Mixed rare-earth modified methane steam reformed nickel-based catalyst and preparation method thereof

A nickel-based catalyst, methane water vapor technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as gaps and achieve carbon deposition resistance Strong ability, enhanced interaction, high specific surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

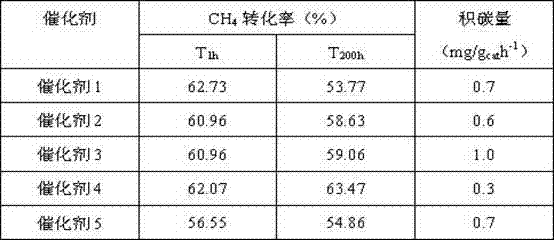

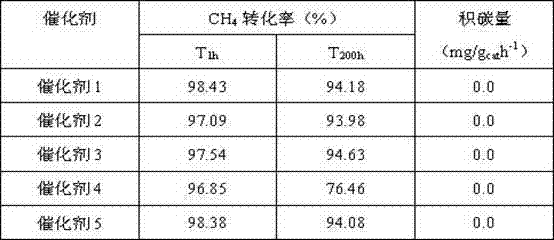

[0020] Example 1 Catalyst 1

[0021] Add 8.3g of spherical γ-Al to the prepared LaCe mixed rare earth nitrate solution 2 o 3 , impregnated at room temperature for 24 hours, evaporated to dryness in a water bath at 80°C, dried at 110°C for 12 hours, and roasted at 800°C for 4 hours. 3 ) 2 ·6H 2 O solution, soaked at room temperature for 24 hours, evaporated to dryness in a water bath at 80°C, dried at 110°C for 12 hours, and calcined at 800°C for 4 hours to obtain a finished catalyst.

Embodiment 2

[0022] Example 2 Catalyst 2

[0023] The preparation process is the same as catalyst 1, the only difference is that the mixed rare earth is LaY mixed rare earth.

Embodiment 3

[0024] Example 3 Catalyst 3

[0025] The preparation process is the same as that of Catalyst 1, the only difference is that the mixed rare earth is LaPr mixed rare earth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com