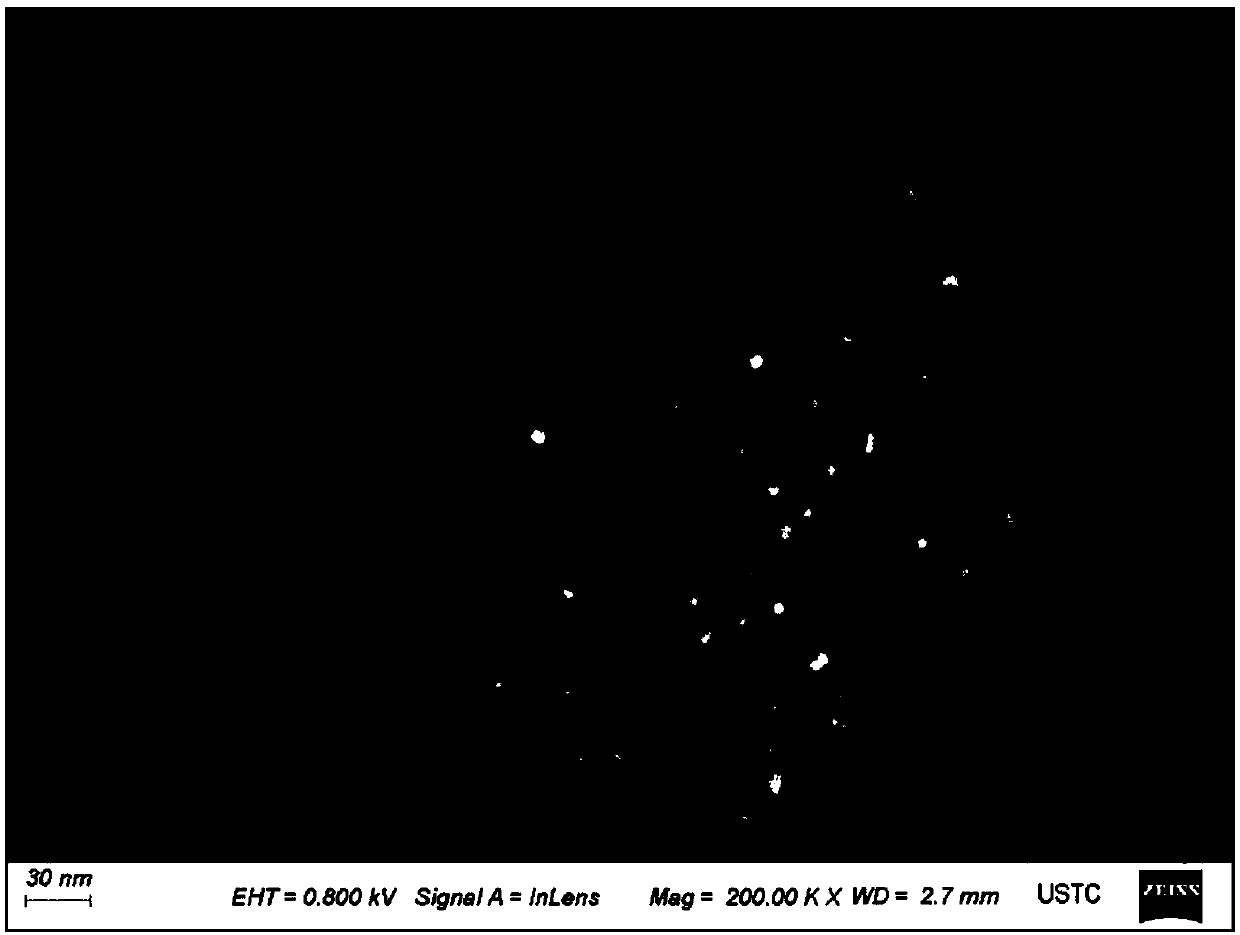

[0139] see Figure 4 , Figure 4 TEM image of the octahedral Pd nanocrystals prepared in Example 2 of the present invention.

[0140] Depend on Figure 4 It can be seen that the present invention prepares octahedral Pd nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com